Group members

Jakob Nilsson

Hanne Eriksen

PArt 1: Mechanical design

In this weeks group project we decided to make a "pingpong" game. The FabLab has large windows out to the streets, so we decided that we wanted to make something in the end would be interactive and fun for the people passing by. Since this week was just about making the mechanical part, we ended up dividing the task in the way that Jakob focused on the mechanical part, and I on the framing and layout layout of the game. Jakob with this engineering backround dived in on the project with great endavour, and ended up after 3 prototypes with a "shooter" that works (maybe too) well. We found out in the process that we would keep the concept of the game as easy as possible on the first run, and instead make some changes when we would automate it.

Hanne - Mechanical design week

Jakob - Mechanical design week

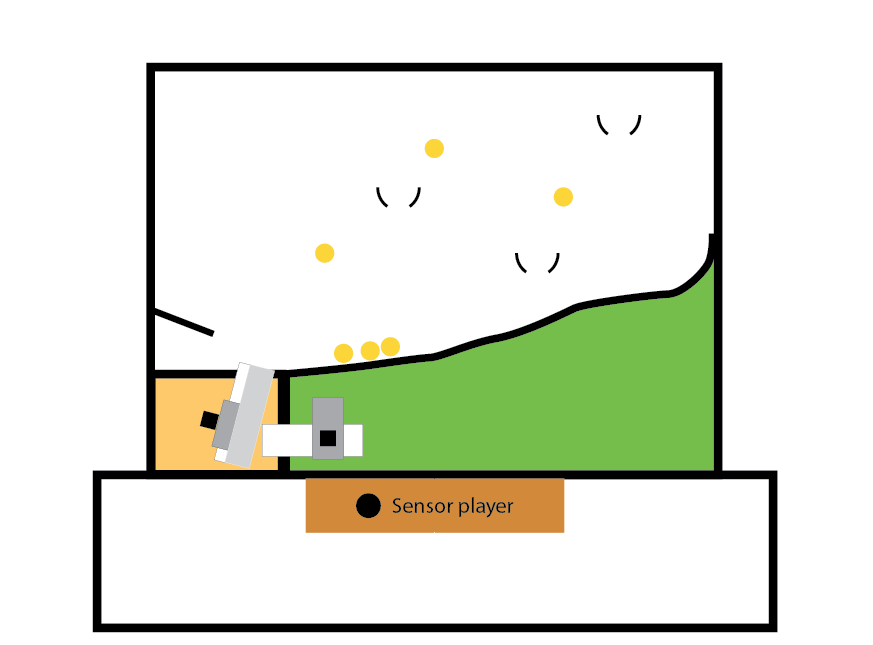

Game Concept

The concept of the game is to make an interactive pingpong/flipper game - that would stand in one of the lab's windows towards the street. The game consist of a shooter that is placed in the bottom left corner - and is connected to two motors. One motor rotates the shooter, and the other one "loads" the shooter. The game has 3 "targets", where the aim is to get the balls to pass through them. To make the game interactive, we would add some sensors that is turned out towards the window. That way, the "public" can activate the shooter fromt the outside, trying to hit the different targets.

Shooter

The shooter is made from 4 mm plywood on the lasercutter and powered by simple tension springs. We first built hand operated versions (shown on the left) to get a grip on tolerances and the forces involved. When we had a working concept we proceeded to add an automatic release mechanism that loads and launches the ball using one straight movement.

