WEEK 9 - Mechanical Design, Machine Design

TASK:

Within 2 weeks,

* make a machine, including the end effector.

* build the passive parts and operate it manually.

* automate your machine.

* document the group project and your individual contribution

* Decide on a project and organize development in a group. Access consolidated group work here!

* Individual tasks:

- Research on options for End Effector design

- Design

Decide on a project and organize development in a group

Project: 3-axis machine

Group members:

Hendra

Keith

Steven

Shin Jen

Access consolidated group work here!

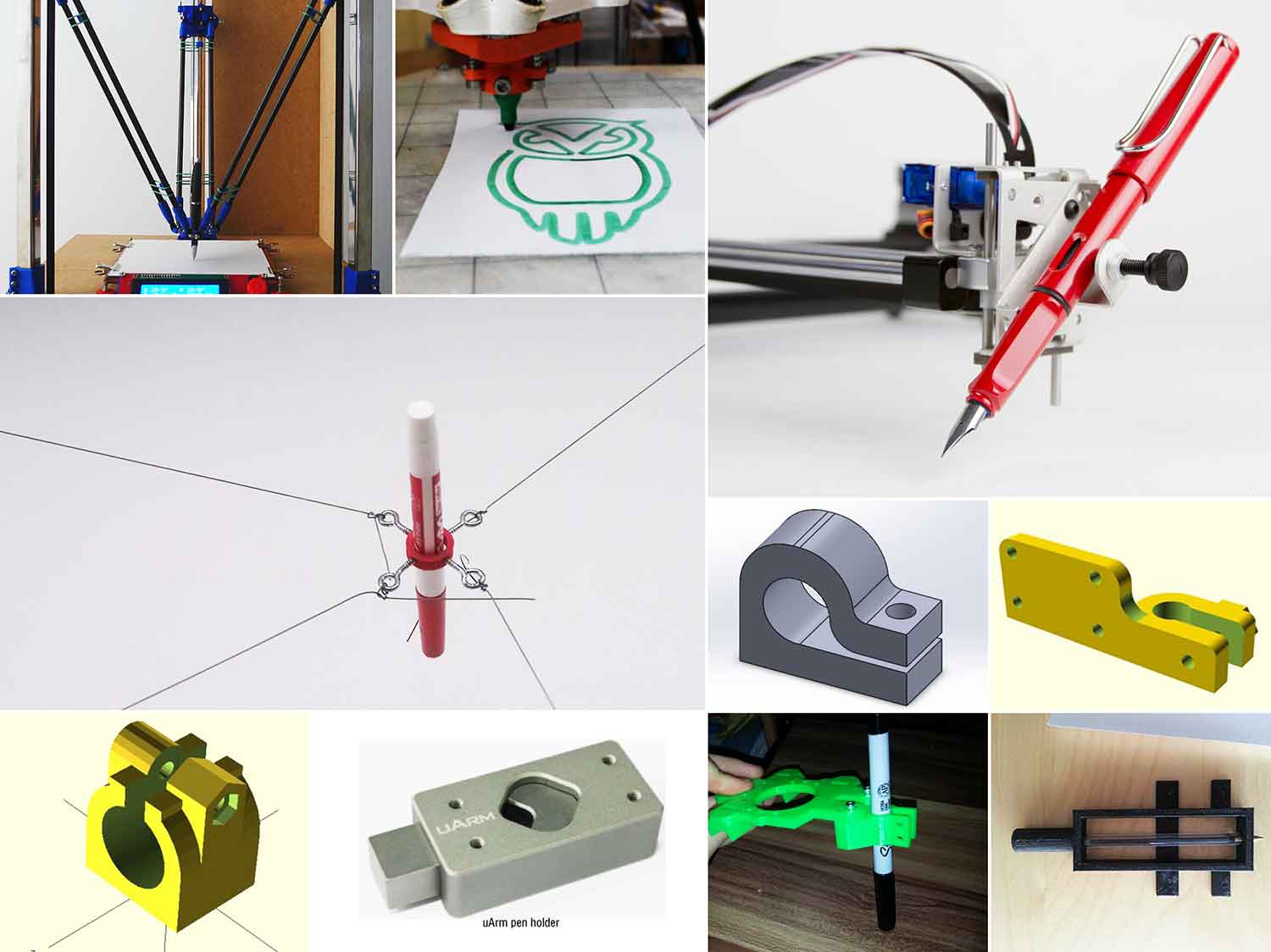

Research on options for End Effector design

An End Effector is a device at the end of a robotic arm where it interacts with the surrounding environment. For the 3-axis machine project, the team has decided to create one that inscribes with ink. The End Effector should be able to not just secure a pen or a marker on an axis but should also be interchangeable.

Below are links to references:

Cyclops

Steel pen

Axi Draw

Uarm

Melenbrink

Thingiverse 1

Thingiverse 2

Thingiverse 3

Part of the research took into account of different sizes of markers, pens and pencils. One of the main objectives is to identify the various thicknesses and average length. These information was further adapted into the design of the End Effector.

Design

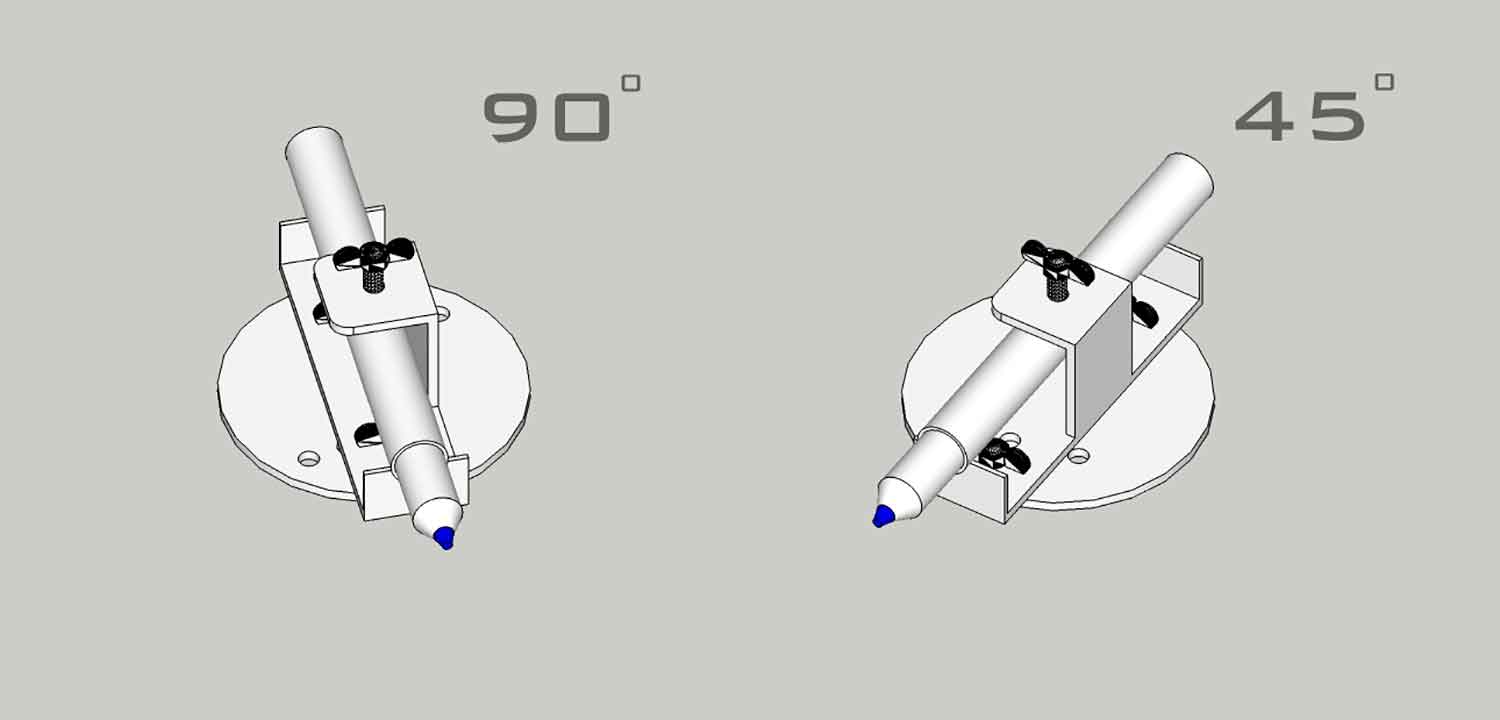

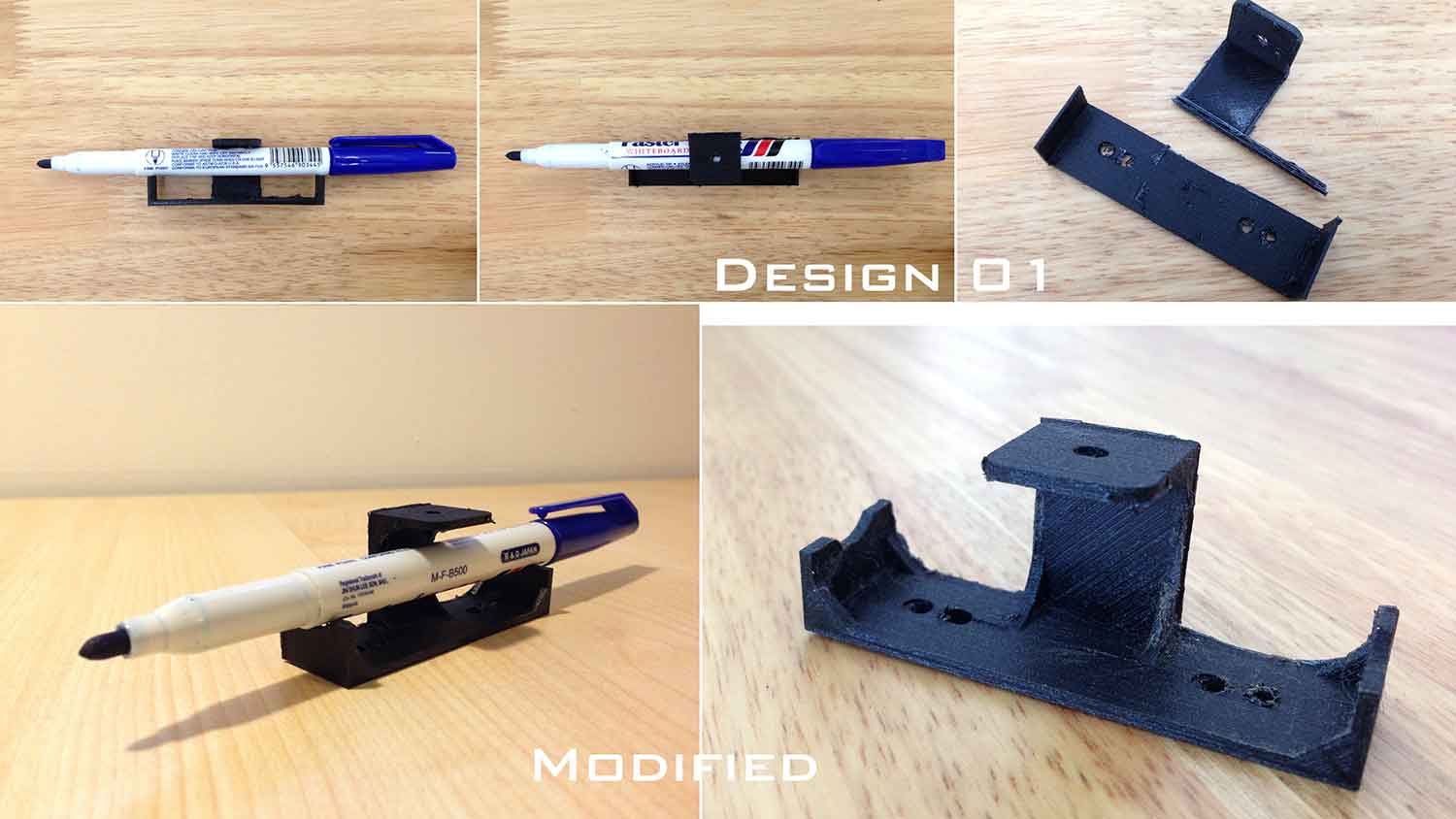

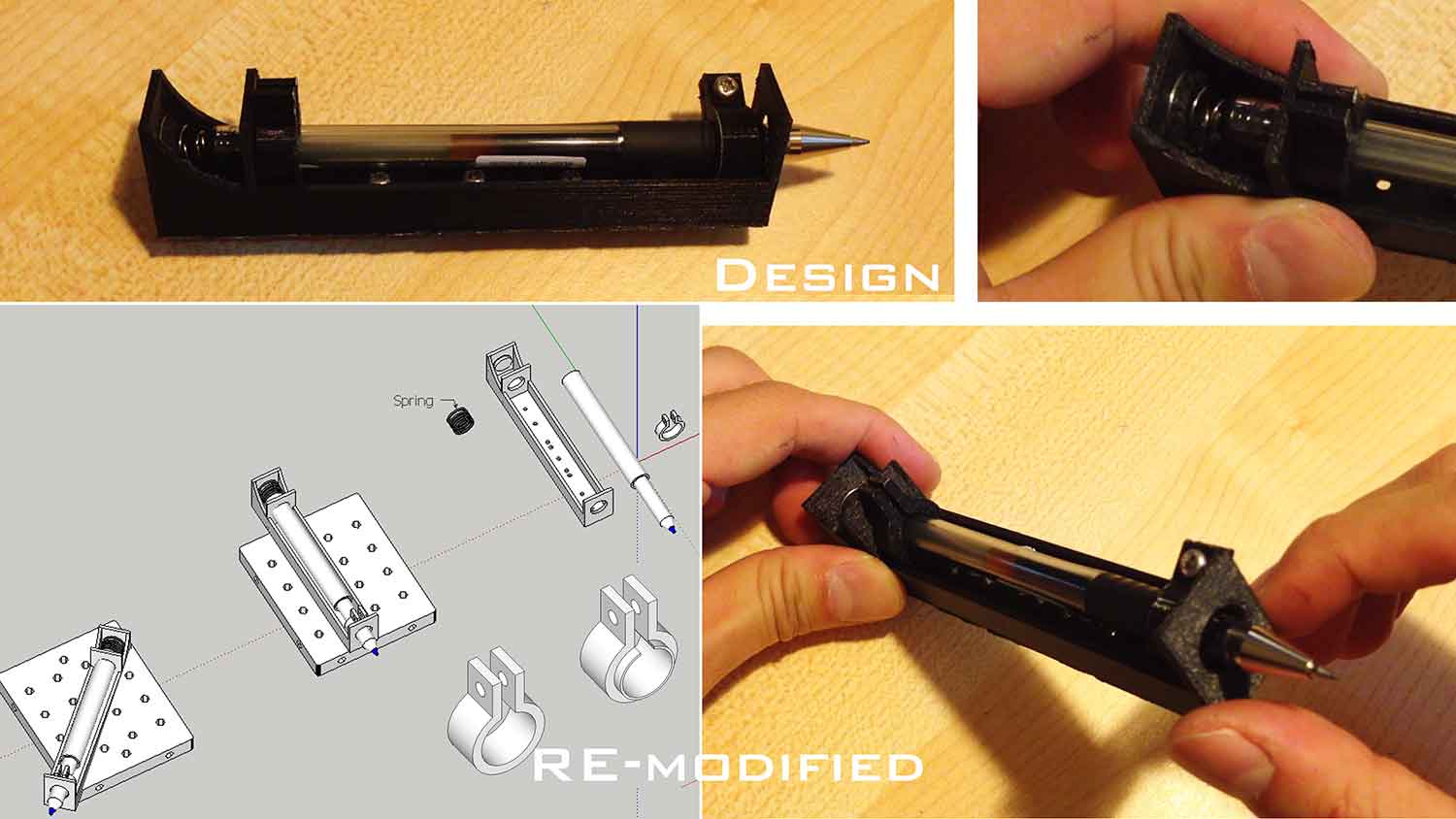

After discussions with the team, a simpler End Effector design was chosen, similar to the Axi Draw machine. The elements consists of a grip, capable of holding onto variant sizes of markers, pens and pencils, fastened using 4mm M4 Wing bolts. The grip shall be attached to a circular plate which is essentially connected to the 3-axis machine to allow for changing of inscribing angles.

