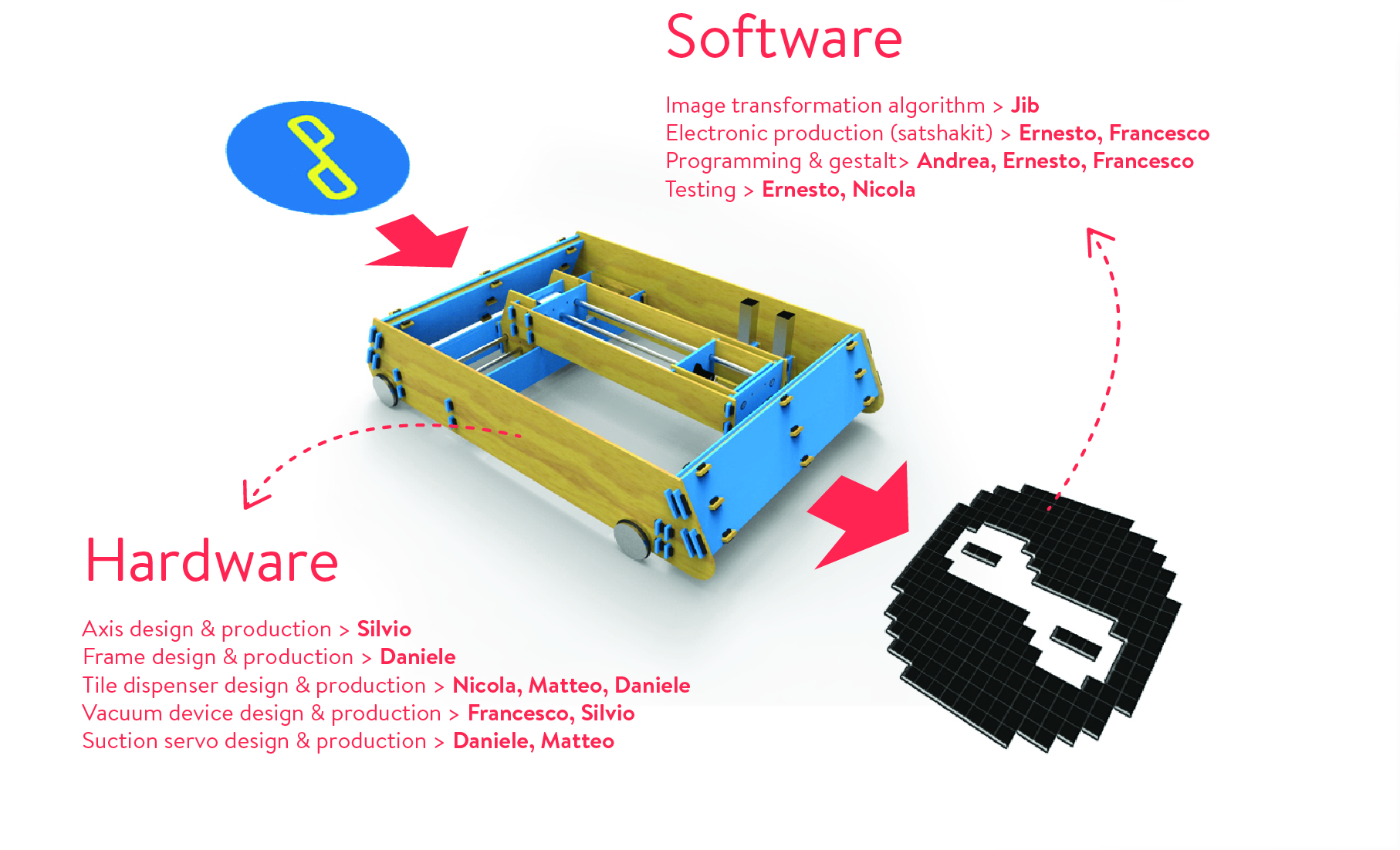

We decided to design two machines for the assignment: one Pick and Place machine and a Liquid extruder machine The main applications that we imagined for those machines are a bi-chromatic mosaic maker and a bleach printer for textiles. The machines will have 4 axes, and the main structure will be the same for both

