Third Week Assignment:

Contents:

Requirement:

- Do in group a fit tester

- Cut something on vinyl cutter machine.

- Design, make, and document a parametric press-fit construction kit on the laser cut machine

For this assignments I have to use the laser cut and vinyl cutter machine.

Group assignment

Team work

In FabLab Tecsup we have a great work group:

- Armando Sarco Montiel

- Diego Santa Cruz Meoño

- David Maita Franco

- Jhon Irwin Lozano Meza

- Juan Diego Ernesto Cerrón salcedo

- Ingrid Midori Nuñez Yamaguchi

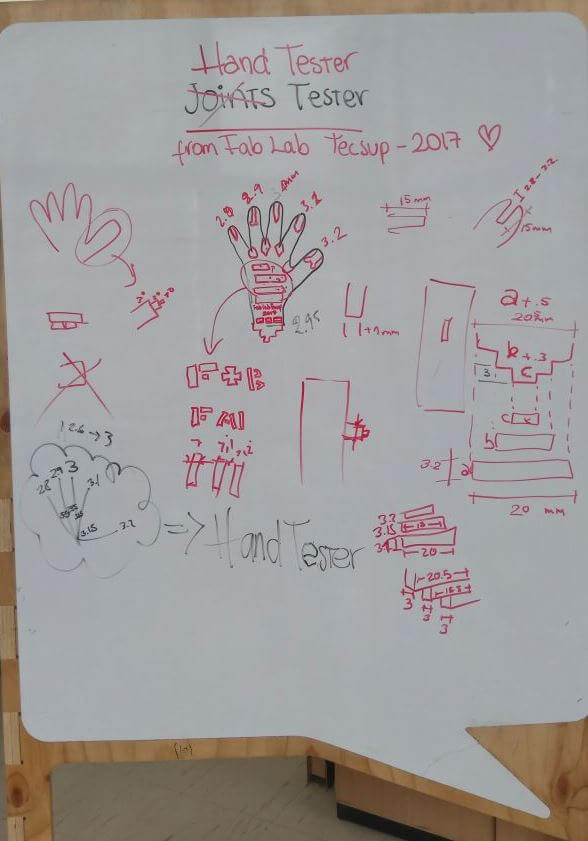

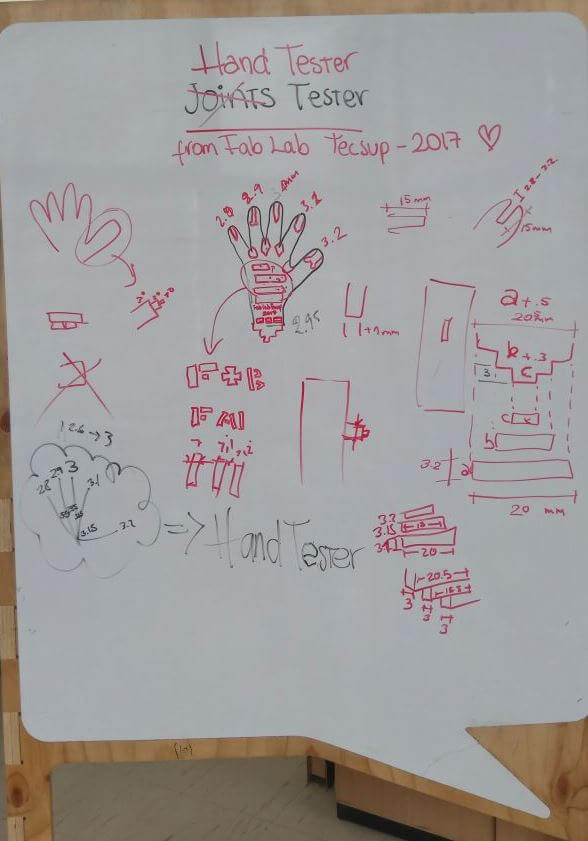

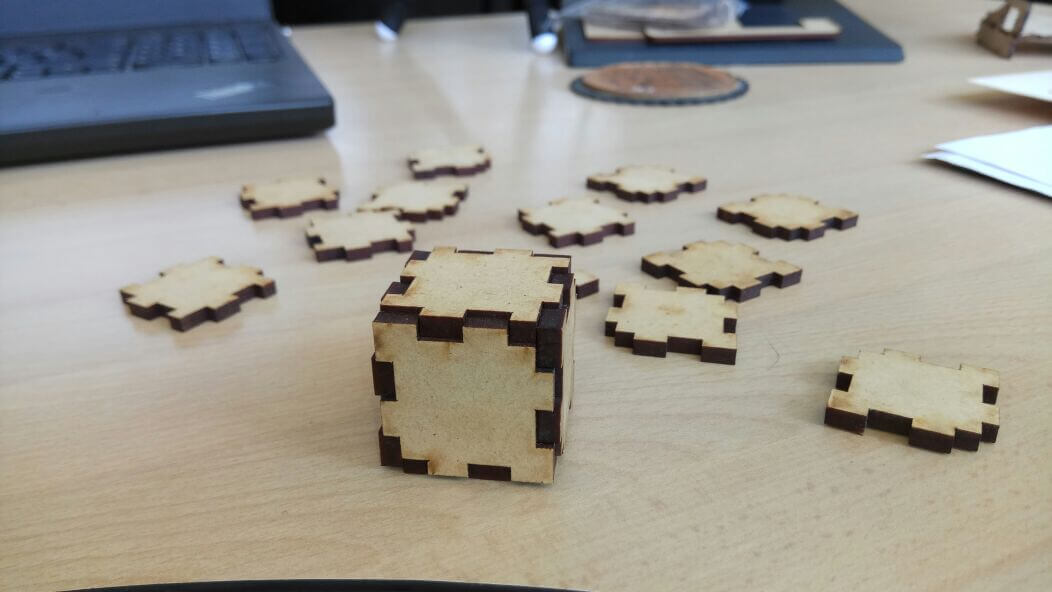

For this group assignment, we decide to do literally a hand tester to prove different sizes of press fits, we take as material of reference 3mm MDF.

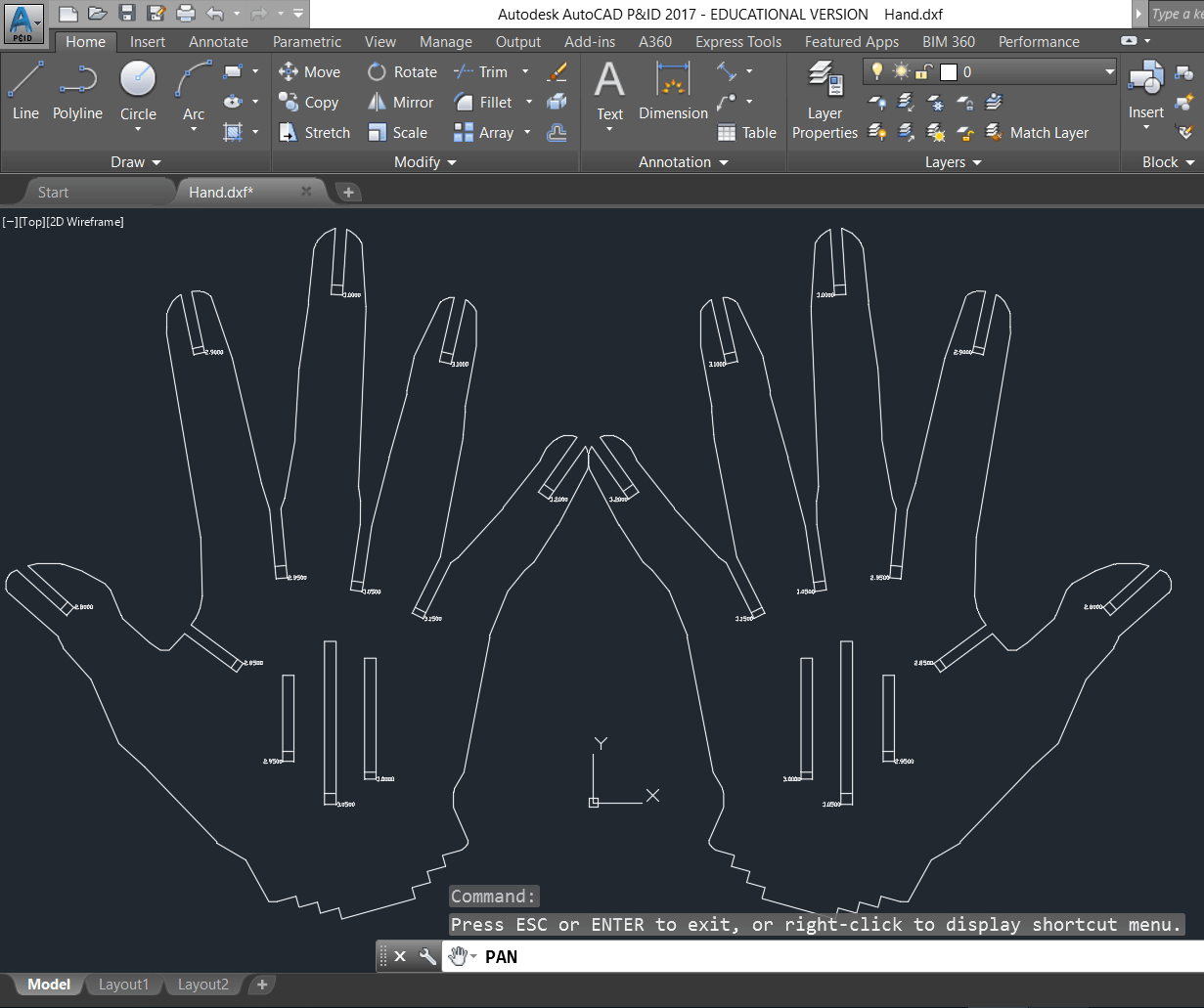

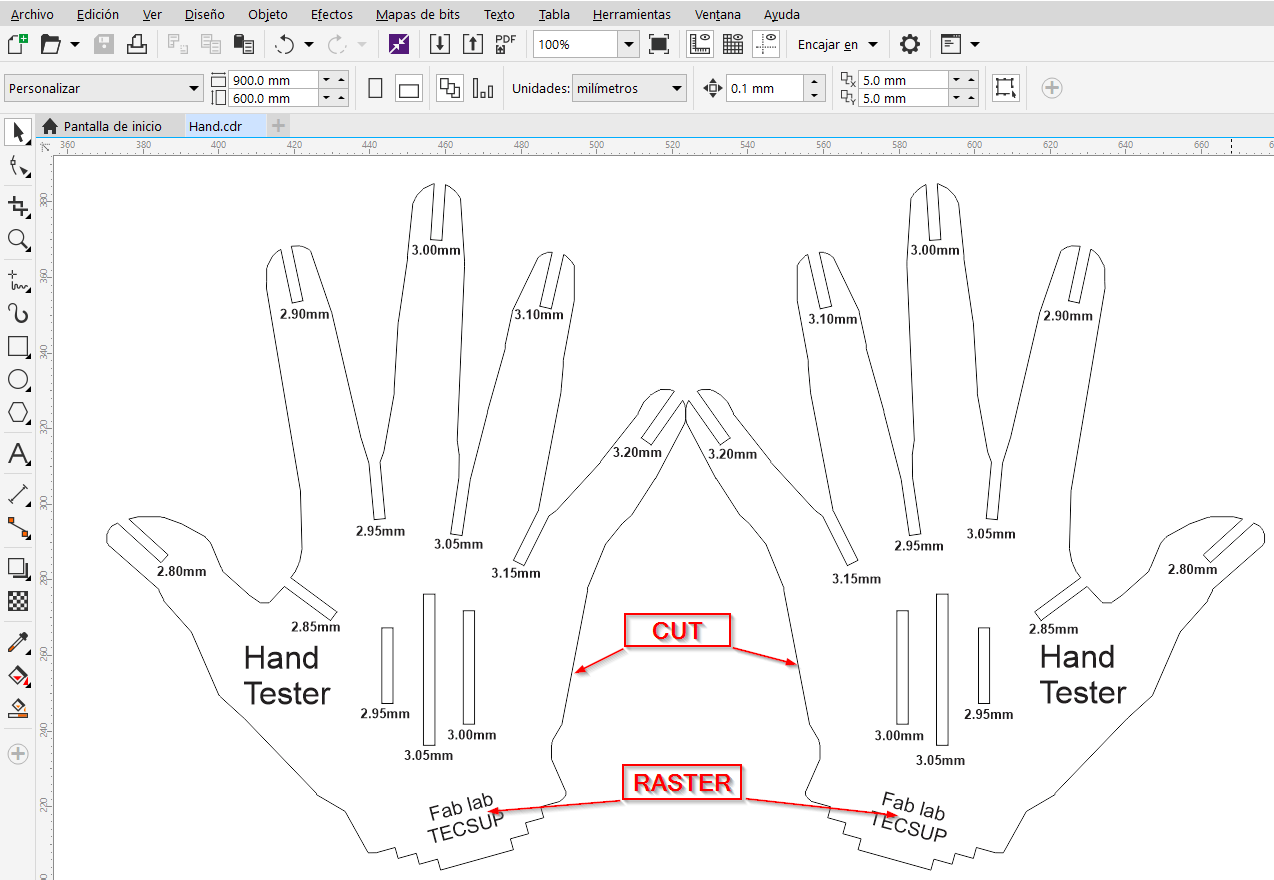