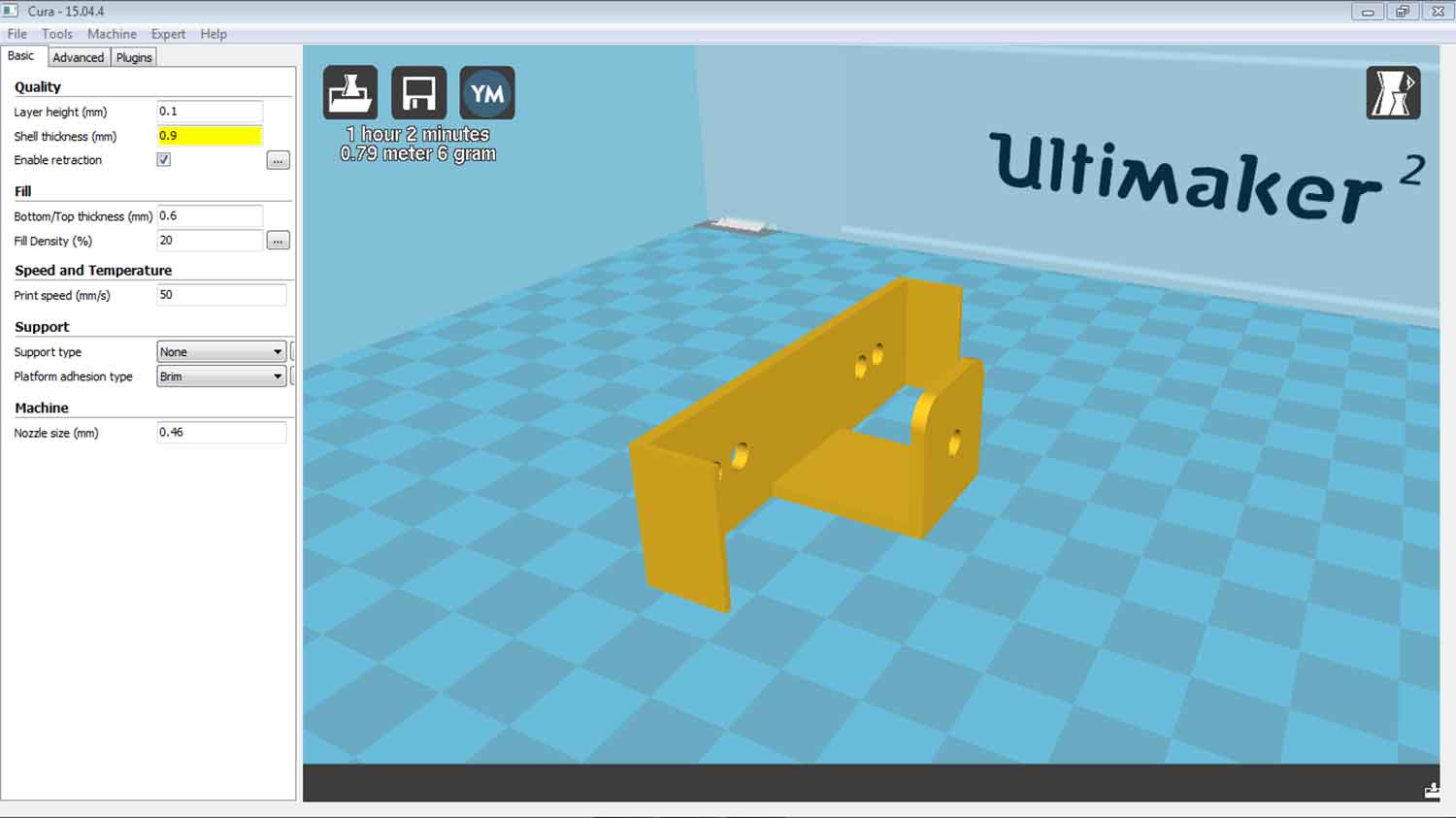

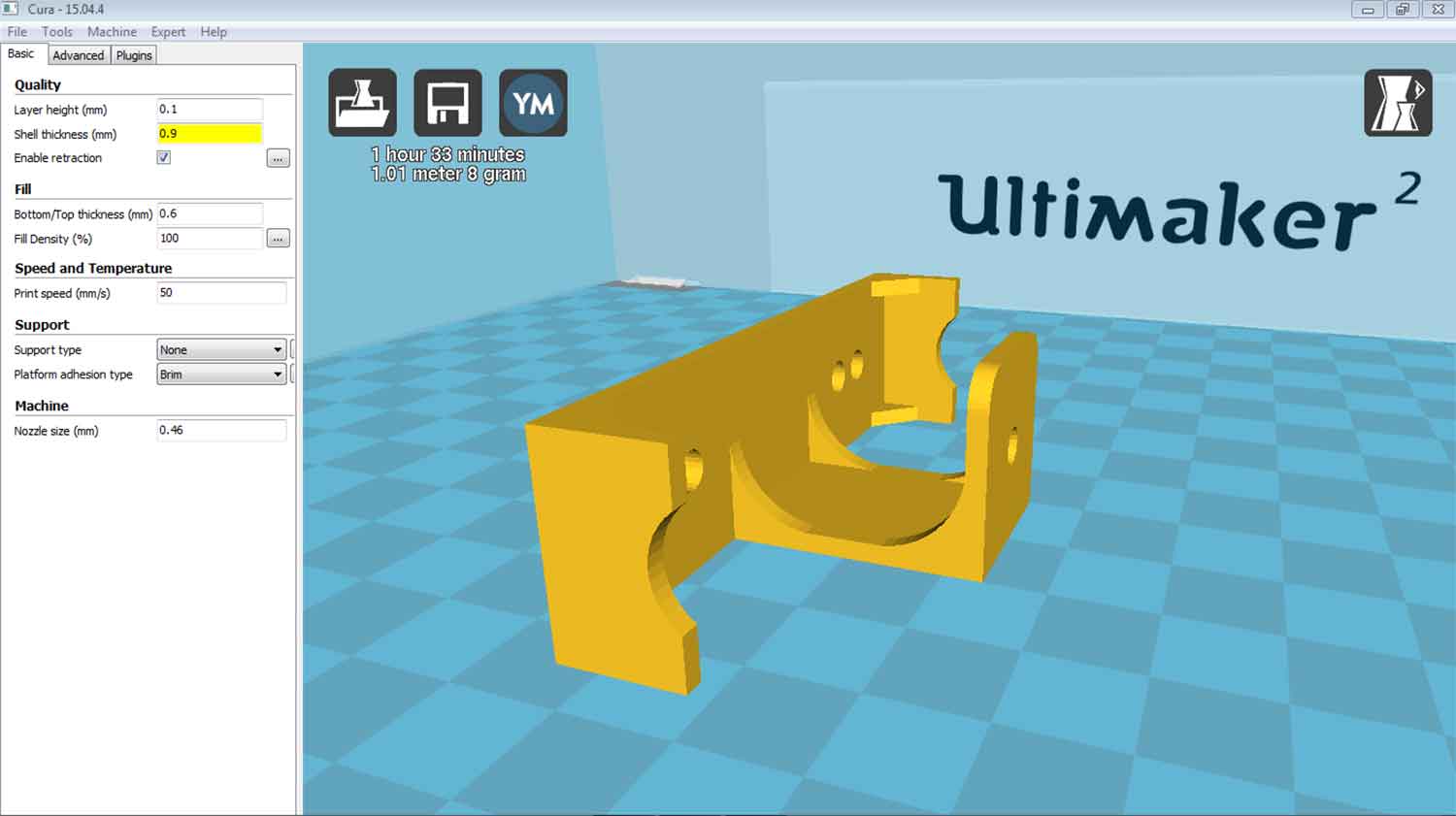

The model was created using sketchup and exported as stl format for printing. Creating the model was simple and straight forward as the design consists of simple geometries. Extra efforts were put in grouping the components as they needed to be saved as seperate stl files for 3D printing.

End Effector Sketchup file: Download

Cura for Ultimaker: Download

Modified End Effector Sketchup file: Download

Using Cura, the End Effector model was initially set to a default of 20% fill density. The printed model was further experimented with bending and pressing to test for possible breakage. It was broken quite easily. A second attempt was done but this time supports were added at all corners and overall thicknesses were increased to 2mm. The second attempt was also printed with 100% fill density and the print result was a lot more sturdy and firm. Fitting the various stationeries onto the End Effector was a breeze.

Reflections

This week has been quite interesting as the team was splitted up into groups. For the first time all disciplines came together to complete a task. One of the challenges when creating the End Effector has been the lack of good examples for referencing and getting parts together hasn't been easy as team mates were still caught up with their own roles in the project. Having said that, we are looking forward to next week as we gear towards gathering parts and completing the final tasks.

All-in-all, this week has been very interesting!

Modified End Effector Sketchup file: Download

End Effector Sketchup file: Download