Mechanical design

MECHANICAL DESIGN (week 1 of 2)

Make a machine, including the end effector, build the passive parts and operate it manually.

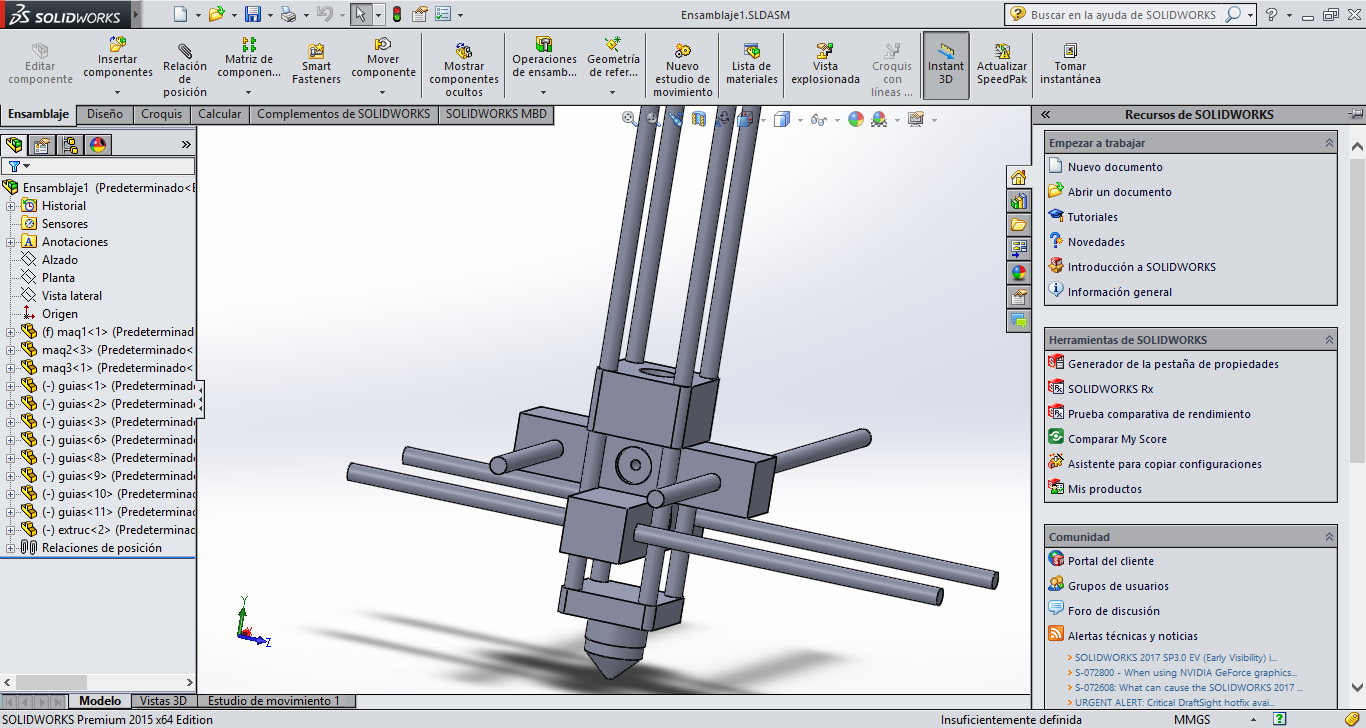

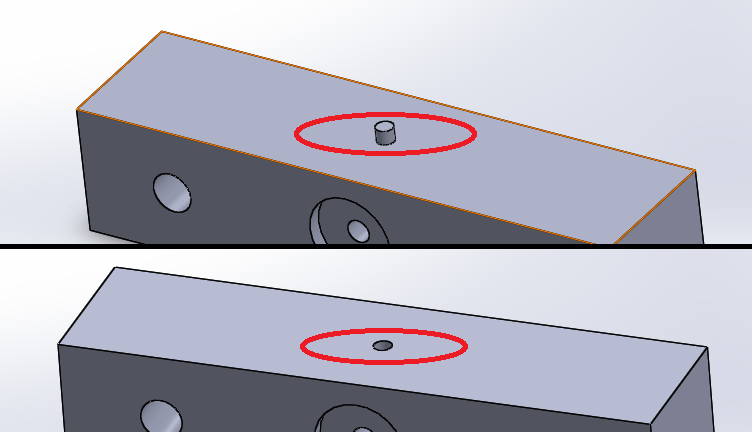

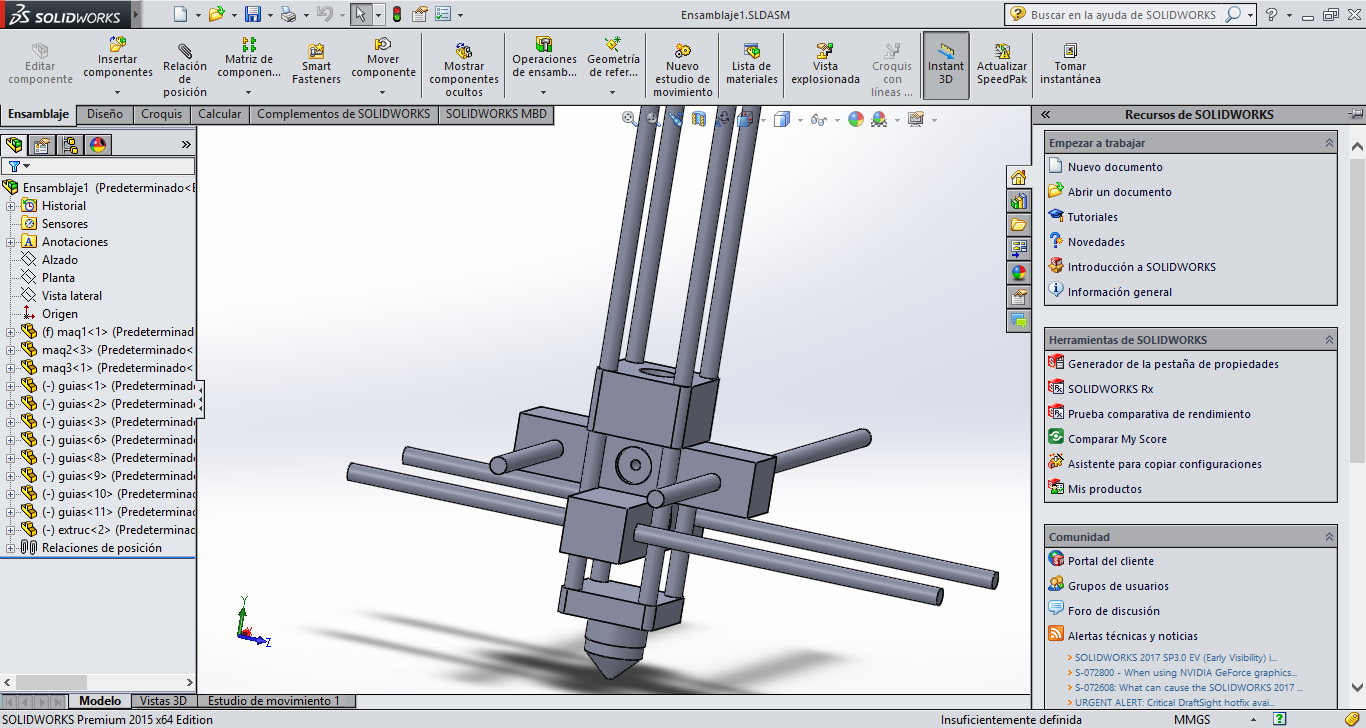

For this assignment I contribute with the design of the head of machine, the design is made in solidworks, this design is like a sketch because I was learning to use the

software, when this sketch is to the new position of the motors in the machine, in this position the motors gave less opposition to the movement and then I show you how made it.

