Group work

This week we got tast to test the Design rules of 3d printer. we decided to try different test files to define our 3d printers modeling capabilities. We are going to test our flashforge dreamer.

flashforge dreamer

Technical Specifications

| Printing Technology |

Fuased filament fabrication (fused deposition modeling (FDM)) |

| Build Volume |

230 L X 150 W X 140 H mm |

|

Speed range :

|

10 - 200 mm/s

|

|

Travel speed range :

|

10 - 200 mm/s

|

| Materials |

ABS, PLA Prime. (Others : Flex, T-glass and composite materials such as woodFill, copperFill, and brassFill) |

| Layer Resolution |

0.1-0.5 mm |

| Filament Diameter |

1.75 mm |

| Softwere firmware |

Flashprint |

| Nozzle Diameter |

0.4 mm |

| Extruder Quantity |

Two |

| File type |

STL,OBJ |

| Connectivity |

Wi-Fi, USB Cable, SD Card |

Click here to get more imformation.

Test the design Rules of printer

Our goal is to know 3d printers Limitations. so we decided to print different test files.

Files we test -

Minimum wall Thickness test

Minimum thickness of the slot

Tolerance test

Z-axis callibration test

Overhang test

Settings for all test

Below is our settings for All tests.

Material - PLA

Printing Resolution - 180 micron

Print quality - Standard

Printing Speed : 60 mm/s

Travel speed - 80 mm/s

Infill - 15 %

Nozel Tempreture - 200 Degree

Bed Tempreture - 50 Degree

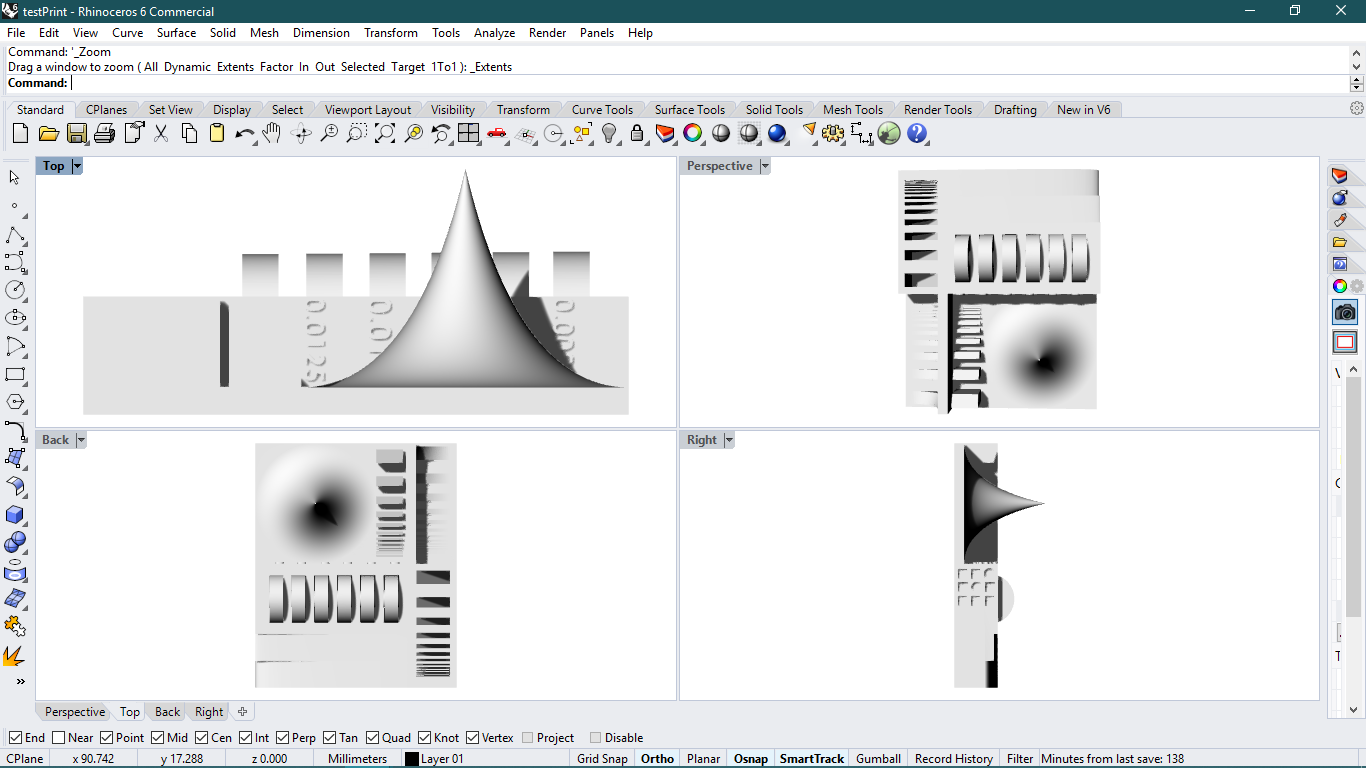

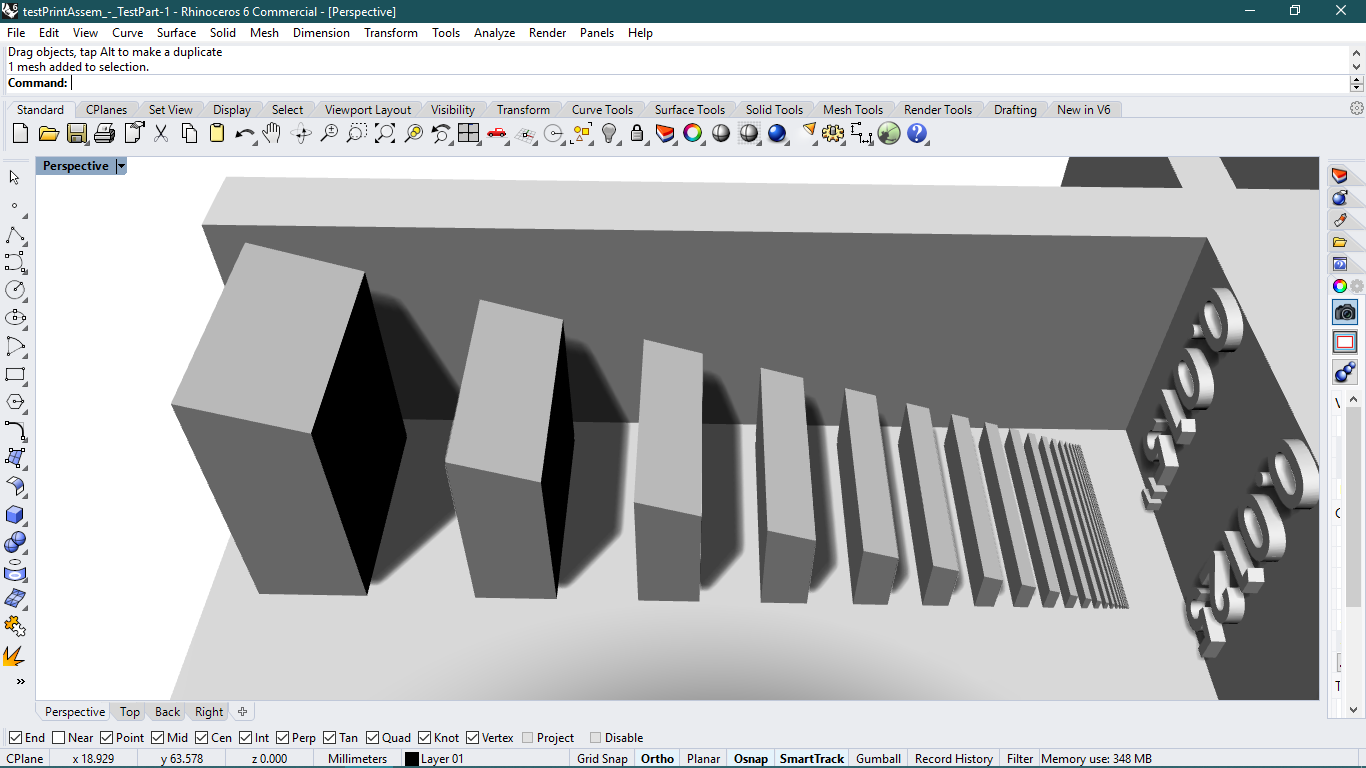

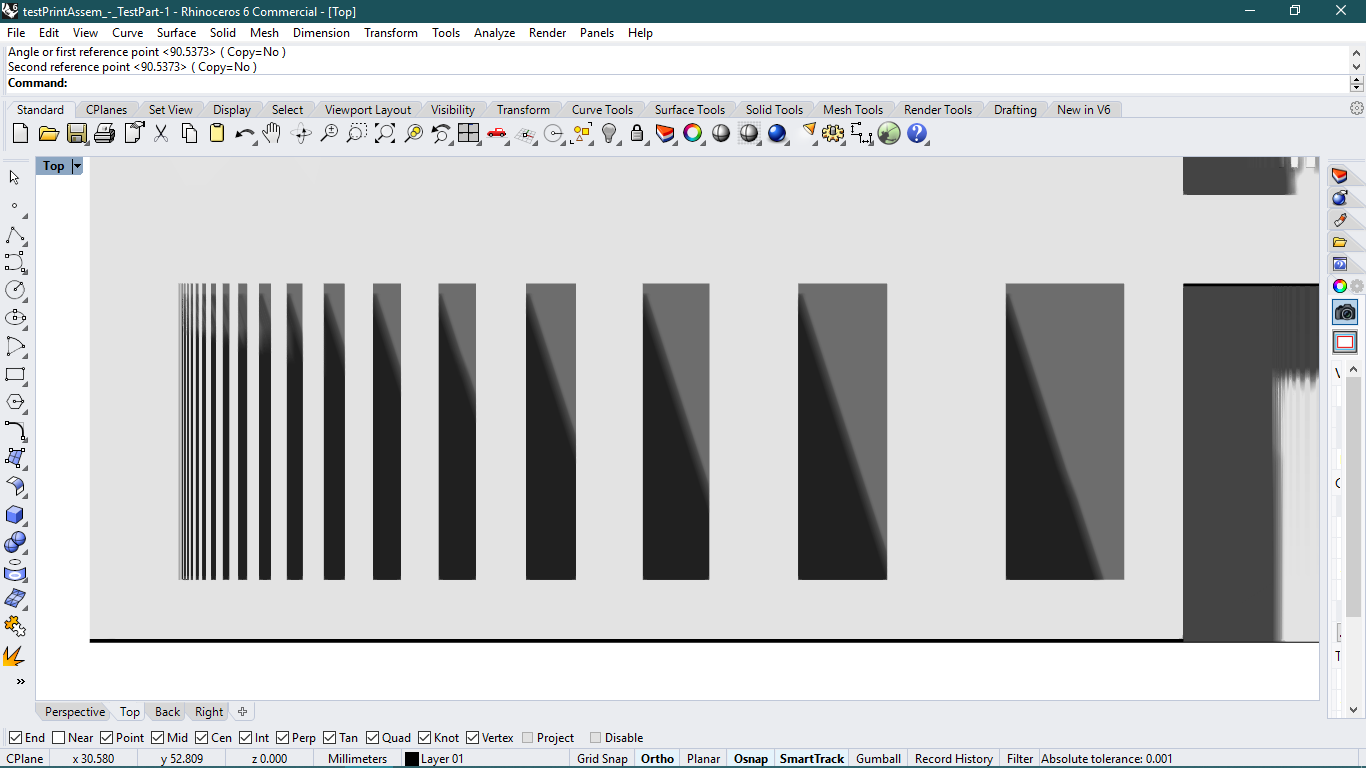

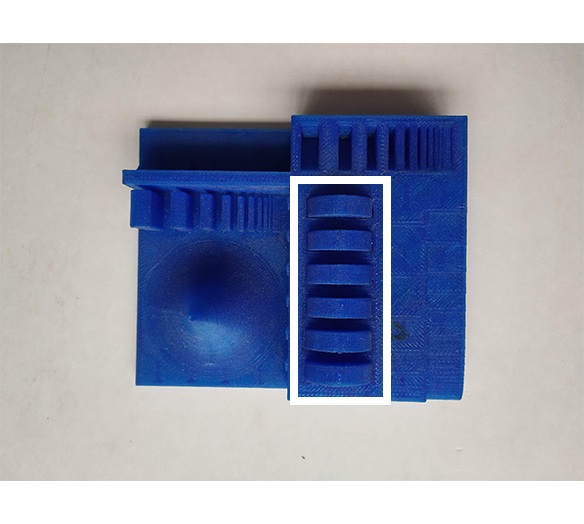

Multi test file

We did our three test on this this file , this file as many test but we cant find their puerpose , but we were able to figure out about Wall thickness, Slot thickness, and Tolerance test from these file. click here to get source of this file.

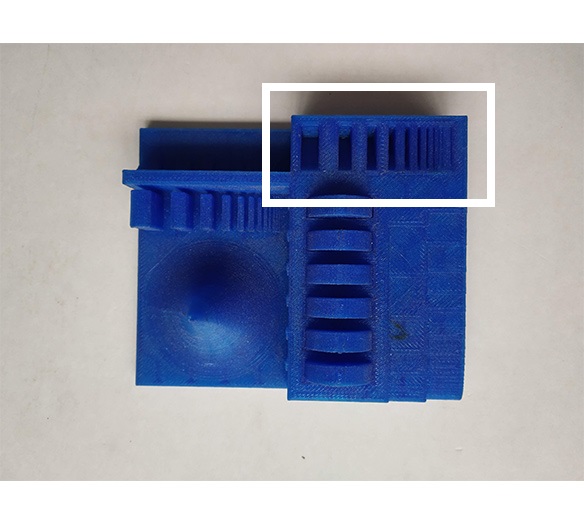

Minimum wall Thickness test

Observation

We tried to print walls of varying thickness of 5 to 0.1 mm. printer gave perfect results up to 2 mm thickness. it gave quite good quality of print between 2 mm and 1 mm but below 1 mm it is not advisable to print. If ones structure has some curvature or overhang , for better print quality their wall thickness should be above 2 mm.

Download file

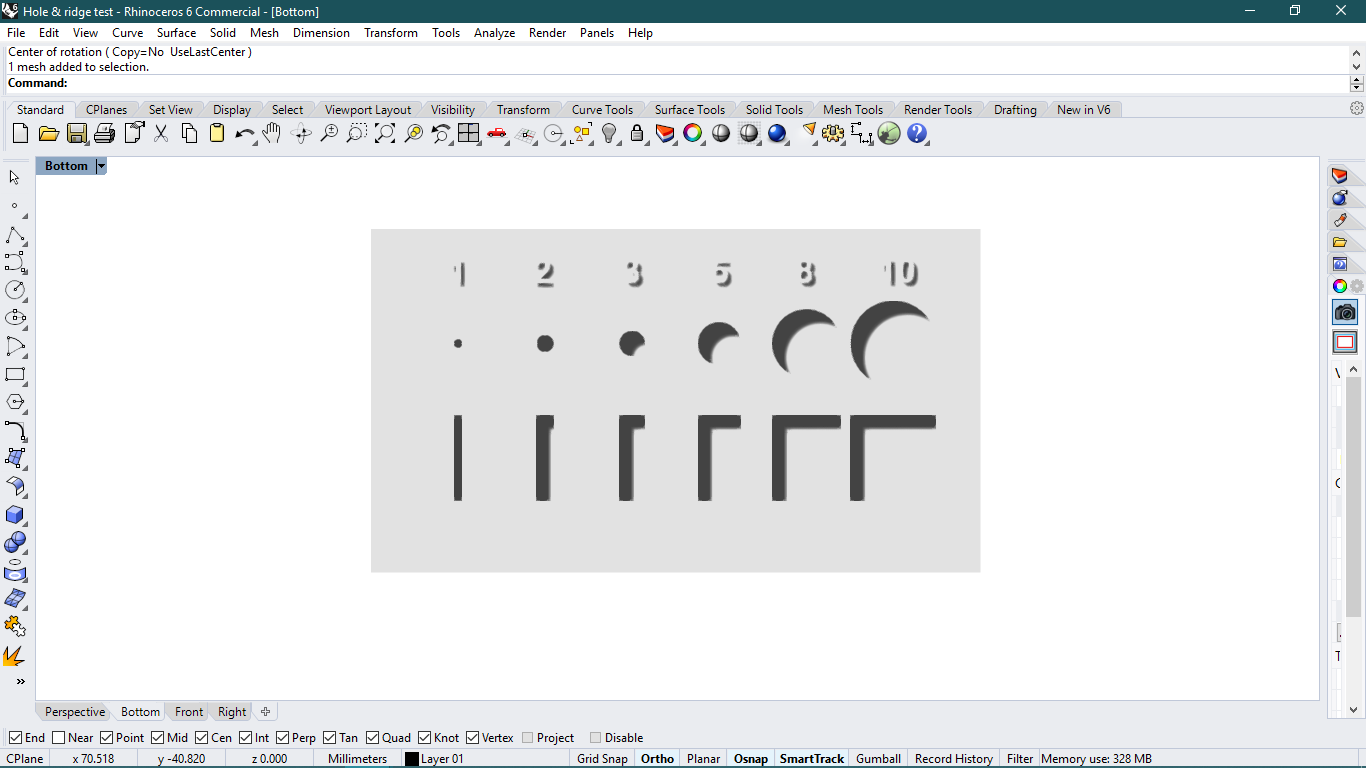

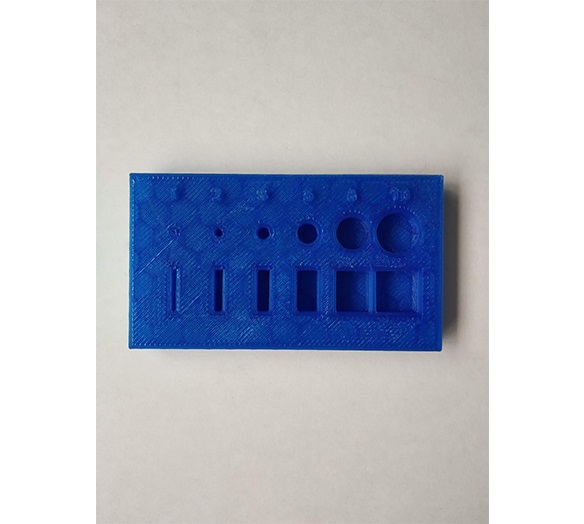

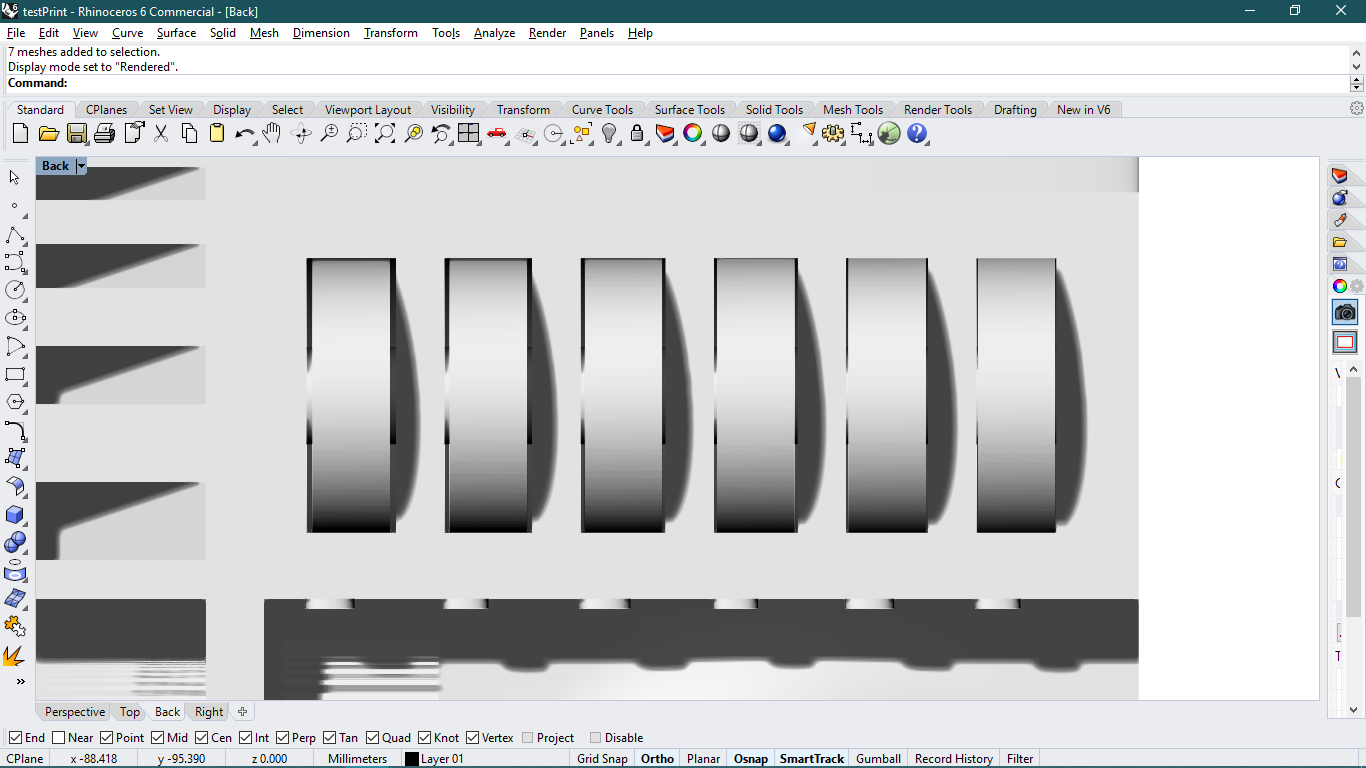

Minimum thickness of the slot

Observation

In minimum slot Thickness test we try to print walls varying from thickness 5 mm to 0.1 mm.

Printer is able to give good quality of print upto 1 mm

it can go below upto 0.25 mm if quality is set to Hyper.

we test another file for Slot test. we test betweeen 1 to 10.

Observation

for rectangle print was perfect upto 1 mm

For circle Diameter = 2 was limit. it cant go below it.

Download file

Tolerance test

Observation

In Tolerance test we vary Tolerance between 0.015" - 0.0025" mm. (0.015", 0.0125, 0.01", 0.0075", 0.005", 0.025")

In Tolerance test rollers are good in movement upto the 0.4mm(0.01").

After that they are quite difficult to move . on 0.0125" its was very smooth roll , with less noise.

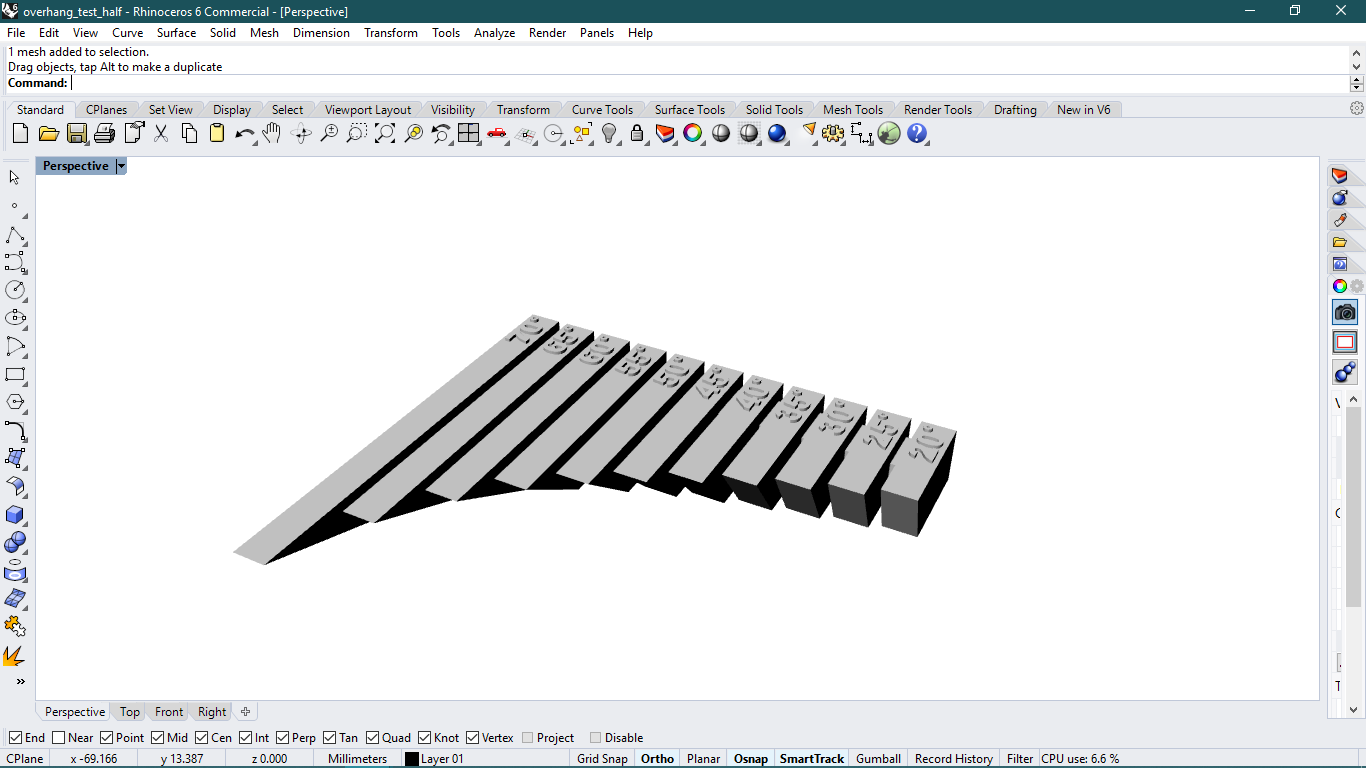

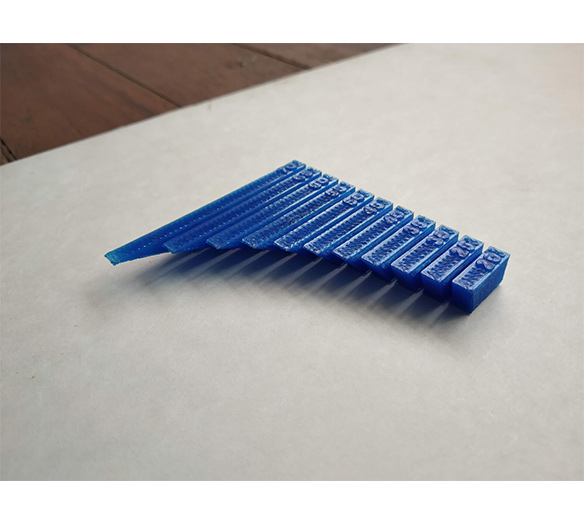

Overhang test

Observation

IN overhang test we tried angle between 20-70 degree.

All angles printed well on this settings

printer was able to go straight (0 or 180 degree) for average 15 cm distance

Download file

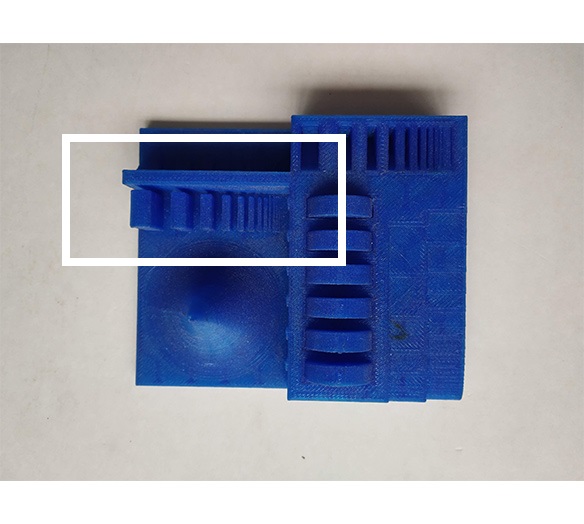

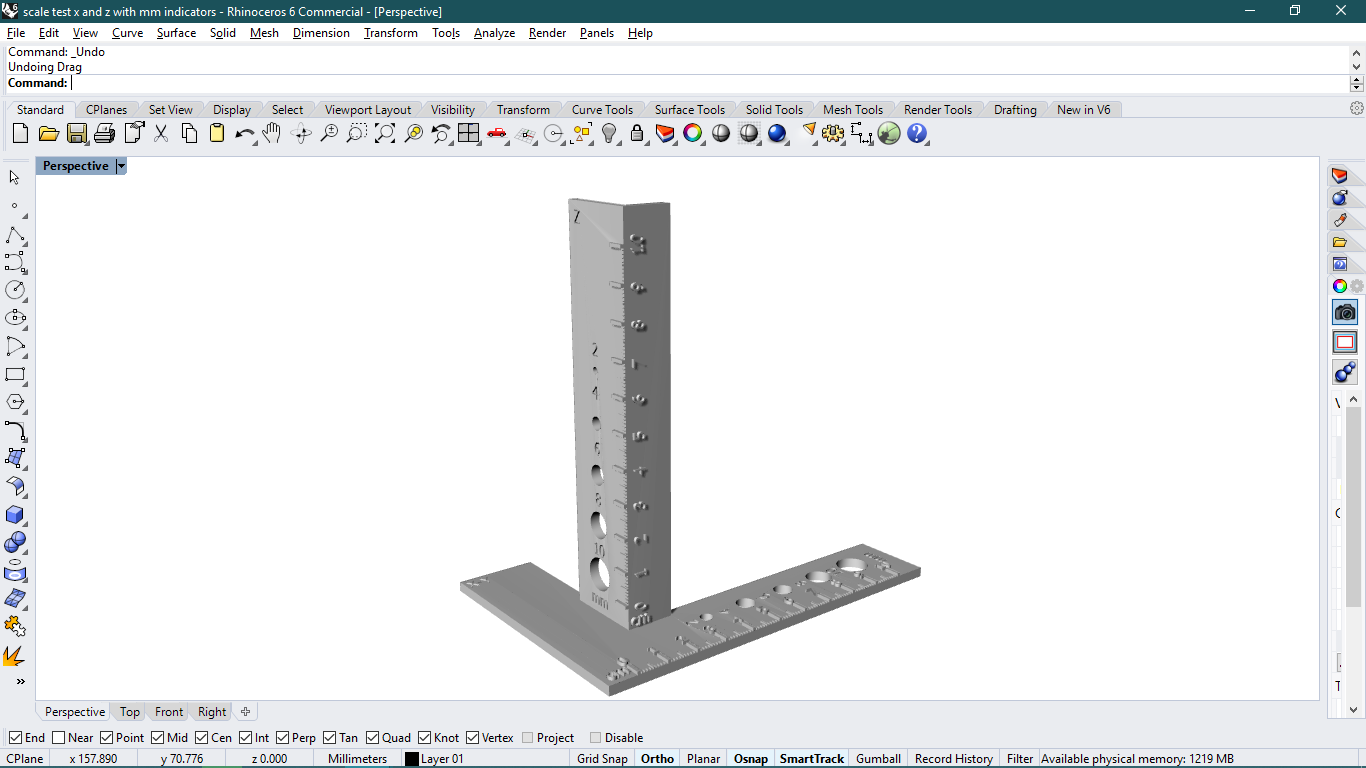

Z-axis callibration test

Observation

In Z axis callibration we want to print one Rular by Flashforge and one to see its dimension accuracy with Layer-hieght.

results were amazing , we barely find the differance between real and printed rular. File also had holes with hieght so we can measure print accuracy in different perspective

Thought as a negative point , Hole of 2 mm is not printed accurate at hieght(65 mm). its diameter was 1.8 mm. in this perfect dimentions can be achieved on higher quality.

Download file

General conclusion

In Wall thickness printer is able to print walls or objects having thickness of 2 mm without any issue , object has good strength also but when one want to print below the 2 mm like between 1.5 to 2 mm one should go for higher quality and reduce Build printer speed of printer to 30-50 mm/s depends on design. if design is more complex like patterns set retraction speed higher and reduce travel speed.

In Minimum slot thickness printer was good upto the 1 mm. it is good thing because it shows printers ability to controll the layer sprea on sides. Flash forge can go down to 0.5 mm if perfect settings are found.

In Tolerance test as i told printer is quite good for printing in small width slots. it gives advantages in Tolerance also. 3d print gone well upto 0.01". best value was 0.0125" for us.

In overhange test it can go upto 85 90 degree without any supports and printer can go straight to 0 or 180 degree for average 15 cm distance.

by Z-axis callibration we found printer is acuurate enought with increase in number of layers. it has only some problems in making holes as hieght , it can be componset by changing settings.