This week our assignment is design a mold, machine it and cast parts from it. There is a sop workshop near our space. So this week, I made a mold for soap.

First I made a 3D model in computer and got it 3D printed.

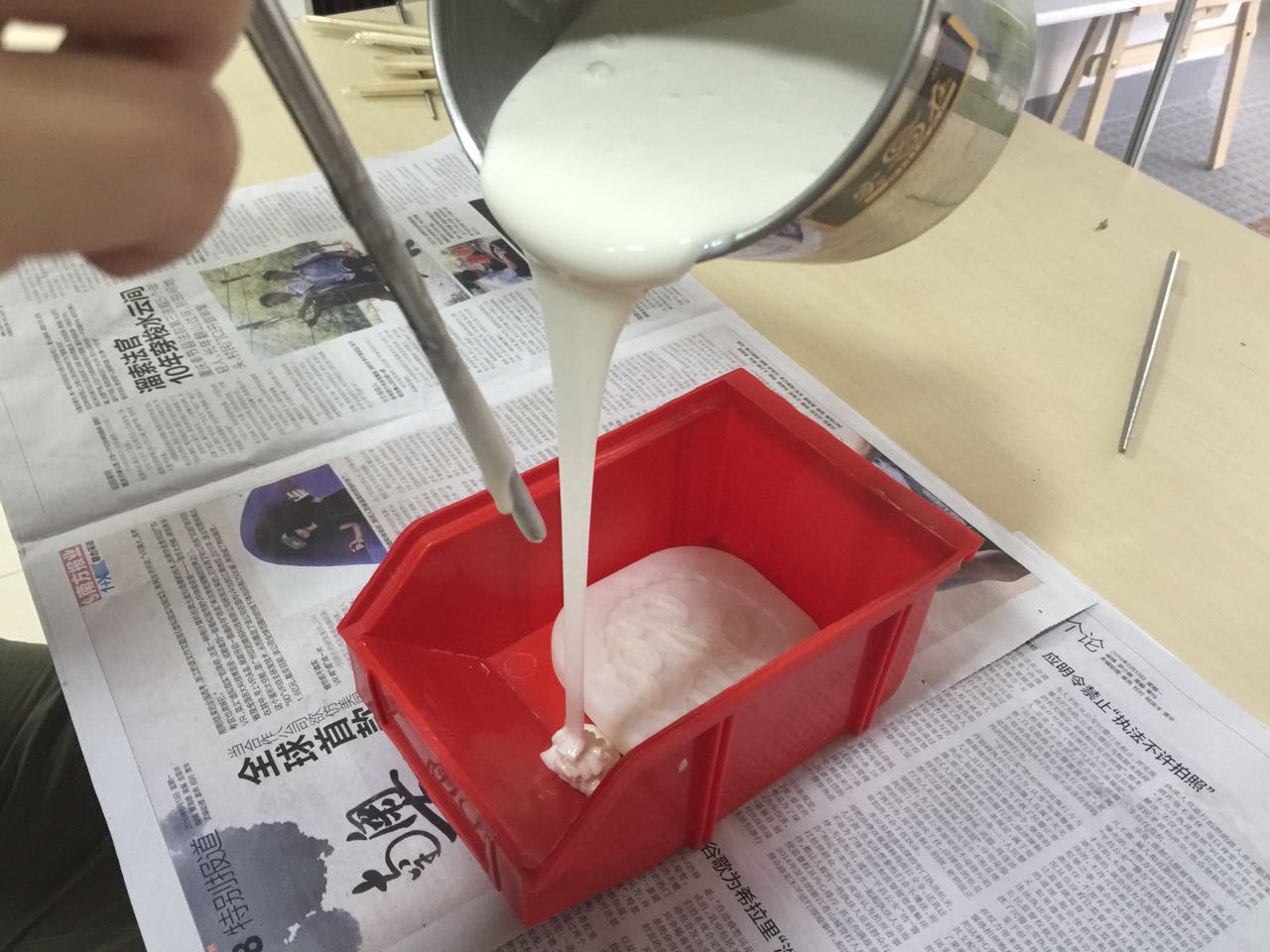

And then I found a container for the following for silicon. Mold release wax is required to apply on all surfaces that are possible to expose to silicon, the container, the 3D printed object, and the cup you are going to mix silicon.

