Group Work

With the 6 students at FabLab Oulu 2017, our Fab Lab manager, Jani, instructor suggested that we form two groups. I was working with Iván and Mikko, and a detailed description of the project, the Liquid Handler, is on the page of our group.

Because all of us were able to commit a good amount time to fulfill the assignment, it was easy to collaborate and we achieved the goals of both week. We also worked together with the other group at FabLab Oulu helping each other with the assignments. Thanks everyone for cooperation and knowledge-sharing!

Individual Contribution

Although my previous experience and knowlegde of concepts needed for completing the assignment is not as good as my teammates', it was an excellent chance for me to get a better understanding in the field of machine designing and automation. I did my best to participate and contribute to different activities required for completing the project.

I started with reviewing articles at http://mtm.cba.mit.edu/machines/science/ and at http://archive.monograph.io/james/m-mtm. Then, when we decided to build a Liquid Handler.

Overall, I managed to help the most with documenting the group's project, assembling the cardboard stages, assembling the machine, milling, stuffing and soldering the board, designing parts of the support for the machine, laser-cutting and assembling the support, and making the final presentation slide and the videos: the summary of week 9 and the final video.

The support design I made was the modification of Iván's original idea for the lateral part of the whole support structure. Mikko suggested to widen one of the pieces and add holes for the wheels to it, when we figured out that the initial design might not be able to be reliable to hold up the machine and the support will need wheels to move on the surface.

I also made an additional piece for the main support when after testing it was apparent that it will be required to hold up the machine.

Alhough most of the coding we actually used to guide the machine was done by mostly Mikko and Iván, I installed Python 2.7 tried running setup.py on my Windows 10, just to see how it works and understand better the overall process. I downloaded the pygestalt repository opened the command line, cmd.exe, navigated to the correct directory, and ran installation

Then, without connecting the USB, I ran the code we used to test only one motor examples/machines/htmaa/singlenode.py.

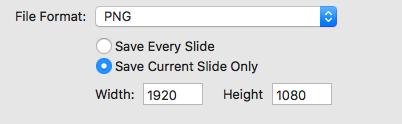

For the final step, the presentation, I created a slide in PowerPoint and exported it as a .png file with the required resolution which is very easy to set.

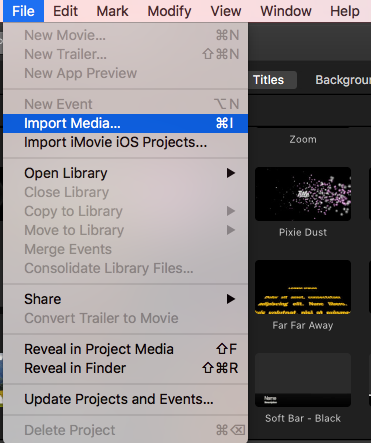

File - Export - choose needed settings - Next...- choose name and location to save - Save

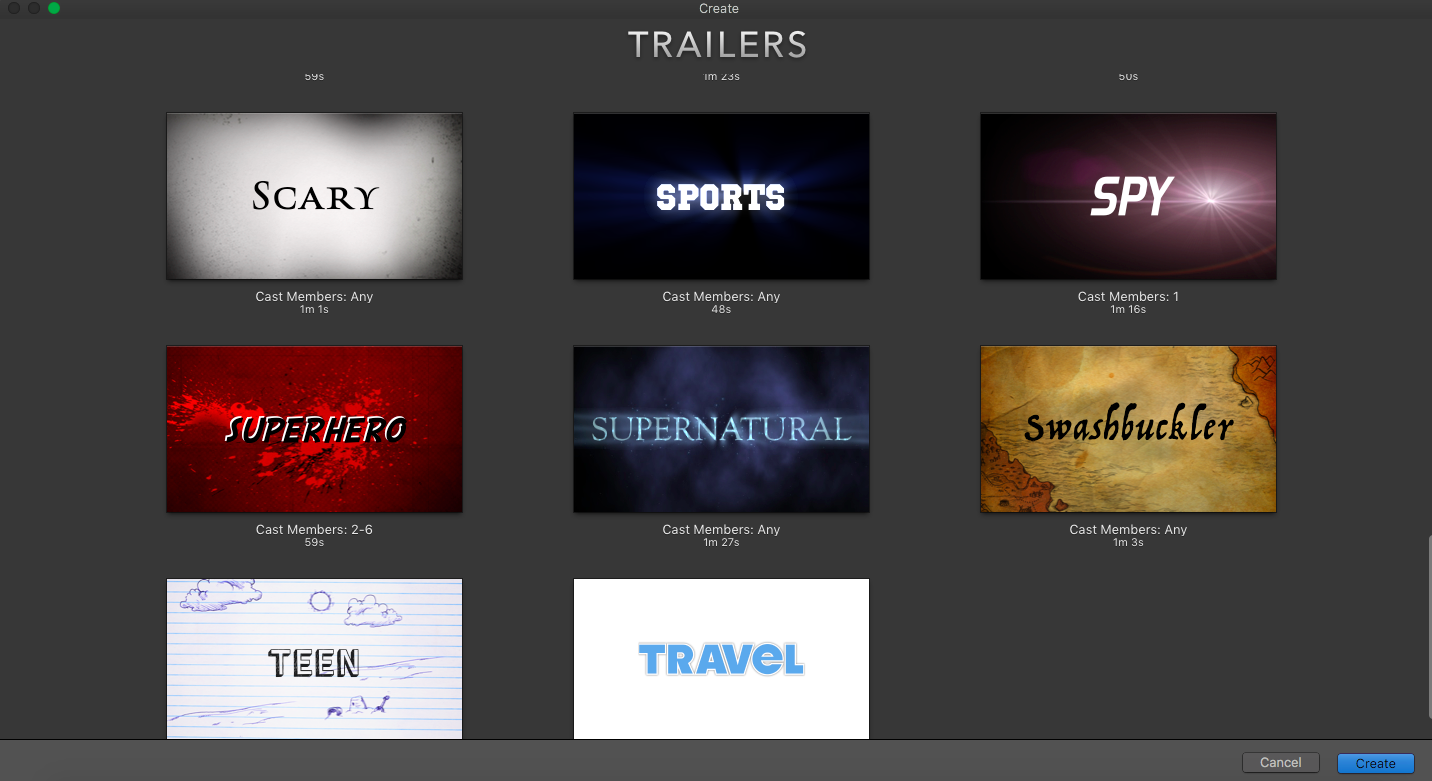

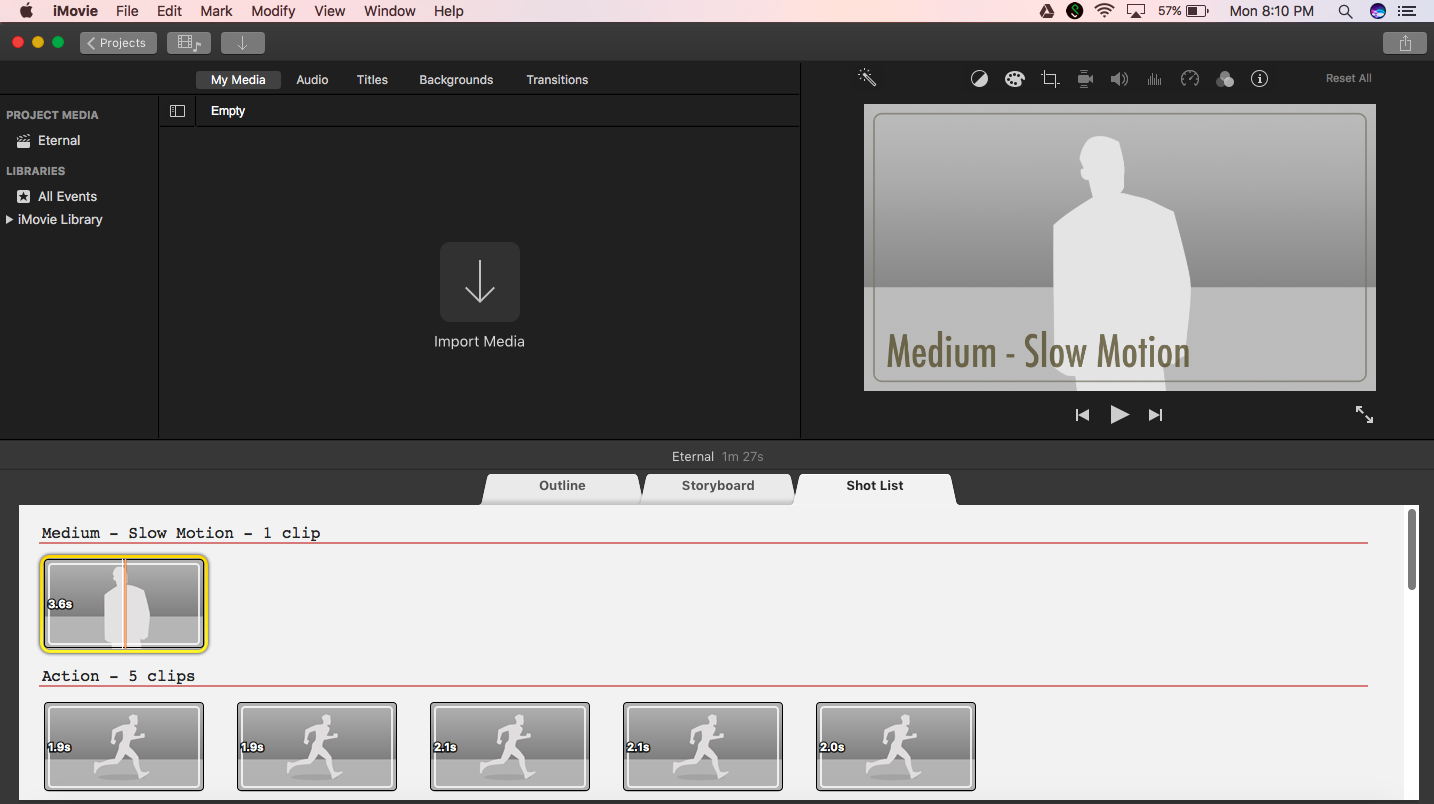

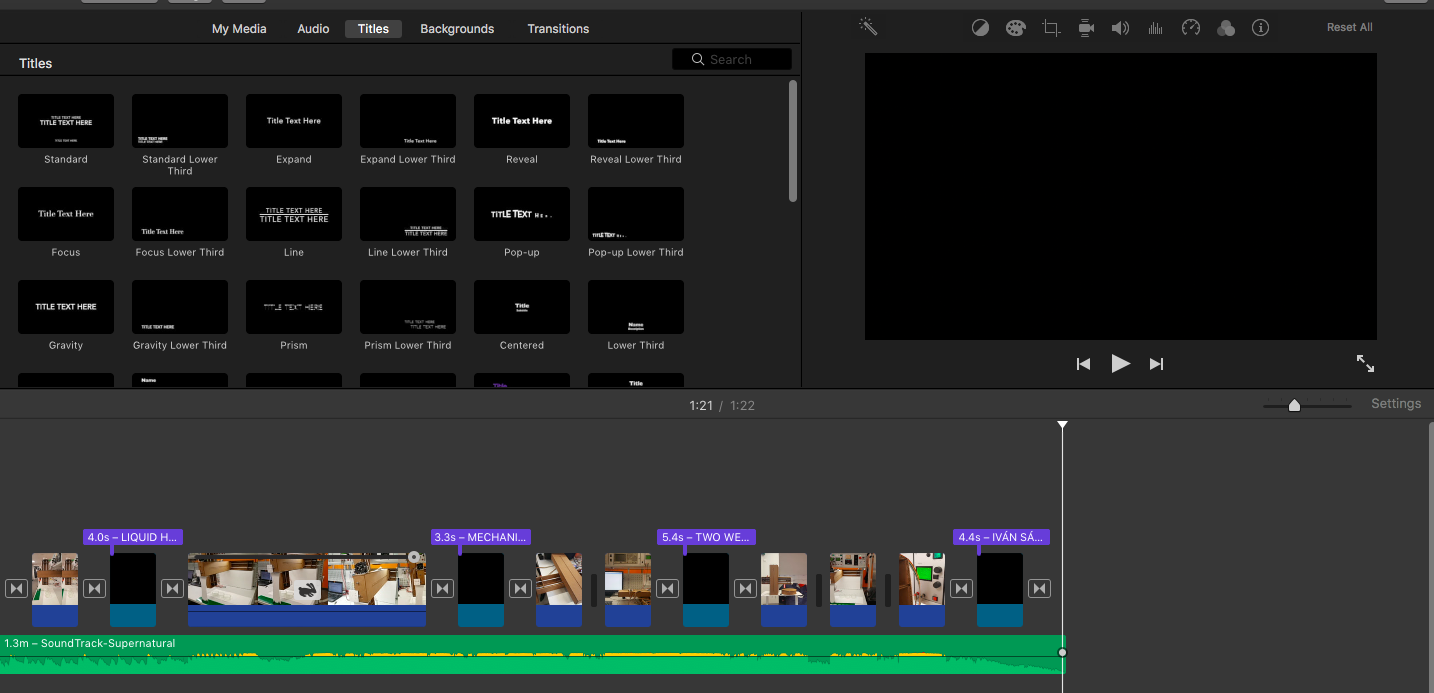

Making a video using iMovies on Mac was interesting. Based on one of the sample trailers, I made the story outline for our video.

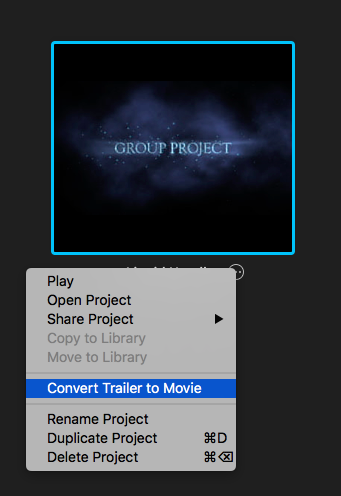

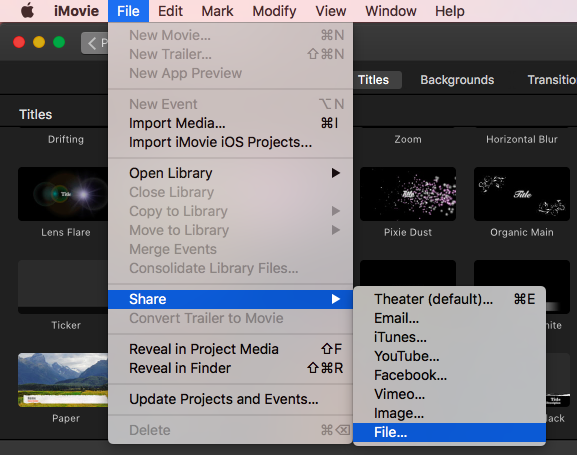

Since trailers have a very limited editing options, I converted the trailer to a movie and continued editing.

When exporting the video, I realized that the resolution required, 1080p, is not available because of the quality of the video I had set on my phone. So I needed to make a conversion. I found a useful software for that HD Video Converter Factory for Windows 10. The software is very straighforward and clearly indicates how to upload and conver a video to the desired format and resolution.

Future Improvements

Although the Liquid Handle was stabilized enough to be able to move on its own (without any support otside), the support structures need further improvements. The lateral support should be enhanced in a way that the active part of the handler is moving smoother than currently. The design of the pump has to be finalized and tested to make sure that the liquid movement is happening as intended. Additionally, a nosel(s) should be designed; we did not have time at all for this during the time we had for completing our project. Also the cardboard stages, which are work very well for rapid prototyping, would have to be replaced with a more durable material.

Files:

See group page.

Remember, remember...

- Plan and schedule groupwork, agree on methods of communication.

- Have a brainstorming session where the final goal is clearly established.

- Outline processes to be done to achieve the end result.

- Plan to have the project done a few days before the actual deadline to have time to make corrections and deal with unpredicted circumstances if necessary.