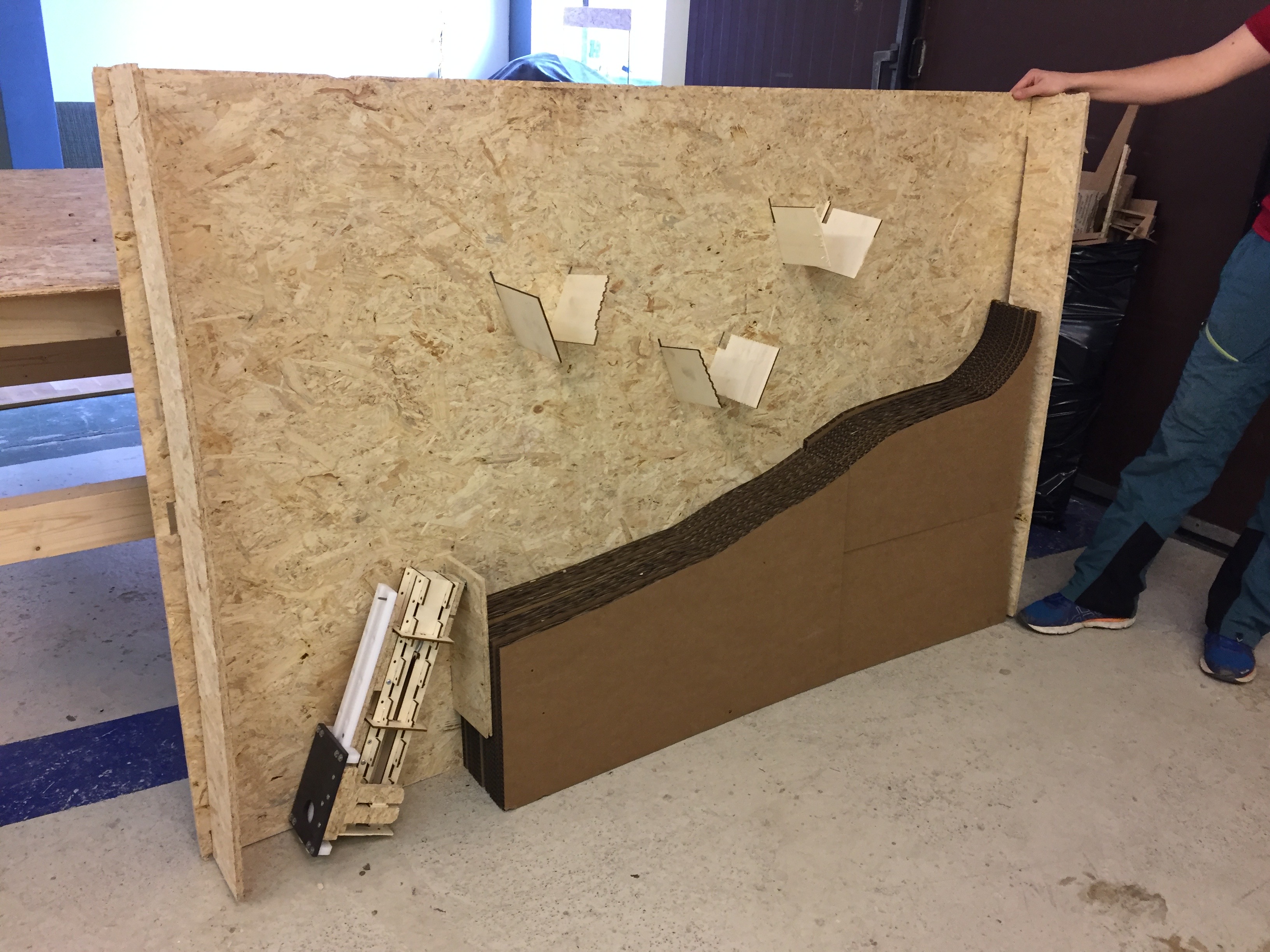

The frame

The frame is made in the full scale of the window. And it is meant to stand towards the window - making the window the "front wall", so the balls will be contained inside the frame.

The frame is made of OSB and milled on the CNC with a 3mm endmill. We luckily managed to fit in all the pieces needed for all the parts in one sheet of materials. The "slope" that leads the balls back to the shooter was made on the lasercutter with double layered cardboard.

Group project

PArt 2: machine design

On the second week of the group project, the task was to add output devices to the project and "make it do something". For us, this meant that we would be adding 2 steppermotors to the game we were already making.

Hanne - Machine design week

Jakob - Machine design week

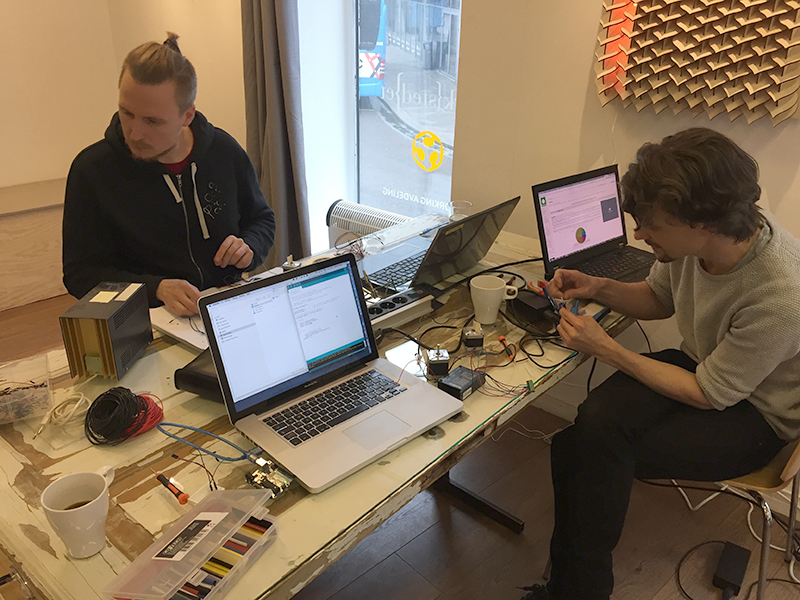

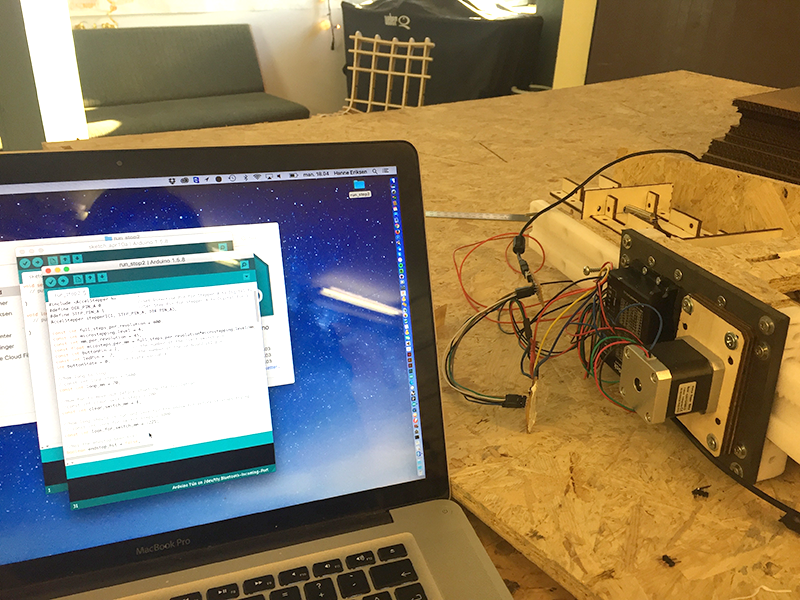

Connecting and programming the motors

The motors was first connected with the Microstepper and to an Arduino, to make get it up and running and testing the code. We then went over to program the FabISP by using the HelloEcho board we made in the previous weeks by doing these steps.

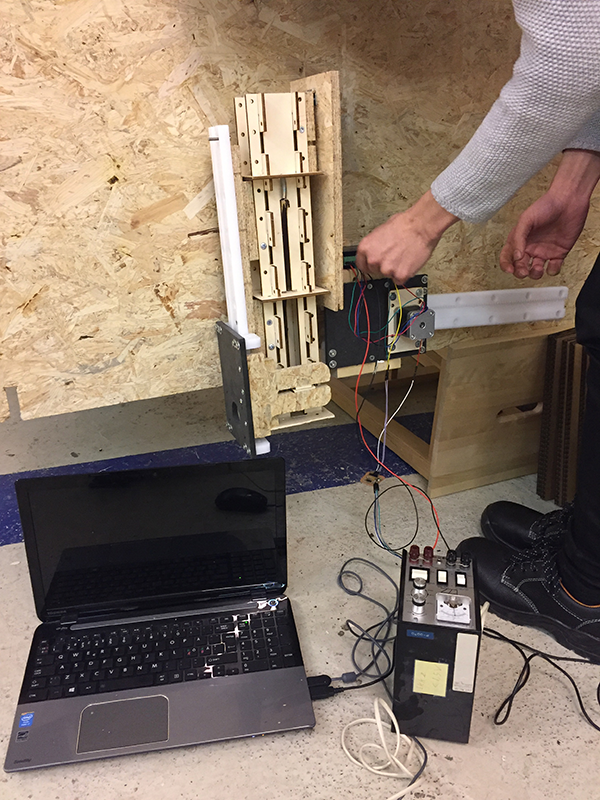

Attaching the motors to the mechanical parts

To make the motors move and operate the shooter we used linear axis made from POM and Valchromat machined on "Hank" a fab lab made CNC milling machine which is part of the fabricateable machines project. Here is a video for the axis being milled.

Programming the motors

To tell the machine which position is "home" we used limit switches.

Programming roadmap:

1. Move carefully towards home switch.

2. When switch is found:

Stop and reverse a short bit to clear the switch.

3. Start back and forth movement.

4. Repeat pendulum movement forever.

Last touches

When the motors were in place and more or less working the way we wanted it to, we found out that we had to do some minor touches the structure of the frame. The shooter had ended up becoming a bit longer than the initial plan, resulting it to not be able to rotate as far as we needed/wanted to load the shooter. This was resolved by adding a piece of materials at the top of the vertical piece. That way we could fasten the shooter at a higher point while still touching the horisontal axis. Hanne also accidentally managed to break her FabISP when programming it, so we ended up having to programme both motors with the one we had left.

Final game

The final game ended up more or less the way we had planned. Although we decided to not cover up the "Shooter", since this in fact is the most interesting part of the machinge. We are also left to cover up the area around the shooter, so the balls would go back into the "barrell" instead of outside it.

Further development opportunities

Files

Code

Arduino code, horizontal-aming axis. Requires this stepper library.

Arduino code, firing mechanism. Requires this stepper library.

Launcher

Fusion360 file ping pong ball launcher

Step file assembly of the ball launcher

DXF-cutsheet to make the launcher

PDF-cutsheet to make the launcher

Electronics

Board (Not made, hacked from the hello echo card)

Traces (Not made, hacked from the hello echo card)

Schematic PNG image

Schematic PDF document

Board EAGLE file

Schematic EAGLE file

Axis

Ø5mm ID, 9 tooth pinion STL for 3D printing

2D and 3D of rack and pinion 3DM for Rhino

3D of rack and pinion STEP file

GITHUB Source repo for the rack and pinion

Materials and components

Materials

OSB sheet 1200x2400mm

Double layered cardboard

4mm plywood

Nuts and bolts

Electronics

Arduino

FabISP

HelloEcho

Steppermotors (Nema17) x2

Makeblock stepperdriver x2

Endstops x2

Linear axis made from POM and Valchromat x2