Press Fit Kit

Laser cutting is a technology that uses a laser to cut materials, for this machines you migth use CAD softwares for designs. FabLab Yachay has a 40 Watts EPILOG ZING LASER cutter.

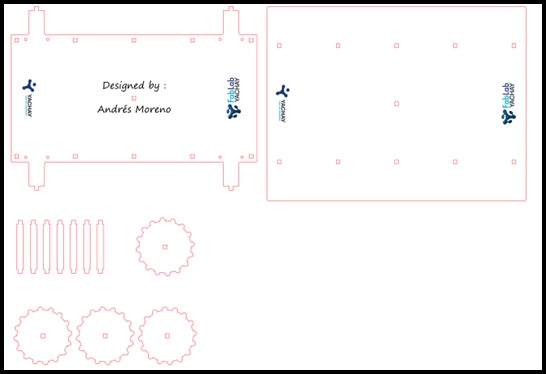

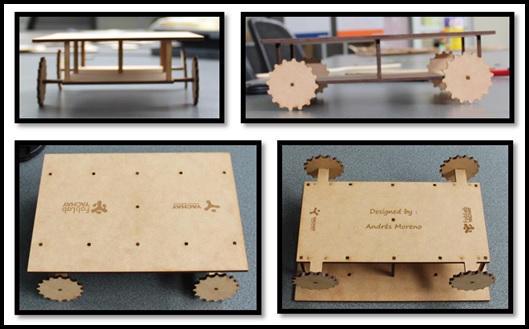

For this assignment, I created a press fit kit to assemble the structure of FAB-BOT.

You can download an Inkscape file for laser cutting of press fit kit here.

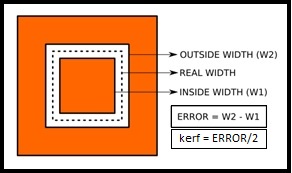

Reviewing Academy tutorials, I found the steps to determine the base size of a press-fit notch:

With calipers, measure the kerf created by your laser cutter. Cut a square, then measure the inner dimension of the hole and the outer dimension of the piece. Subtract and divide by two: this is the kerf for that material. Use these measurements to draw your best guess for a notch. Duplicate the notch a few times and bracket in .001 inch increments (i.e., make some at w-.002, w-.001, w+.001, w+.002 etc.). Cut and test the fit.

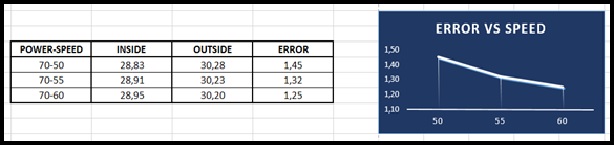

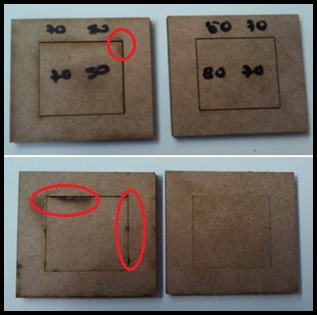

In my case, I used MDF of 3mm and I measurre de kerf for differents speeds. In the next image you can see the results.

In conclusion, the error is inversely proportional to the cutting speed. When working with higher speeds, the cutting is incorrect, and at lower speeds the material can be burned. You can see this effect in next image.

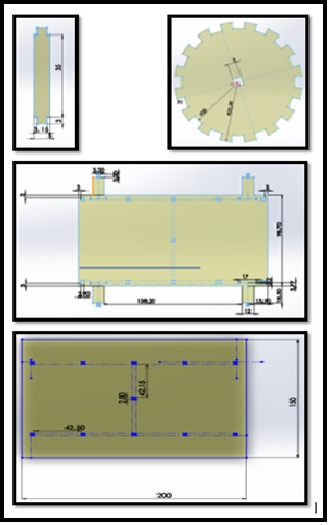

Whith this tips, I designed the parts of kit in Solidworks, is important to design parametric models to modify the dimensions quickly.

You can download the original files here.

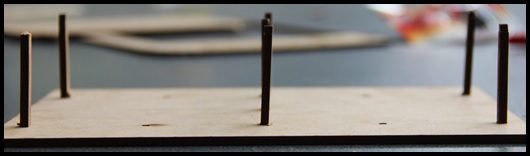

After designing the parts of press fit kit, I cut each piece in MDF board and finally assemble the robot structure. You may notice that the brackets are entered with much pressure.

And the results of assembling are illustrated in next image.

In parallel I tested vinyl cutter to create stickers for my cellphone.

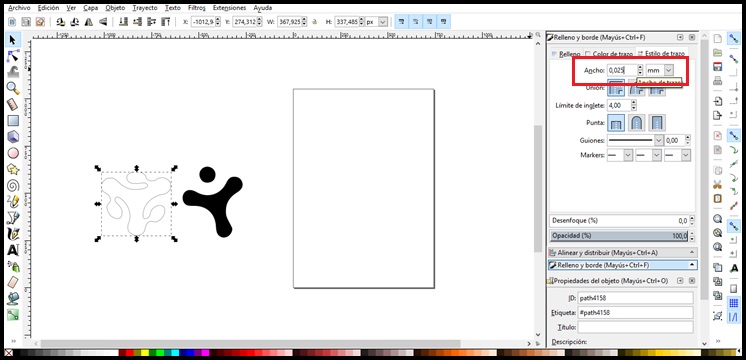

First I download the Yachay and Fablab Yachay logos and imported in Inkscape.

After, I vectorized the pictures and set the line thickness in 0.025mm. You can download the Inkscape file here.

For cutting the stickers I exported the file as PDF format and printed directly with Roland Vinyl cutter. The machine is setted to cut at 20gf/cm2. The results are the nexts: