Week 4 - Electronics Production

Assignment

Make an in-circuit programmer

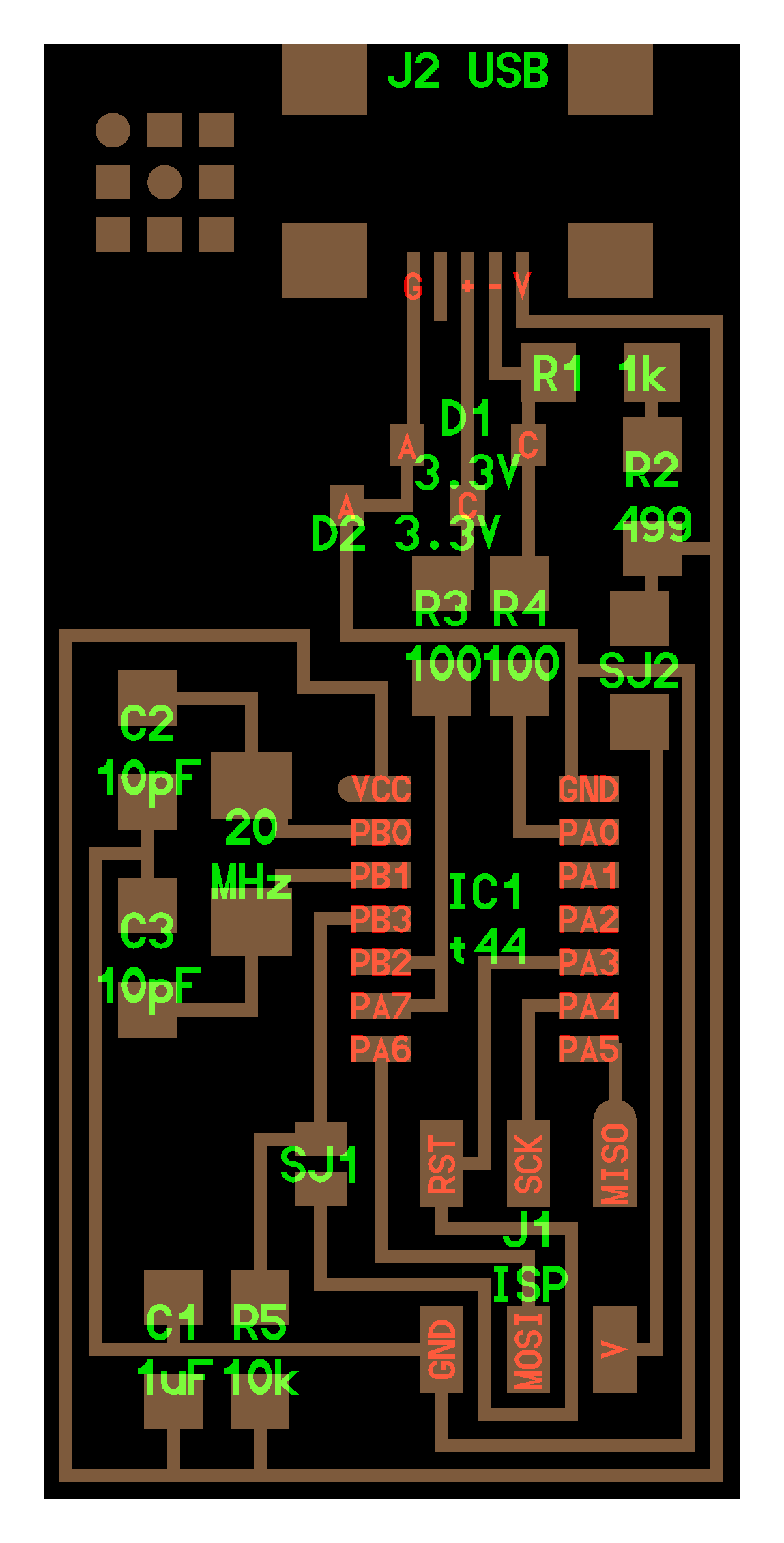

The goal is to mill this board and stuff it with all the components:

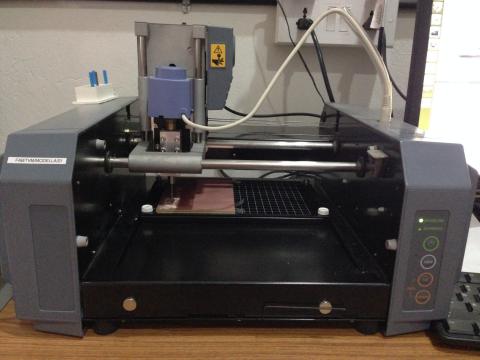

Milling the Board

I followed this excellent tutorial by Adam Harris to get familiar with PCB milling.

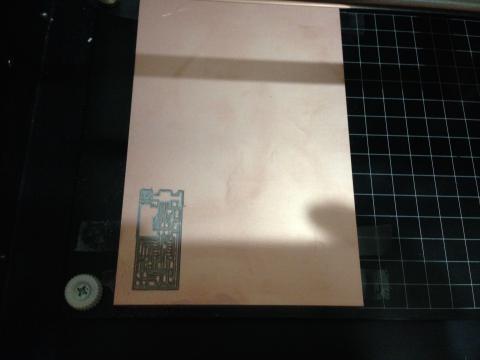

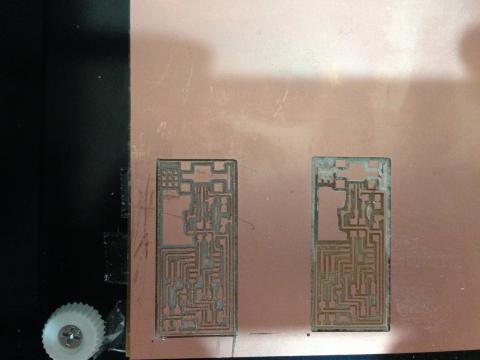

My first attempt did not work out well.

I used the 1/32nd end-mill for cutting the traces instead of the 1/64th one and the traces were either too narrow or completely missing in some cases.

Also, the board wasn’t stuck tightly enough to the sacrifical layer and was moving around a little during cutting.

Here is the board:

Here are the different end-mills from 1/64th, 1/32nd, 1/16th and 1/8th, so that I don’t make this mistake again!

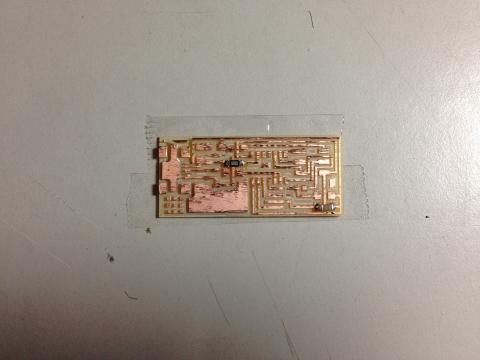

Here’s the 2nd attempt. This time I used the correct end-mill and used double-sided tape to stick the board tightly to the substrate. This time the traces were much wider.

Here it is after cleaning it with soap (to get fingerprints off):

Stuffing the Board

Here’s the inital inventory:

I watched this Collin’s Lab tutorial on surface mount soldering, which helped a lot. But it did take a while to get a hang of the soldering process and figure out the correct way to get the solder to flow.

This is after the first 2 components were soldered.

I’m using double-sided tape to hold down the board.

Here is the board strapped up:

While soldering I noticed that one of the traces (the right most one coming out of the Mini USB pads) had got cut during milling. I bridged this trace with some solder.

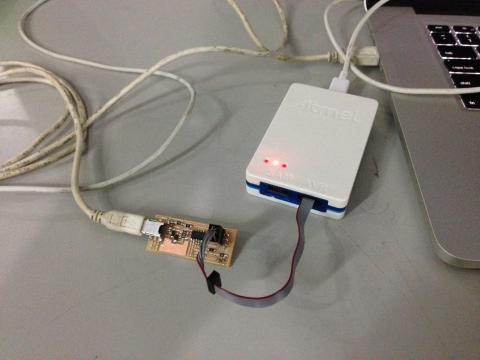

I then followed this tutorial to program the ISP.

Here it is hooked up to another FabISP to be programmed:

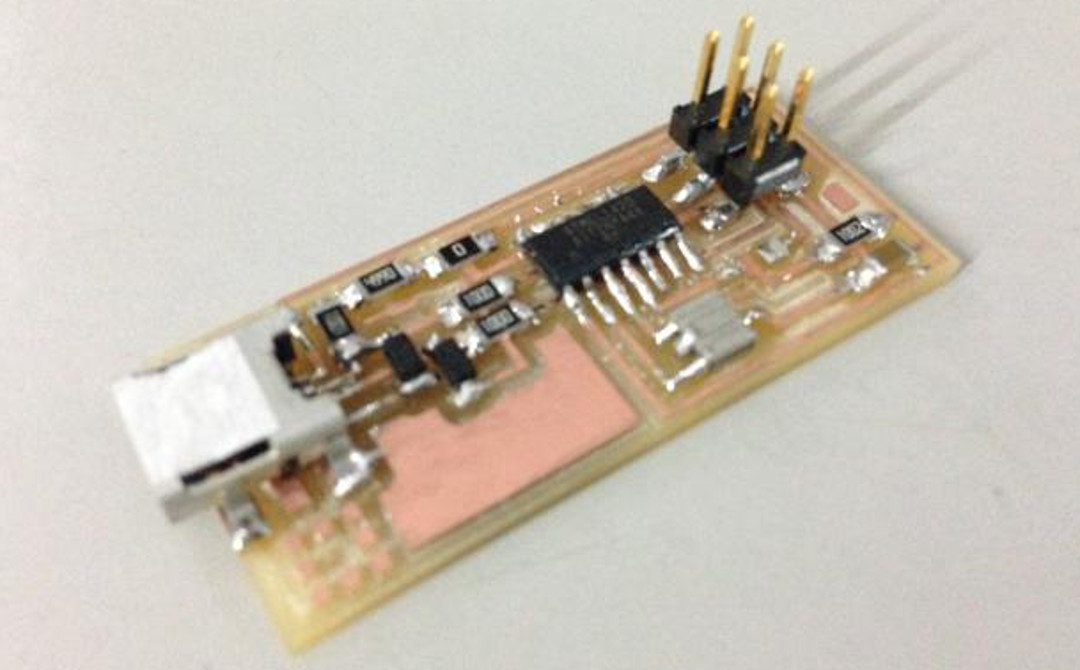

Here is the final ISP: