For this week, the assignments to be accomplish are:

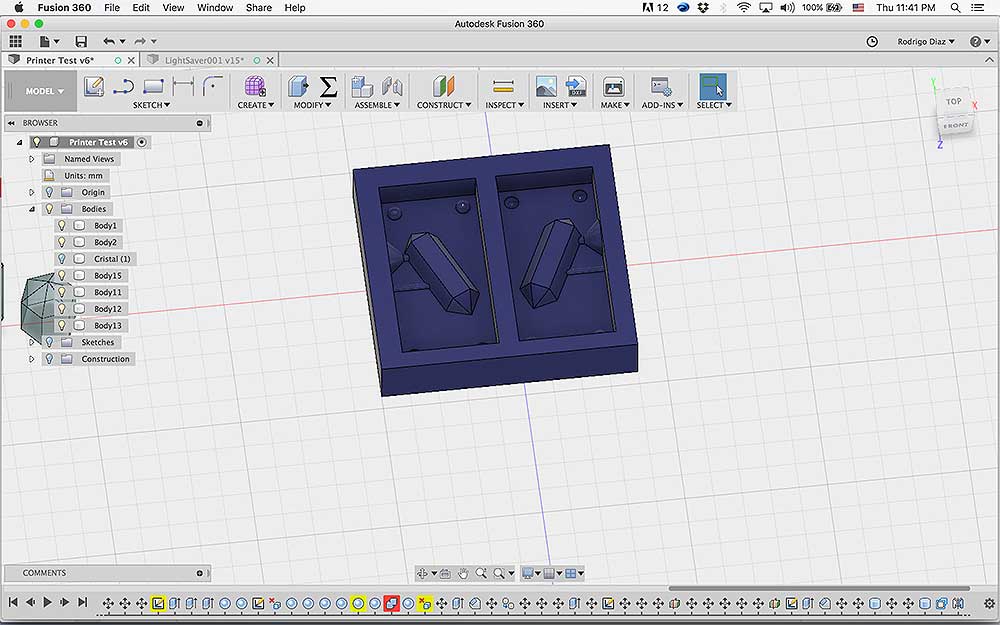

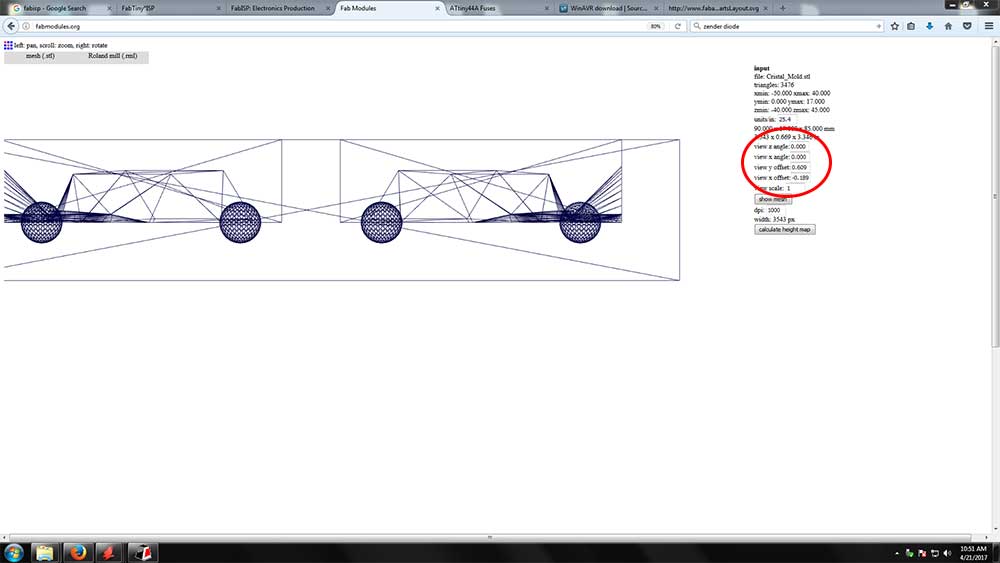

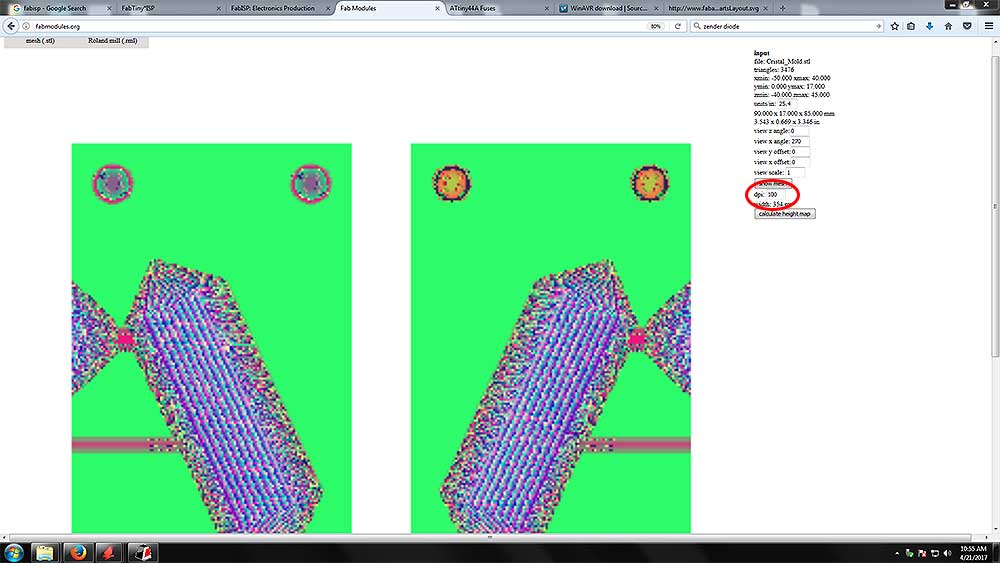

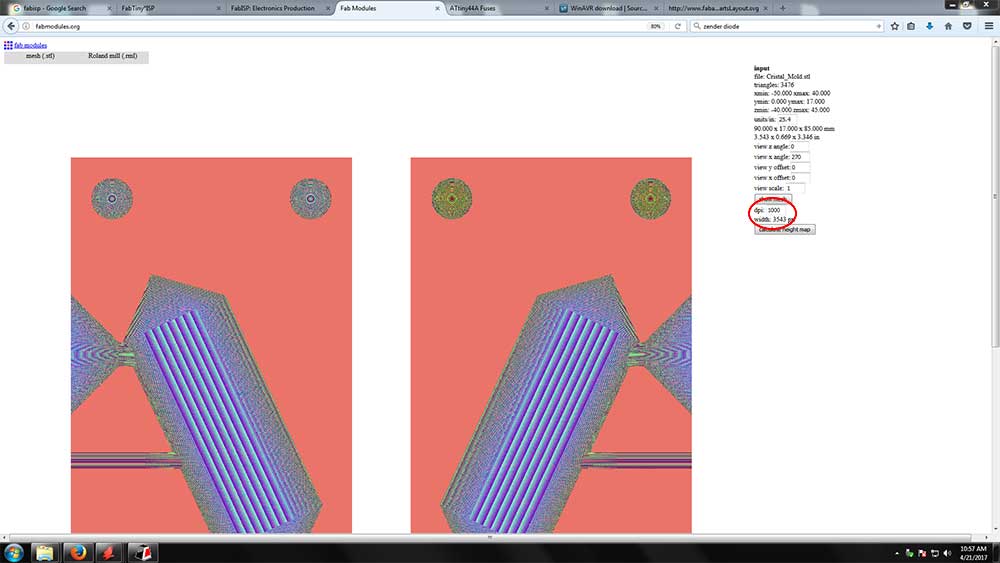

