Thank you to the FabAcademy staff, FLS instructor and Neil for creating and running this awesome journey of struggle and joy to become part of this community that has so much potential!!!

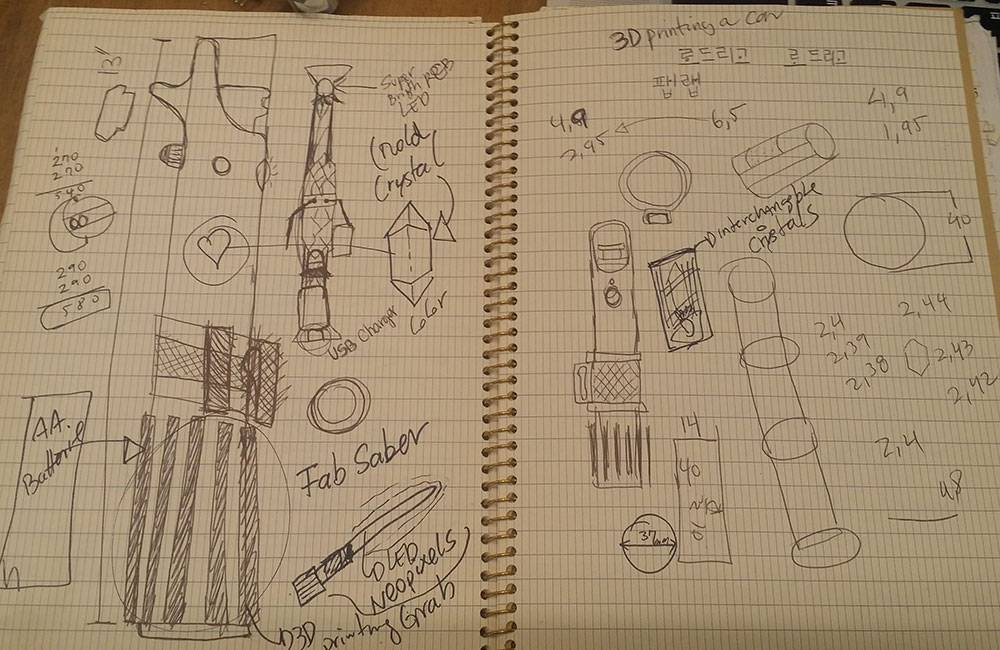

Here are the pictures of how I made the FabSaber and all the struggle that came accross, although, at the end was more joy!!!. The pictures below are not in chronological order but I try to put them together to explain the processes that were used for the creation of it.

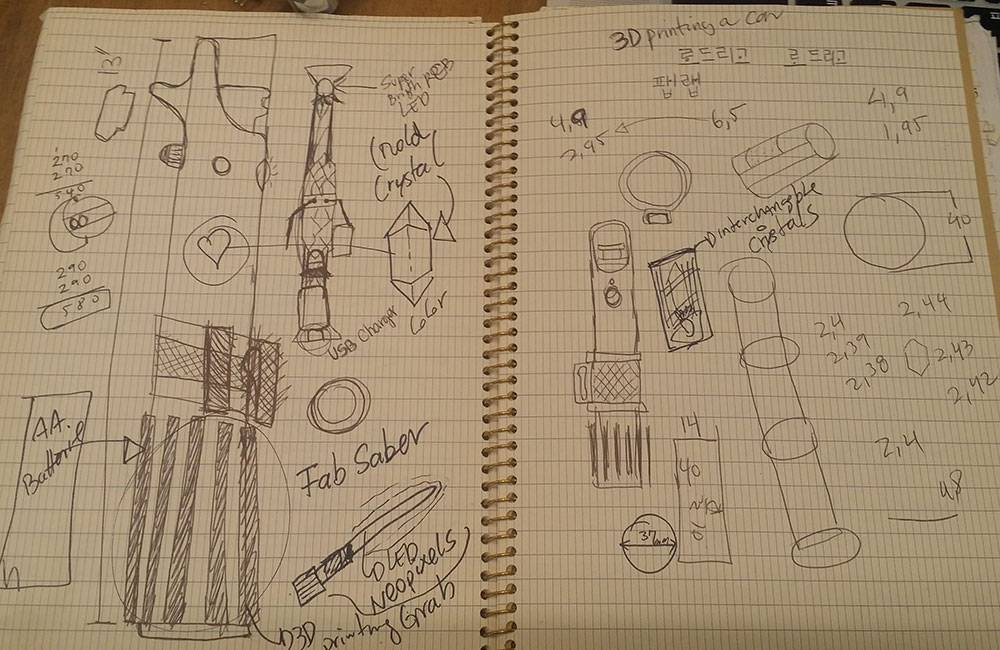

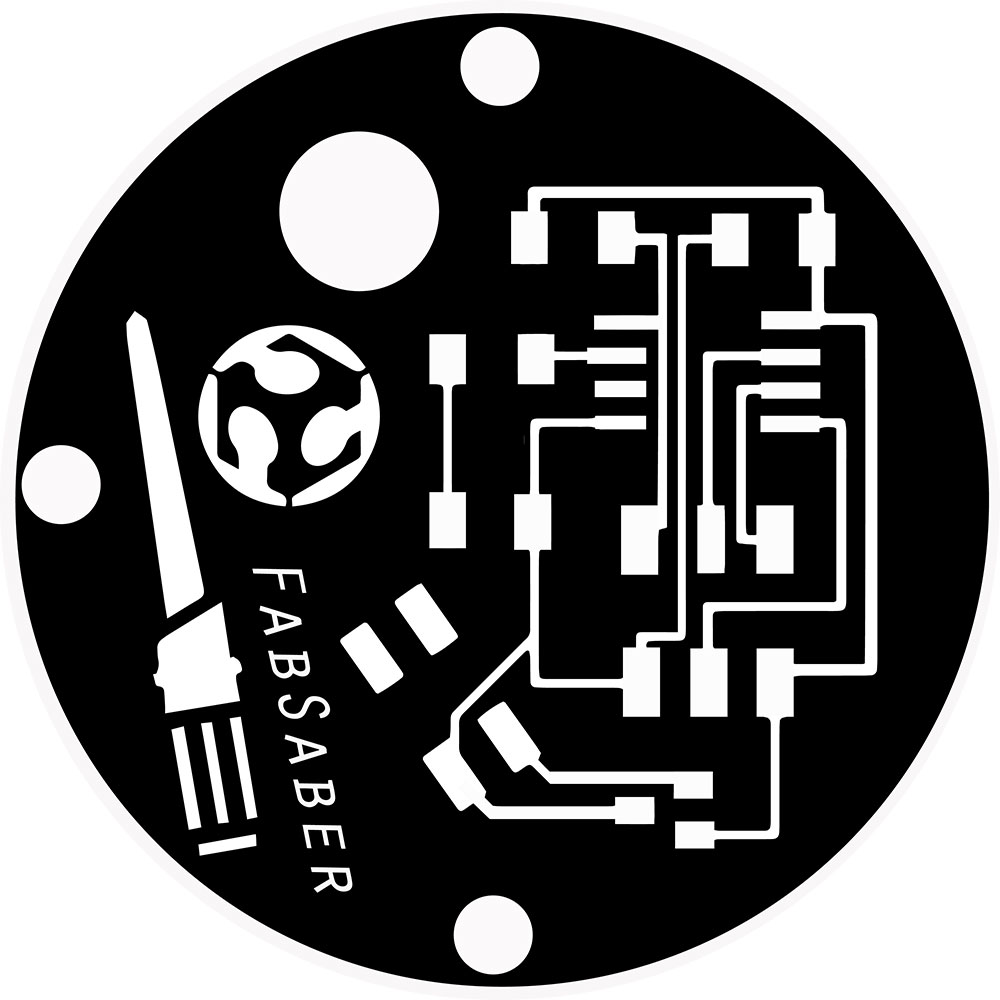

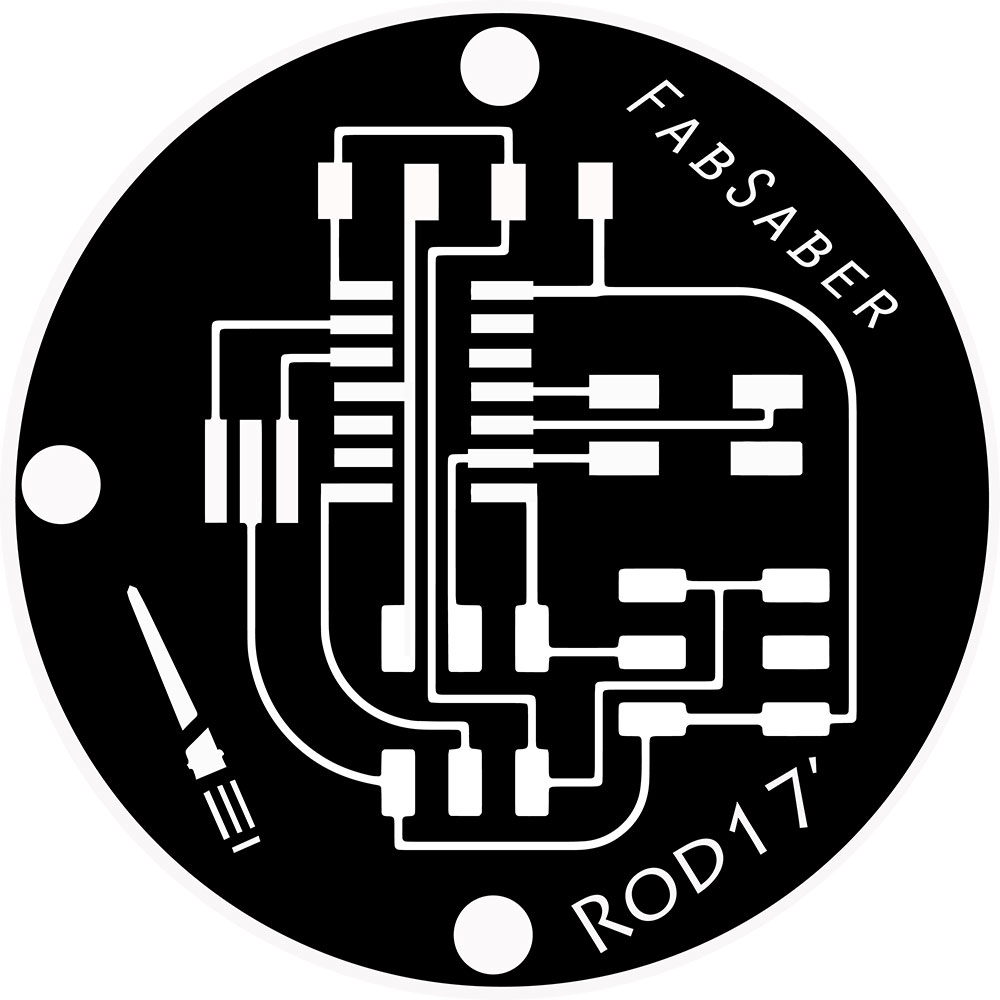

This is the concept of the FabSaber,Crystal molded, cnc parts, laser cutter, 3D part and electronics. The project represent my personality very well because I dint plan much but was adjusting it while making it

This is the concept of the FabSaber,Crystal molded, cnc parts, laser cutter, 3D part and electronics. The project represent my personality very well because I dint plan much but was adjusting it while making it

This is the concept of the FabSaber and I did it on Fusion360!! awesome application!! I need to get better at it!!

This is the concept of the FabSaber and I did it on Fusion360!! awesome application!! I need to get better at it!!