See more photos of work in progress here

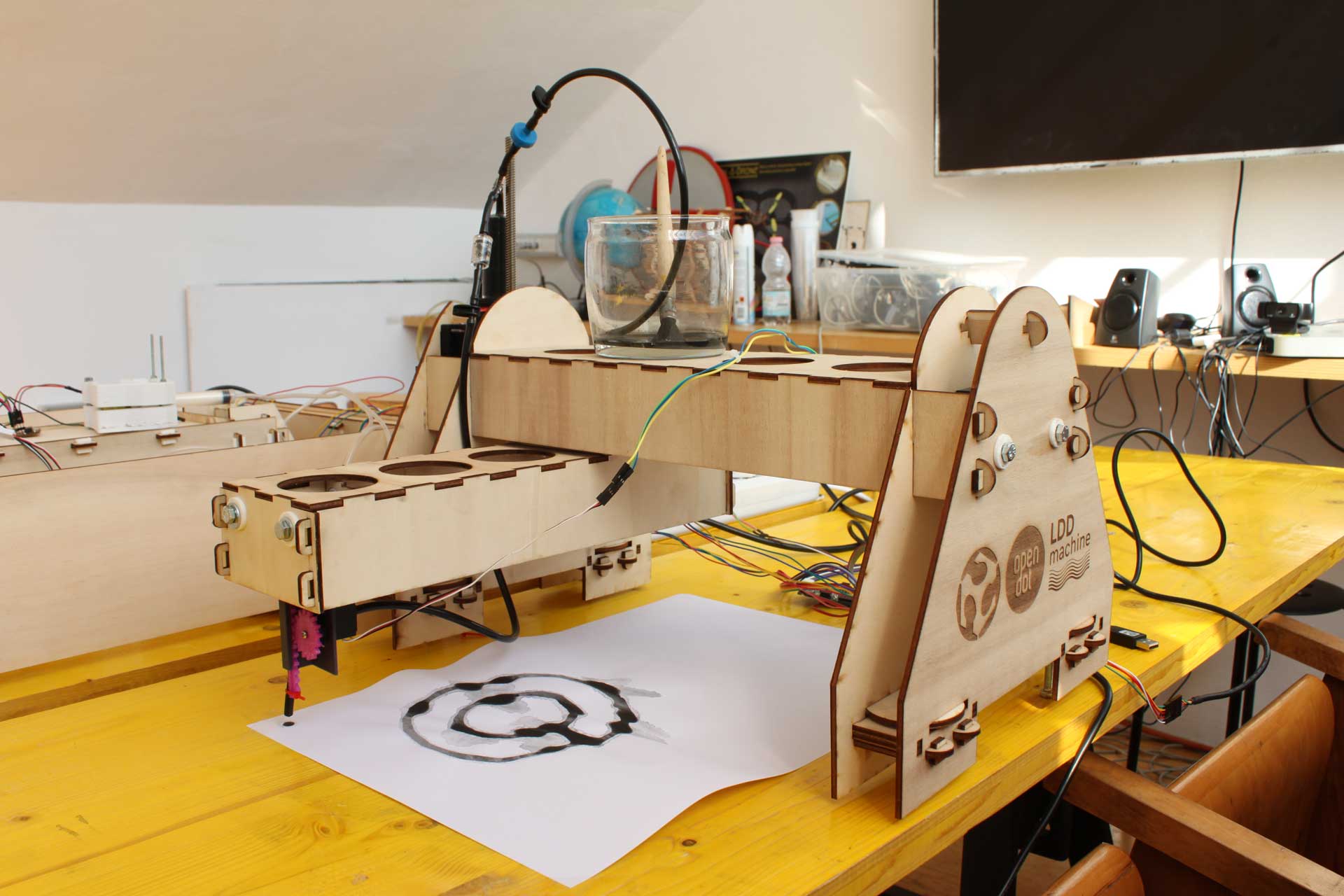

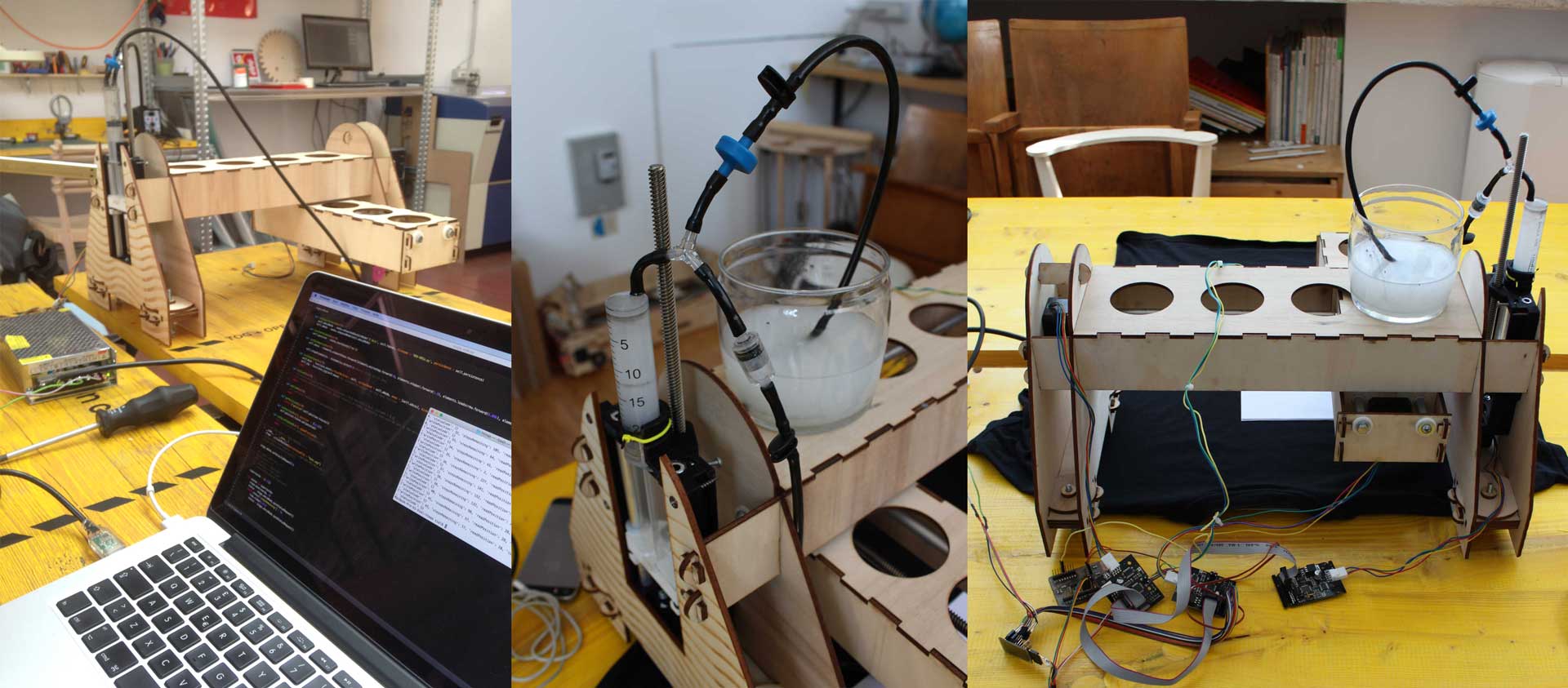

The initial concept was a liquid deposit machine for moss art. After a bit of research we realized that we could have some problem in making the right