Mechanical design

This week's assignment is groupwork!

Kondo-san, Monma-san, and me from Fablabkamakura.

◆Idea

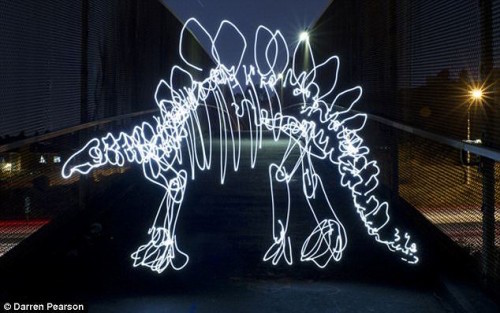

We want to make CNC with Lighting part,and its trace can be recorded as a drawing as you like.

↑This is just a image.

I'm mainly in charge of Fabrication(Laser cautting, CNC milling).

Other members create LED blinking and Programming part this week.

◆Preparing data

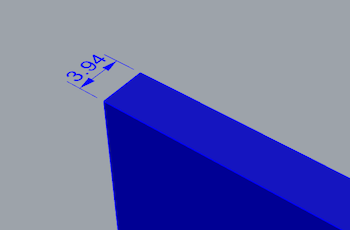

In Japan, it's a little difficult to get Inch standard cardboard.So I need to get Miri standard one, and adjust existing CAD file.

In class page, the link to grasshopper file is expired,

so I got it from Shiraishi-san, FabAcademy2015 student.

But I failed to use grasshopper file because of version problem.

- In Rhinoceros4(Win), some components cannot be open.

- Rhino5 for Mac WIP, it can use grasshopper by type "Explicit history" command,

But when I open Nadya's file, program will be closed. - Rhino5(Win) + grasshopper works (Later I checked)

The original file uses 3.94mm thickness, but I want to use buy 5mm one.

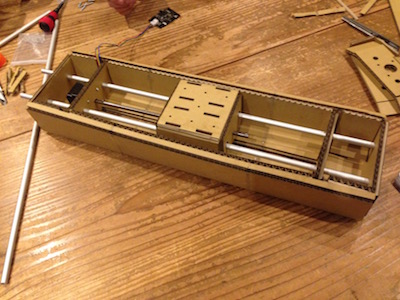

◆Make making

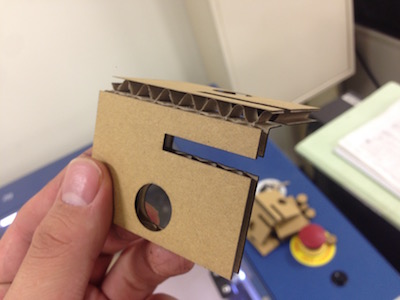

There is two type of cutting.One is just cut, the other is cut only surface.

We need to use 2 parameters.

I also made FabNET by CNC, and We assemble Kit!

Cause of manual adjusting, this one is not good fit.

under construction...

This is 5mm thickness version of the machine.