assignment 14

composites

14th week

This week´s assignment is make a fiber composite practice.

Because at the make something big week I only used the CNC for cutting, the aim for this week was to use the CNC again and work with the Z axis too, to mill the volume to then make the composite.

Milling

I used a similar STL terrain generated in Processing as I made for the 3d Printing & Scanning week.

I had to adjust the STL scale in Rhinocam to fit into the material height (the chosen material is a piece of foam, 30mm height). We generated the 3 routines (rough, finishing and final cut) from it.

We used a 6mm diameter end-mill for the rough cutting and a ball-nose mill of the same diameter for the finishing/ending (45 and -45 degrees finishing).

The milled piece!!

Composite

Nedded materials: Unmolding spray, resin, a vacuum bag, burlap, transparent plastic film, and a piece of fabric.

Preparing the vacuum bag, our friends from the automotion workshop at the university had a special plastic and some kind of double-sized tape that looked like plasticine to seal up the bag.

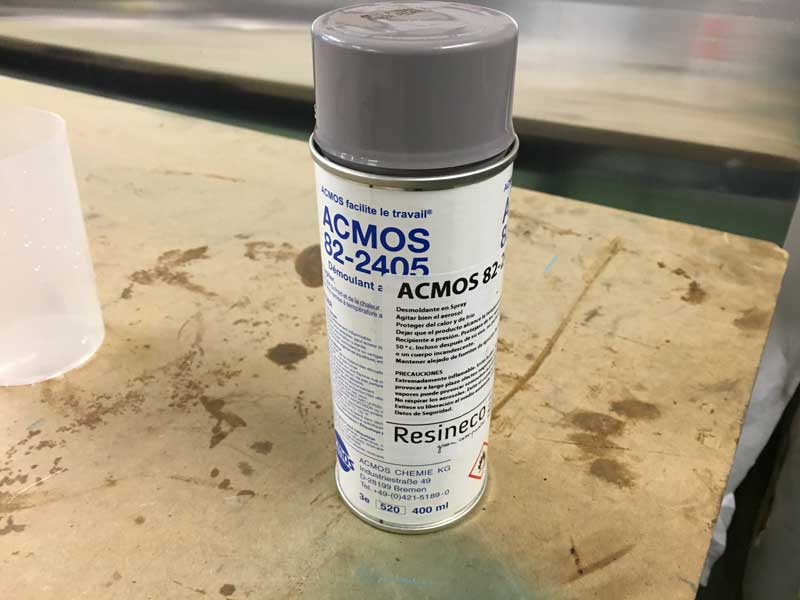

Unmolding spray:

Cutting the fabric to a proper size:

For the resin, 100 of A part and 16 of B part, we made double just in case.

Aplying the resin:

Aplying the plastic film at the top:

Fabric top and folded blanket to avoid to mess up the composite because of the pressure with the valve:

Closing the bag carefully to avoid void spaces:

Cutting the plastic to introduce the valve:

All ready¡¡

We left the vacuum pump turned on for 48h, the whole weekend.

The "unboxing":

Conclusion: we put too much material and it got no uniform over the surface. Also maybe we should have used other unmolding material (like wax?), it got super glued to the surface, taking it out one layer of the polyetrylene.

I think that fabLab should had provided a proper fabric to this assignment. This sintetic one is not the best for this purpose.

COMPOSITES |

|

Shown how you made your mould and created the composite |

X |

Described problems and how you fixed them |

X |

Included your design files and ‘hero shot’ photos of the mould and the final part |

X |