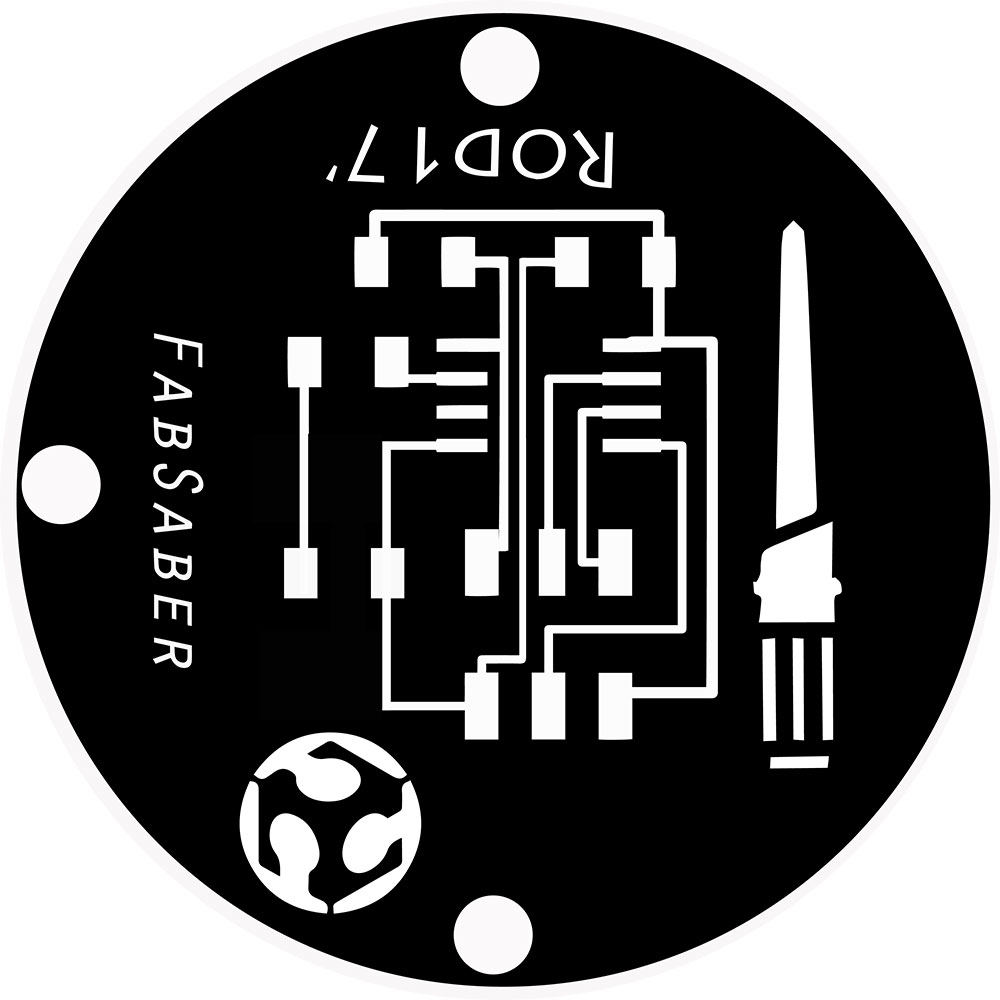

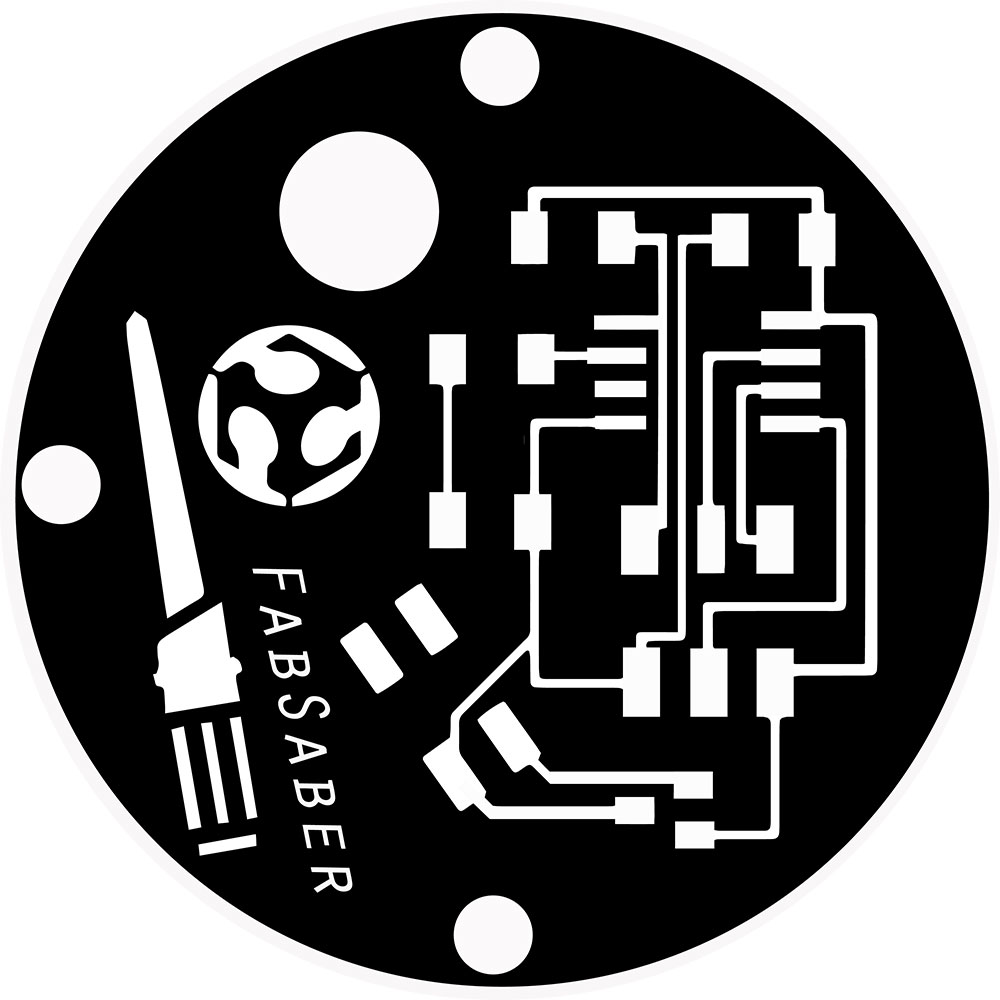

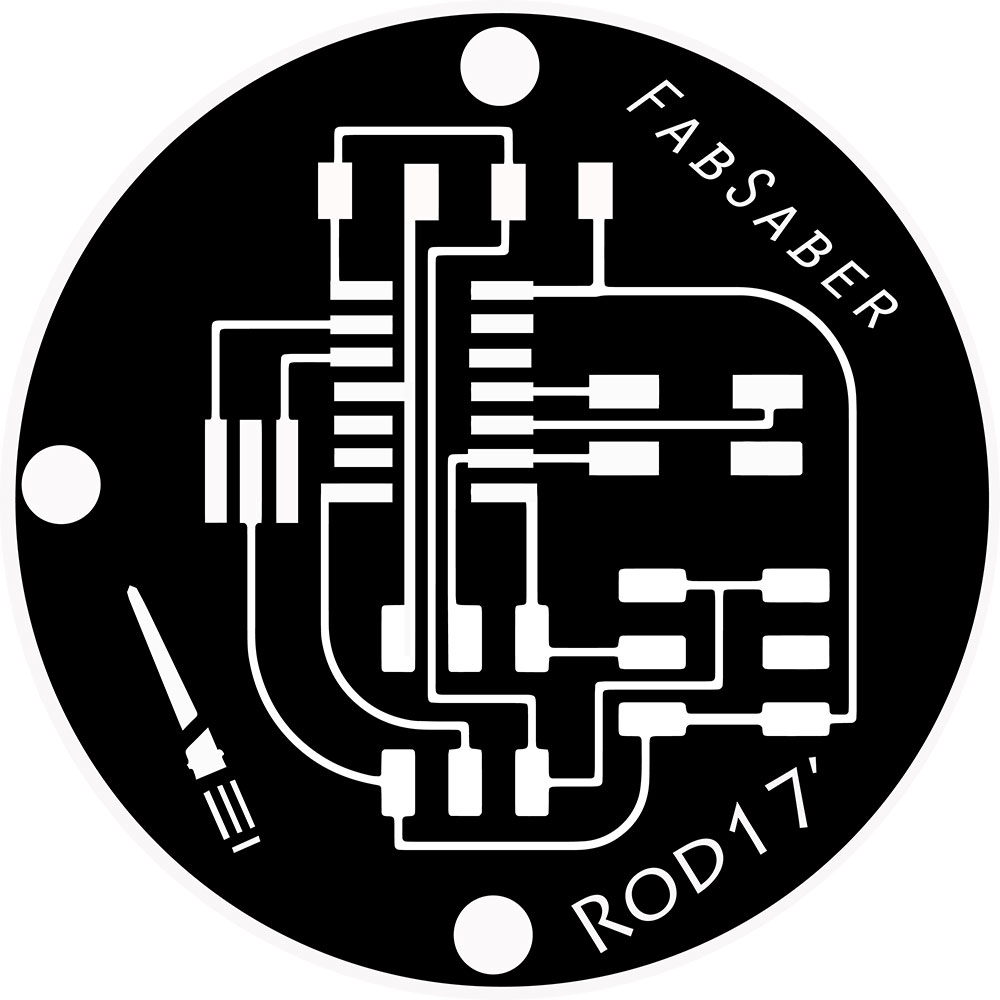

even though the file on the left shows all the 2D files that I used to complete the saber I made one by one to test how they would fit!

even though the file on the left shows all the 2D files that I used to complete the saber I made one by one to test how they would fit!

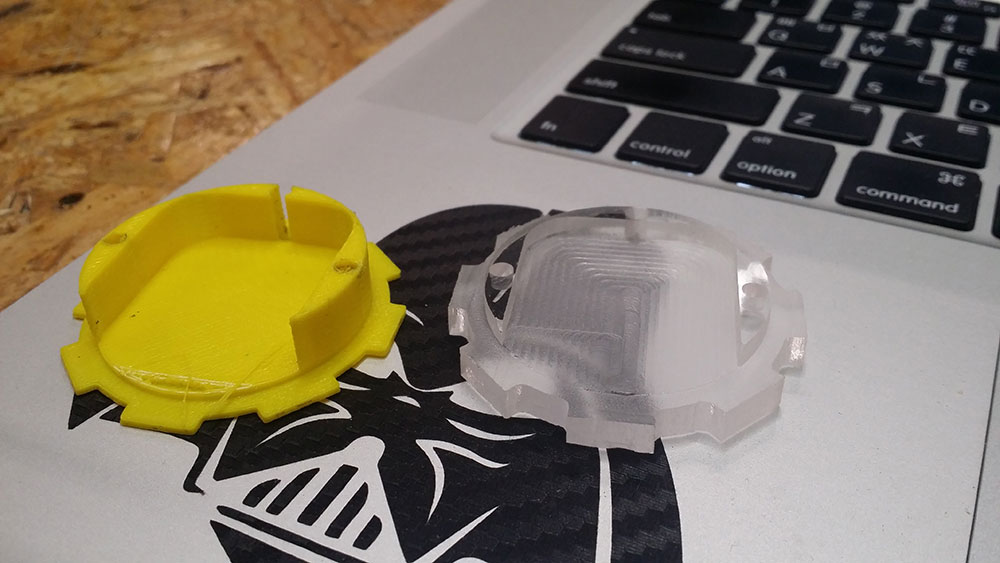

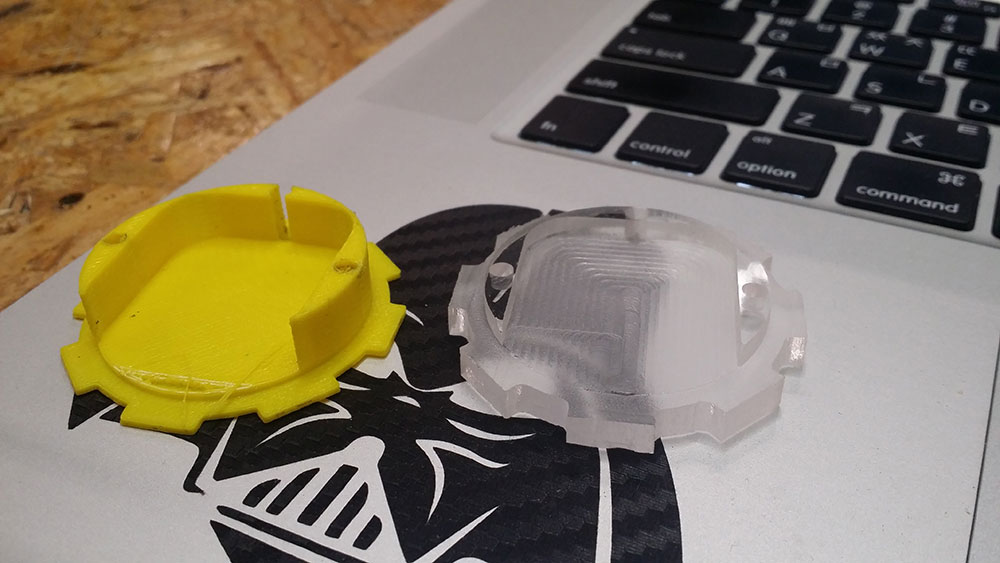

First, I got the power supply 8 AA batteries for 12V, I also prototype the pommel in 3D printing to see how fit!

After that I realized that the pommel could be made on the CNC and look way cooler!!

After that I realized that the pommel could be made on the CNC and look way cooler!!

I failed few time looking for the right feed rate and RPM and I had to addapt. Since the pommel was to small I had to use to use an low feed rate that change the whole cheapload values. I endup having a 6,000rpm 50inch/s and 40% stepover! (I have to recognize that I got addictive to the shopbot!! singing.....I I I love the shopbot~~~)

Happy Happy pieces and I cut a bunch of them and try to engraved on them the logo I made!!

Happy Happy pieces and I cut a bunch of them and try to engraved on them the logo I made!!

I was struggling with the position of the engraved, untill I realize that the pieces were transparent!!

I engraved first in a wood and then position my piece on top of it and voila!!!

I engraved first in a wood and then position my piece on top of it and voila!!!

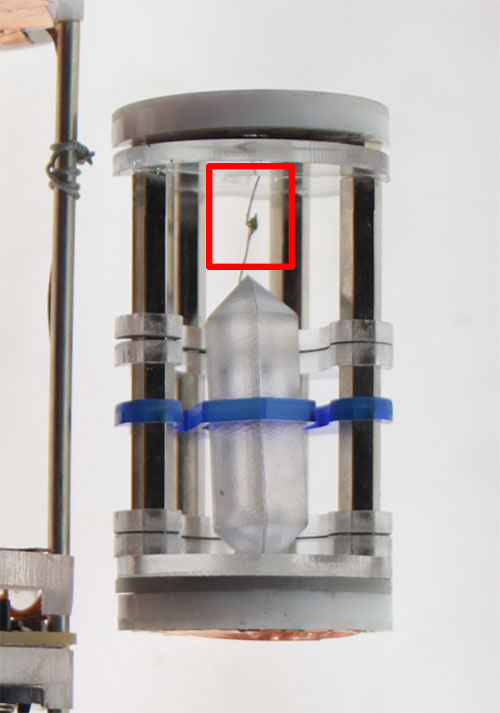

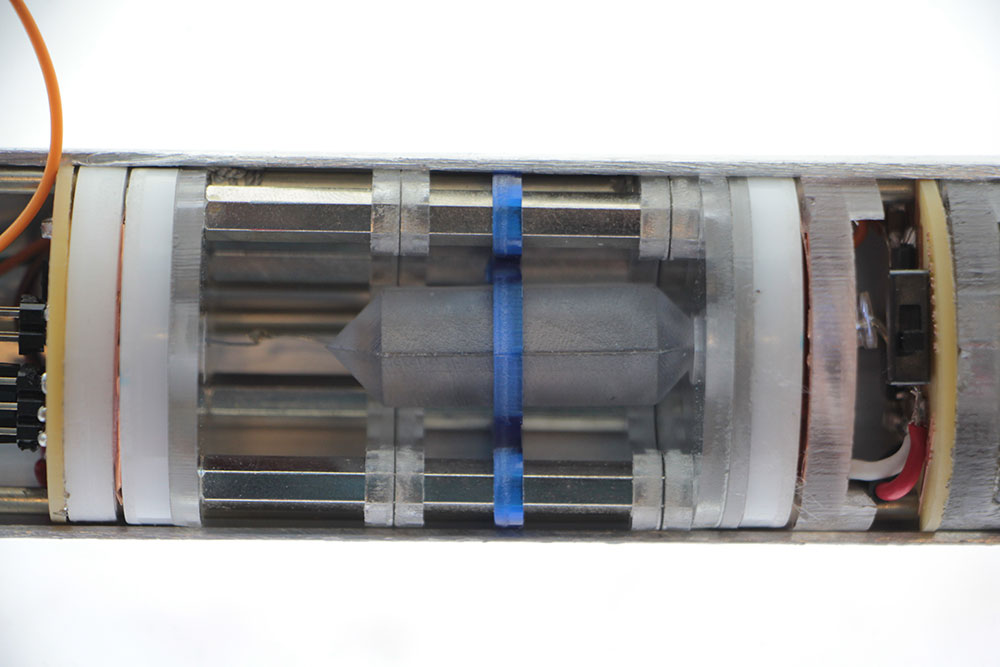

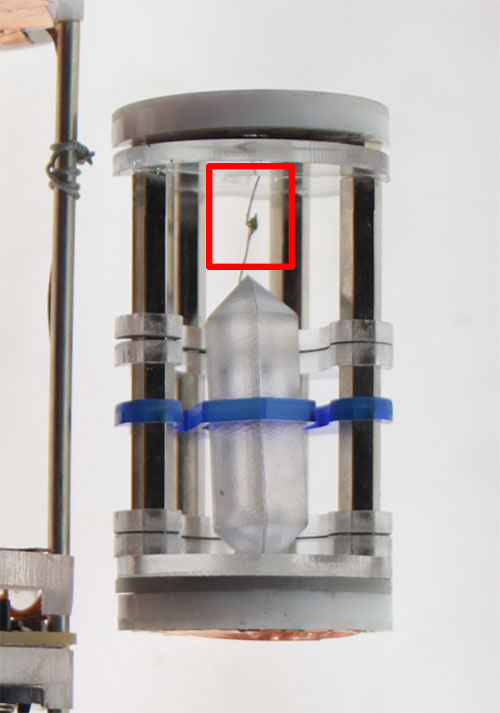

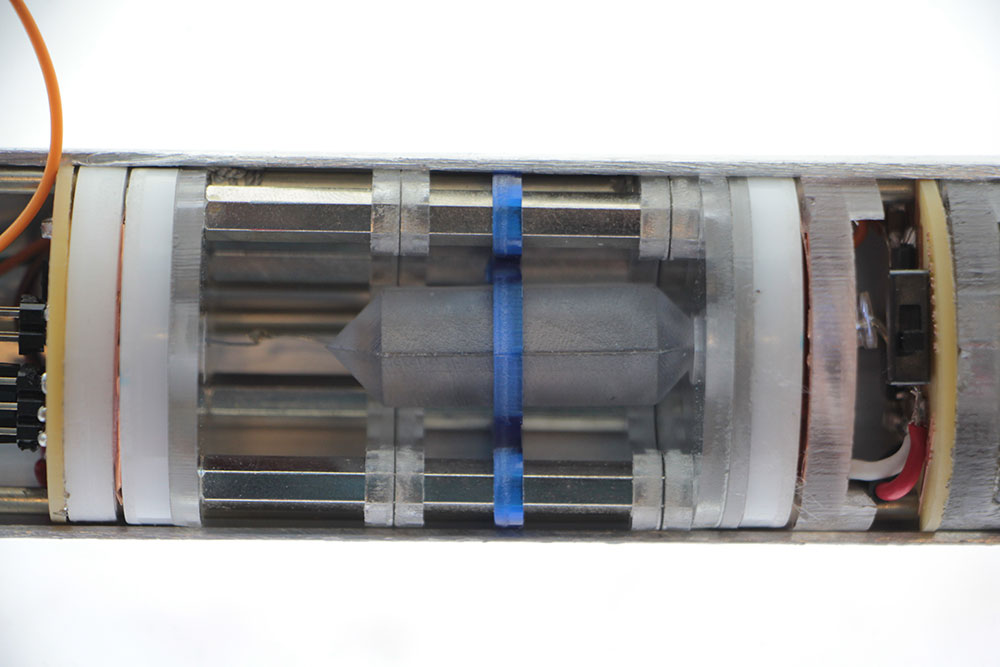

The Crystal on the right show how the resistors is hiding in the back.

this two pictures summarize the ordeal that I went through to make crystal chamber by hiding the resisters inside the pocket and finding the curf for the colums in hexagon shape. (no glue was applied its all pressfit!)

this two pictures summarize the ordeal that I went through to make crystal chamber by hiding the resisters inside the pocket and finding the curf for the colums in hexagon shape. (no glue was applied its all pressfit!)

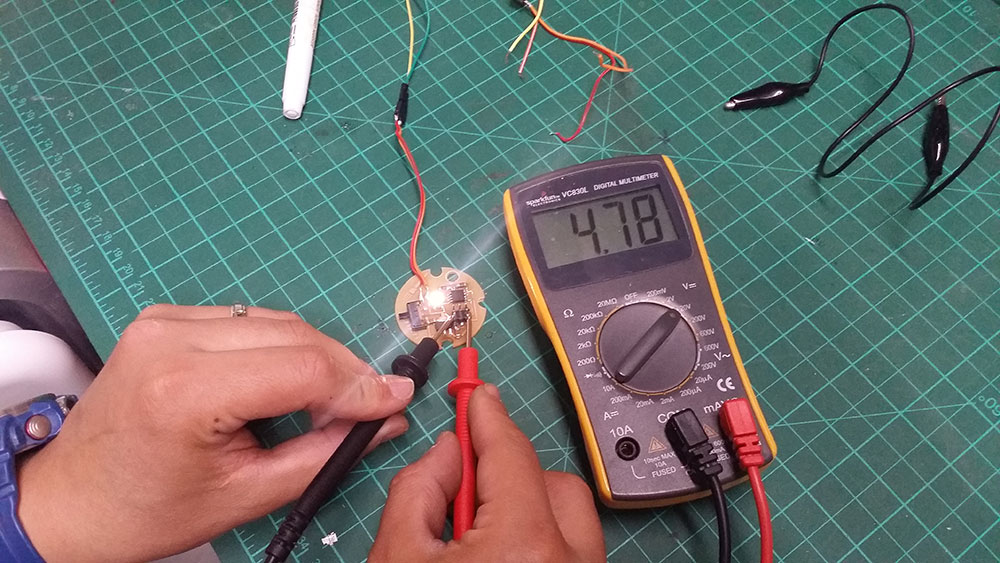

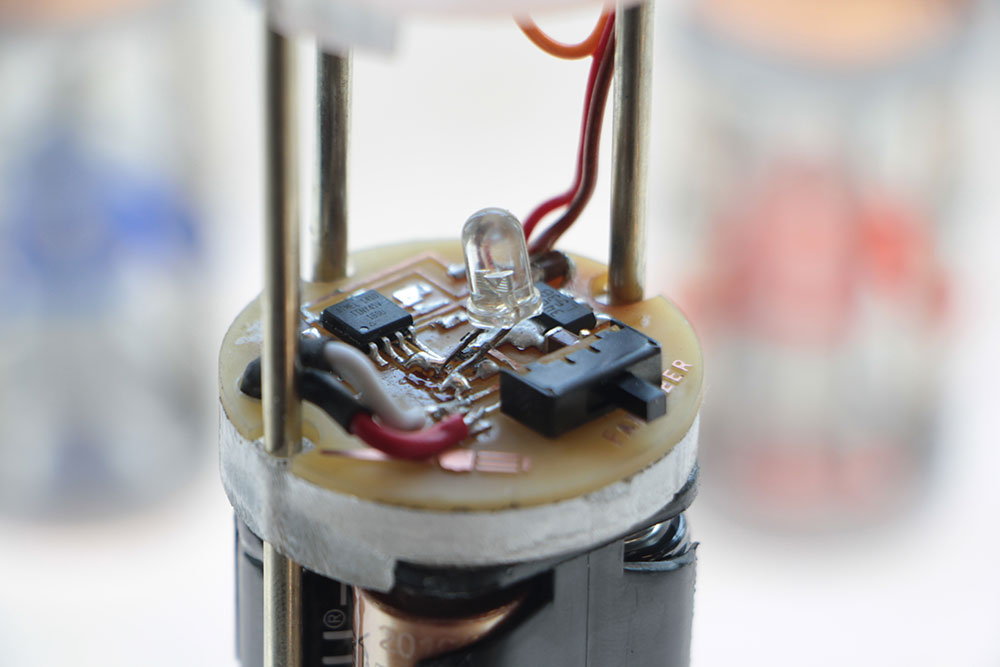

and I connected my board and it was looking pretty cool!

and I connected my board and it was looking pretty cool!

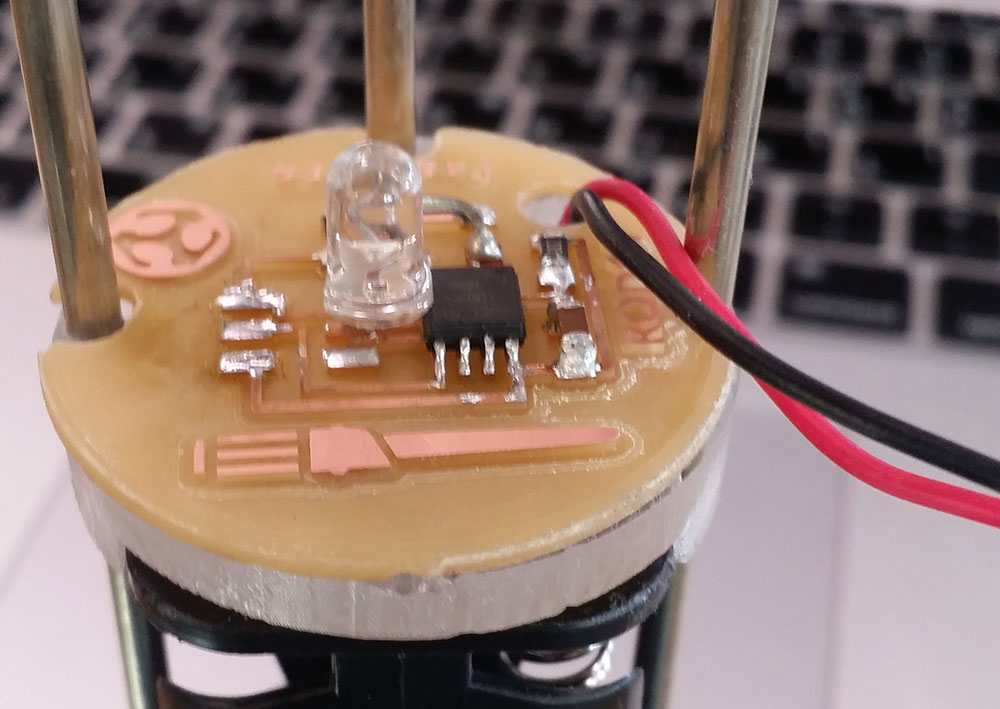

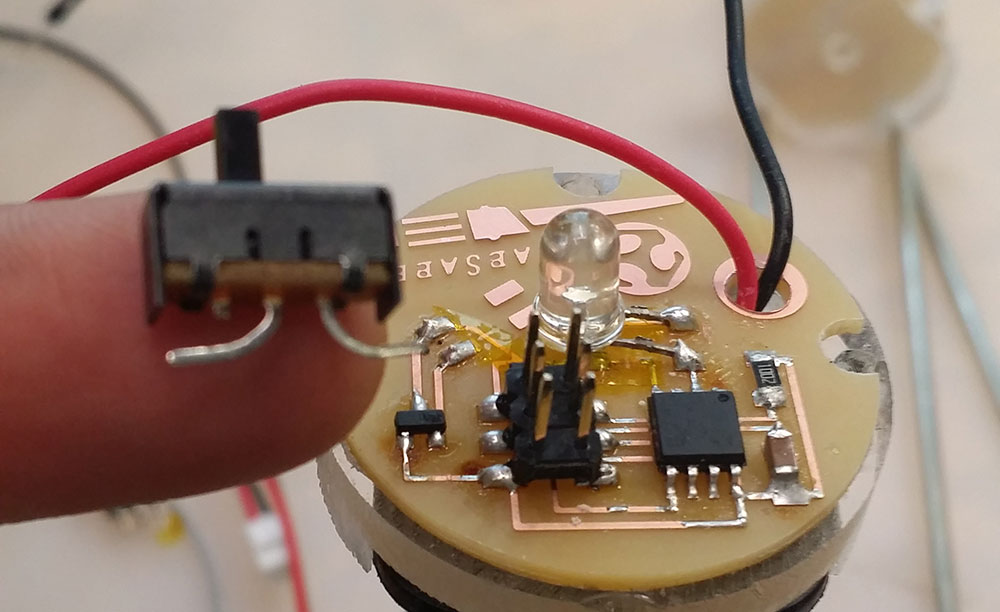

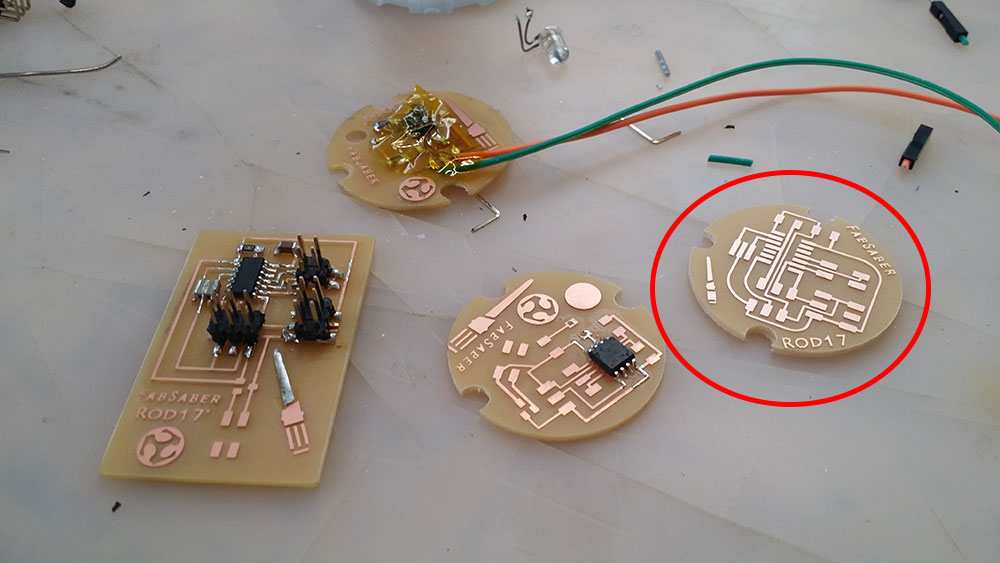

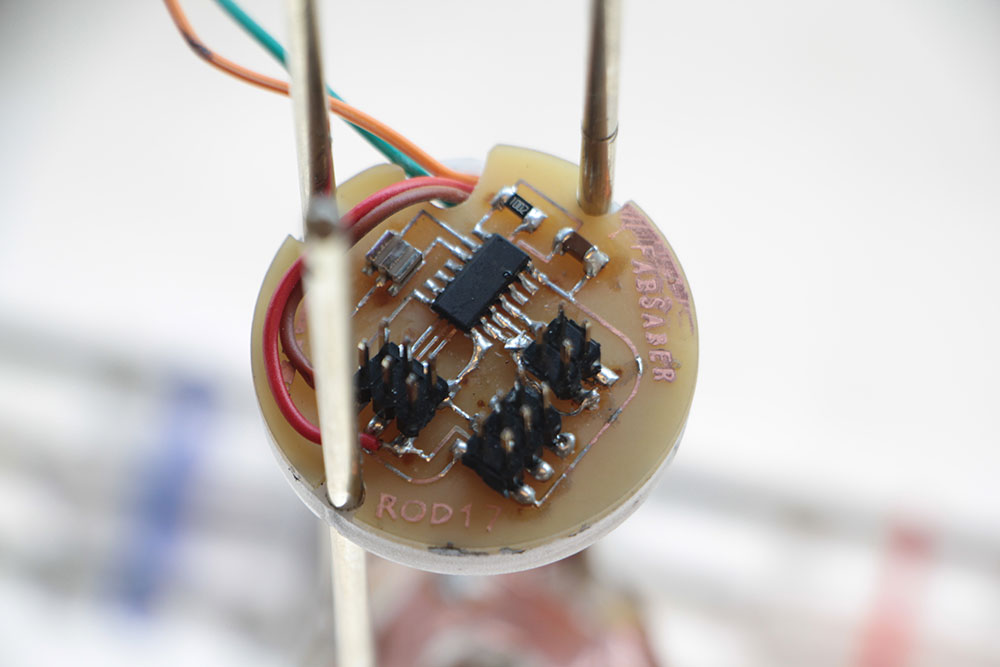

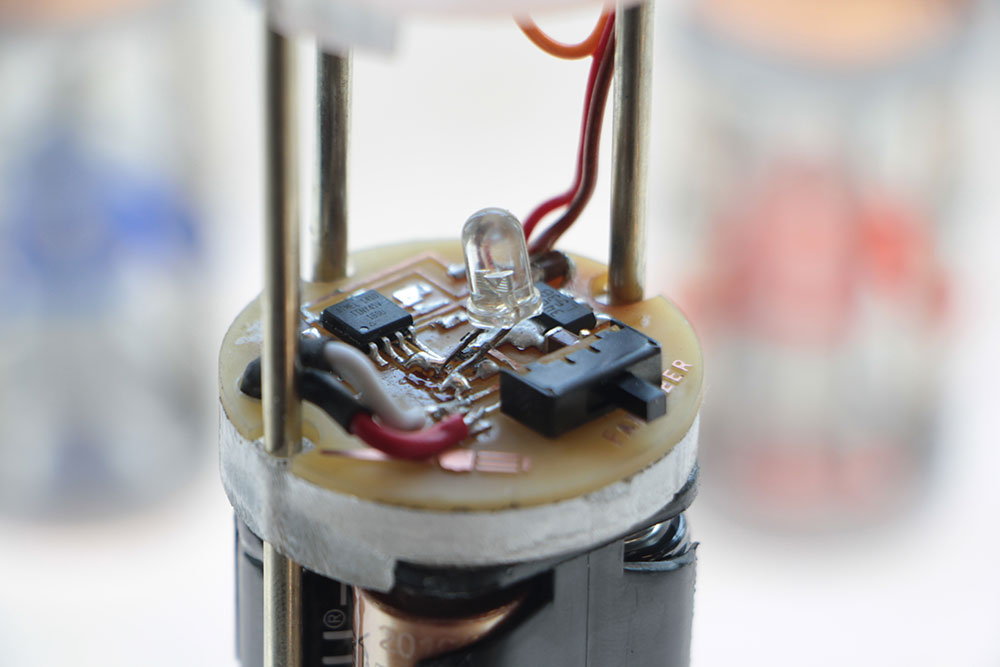

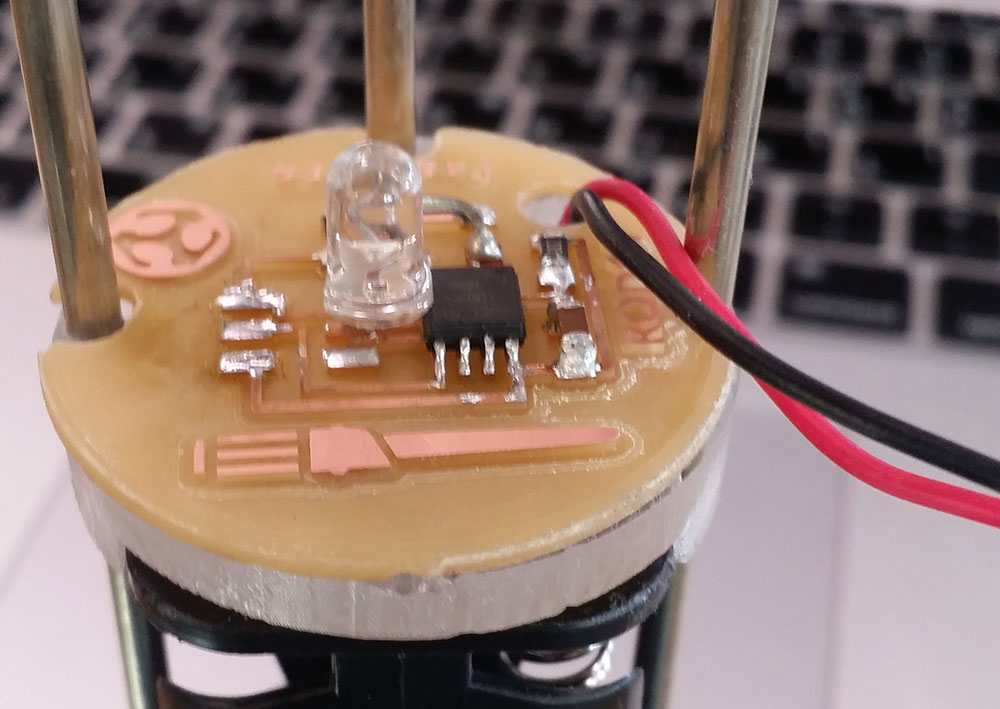

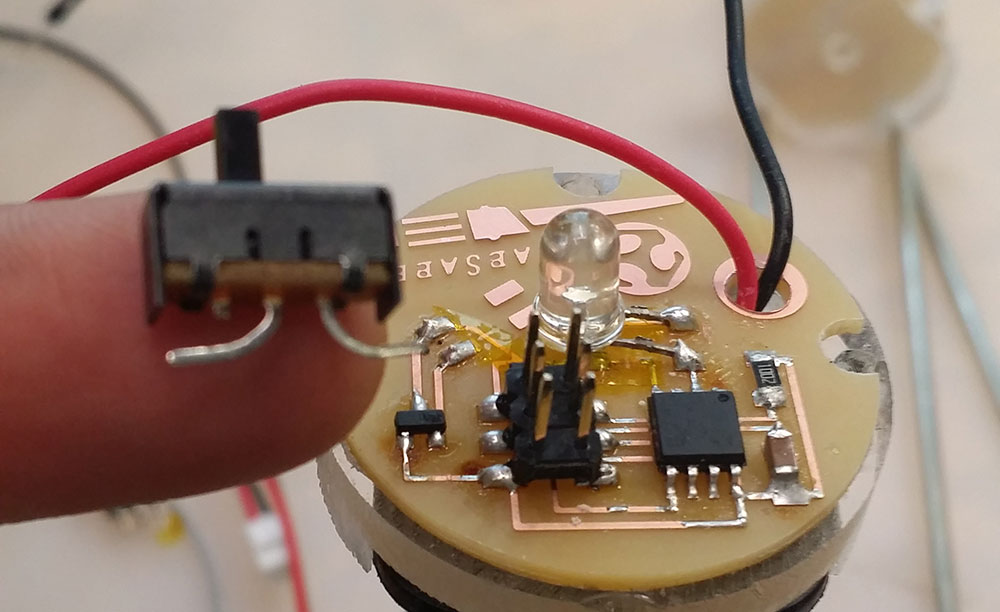

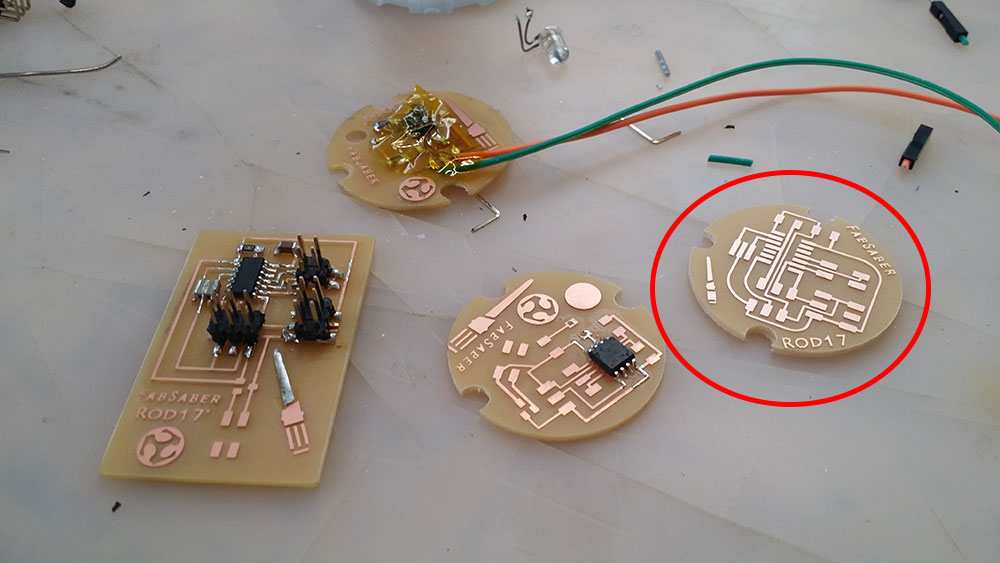

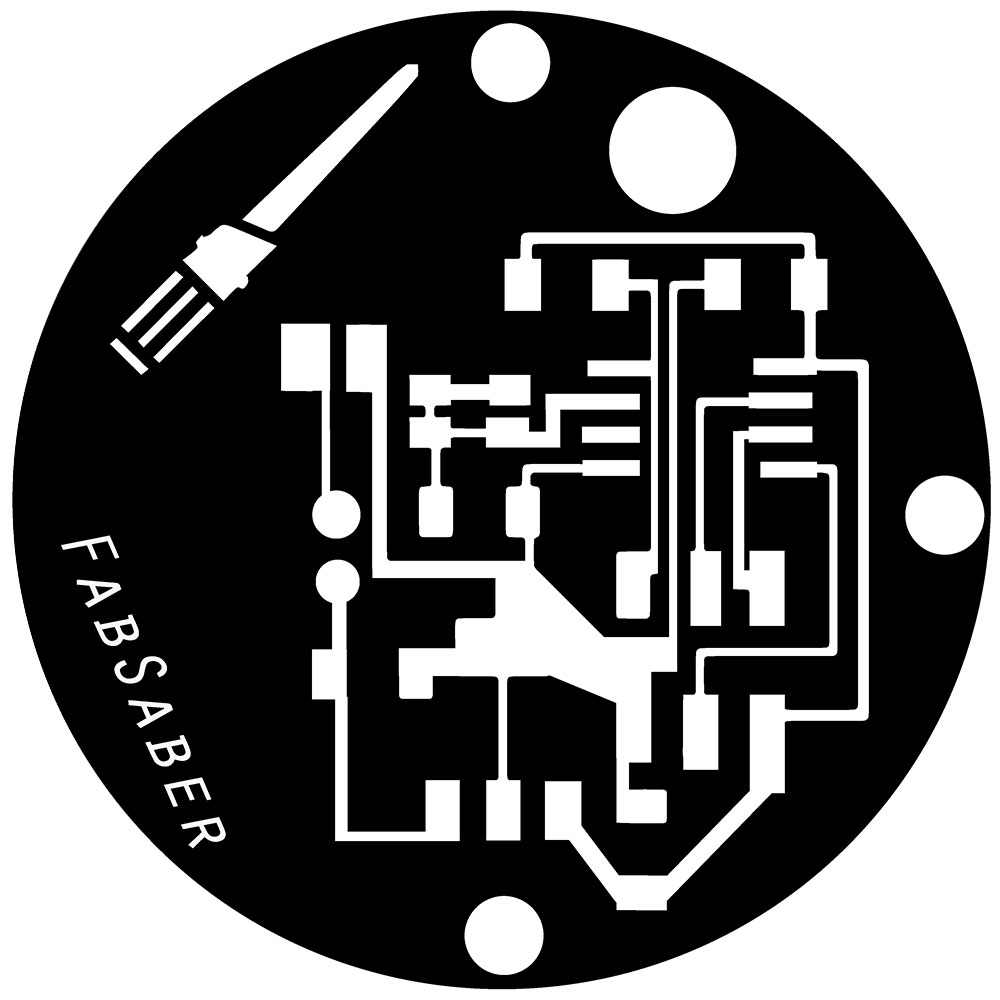

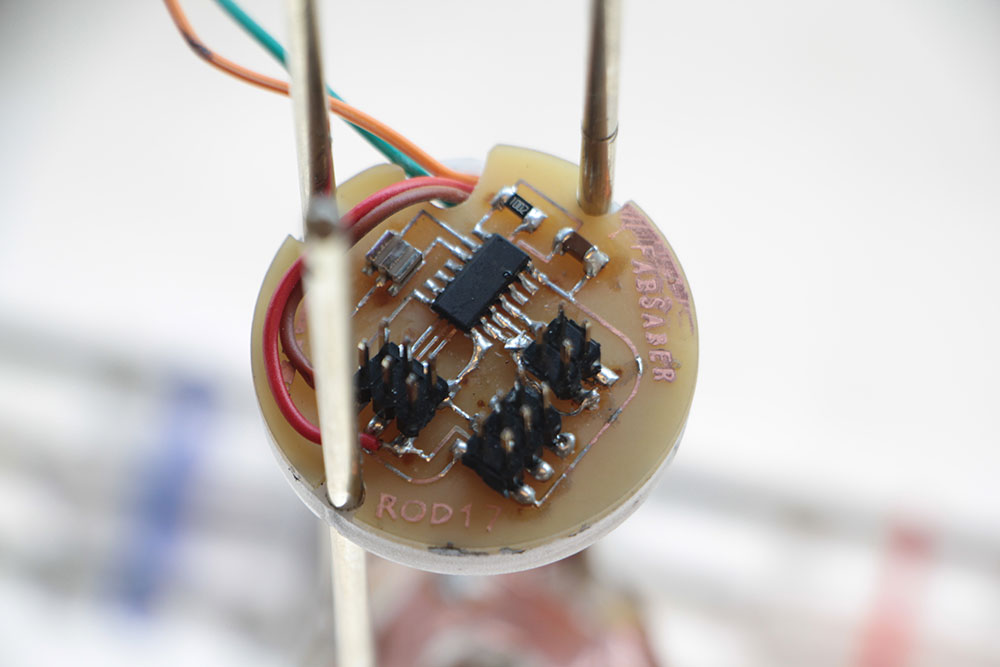

these two boards were prior to the final one and show that I did struggle in my electronics too.

these two boards were prior to the final one and show that I did struggle in my electronics too.

When I realize the small space that the main board would have, I decide to divide the task of suppling the 12V from bottom to top. Was a nice strategy since without relize I avoid a lot of cables fliying around.

When I realize the small space that the main board would have, I decide to divide the task of suppling the 12V from bottom to top. Was a nice strategy since without relize I avoid a lot of cables fliying around.

I did prototype few time the crystal chamber few times to see how it look. So far I was happy with it.

I did prototype few time the crystal chamber few times to see how it look. So far I was happy with it.

mean while I engrave some details on the pommel and took out the 12V to the main board added to the bottom board and cut them.

mean while I engrave some details on the pommel and took out the 12V to the main board added to the bottom board and cut them.

I connected and totally failure!!!

I connected and totally failure!!!

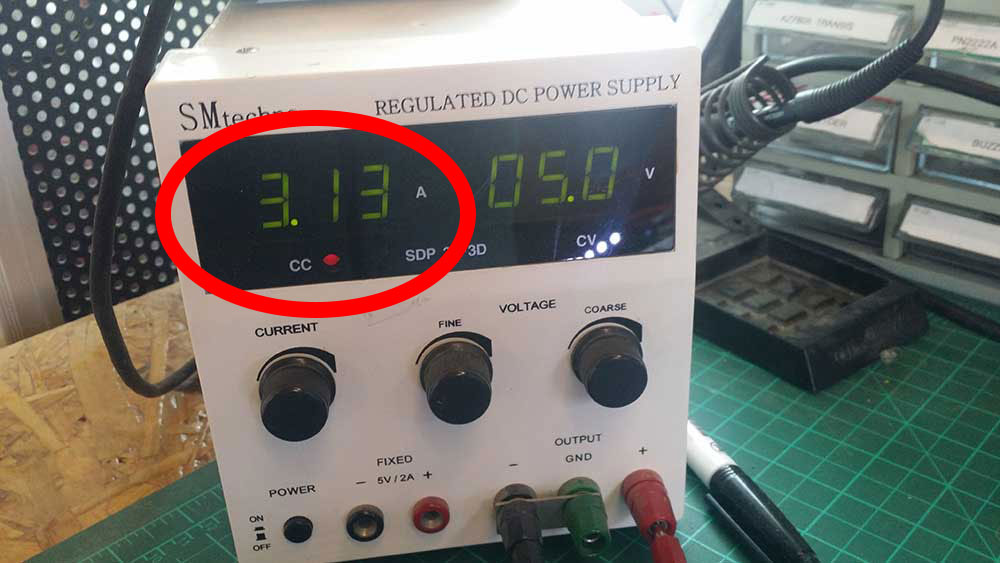

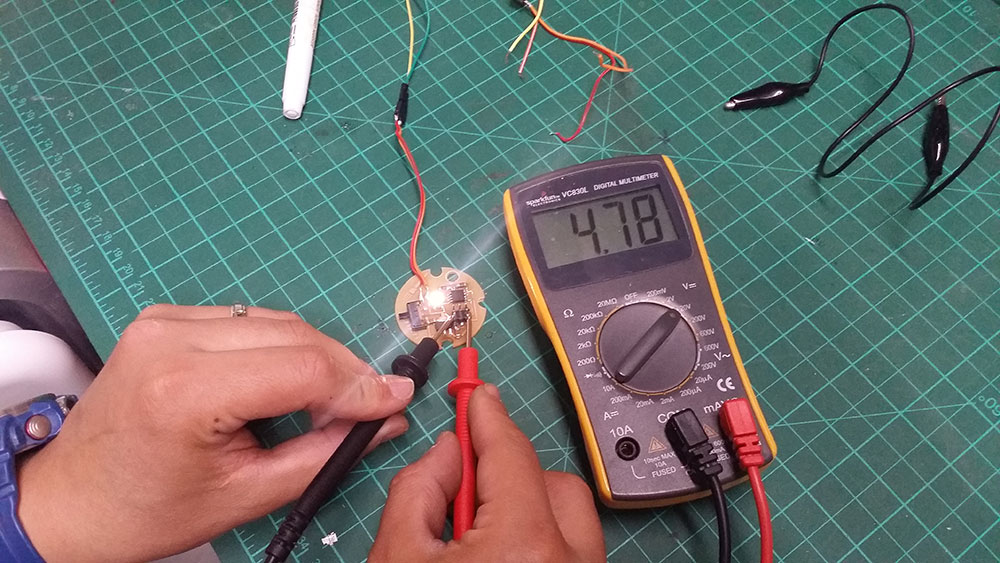

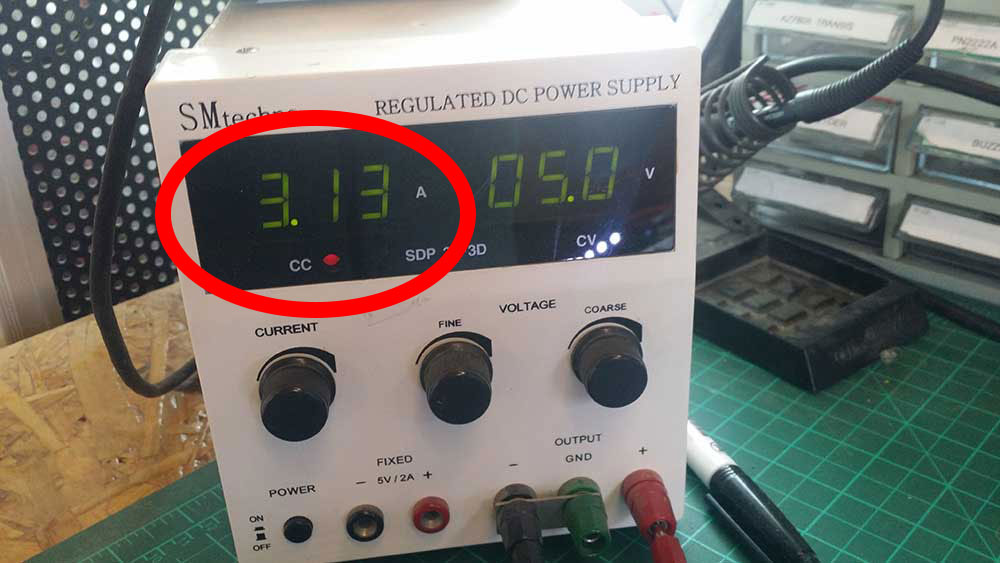

My LED strips were using too much power! 3.13amp

My LED strips were using too much power! 3.13amp

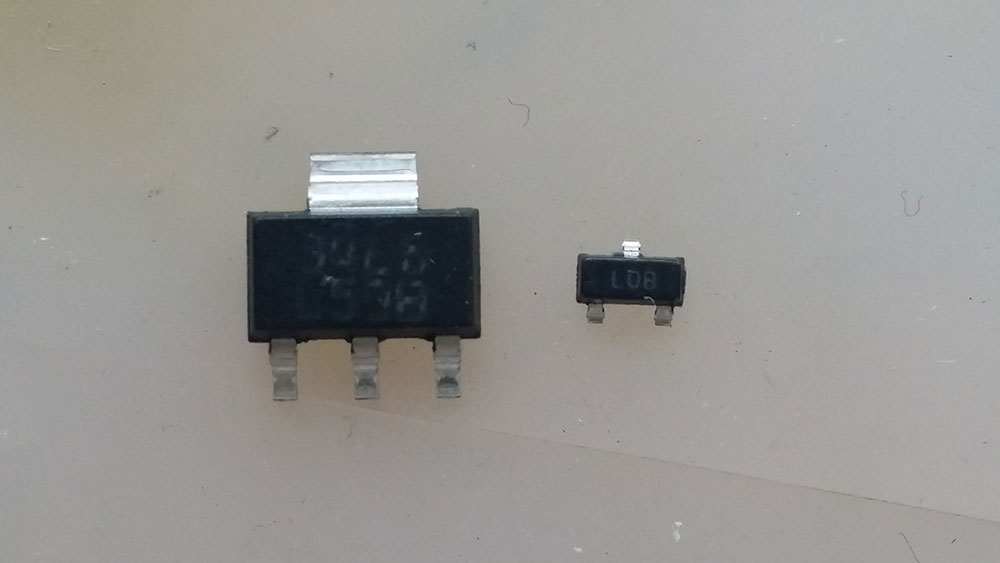

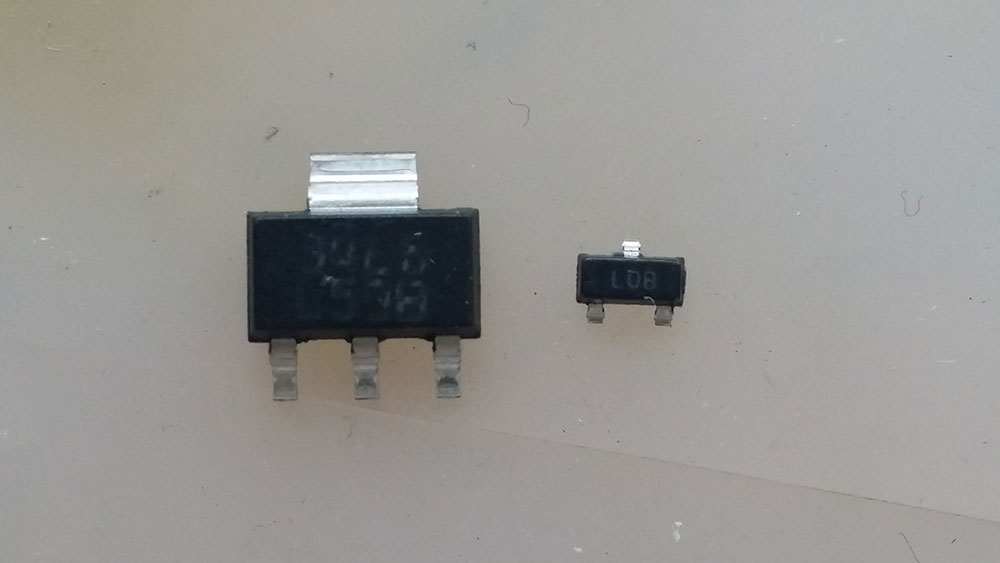

So I had to do two major changes!! 1st, get a bigger voltage regulator! and get rid of LED (in the strip I was using 120 Neopixels)

I read the datasheet and check how this new voltage regulator had to be wired including some capacitors and a lot of GND for the heat dissipation.

I read the datasheet and check how this new voltage regulator had to be wired including some capacitors and a lot of GND for the heat dissipation.

Made it, tested and it worked!

Made it, tested and it worked!

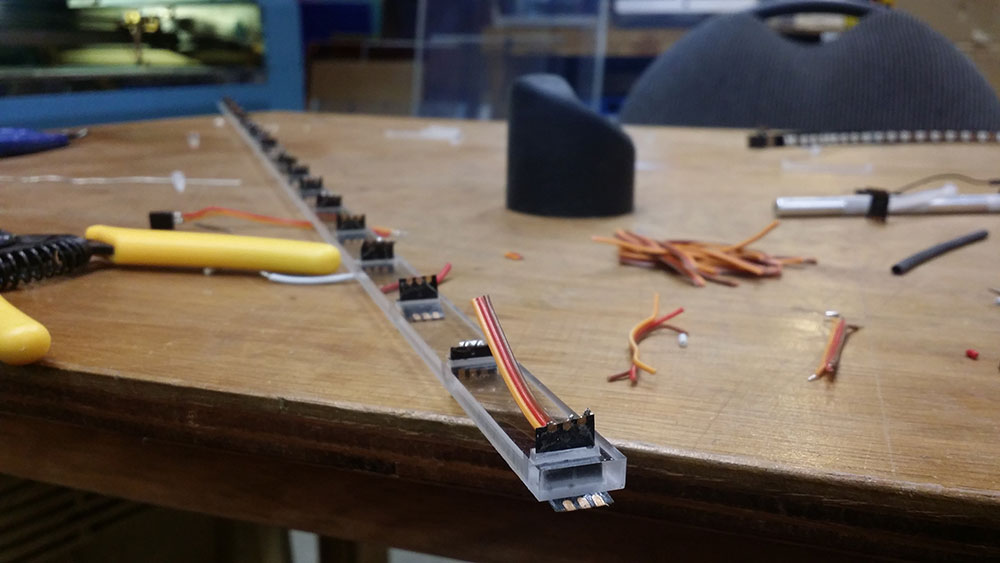

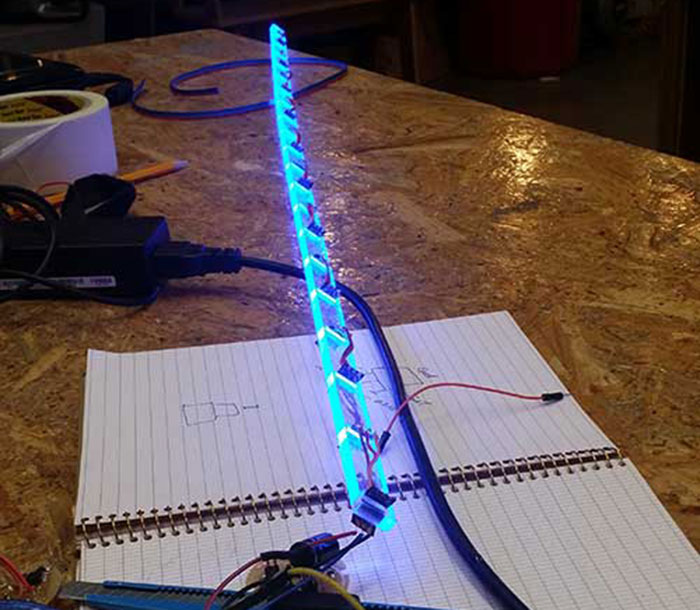

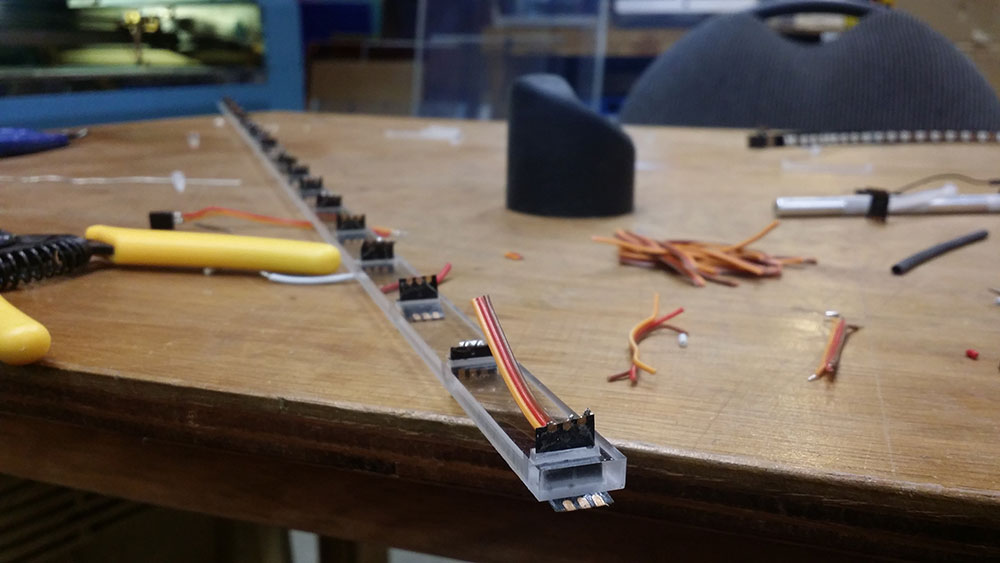

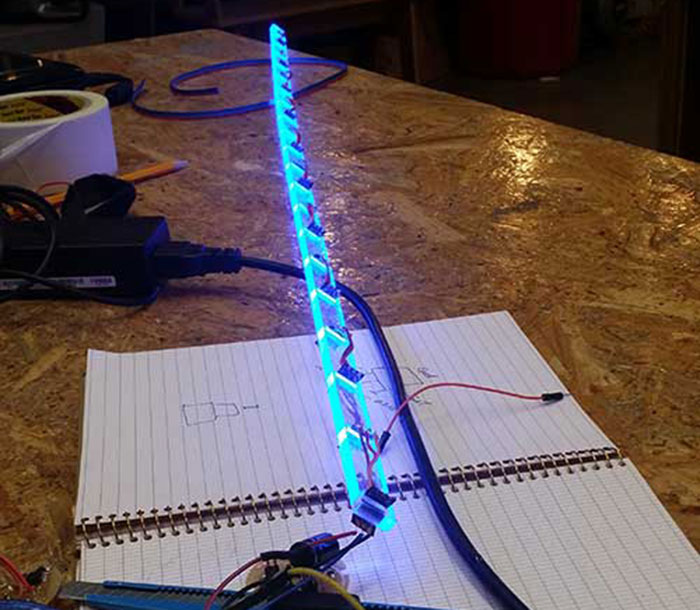

after that I made a long channel to install the neopixels and had to solderthem together. In total were 120 pads soldered during 3 hours!!

But totally worth it!!

But totally worth it!!

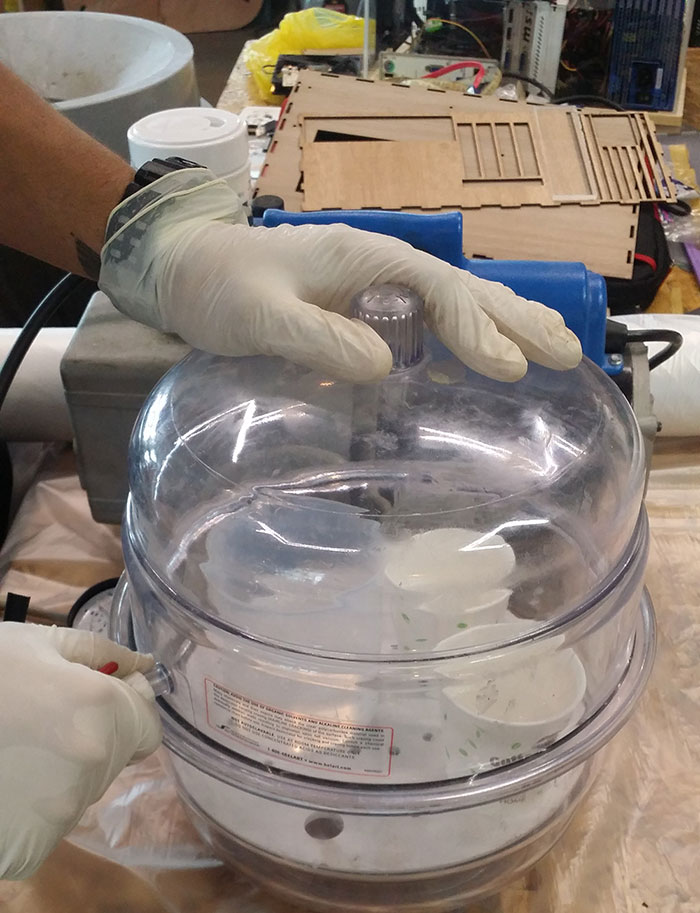

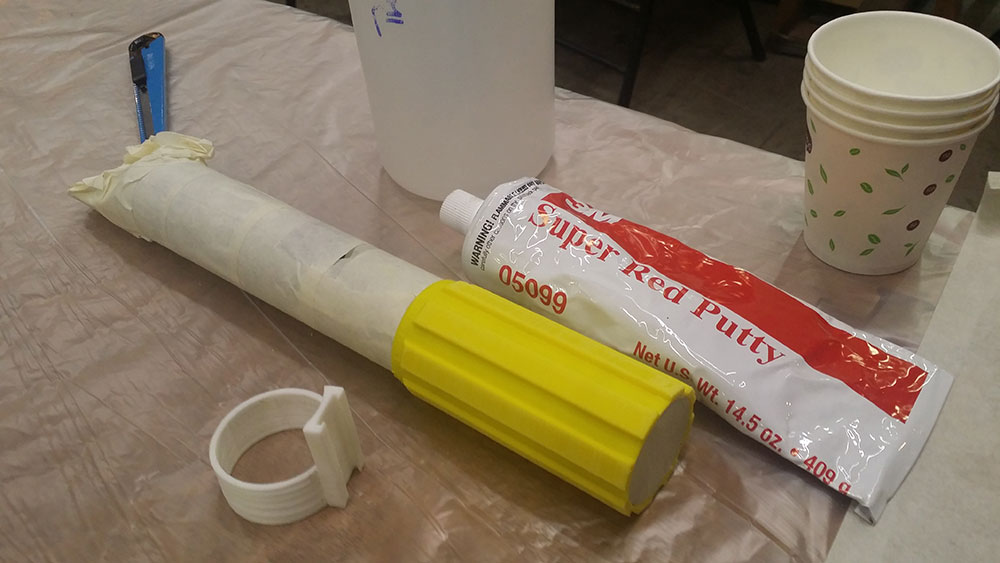

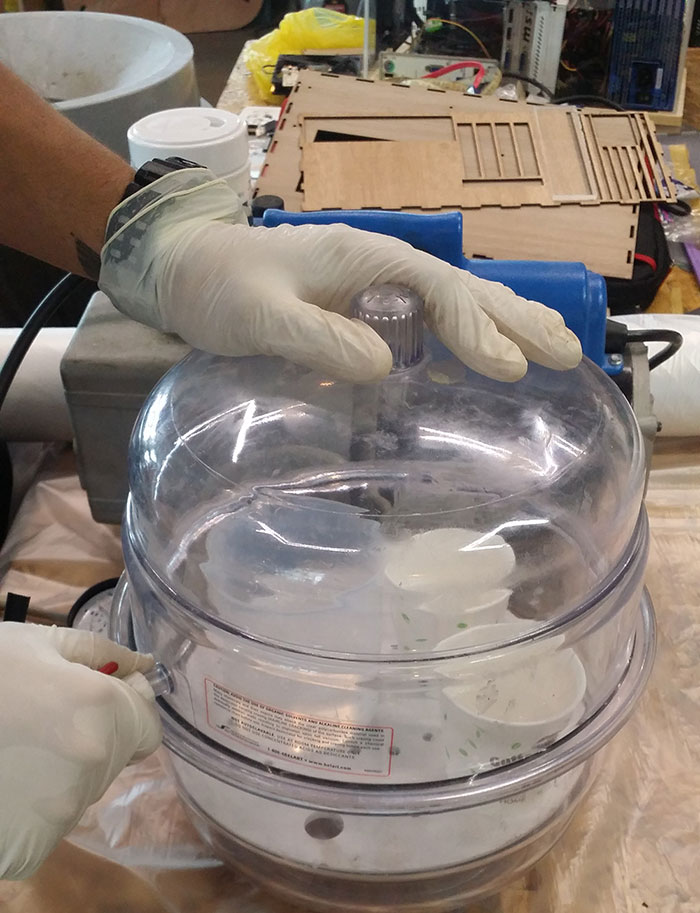

I also cast my crystals again using cristal clear, vacum pump and injection molding!!

so much fun! check the link for my molding and casting week to see how I made the mold and the cast for the first time.

so much fun! check the link for my molding and casting week to see how I made the mold and the cast for the first time.

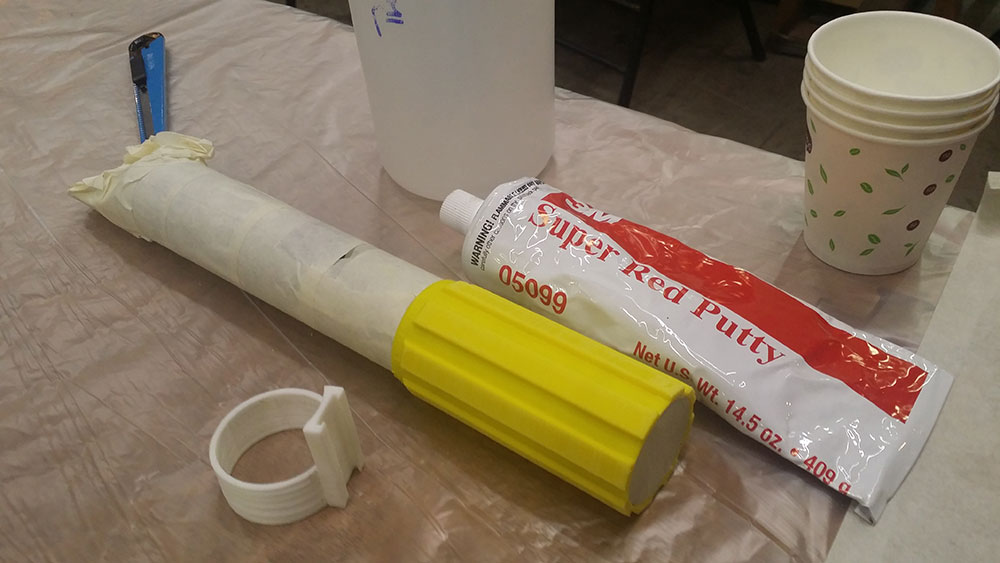

I wanted to make it look like a real lightSaber once done, so, I did weathering on by paiting it grey (primer) and spraying black color and rubbing it using an sponge to create the "old" look.

I wanted to make it look like a real lightSaber once done, so, I did weathering on by paiting it grey (primer) and spraying black color and rubbing it using an sponge to create the "old" look.

By putting masking tape in the outer part of the handle and doing painting again will make an small difference in the tone of the handle representing the years hold and how the person hold it.

Pretty nice and then connected the new board with the blade.

Pretty nice and then connected the new board with the blade.

I diffesed the LED by using marking paper.

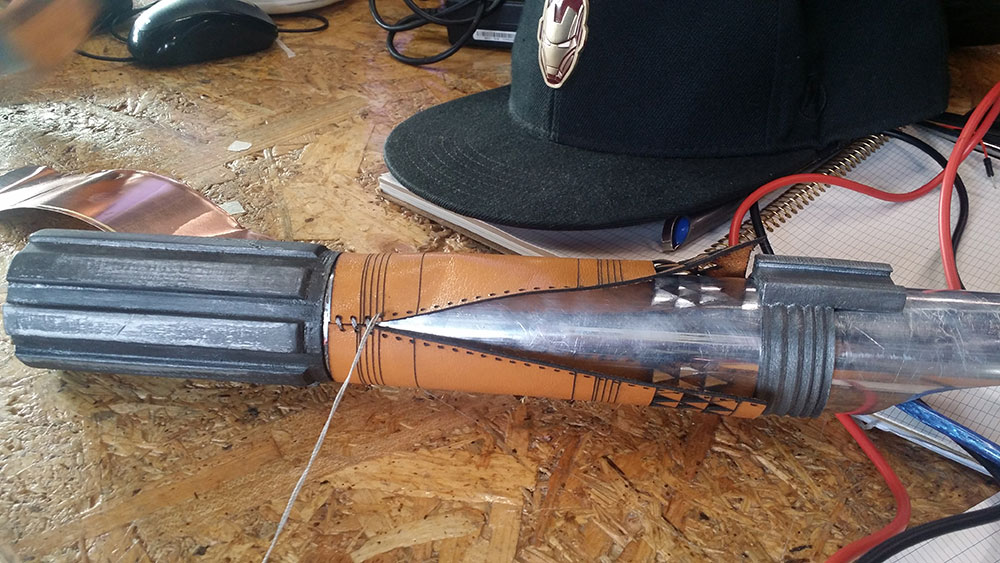

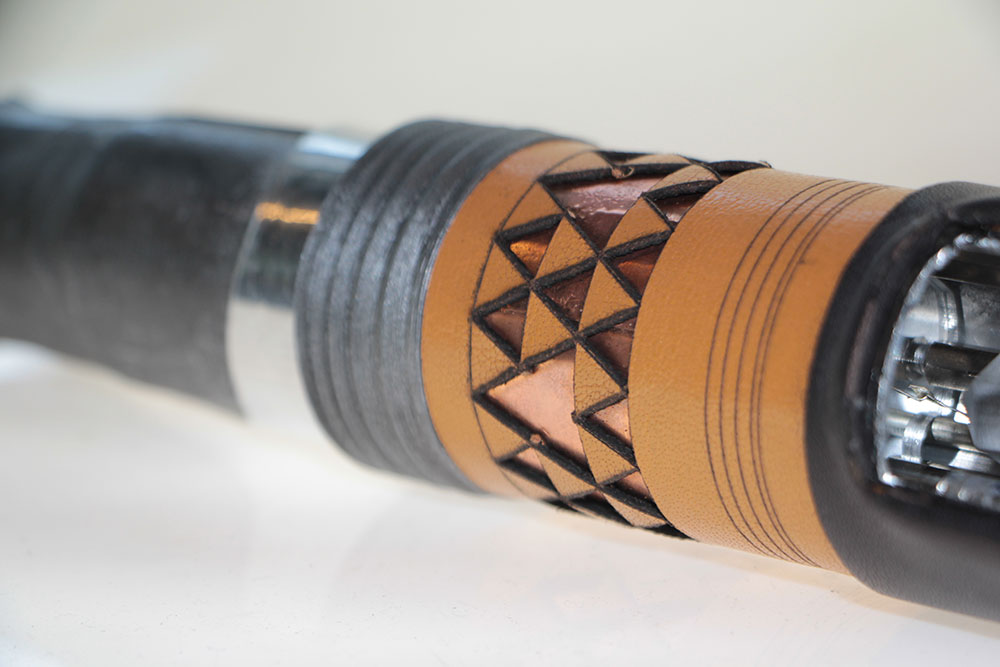

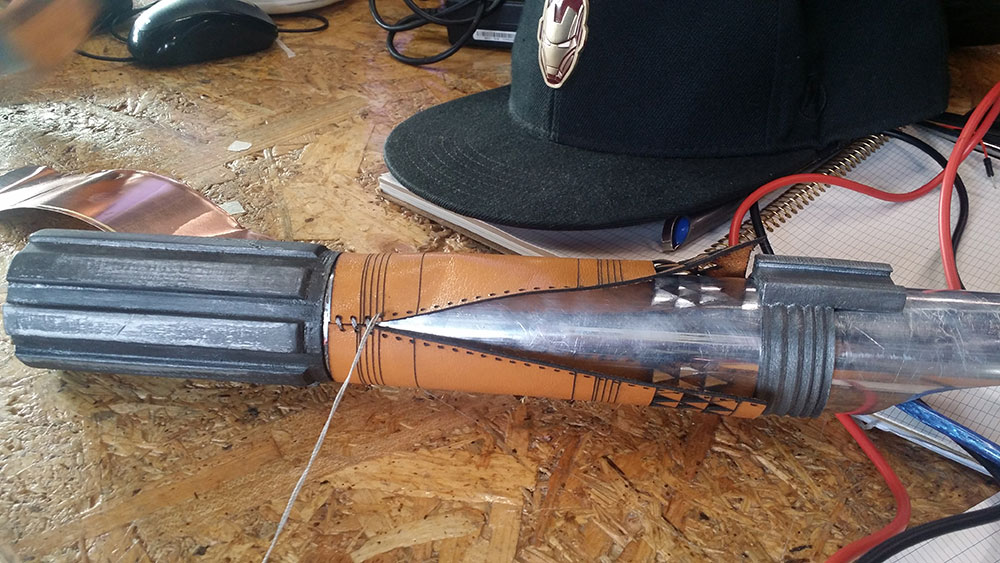

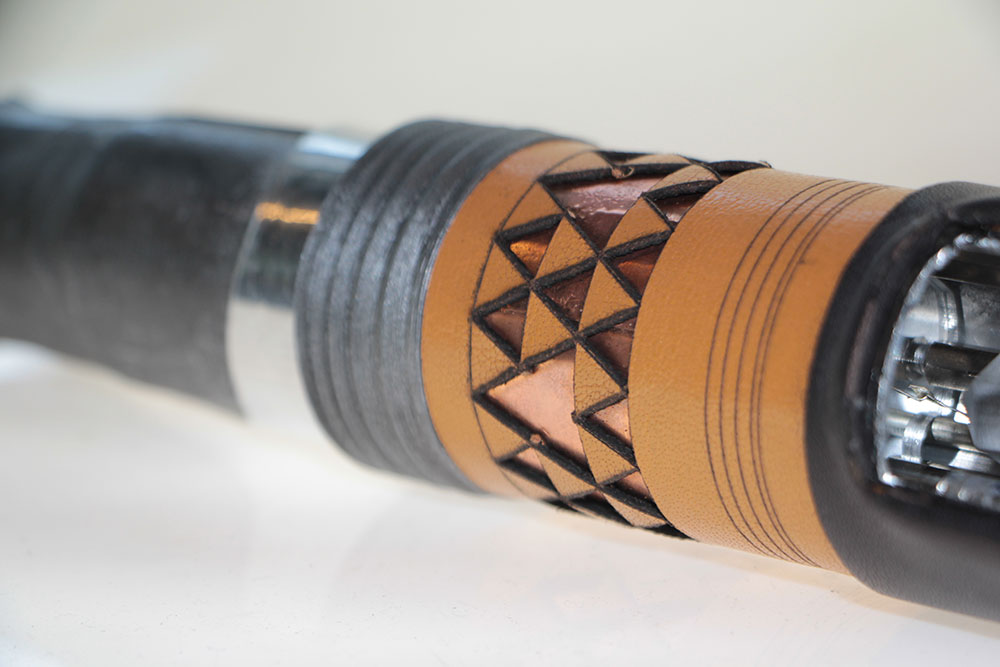

My instructor help me by adding leather on the outer shell and it looks out of this world!! (maybe tattoine)

My instructor help me by adding leather on the outer shell and it looks out of this world!! (maybe tattoine)

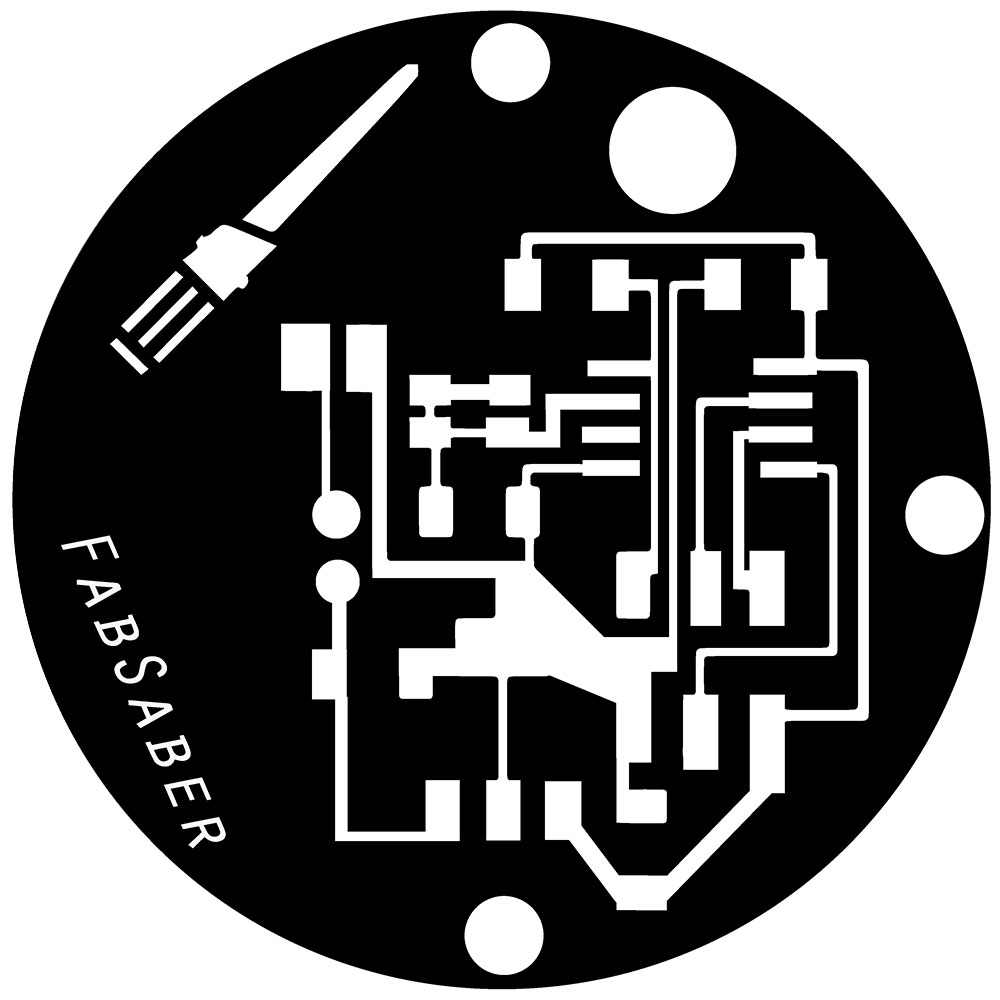

also I made a PBC that it does not work as a PCB but its just the name tag on the side!

it looks to nice to be real!!

it looks to nice to be real!!

Close up picture can show the love that was invested in this project.

Close up picture can show the love that was invested in this project.

under the leather it was copper tape that I used for the capacitive sensor, top board also looked great.

under the leather it was copper tape that I used for the capacitive sensor, top board also looked great.

More nice picture!

More nice picture!

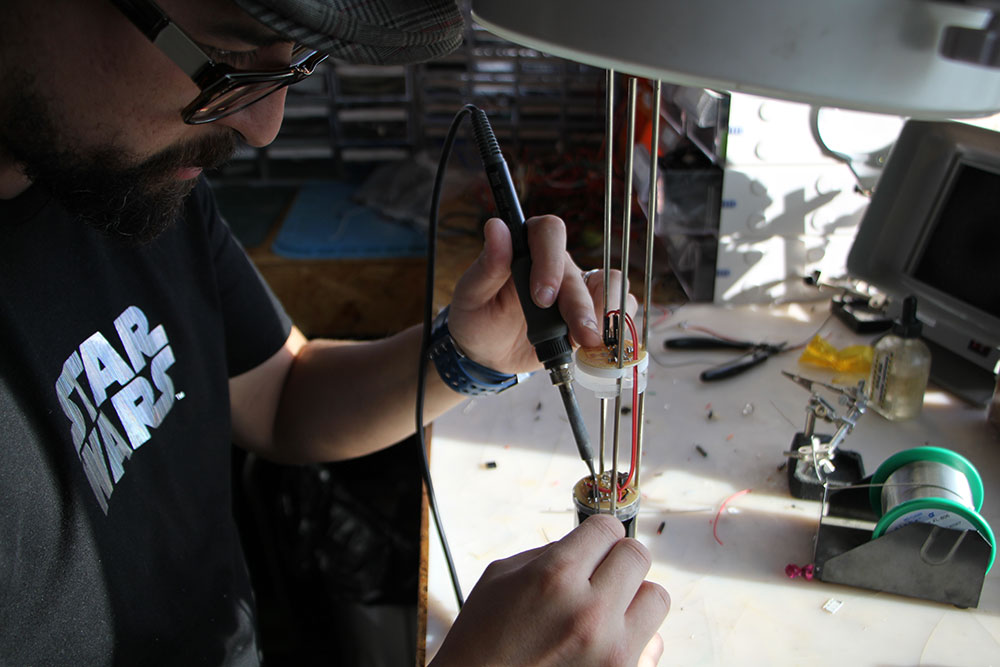

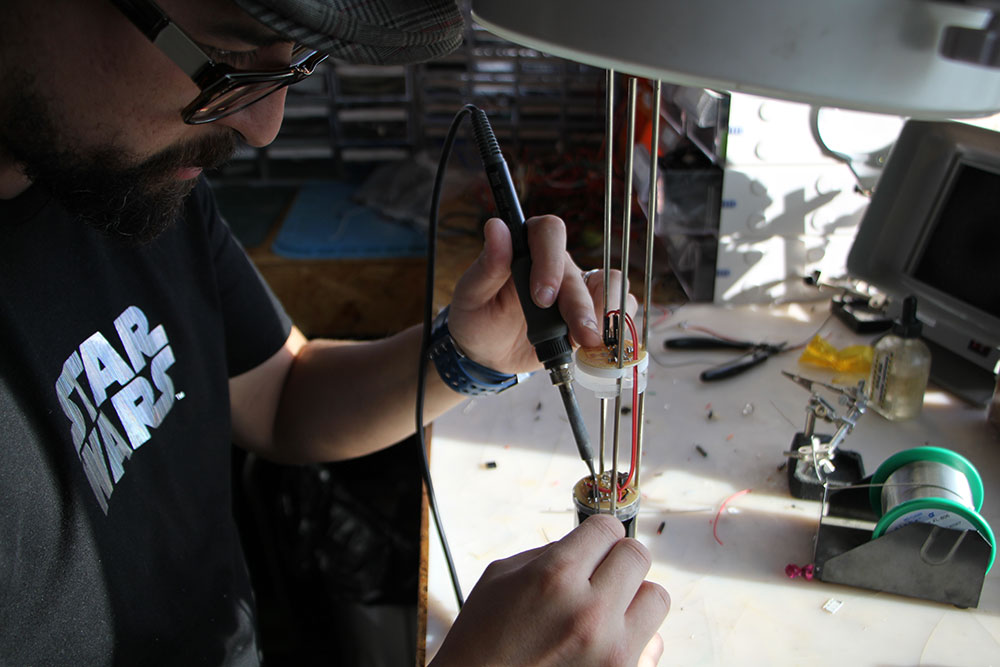

Me loving the project!!

Me loving the project!!