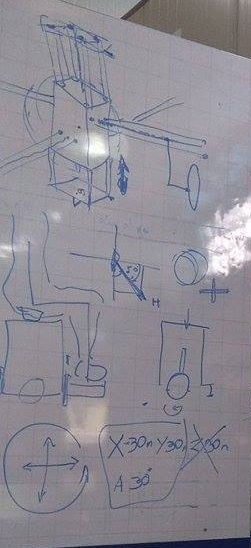

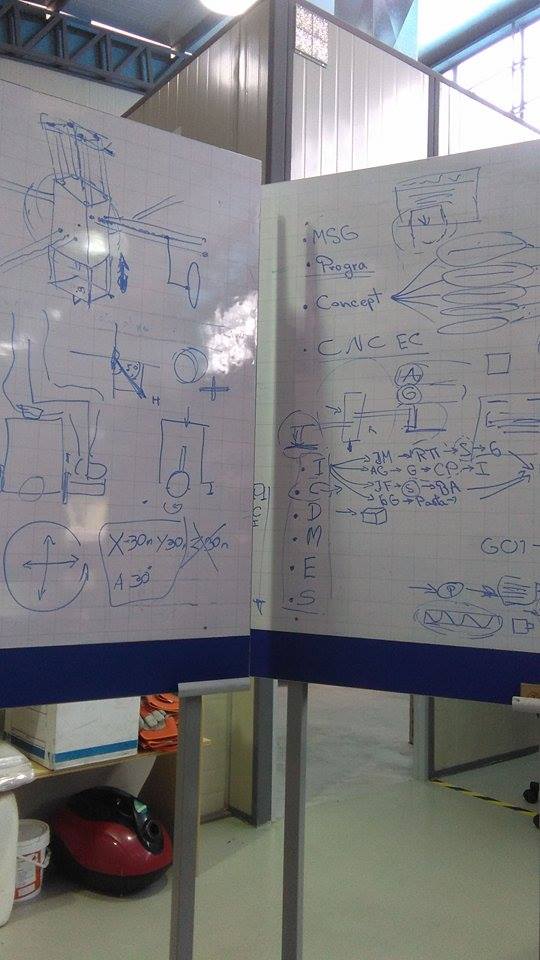

To make a machine first going to be sketch, and how it could work, in this process we decided the work of each and the contribution, establish the bases of

the machine and the materials that will use, also we must investigate about the machine to make, to have a base of operation and how it can be improved.

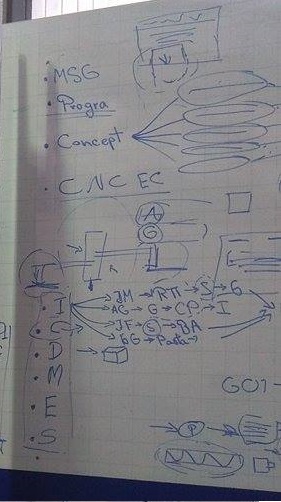

Farmbot

to supplement the machine, all investigate about the machine CNC and a good example is the machine farmbot because have the same objective use the presicion

of machine CNC to make different activities, the investigation can help in the final project, the porpuse is to know the operation and apply it based on our

requirements.

SolidWorks

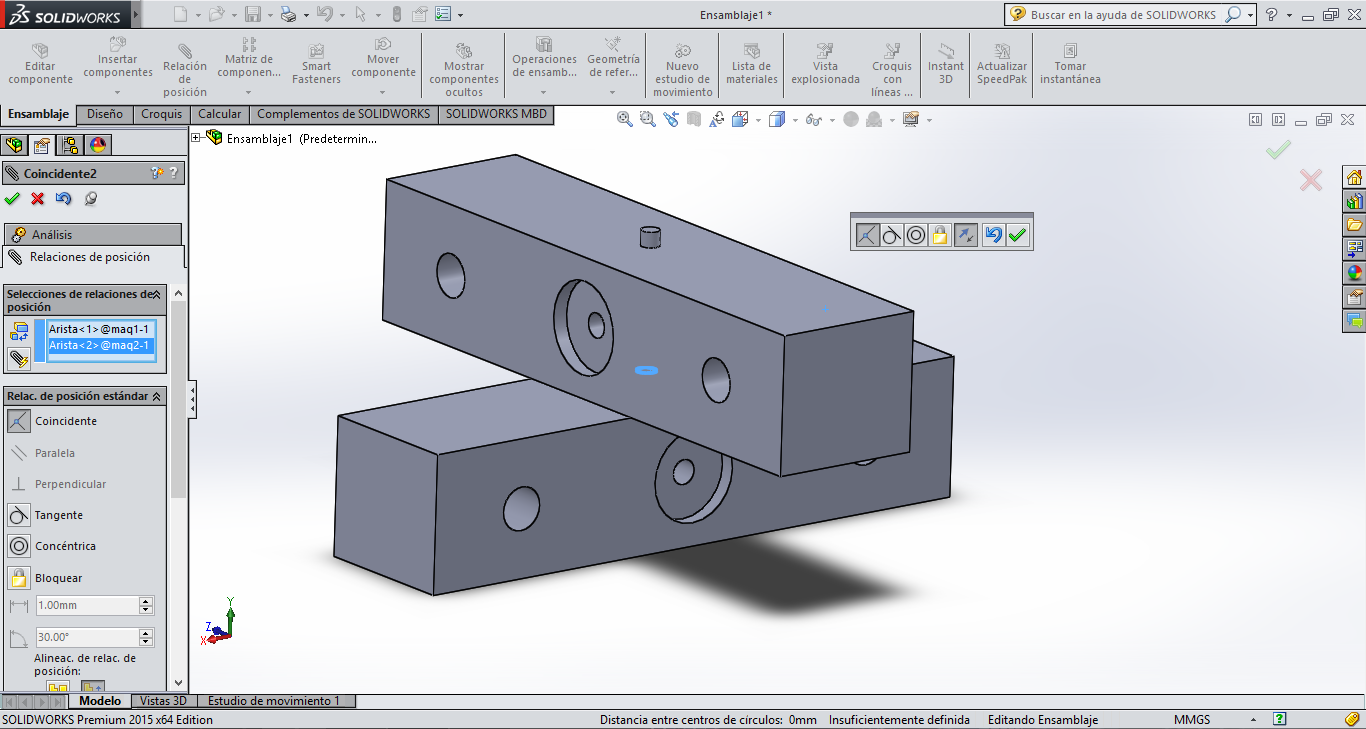

In this week, I used the program solid works to make a render at approximated design of the machine to build, this program make a very complex design,

you can simulate Its functioning, solid works allow us export a different format for later work whit a machine.

Whit this simulation we can know if the design requires corrections and see the correct functioning.

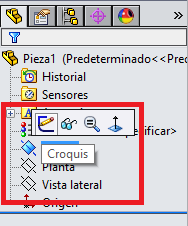

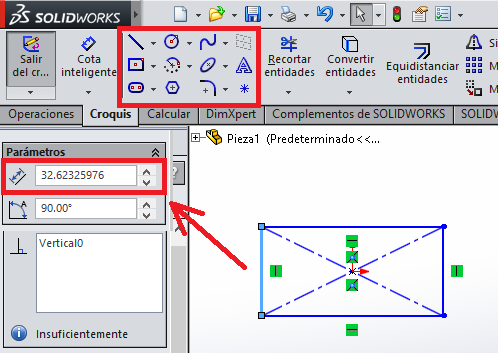

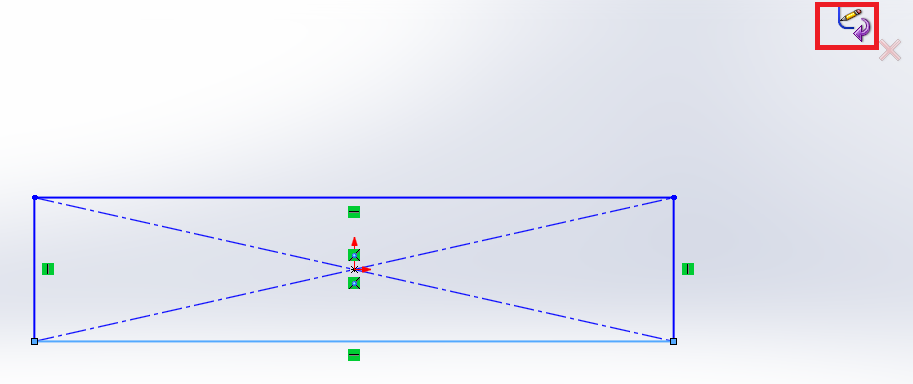

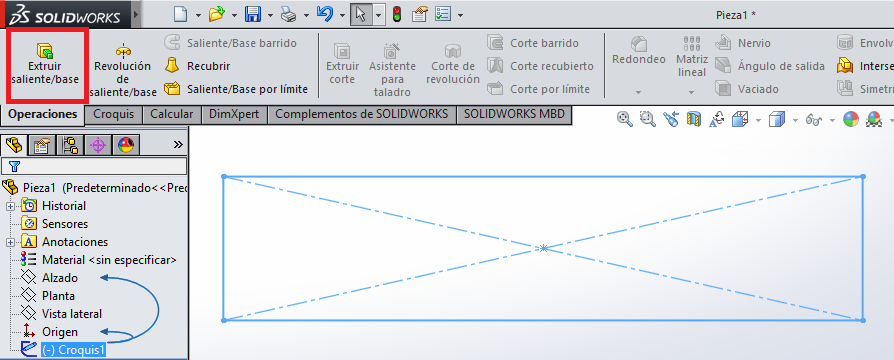

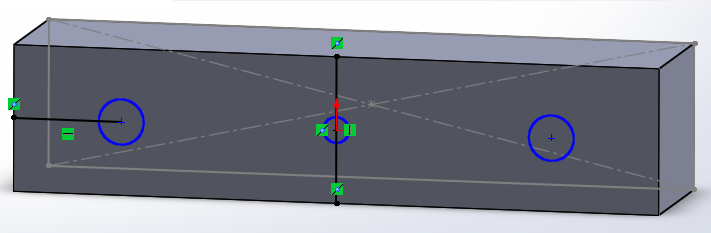

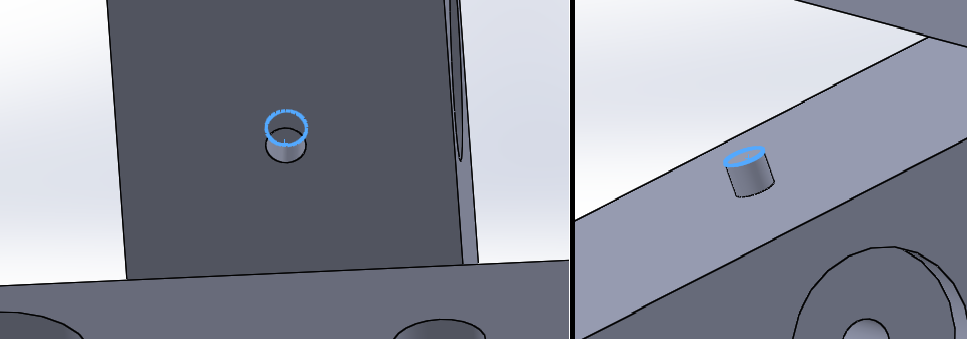

To initiate for make any design, solid works allows us work in plane, first we choose in plane to make a work to start the design and select whit a click and

press in the first image "croquis", next select the figure or line to edit and make a design, to give a measure you have click in a line and in the specifications,

you can change the length and another measure, when you decide finish the edition press in leave the sketch.

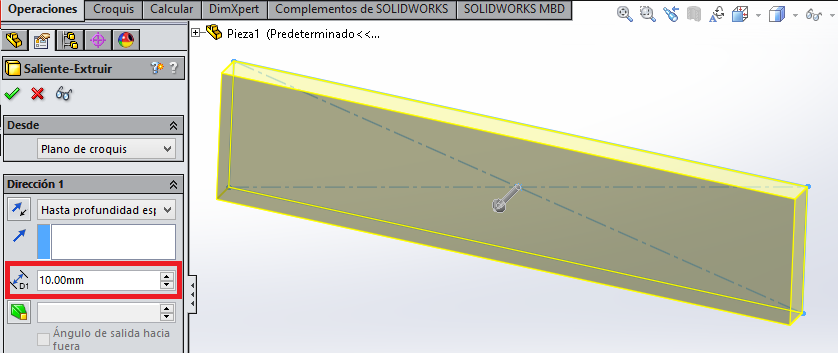

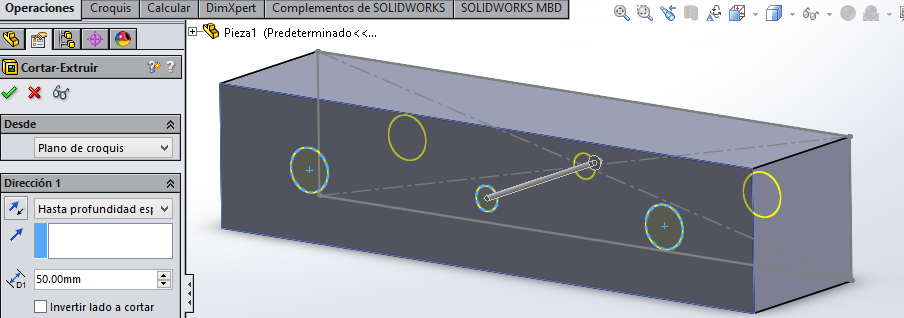

The next step we will extrude the figure, to be able to perform this step we must be sure to leave the sketch and in the toolbar, press in operations you have

all the tools to edit 3D any design also has to make extrude cut, once the extrusion has been made, if you wish make an extrude press in the bottom, then you can

modify the value of the extruder in the options that appear.

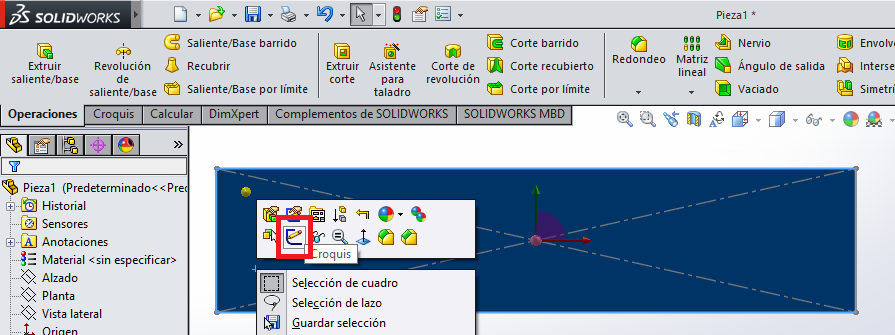

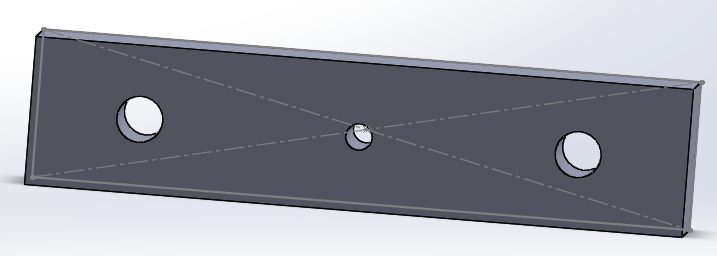

To perform extrude cut you can work in the plane of the figure made, with a click in the plane to work and select sketch, you can edit all you need to make an

extrude cut, is a similar prosses previously, then to finish edit leave the sketch and go an operations whit a difference select a tool extrude cut and edit whit

the same prosses as before, in the options change the depth cut.

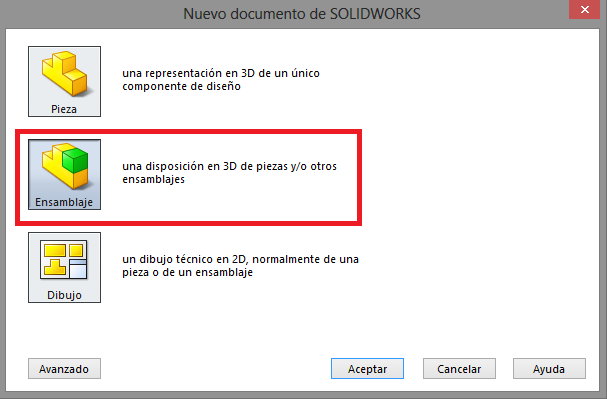

When finish all the pieces, make sure to work on different files each pieces, you must have a method of anchorage or assembly, taking these steps into account

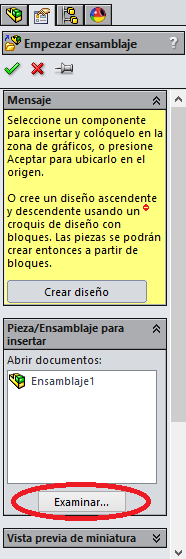

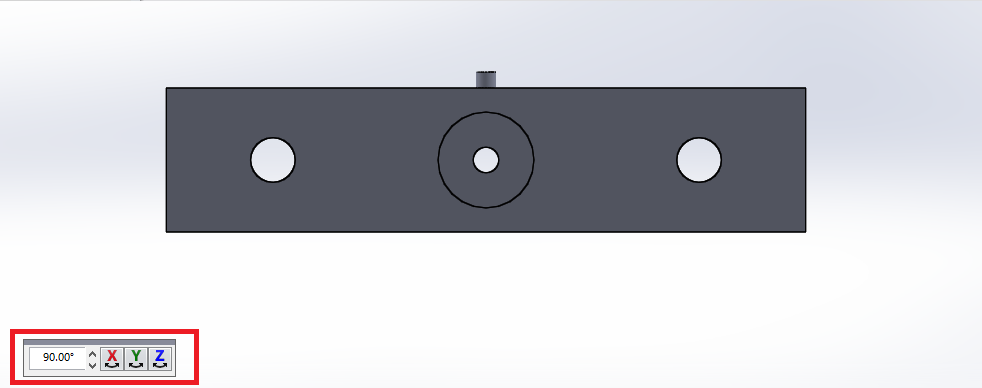

proceed to an open a new file and choose assembly, a blank solid works window will be displayed and you can export all the pieces for assembly, when you export the

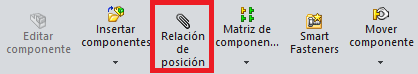

piece you can turn in the axes x, y and z, to adjust in the correct position, with the tool Position ratio you can assembly the pieces with method that you have done,

you select the ranges to fit well, if you choose the correct limits the pieces they will join and repeat this with the others pieces.

MACHINE DESIGN (week 2 of 2)

Automate your machine. Document the group project and your individual contribution.

For the group contribution, you can see in this >>page<<, the individual contribution is in the first objective of assignment.

To know more about the realization of this assignment you can go to >>this<< page.

Learning outcomes:

- Work and communicate effectively in a team and independently

For the communication is very good, you learn to communicate your idea and to work in good shape, to get your idea is very important in a group work so as not to have discussions.

- Design, plan and build a system

The design plan makes in a day like brainstorming, all the students contributed with an idea of how make the machine, and we established its operation and what applications we could achieve.

- Analyze and solve technical problems

The problems we were solving them while completing the machine, These problems were generated at the time of

arming the machine by effects that we realized at that moment, the problems were solved by other processes to improve the operation of the machine.

- Recognize opportunities for improvements in the design

The information to of improvements in design you can see in the page of the >>project<<

or in the project final of >>Guillermo<<

Have I:

Explained your individual contribution to this project on your own website

All explanation can be found at the beginning of the website.

Dwonload files

Files in Repo