Programming

Embedded Programming

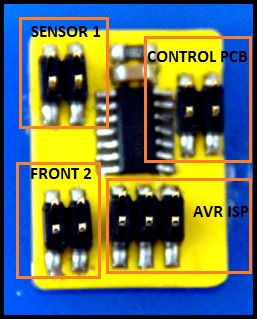

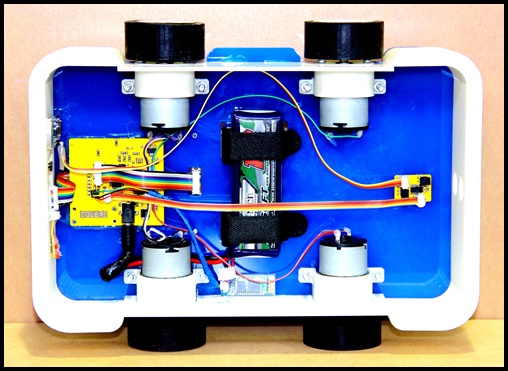

I used Arduino IDE for programming the control PCB. You can donwload files here: Control pcb programming, Input-output pcb programming, Ultrasonic pcb programming.

Control PCB programming files are in control.rar, in this compressed file you will find three files:

- Config.h, in this file you can change pinout and some constants for example the time of beeper.

- Control.h, in this file you will find core functions to control the robot, you should't changue this file.

- control.ino is the Arduino file programming.

For upload the programm in ATMEGA328P you must extract and copy fab2d2 folder in hardware folder of Arduino preferences path. Next, restart Arduino, select "fab2D2" as board and set clock as "20 MHz (external)".

IO PCB programming file is io.ino file. For upload the code in ATtiny45 you must select "ATtiny" as board and, "ATtiny45" as processor and set clock as "8 MHz (internal)".

Ultrasonic Sensors PCB programming file is ultrasonic.ino file. For upload the code in ATtiny44 you must select "ATtiny" as board and, "ATtiny44" as processor and set clock as "8 MHz (internal)".

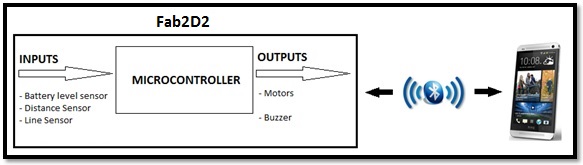

The robot has three modes of working, the user can switch working mode by pressing the SET button, if the user press the button for more than one second, the robot executs the working mode selected. Next, each working mode is explained quickly:

Calibration Mode

In this mode the robot moves forward and takes 300 samples of each line sensor for find minimun and maximun values. These values are stored in eeprom memory.

void runCalibrationMode(){

setSpeed(127, 127);

calibrateLineSensors(300);

stopMotors();

saveCalibration();

}

Autonomous Mode

In this mode the robot finds its position with respect to the black line and executs a proporcional-derivative (PD) control to stay on it, thus gets to move aotonomously. When the robot reaches an intersection it stops for 5 seconds.

void runAutonomusMode(signed int speedMin, signed int speedMax){

unsigned int sensors[5];

signed int ev=0, cv=0, dv=0, lastError=0;

signed int speed = speedMin;

resetPD(&ev, &cv, &lastError);

while(isButtonOff() && mode==AUTONOMUS_MODE){

runBeeperService();

runDataOutService();

if(checkError()) break;

ev = getLinePosition(sensors);

if(sensors[0]>500 && sensors[4]>500){

if(runAutonomousParking()){

resetPD(&ev, &cv, &lastError);

speed = speedMin;

continue;

}

else

break;

}

PD(&ev, &cv, &lastError, speed, 5, 100);

if(cv > 0) setSpeed(speed, speed-cv);

else setSpeed(speed+cv, speed);

if(speed < speedMax) speed++;

}

stopMotors();

}

Manual Mode

In this mode the robot waits until a command has been send trought serial port. The robot executs only next comands :

f : move forward

b : move backward

l : turn left

r : turn right

L : fast turn left

R : fast turn right

s : stop

void runBluetoothMode(signed int speed){

char data = 0;

while(isButtonOff() && mode==BLUETOOTH_MODE){

runDataInService(&data);

switch (data){

case 'f':

setSpeed(speed, speed);

break;

case 'b':

setSpeed(-speed, -speed);

break;

case 'l':

setSpeed(speed/2, speed);

break;

case 'r':

setSpeed(speed, speed/2);

break;

case 'L':

setSpeed(-speed, speed);

break;

case 'R':

setSpeed(speed, -speed);

break;

case 's':

offMotors();

break;

}

runDataOutService();

if(data=='f' || data=='l' || data=='r' || data=='b') runBeeperService();

else digitalWrite(SPK, LOW);

}

offMotors();

}

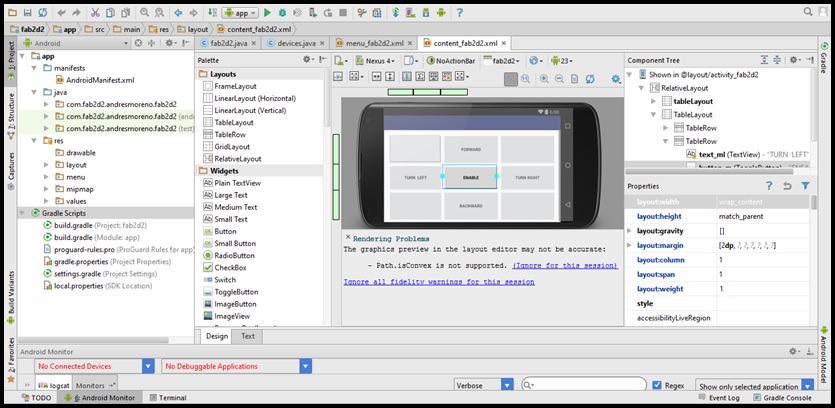

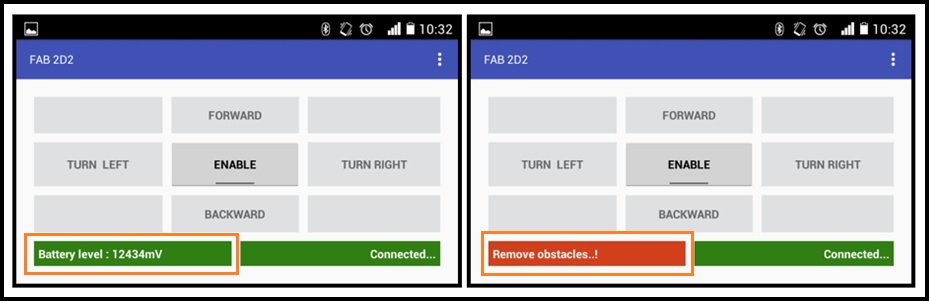

Application Programming

I used Android Studio for developed the App. You can donwload apk files here: App, Android Studio project.

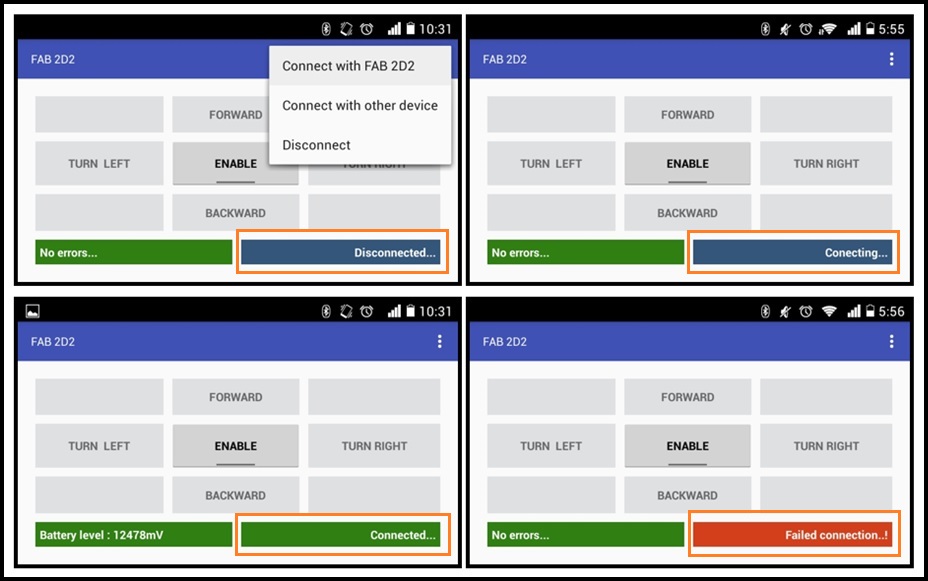

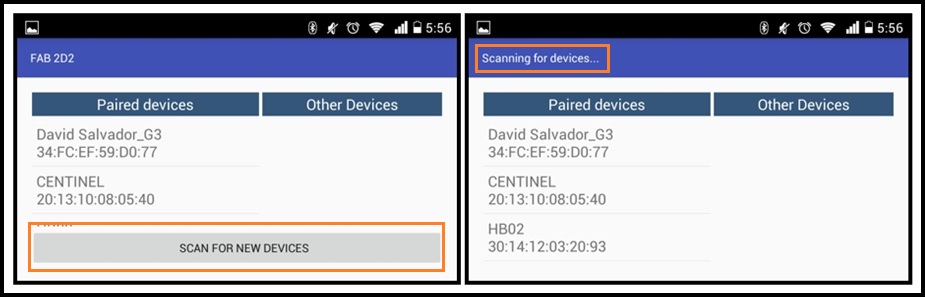

Next, I'll show the features of the app:

Real time sensor monitoring

Real time connection monitoring

Bugs reporting

Bluetooth devices scan