Week 4: Electronics Production

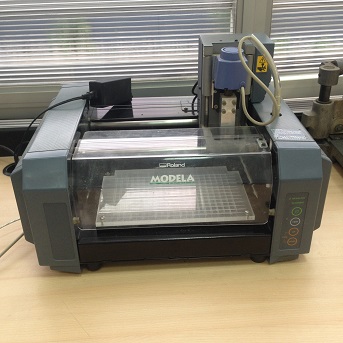

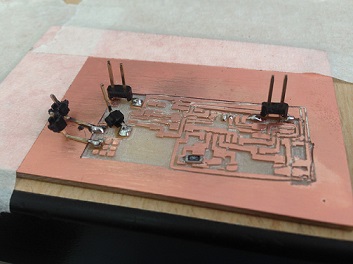

*Make an in-circuit programmer by milling the PCB (program it, so that you can use it to program your board in Electronics Design week, and in other weeks).

*Optionally, trying other processes.

Learning outcomes:

*Describe the process of milling, stuffing, de-bugging and programming.

*Demonstrate correct workflows and identify areas for improvement if required.

Have you:

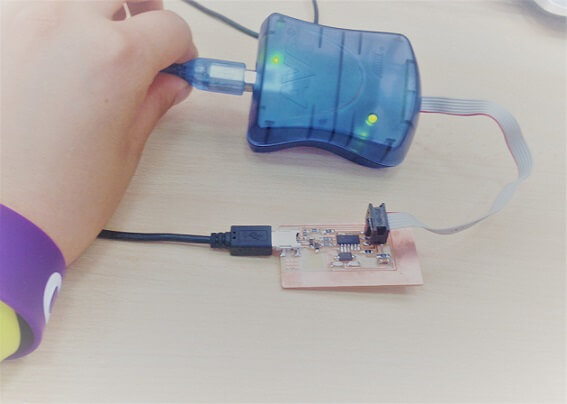

*Shown how you made and programmed the board.

*Explained any problems and how you fixed them.

*Included a ‘hero shot’ of your board.

My global evaluator ask me: In the class page you can download the file to cut the board with a 1/32 mill. Instead you have used a guillotine to do it. Why have you do that?

It is a good question, I didn't try to cut with the 1/32 mill in this assignment, but you can do it, I tried but in this assignmentweek14 and week 16

Honestly, I had not done it because I was told that the sacrificial table could be damaged, and when it was the first time I made a card, the Fab Lab gave me the indication to do it with the guillotine. But after trying in the weeks that I already told you, it was effective, the detail is to do it with a lot of pressure, taking the exact measurements of where you locate the point of origin, this way you can save a lot of material (boards) Cards giving different edges, in this case I only made squares, but it occurred to me that you'd make cards with asymmetrical shapes, clouds, hearts, or others.

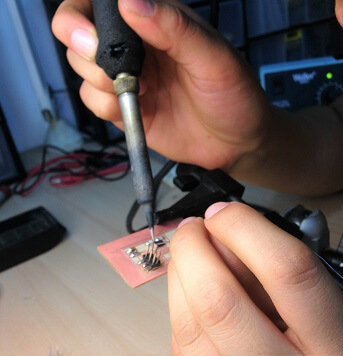

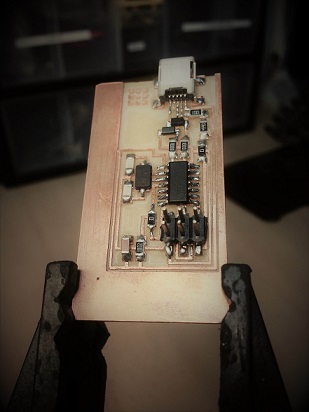

This was my favorite part, to start soldering. I had not done it before and I heard many comments about how complicated it was and the care it required.