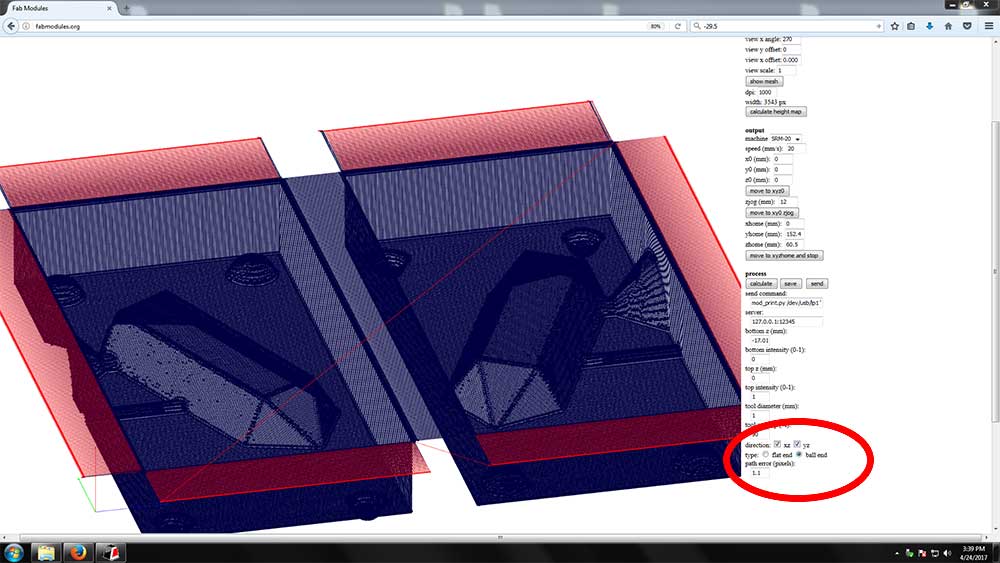

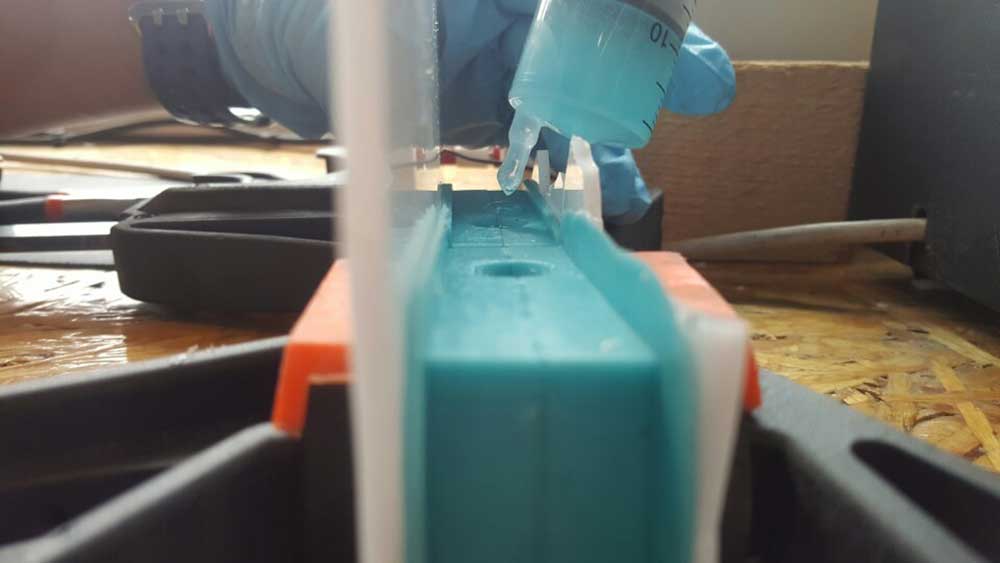

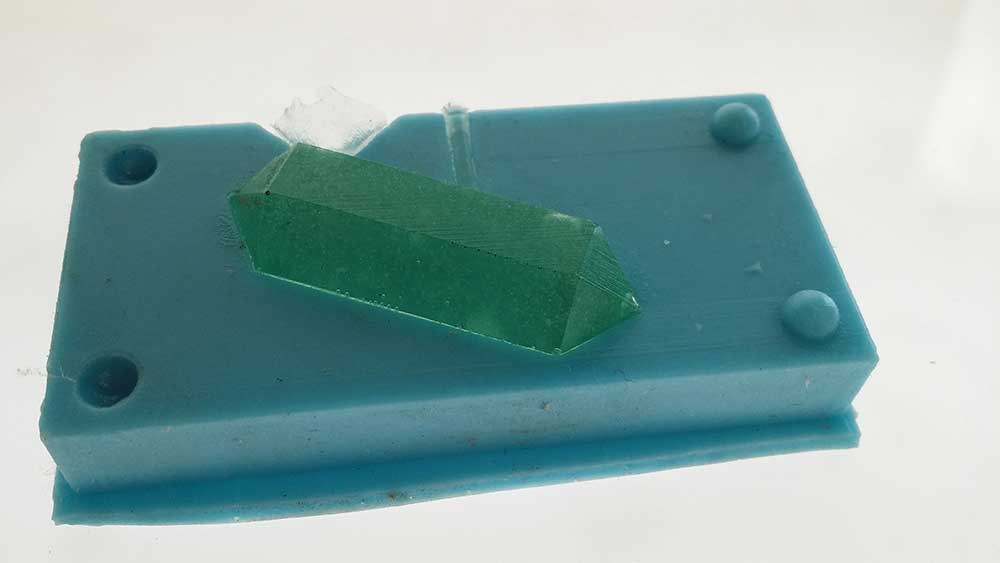

Since I have change my mind regarding the final project I realized that I need to start working ASAP if I want to make it in time, therefore, this time I made a mold for a Kyro Cristal for my Light Saver

What I was not able to do this week:

What I did but need to get better at: