The assignment

This week's assignment was to propose a final project that integrates the range of units covered, answering questions like "what will it do?", "what materials and components will be required?", "what processes will be used?", etc.

What will it do?

As a final project, I’m developing an e-textile modular system. It will consist of modules, that can easily be assembled (ideally without even sewing) to create custom fit electronic clothing. The idea is that anyone can create their custom fit clothes and adapt them over time, by simply re-assembling the modules.

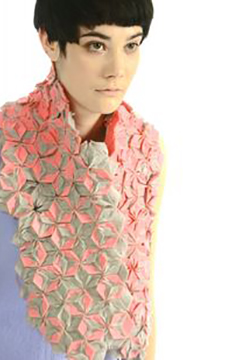

Eunsuk Hur, example of a textile modular system

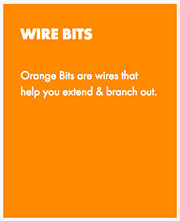

All modules will have the same shape but function can vary. Inspired by Little Bits, modules can be power, wire, input or output elements, pre-programmed, that can be combined and interact with each other.

Little Bits, module's identity and functionns

Users can simply make use of the developed modules, or create their own. Shape and size is what keeps the system modular. (at the moment… eventually, if the project keeps developing, this could vary as well) Materials and technique can vary, allowing self-expression to steer the creative process, so f.x.:

- modules can be lasercutted felt, denim, leather (or other fabric that doesn’t require a seam);

- conductivity is achieved by conductive paint (making use of masks and vinyl cutter) or conductive thread (making use of embroidery);

- in modules that require a microcontroller, this is applied with a socket, so it can easily be re-programmed (not required but encouraged/possible);

- modules can be customized by using a laser cutter (engraving), embroidery, 3d print (3d print on textile), vinyl cutter (textile vinyl and heat press).

So, this modular system is also thought as an exploration tool, covering tools and techniques in a FabLab. I would like to keep it “low threshold, high ceilings”, appealing to both genders, all ages and backgrounds.

It’s mainly thought to be applied to clothes, but can also be applied to furniture and functional home decoration (sound isolation, light, sound, etc).

Atelier Oï, example of a textile modular system applied to furniture

Who's done what beforehand?

I have been looking up for inspiration and references.

Regarding textile modular systems, I took great inspiration on:

- Eunsuk Hur;

- Atelier Oï;

- Ece Tankal & Ilkim Er, FabTextiles.

Regarding electronic modular systems, my biggest reference is Ayah Bdeir’s Little Bits.

For sewing/soft electronics, Leah Buechley, with Lilypad Arduino.

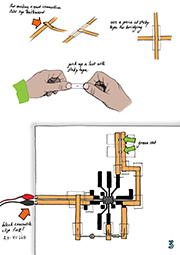

Regarding a conductive strategy, I’ve taken great inspiration from Per-Ivar Kloen’s tutorial on using conductive paint on paper together with a attiny45 (see images below). But I would like to apply it to textile instead.

What materials and components will be required? Where will they come from? How much will it cost?

I have decided to organise this information in three tables, one regarding the final product (minimum modules necessary to develop in order to test the system), another regarding final product extra features (extra modules that I would like to develop if I have the time, in order to show that the system can easily handle diversity in techniques and materials), and another regarding product development (parts and tools that are part of the development of the product, but not of the final product itself, f.x. a mannequin).

Final product:

| MATERIAL | SUPPLIER | PRICE | OBS. |

|---|---|---|---|

| conductive paint | Amazon | 25 USD/50ml | not part of FabLab inventory |

| textile - denim | Stof2000 | 15 USD/m | not part of FabLab inventory |

| electronic components (resistors, capacitors, regulators, batteries, etc) | Digikey | ~20 USD | part of FabLab inventory |

| attiny45 8DIP | Digikey | 2USD/piece | special electronic part, not part of the inventory |

| attiny45 socket | Amazon | 0,25 USD/piece | special electronic part, not part of the inventory |

Making 1 power, 1 input, 1 output, 10 wires and 50 regular modules results in a total of around 110 USD - 50ml of conductive paint, 4m of denim, electronic components from FabLab regular inventory, 2 attiny45 and 2 attiny45 sockets.

Extra features:

| MATERIAL | SUPPLIER | PRICE | OBS. |

|---|---|---|---|

| conductive thread | Amazon | 8USD/18m piece | not part of the inventory |

| leather | Stof2000 | 25USD/m | not part of the inventory |

| felt | Stof2000 | 4USD/m | not part of the inventory |

| PLA filament | ColorFabb | 0,05USD/g | part of FabLab inventory |

| textile vinyl | MDPsupplies | 12USD/m | part of FabLab inventory |

| extra electronic components (resistors, capacitors, regulators, attiny45, sockets, batteries, etc) | Digikey | ~20 USD | part of the inventory |

Product development:

| MATERIAL | SUPPLIER | PRICE | OBS. |

|---|---|---|---|

| white foam (mannequin) | Stark | ? | part of the inventory |

| wood (mannequin) | Stark | ? | part of the inventory |

| screen print mesh | Amazon | 10USD/m | part of the inventory |

| textile vinyl | MDPsupplies | 12USD/m | part of FabLab inventory |

| copper boards (testing modules) | FabFoundation | 1,5USD/piece | part of the inventory |

| extra electronic components (testing) | Digikey | ~ 20 USD | part of the inventory |

What parts and systems will be made?

- a mannequin

- an electronic textile modular system

What processes will be used?

Below, there's an overview of the processes used just in completing the final project (without extra features)

| TASK | PROCESS/TOOL | RELATED WEEK |

|---|---|---|

| mannequin | 2D parametric design (Fusion 360) | week 2, week 7 |

| mannequin | 3d scanning (iSense), 3d modelling (Fusion 360) and 3d sculpting (Meshmixer) | week 5, week 7 |

| mannequin | computer controlled machining (VCarve, Shopbot3) | week 7 |

| textile modular system | 2D parametric drawing (Rhino, Grasshopper) | week 2, week 3 |

| textile modular system | laser cutting | week 3 |

| conductivity between modules | vinyl cutting, heat press and electronics production & design | week 3, week 4, week 6 |

| design of power, input and output modules | electronics design | week 6, week 10, week 13 |

| testing/debugging and programming of power, input and output modules | electronics design & production and embedded programming | week 4, week 6, week 10, week 13 |

| integration of power, input and output modules as a system | embedded programming | week 8 |

What tasks need to be completed?

- finish mannequin;

- develop and test textile modular design;

- develop and test conductivity strategy;

- develop and test conductivity between modules;

- develop and test power, wire, input (mic) and output (RGB led) modules;

- make sure the system works smoothly;

- apply it to an example in clothing;

- document the process during development and final result.

What questions need to be answered?

Can I develop a conductivity strategy on textile making use of conductive paint?

How to develop a truly modular system, where each input can talk to a wide range of outputs?

What is the schedule?

| TASK | 24/05-31/05 | 31/05-07/06 | 07/05-14/06 | 14/06-21/06 | 21/06-28/06 | 28/06-05/07 |

|---|---|---|---|---|---|---|

| finish mannequin | X | |||||

| develop and test textile modular design | X | |||||

| develop and test conductivity strategy | X | |||||

| develop and test conductivity between modules | X | |||||

| develop and test power, wire, input (mic) and output (RGB led) modules | X | X | ||||

| make sure the system works smoothly | X | X | ||||

| apply it to an example in clothing | X | X | ||||

| improvements after feedback from Instructor/Guru and Central Evaluation | X | X | ||||

| document the process during development and final result | X | X | X | X | X | X |

How will it be evaluated?

The final project will be succefssful if:

- I have a functional e-textile modular system;

- I have functional power, wire, input (mic) and output (RGB led) modules, that can work as a system.

Extra credit if:

- I have different techniques tested for conductivity between modules (f.x. conductive thread);

- I have used more techniques and tools to create/decorate modules (f.x. 3d printing on textile, embroidery, etc.);

- the system is ready to work with other input and output modules;

- I have a bigger variety in input and output modules;

- I have packaging for the product, as well as instructions on how to play with it.

Main learnings from this week...

I thought I had my project quite defined, but answering these questions made me tidy up my mind, more aware of future chalenges and more realistic regarding time needed/time available.