I ordered silicon from taobao. And to solidify them, you need some special ingredient, curing agent. Mix it with a certain percentage, 2.5% in this case, then you will have 10-30 min to mix and pour it into the container and remove bubbles.

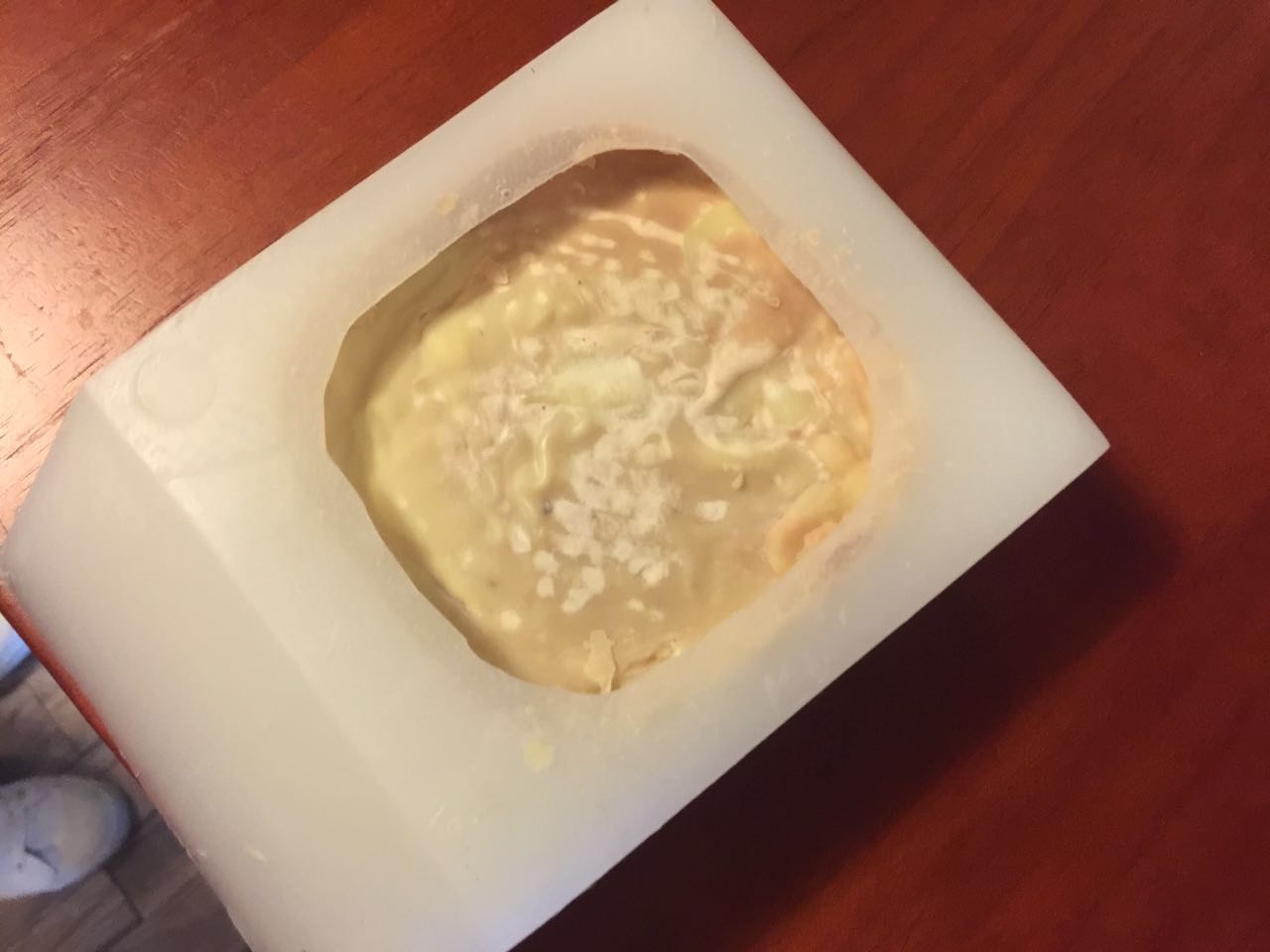

So after ~6 hours, I got this mold. Though we didn’t have a vacuum machine to remove bubbles, it seemed not bad. Soap time!

Thanks to my dear friends, I learned how to make good face washing soap. Main ingredients in this project are: coconut oil, palm oil, walnut oil, NaOH, and water.

Mix all things together, and then can pull it into the mold. After one day, the soap can be removed from the mold. Another 45 days are needed for it to be ready to use.