mixture, so we turned to some backup ideas, using bleach gel to apply on textile.

Here is a recap of the whole process

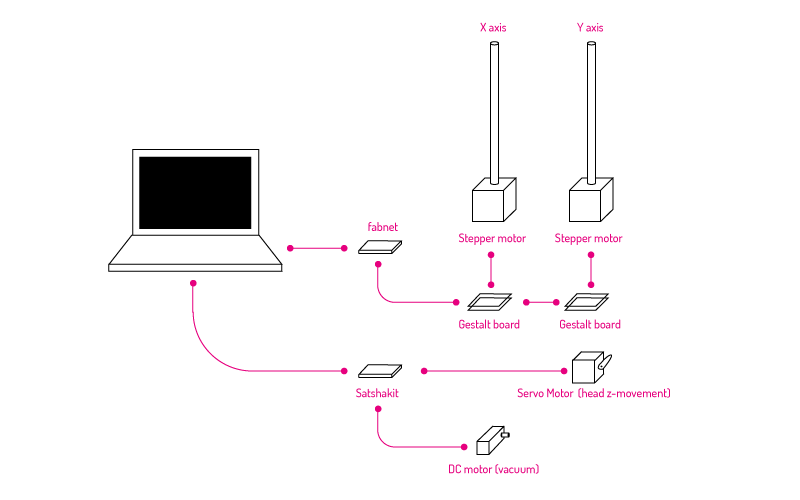

1. Image processing : a program made in vvvv translate a ventor svg file to funcion and x,y,coordinates. Then export a csv

2. Talk to the motors : Python read the csv file and control the 4 motors acordingly

3. 4 Motors : 3 stepper motors control axis x,y of the machine and the syringe's push. The last motor is a servo motor connected to a satscha board to control the hight of the tube.

LDD Machine by volt23 on Sketchfab

.png)

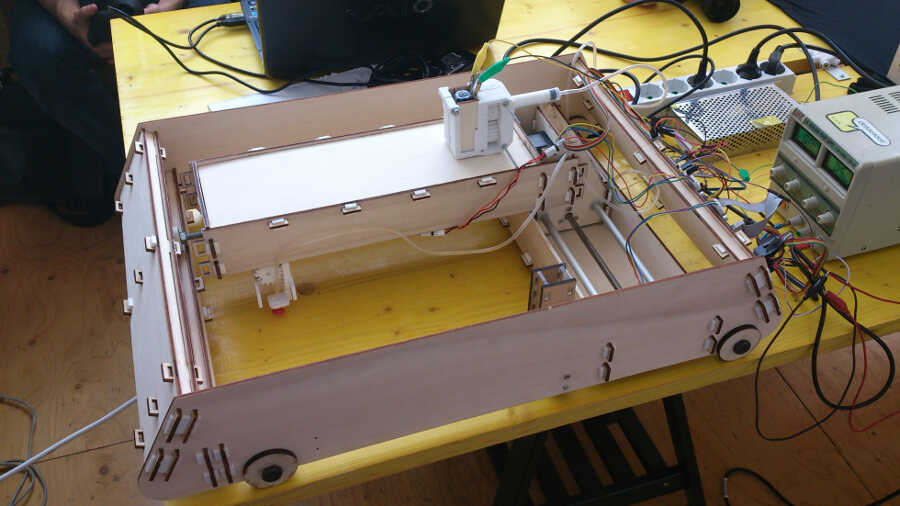

The machine is made up of a head to handle tiles which works thorugh vacuum created by a syringe. A motorized rack gear with pignon acts on the syringe piston.

The feeding cartdridge concept relies on the tiles dropping by gravity and then being pushed in position. In this way, we can avoid the use of another mother.

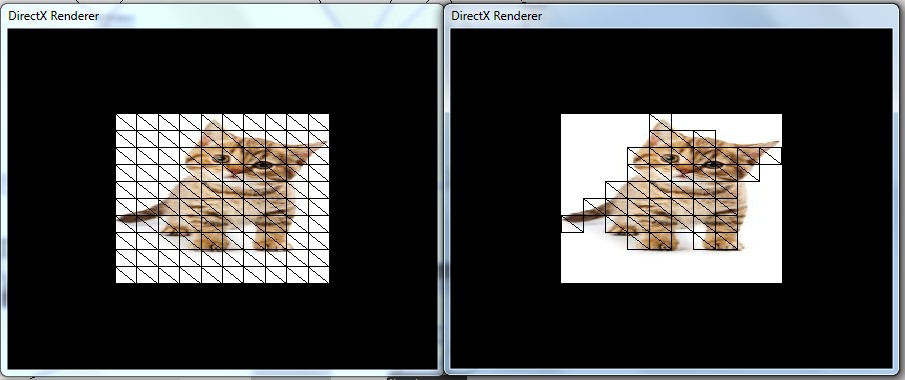

Asmae made some further developments of the Tiles machine, about image processing and controlling the servo motor. She made a software using vvvv in order to process and convert images in coordinates, these are listed in a csv file wich can be read by the gestalt framework. The software scale the picture to 40X40cm, scompose it to 10X10 pieces with height/width of 4cm each, then look for the x and y coordinates of pieces forming the picture, here are the screenshots:

Asmae made some improvements on the sathsakit's firmware that controll the servo motor attached to the vacuum pump. Here some results: