assignment 5

3d scanning and printing

5th week

This week is about 3d printing and scanning.

3d Printing

The goal for this practice is test all the machines available at our lab with the same model generated by ourselves.

My 3d modelling skills are not the best in the world; but i´m not bad at coding. So I decided to play a little bit with tools I already know for generating the STL to print.

I work a lot with Processing, to generate interactive/reactive visuals and graphics. There are a lot of libraries for create 3D environments, like Hemesh or Toxilibs.

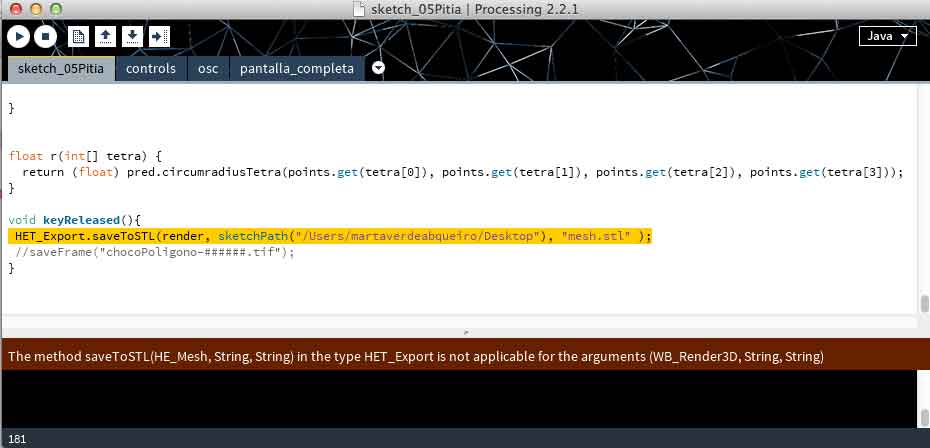

First, I tried to export the geometry from some reactive visuals I made months ago for a musician, but the geometry wasn´t easy to export, created with functions not compatibles with the exporting available ones:

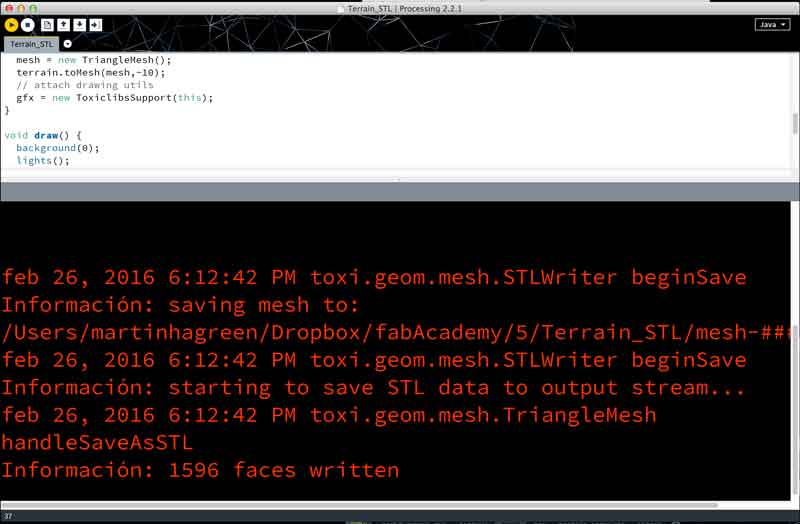

So, playing a little bit and learning about the posibilities of the different libraries about how to export 3D models, I chose to use Toxilibs with a simple model, because this assignment is about test, not create the perfect 3D figure.

Toxilibs gives even a detailed log about the features of the exportes 3D model:

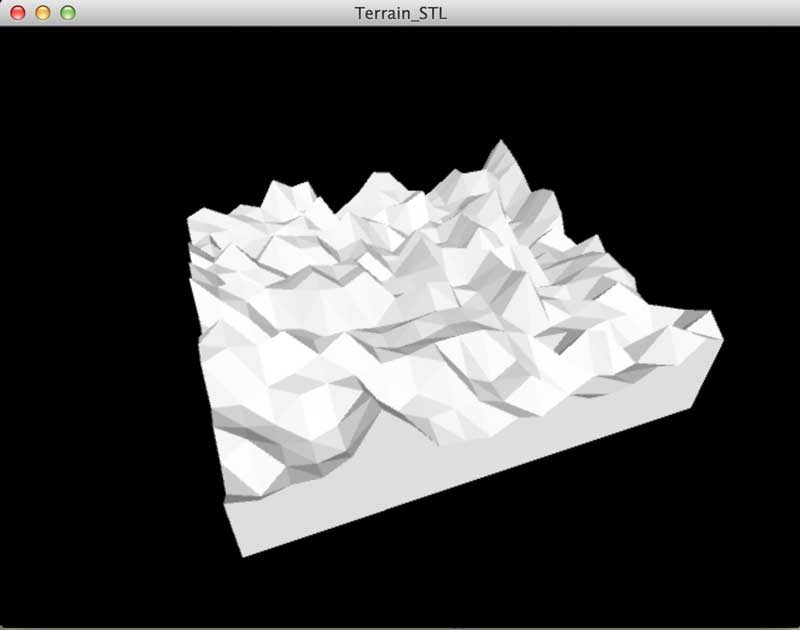

I made a simple terrain, generated by a noise function.

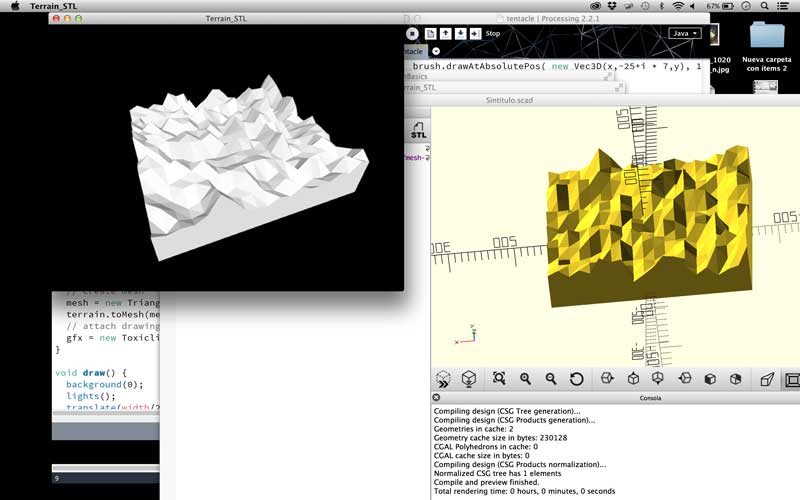

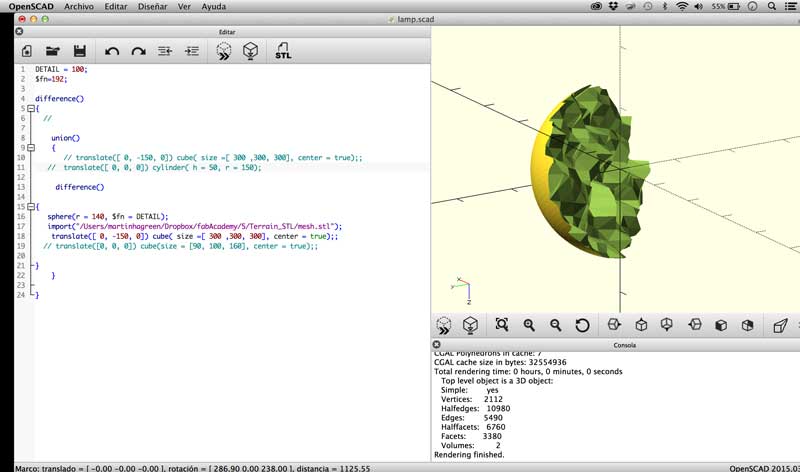

I wasn´t satisfied with only export the simple 3D model with Processing. Moths ago I worked a little bit with OpenScad for a project, so I imported the STL to OpenScad to modify it in some way.

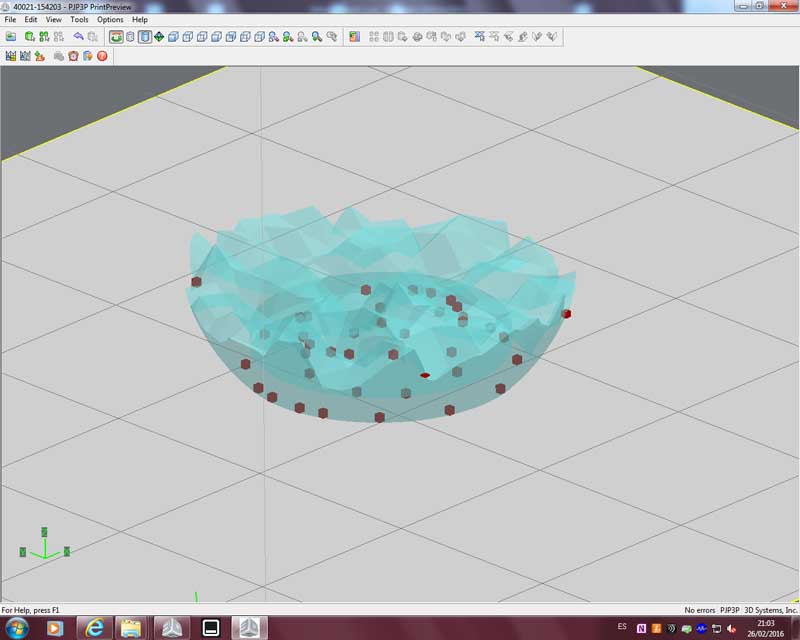

For make the model more complex, I extruded the terrain model to a semisphere, to obtain curves an sharpen shapes at the same time; with a difference() function.

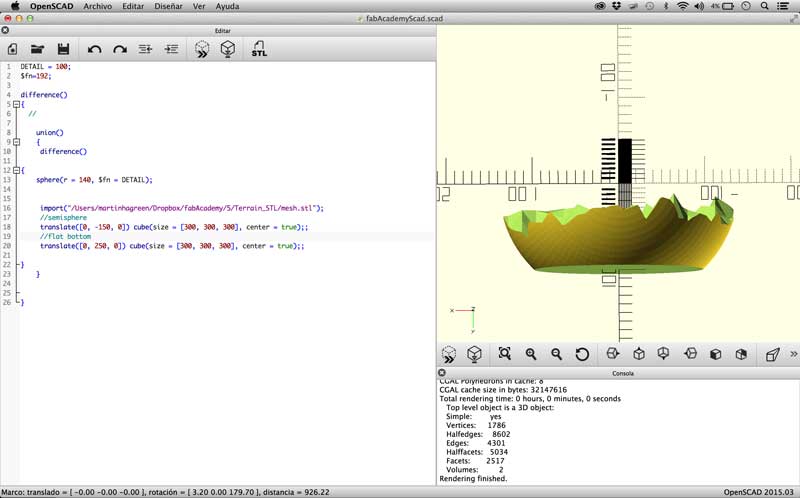

Because the semispehre would be hard to print without supports, I made a flat base to the new figure substracting a cube positioned at the bottom.

Work with openScad is cool, 3D parametric modelling for coders!

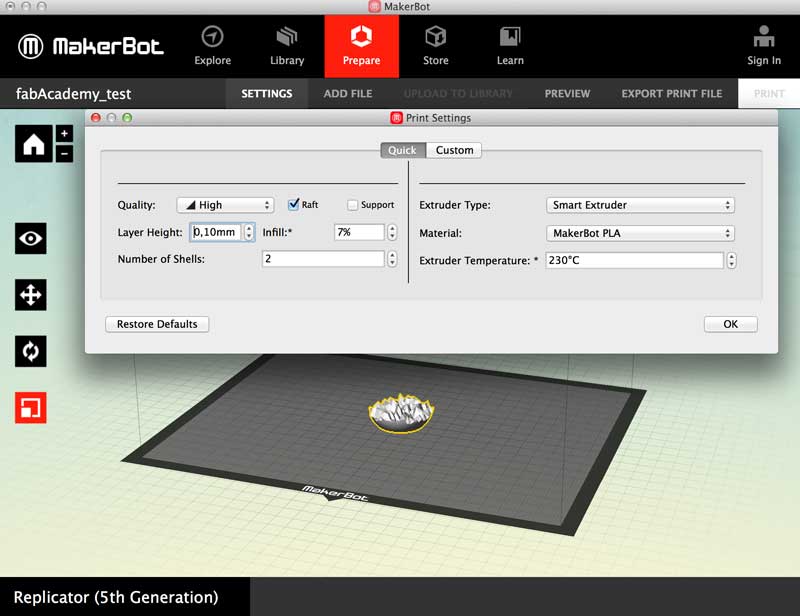

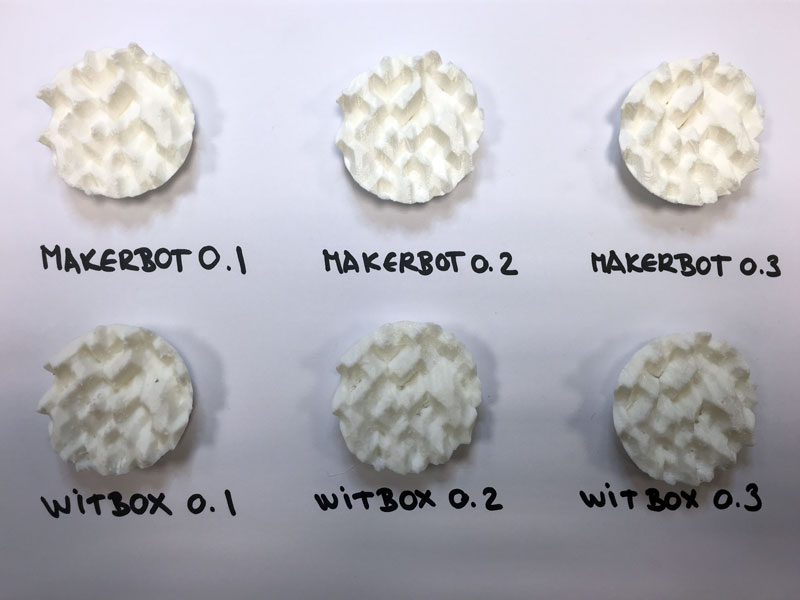

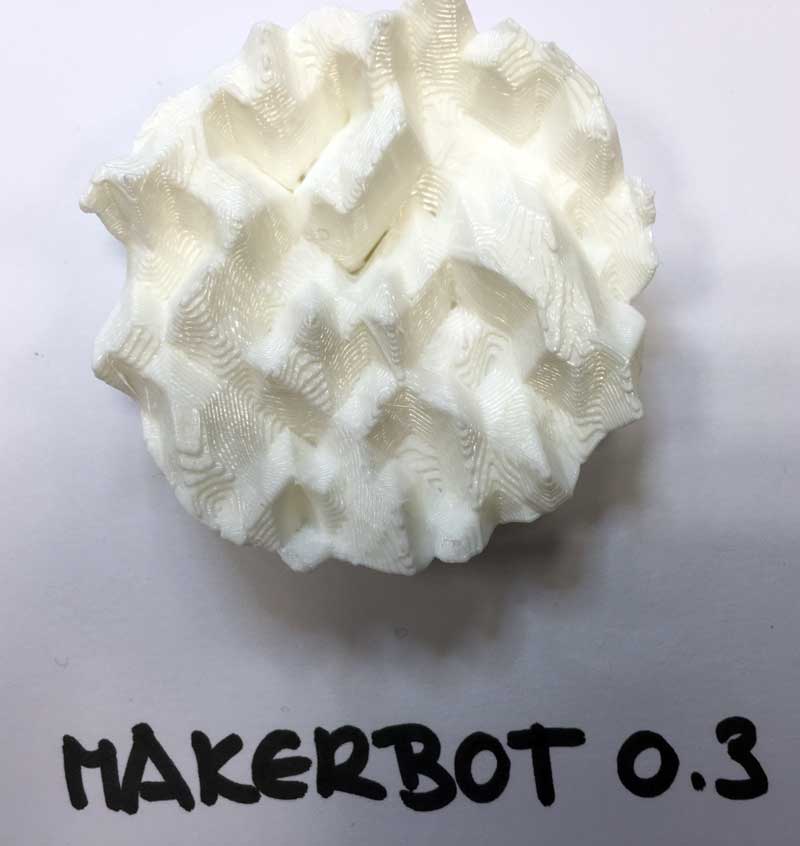

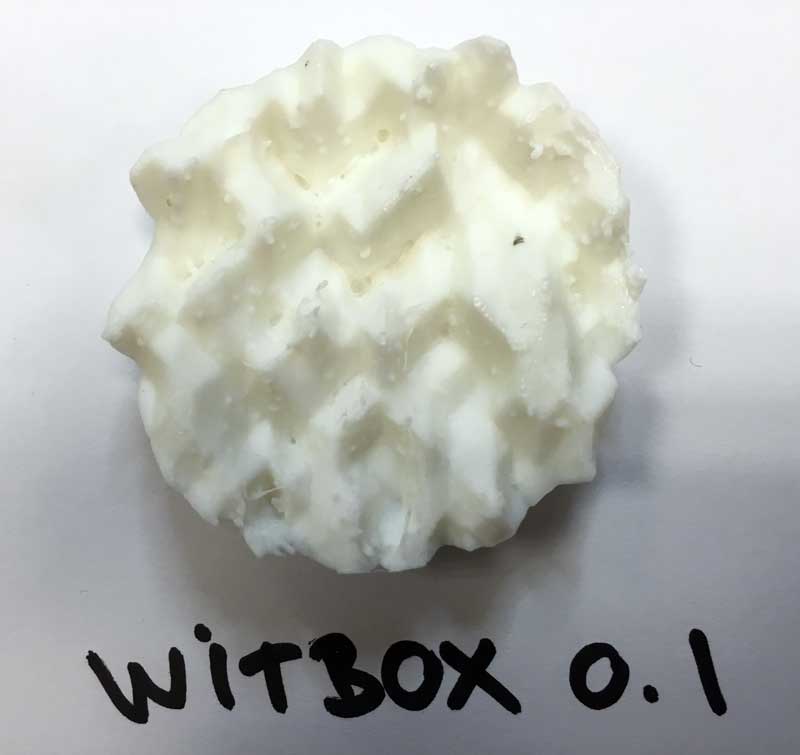

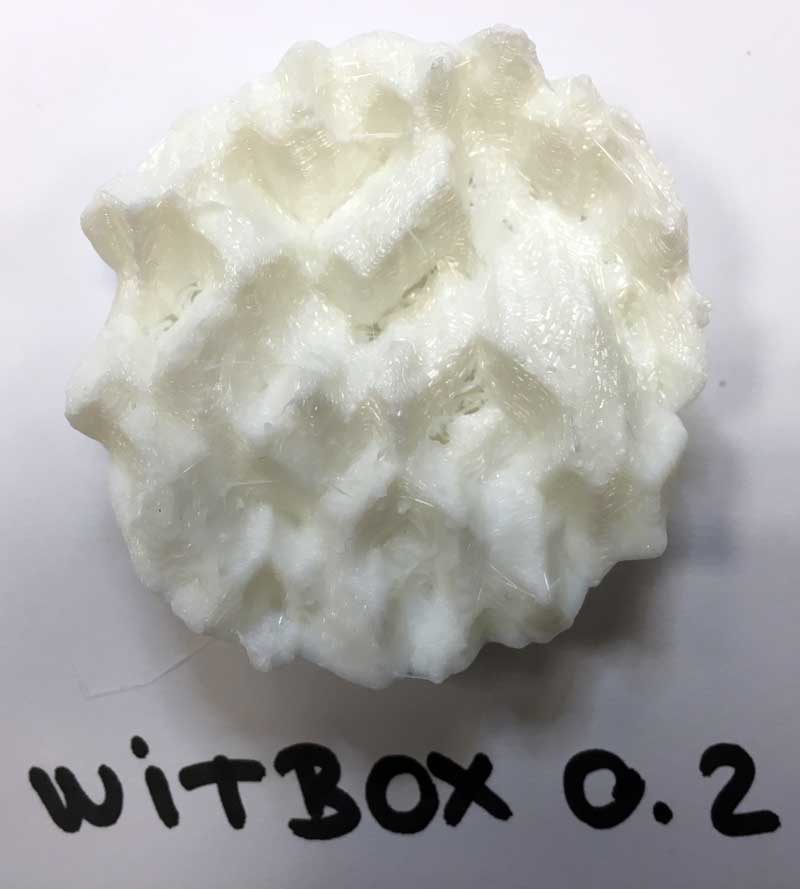

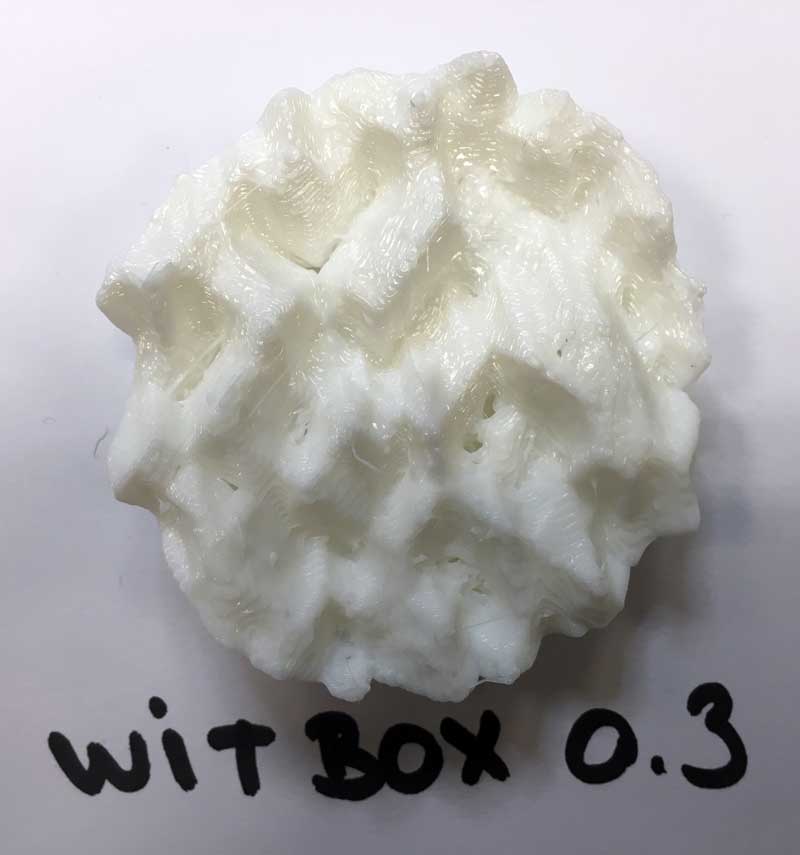

We have different types of 3D printers at the fabLab, first we tested the MakerBot 2 and the BQ Witbox. Both use PLA filament.

Makerbot has their own software to print,

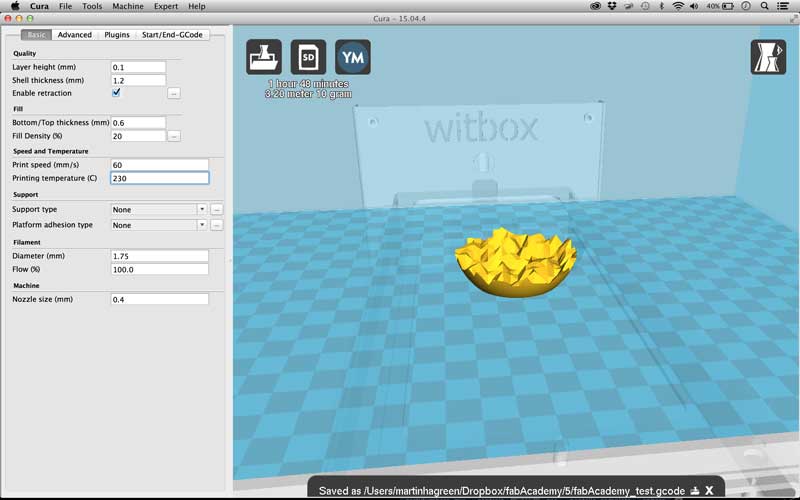

For the BQ printer, we used Cura for generate the .gcode file, with the same settings as the Makerbot software.

I realized that the MakerBot did the infill layers with a honeycomb pattern, and the Witbox with squares.

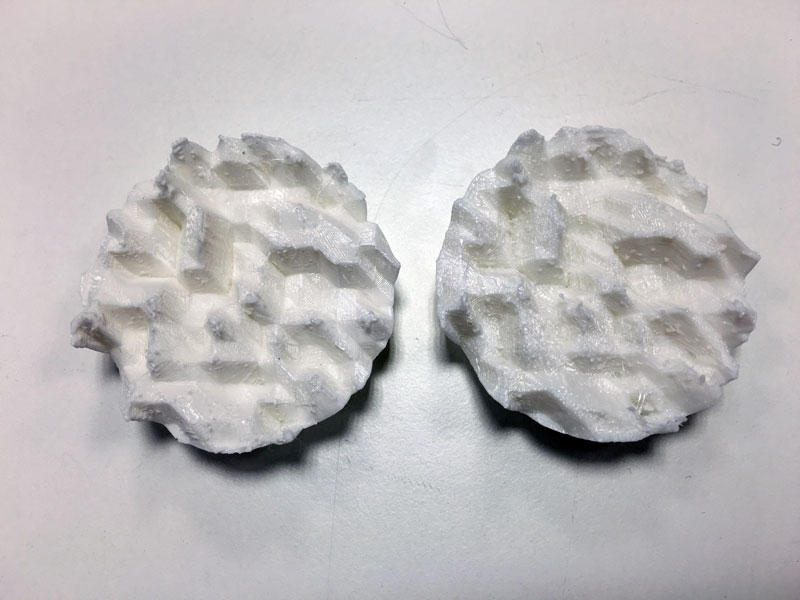

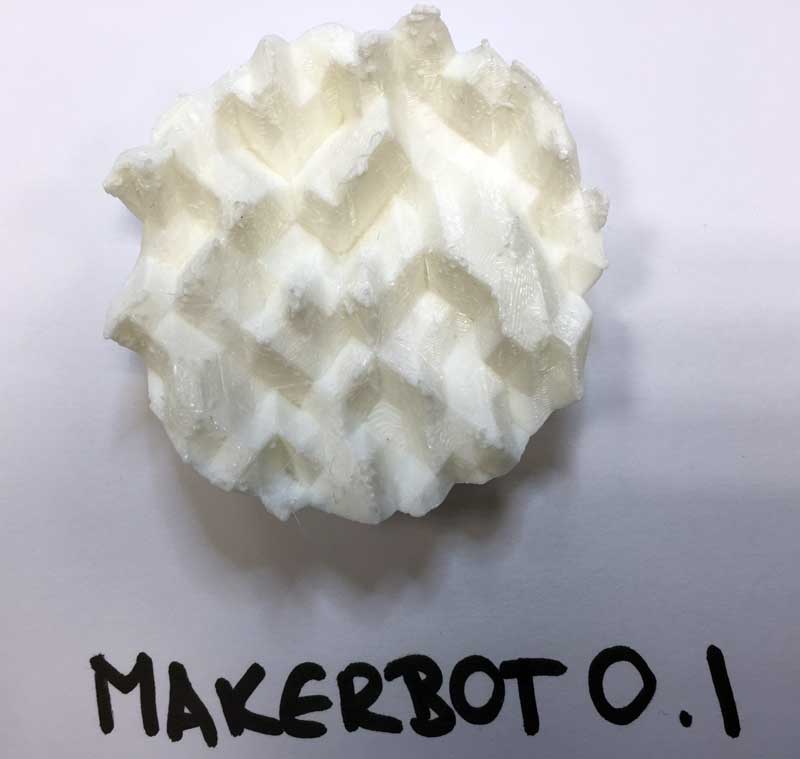

I know that is a challenging figure, but the MakerBot gave us better results than the Witbox, this second one left more remains and dirt plastic. We need to sand it a little bit, and print in both of the printers with different qualities:

We tried to sand the 0.1 Witbox piece with acetone in a glass to make it softer, and it works!

1h 28 min

46 min

32 min

1h 9 min

37 min

26 min

Other Materials & Printers

At the lab, we have other types of printers with different materials.

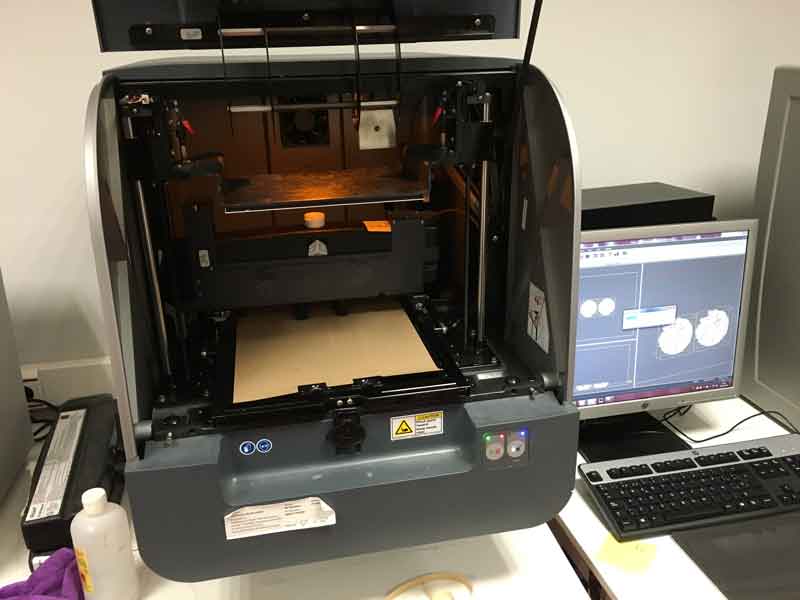

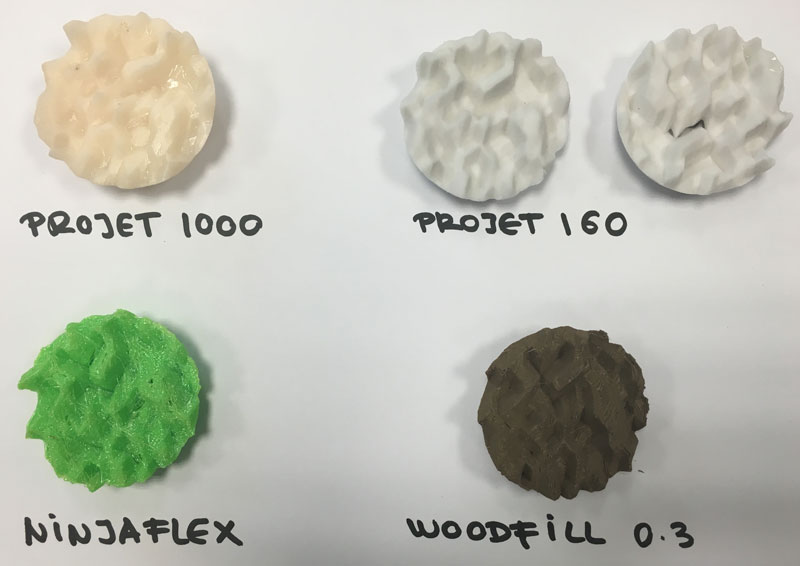

We learn about how to use the 3DSystems Projet 1000 (hard plastic, resin) and the Projet 160 (composite).

Projet 1000, Resin

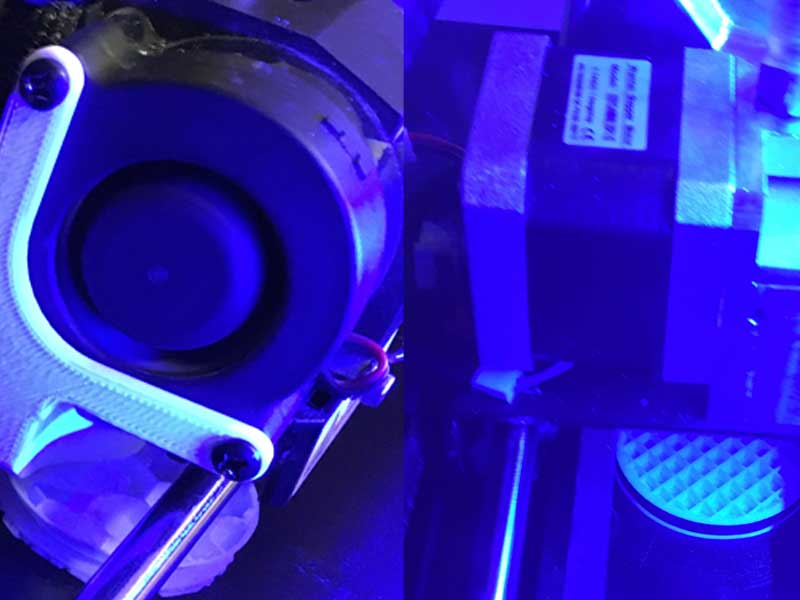

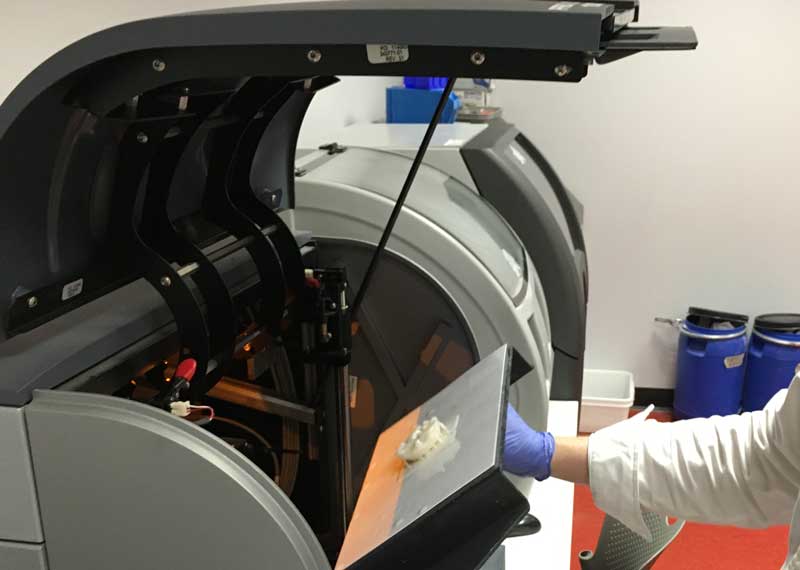

After taking the piece out of the printer, to finish it, its needed to do some chemical process: take out the exceed of resin, wash it and harden it with UV light.

Taking out the exceed of material (5 min):

Washing with water (5 min):

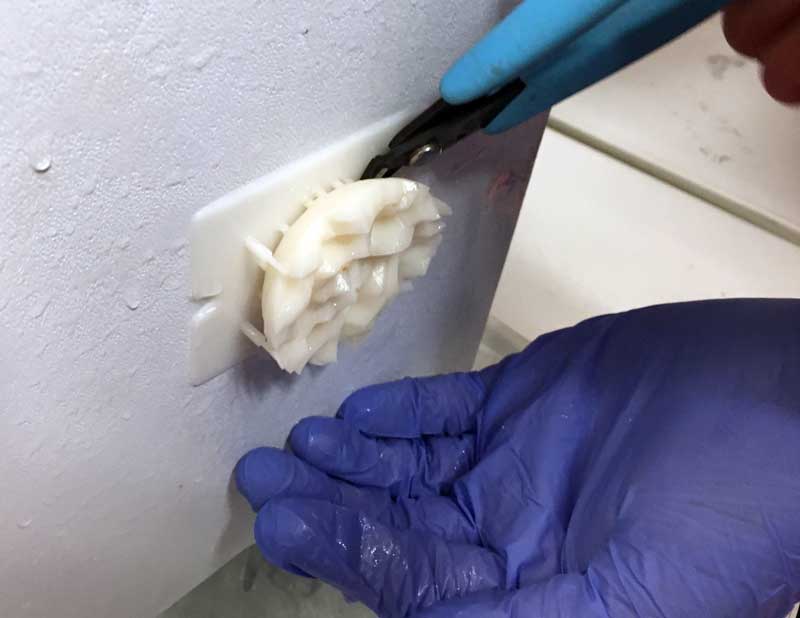

Cutting the piece from the base:

Hardening with UV light (40 min):

The resulting piece is super soft:

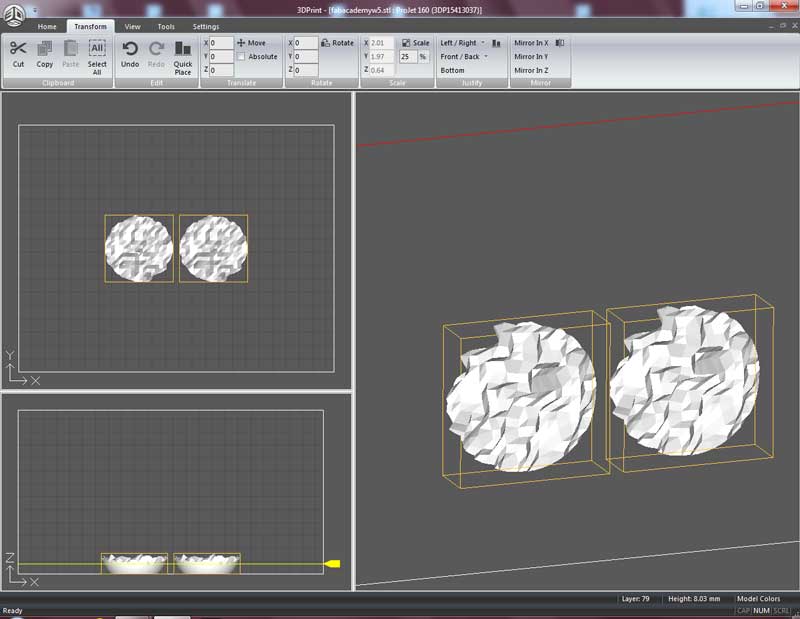

Projet 160, Composite

The composite printers works with a material in "dust", a powder, that reacts with a liquid material to harden it.

We printed the same STL model in two ways, solid and empty, for saving material:

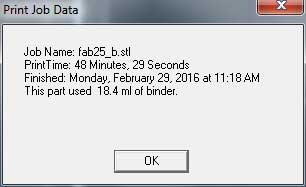

The printing took about 48 minutes.

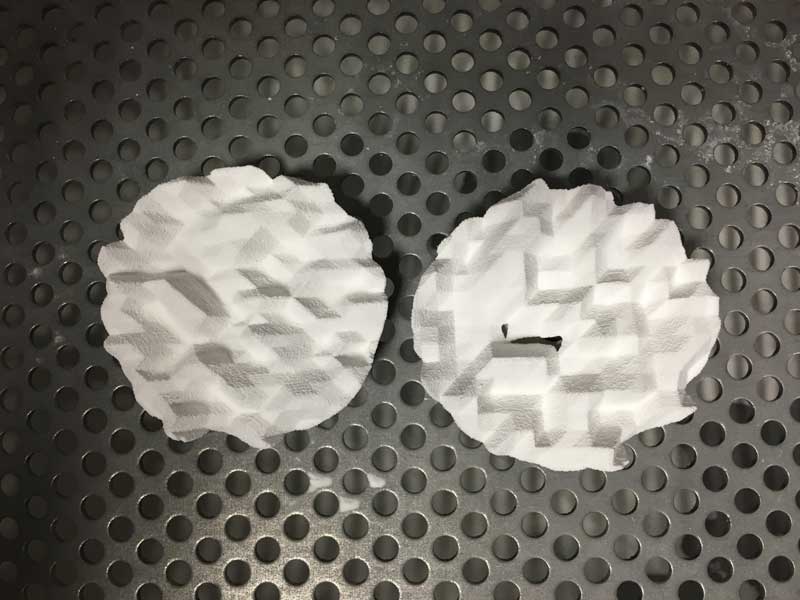

Vacuum the exceed of material and rescue the pieces:

Blowing gently the pieces for cleaning in detail:

The clean pieces, as we can see, the empty one was super thin and we removed part of the surface while cleaning it.

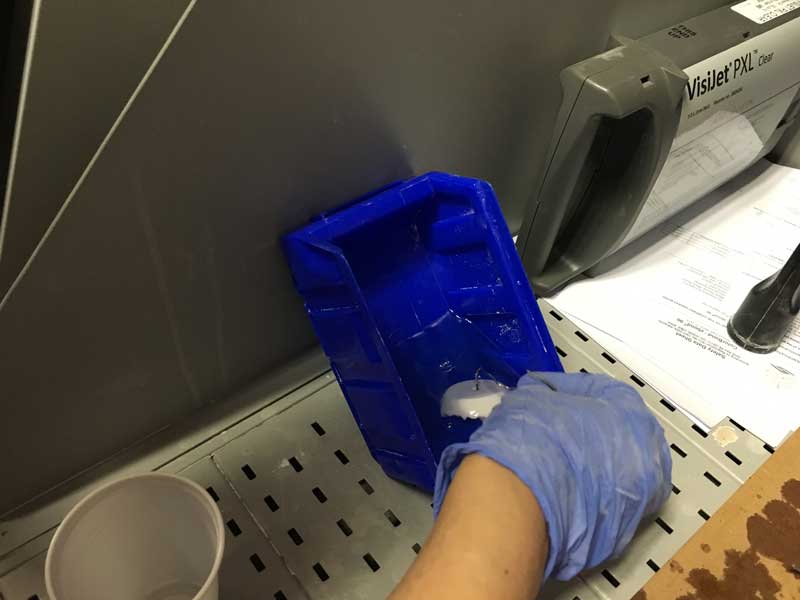

After cleaning them, is needed to harden the pieces with an aglutinant component and let them dry.

The result is quite impressive. super soft faces and definition:

NinjaFlex & Woodfill

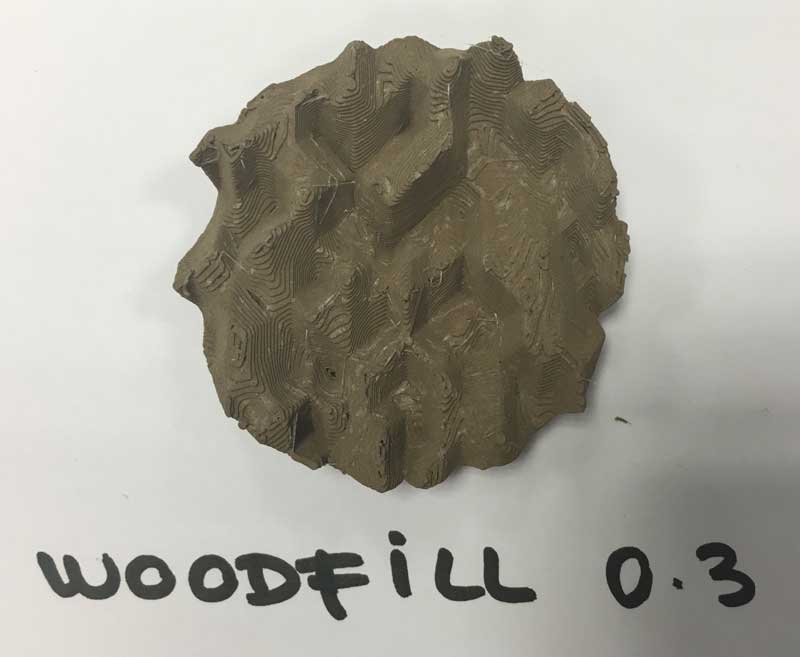

For the last printing tests, we set up the makerBot2 with ninjaFlex (flexible filament) and Woodfill (wooden filament).

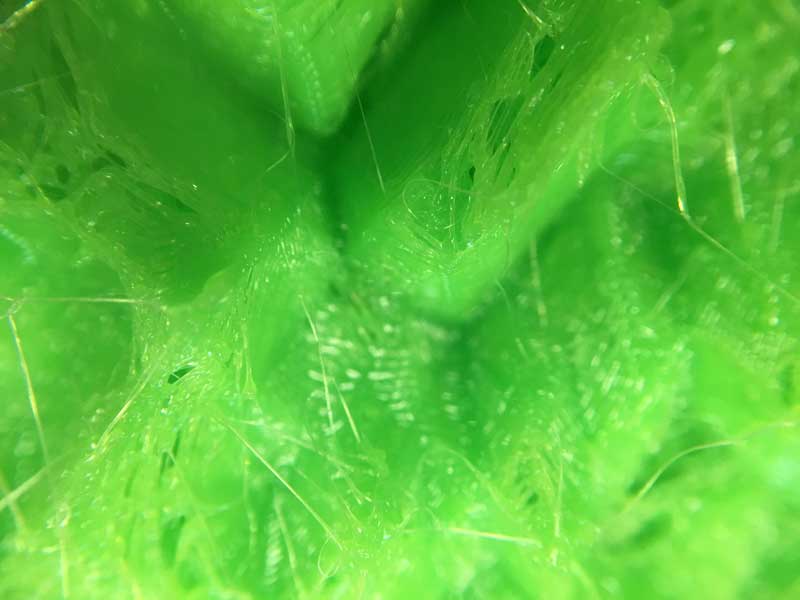

The ninjaFlex is a very weird material, leaves a lot of dirt.

The woodfill is nicer, it looks like chocolate. We printed in low-res.

The final pieces with extra materials, all together:

Angle tests

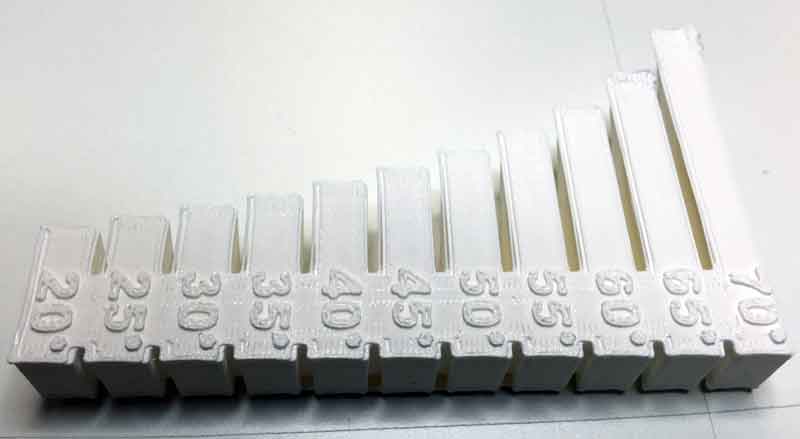

We printed with the Replicator Z18 a test piece to check different angles and look at the behaviours of the material.

From 20 to 70 degrees.

From 55 degrees up, the curve began to be harder. But I think is a good result without using no supports at all.

With the thin walls test, the machine couldnt print anything thinner than 0.40 cm. The original model had 0.05, 0.1, 0.15, 0.20, 0.25, 0.30, 0.35, 0.40, 0.45, 0.50, 0.55 and 0.60 mm walls.

3D Scanning

At th vce lab, we have the Sense 3D Scanner, its like a hand-kinect device. They have their own software to run it, very easy and accurate. The resolution is not the best but is very fast.

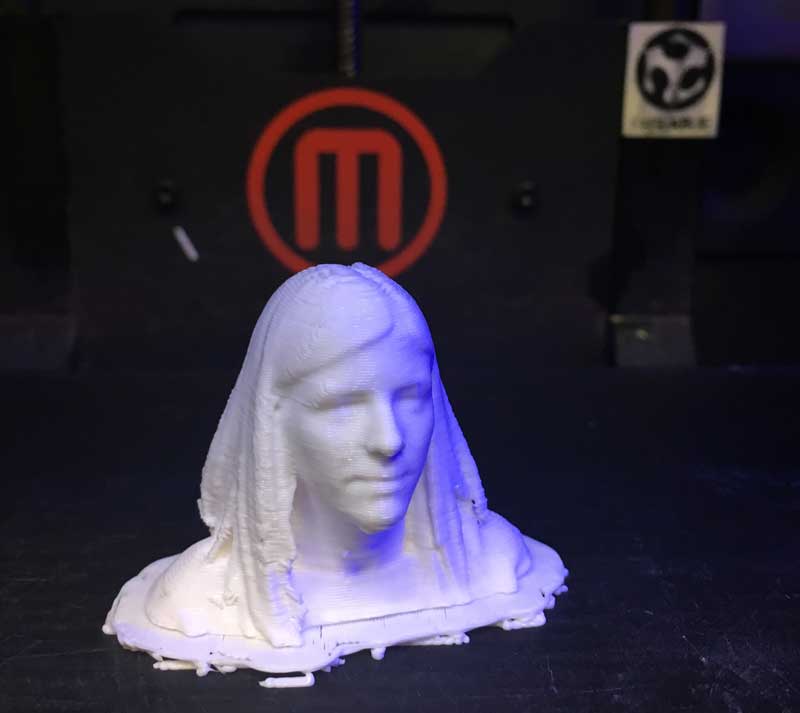

Using a rotating chair is the best way for not lose the tracking or glitch the scan. We scanned each other and used different machines. I chose the makerBot.

3d Scanning & Printing assignment from Marta Verde on Vimeo.

The result was pretty cool, the model took half an hour to print.

Jose printed his scan with the Witbox, and the results were worst than mine with makerBot.

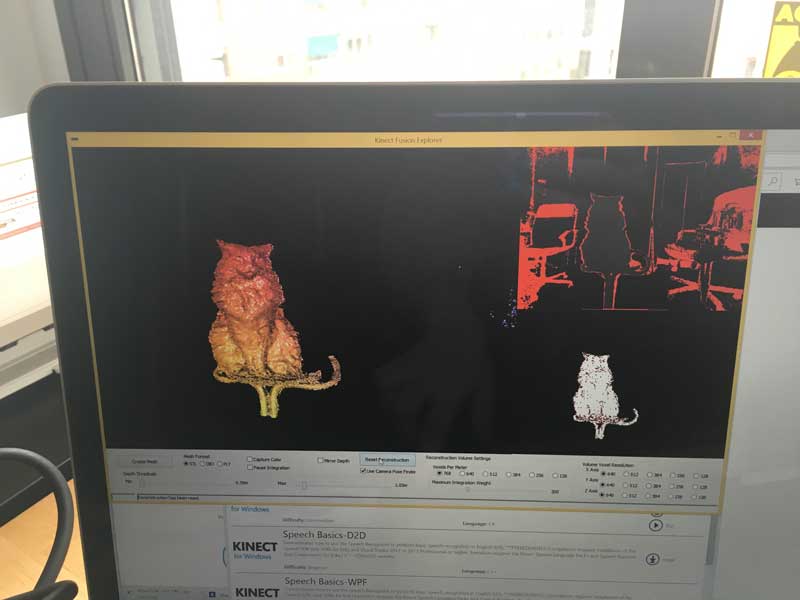

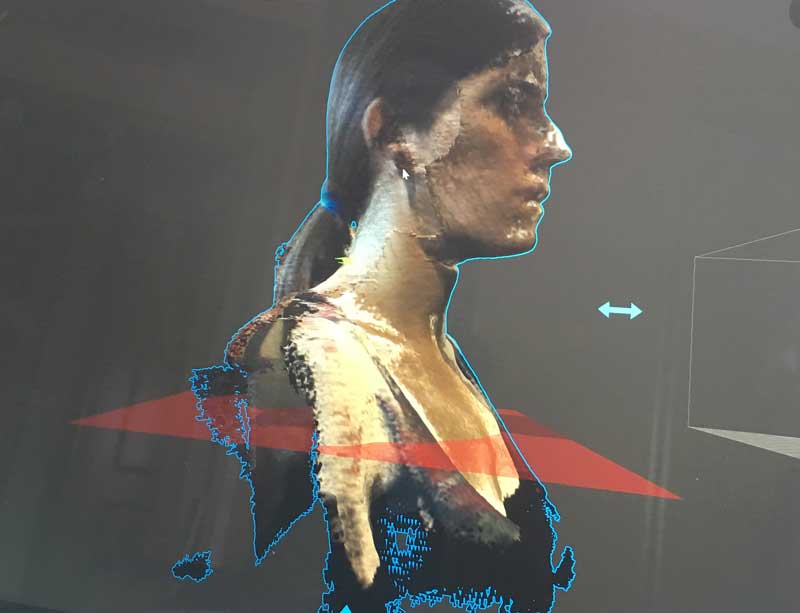

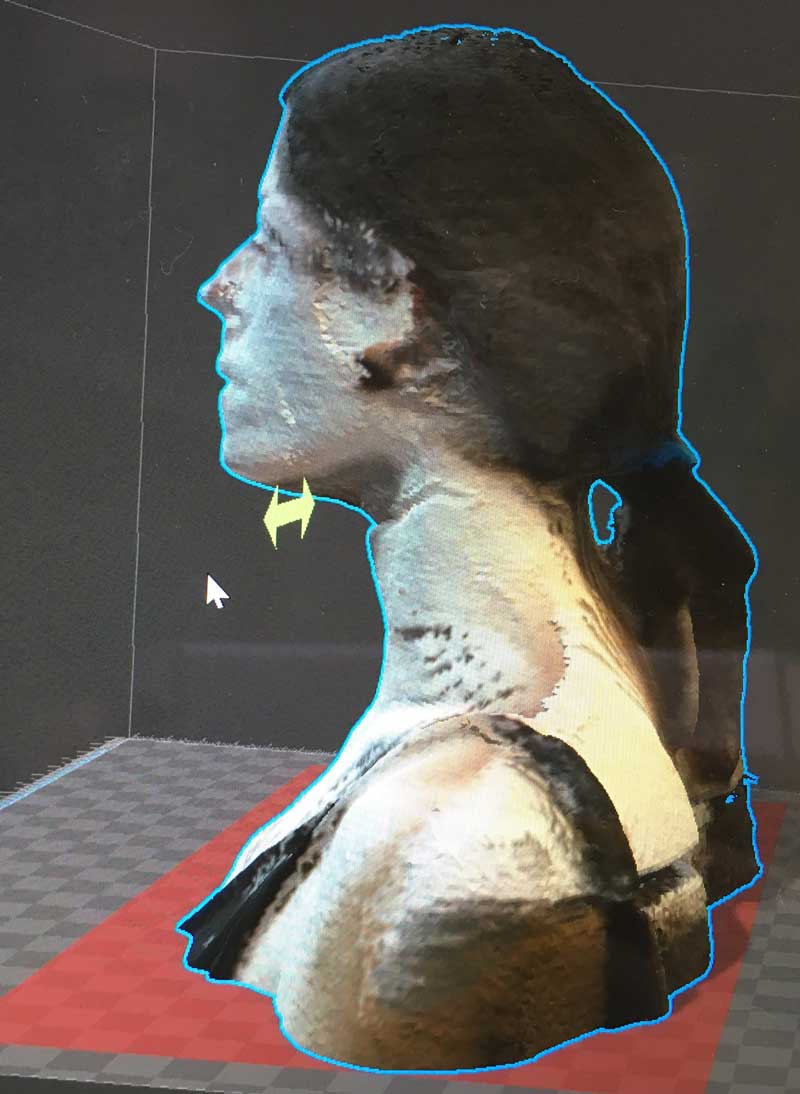

I work a lot with Microsoft Kinect sensor, the first edition was a total blast for the creative coding community. Mine is broken (too much use and travels), but last year I bought the Kinect 2. It has much more resolution than the first model. I downloaded the SDK for Windows 8 and tried the Kinect Fusion App, that allows exporting 3d Models.

Its quite accurate, but because I live alone, I only could try to scan my cat; but Kinect Fusion doesn´t have an option for 360 scanning, and he is not trained to be a scanning model, also he can see the infra-red light that the sensor throws and tried to hunt the light. Bad idea.

For future uses, I discovered a more powerful tool called 3D Builder. It allows to make 360 scans as the Sense software; to avoid capture meshes and join them with MeshLab or similar softwares.

Robot-arm printer

As an super-extra for this assignment, we were able to test how to print with an industrial robot arm. The project is part of a research developed at the Universidad Europea de Madrid, where is located our lab.

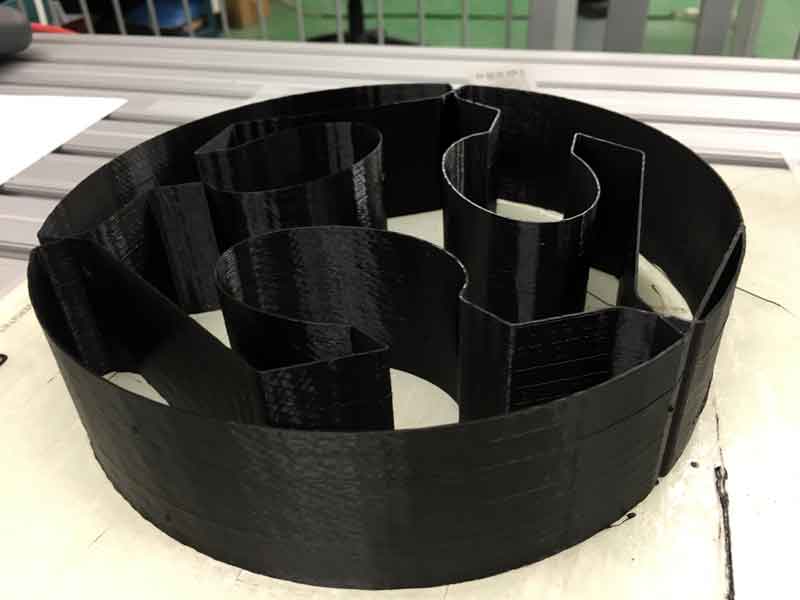

Is still in development, but Adolfo kindly let us try it. It´s an industrial robot arm with a PLA extruder at the end. They work with Rinhoceros, and developed a script for export the meshes to be readable by the robot. For far as now, is a continous printing, so we decided to print the FabLab logo. It took almost 3 hours to print a 20x20x5cm piece.

Robot Arm Extruder from Marta Verde on Vimeo.

Another another another Cat STL

3D SCANNING AND PRINTING |

|

|

Described what you learned by testing the 3D printers |

X |

I learnt about different processes and materials. We should choose the 3D printer, material and resolution depending on the future use and field of the 3D printed object. |

Shown how you designed and made your object and explained why it could not be made subtractively |

X |

The STL model we used on the Projet 160, with the inner void, it couldn´t be made substractely. The others can´t either, that´s why I added the curvy area at the bottom, a milling head couln´t reach that area. |

Scanned an object |

X |

|

Outlined problems and how you fixed them |

X |

|

Included your design files and ‘hero shot’ photos of the scan and the final object |

X |

|