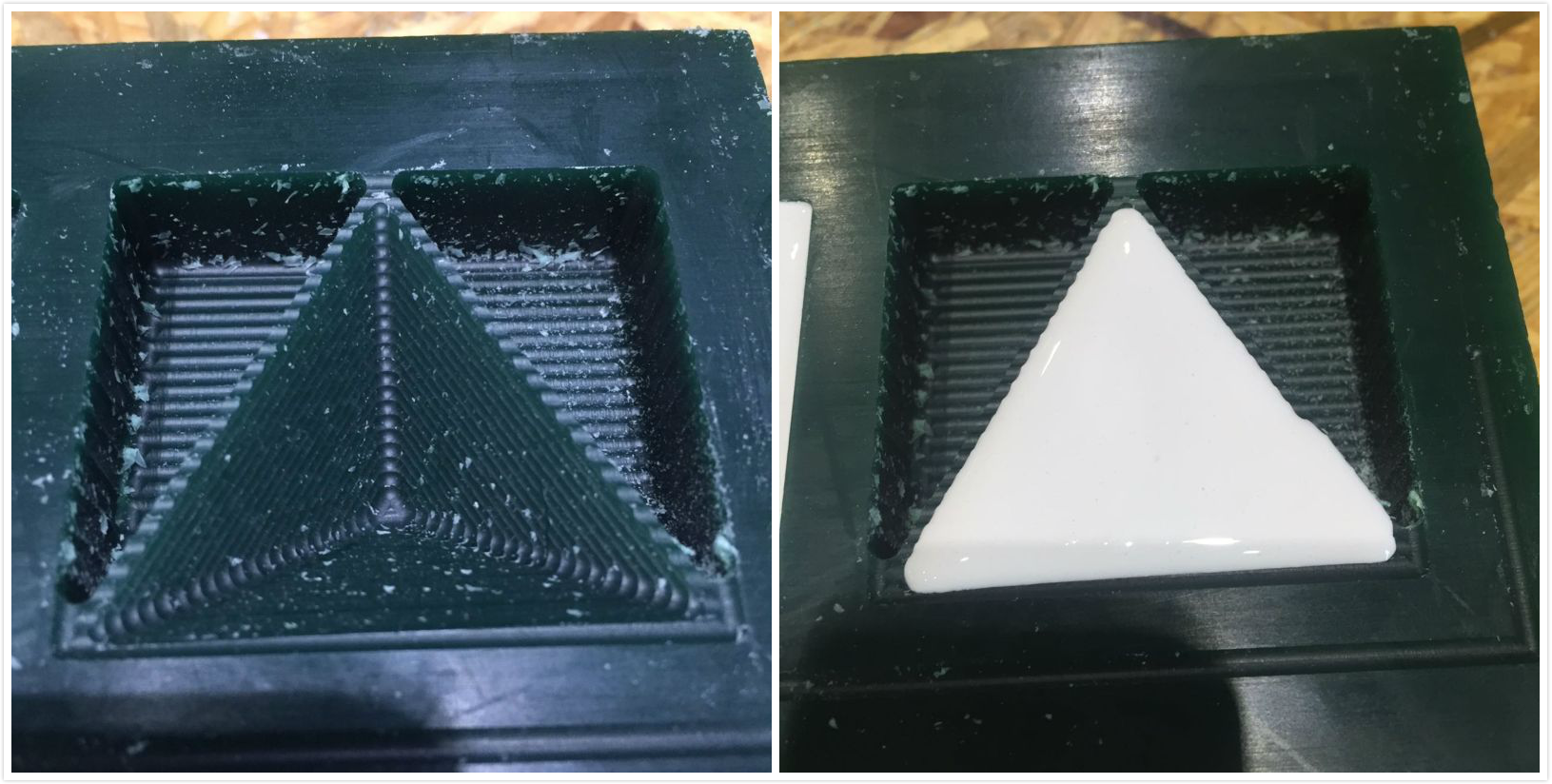

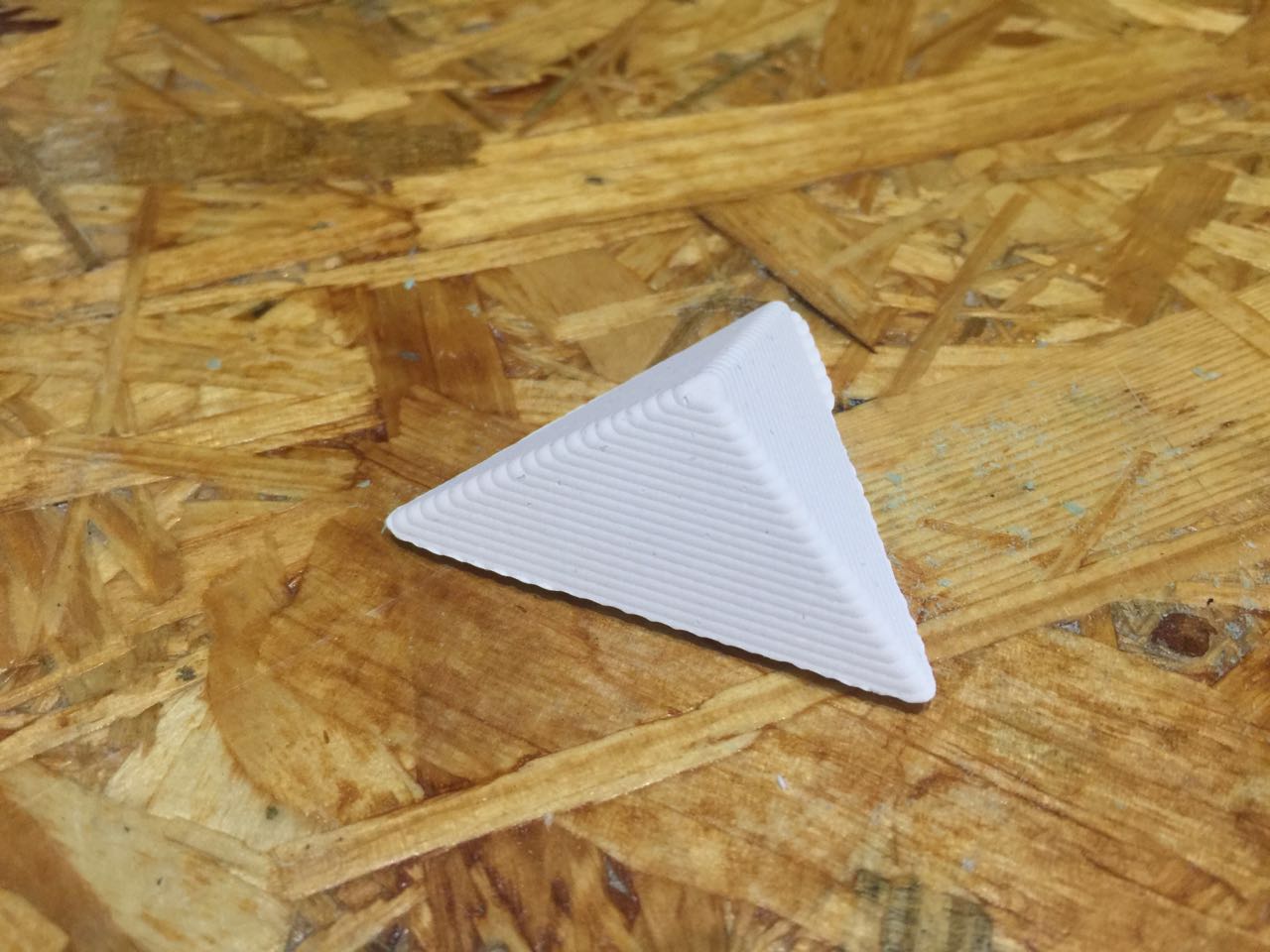

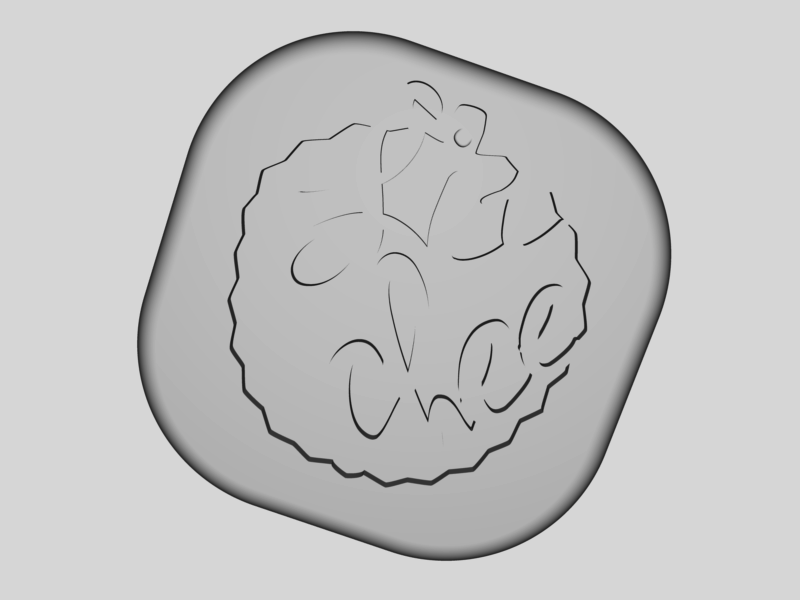

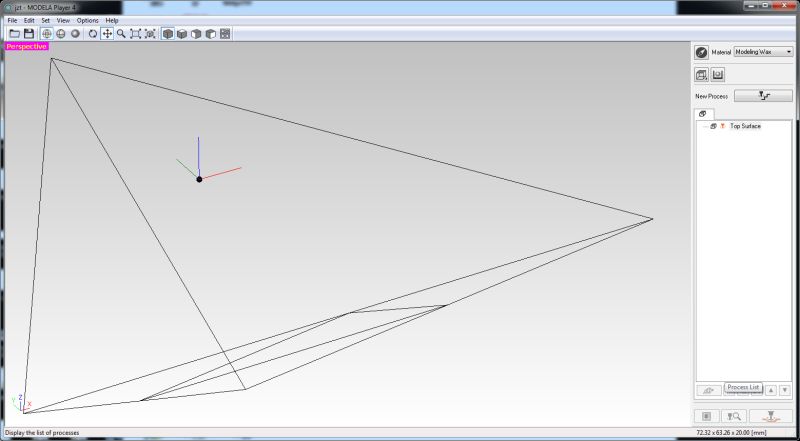

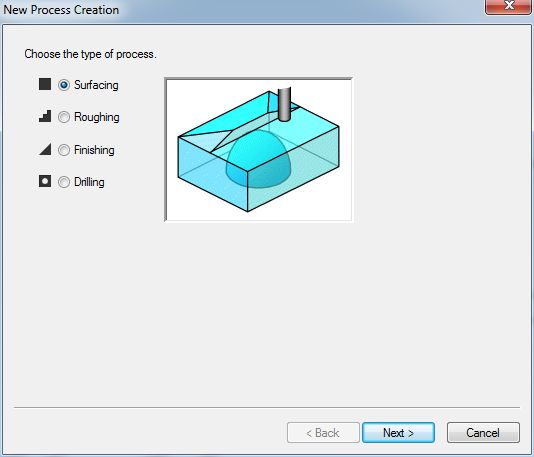

I tried to use a milling machine to make a mold this week also. The model is quite simple. You can find the design file on the right also.

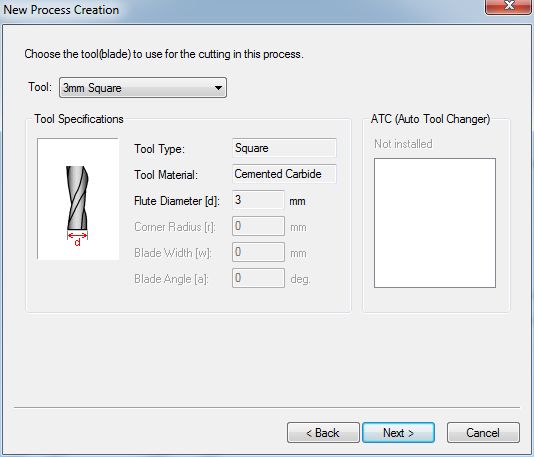

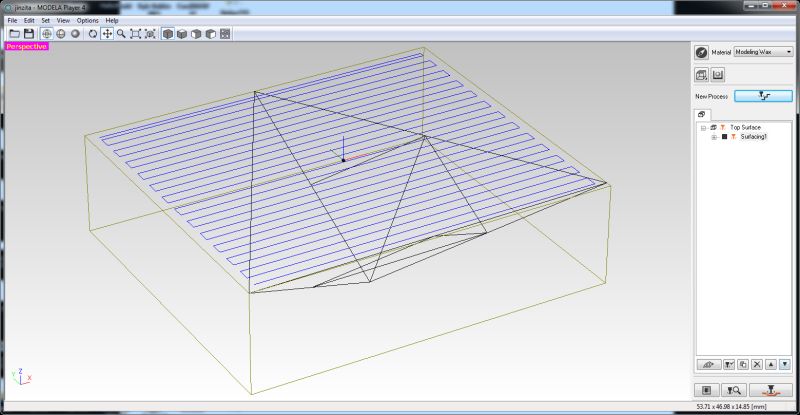

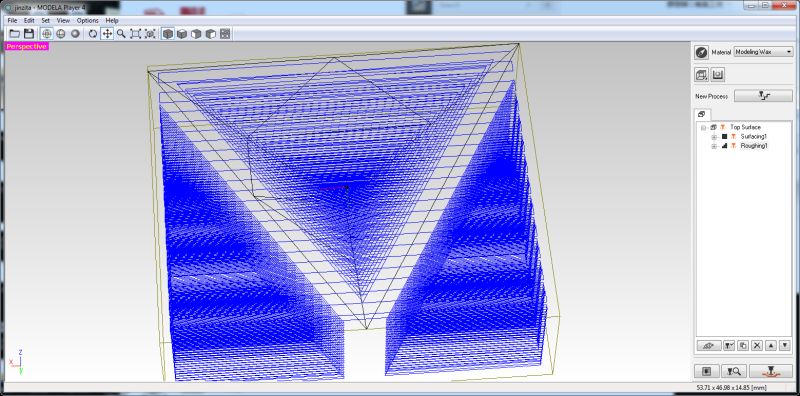

I used the software from Roland to mill this model. In the software, need to enter information about endmill, material and so on.

And then can see the pattern of the knife.

Let's mill it!

Pour plaster to the mold and welcome a pyramid!