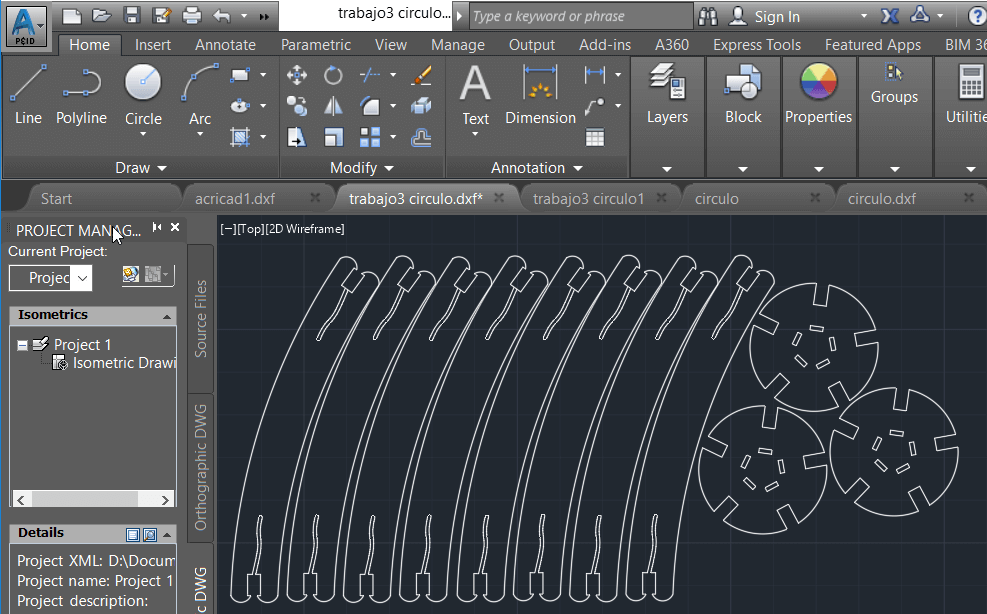

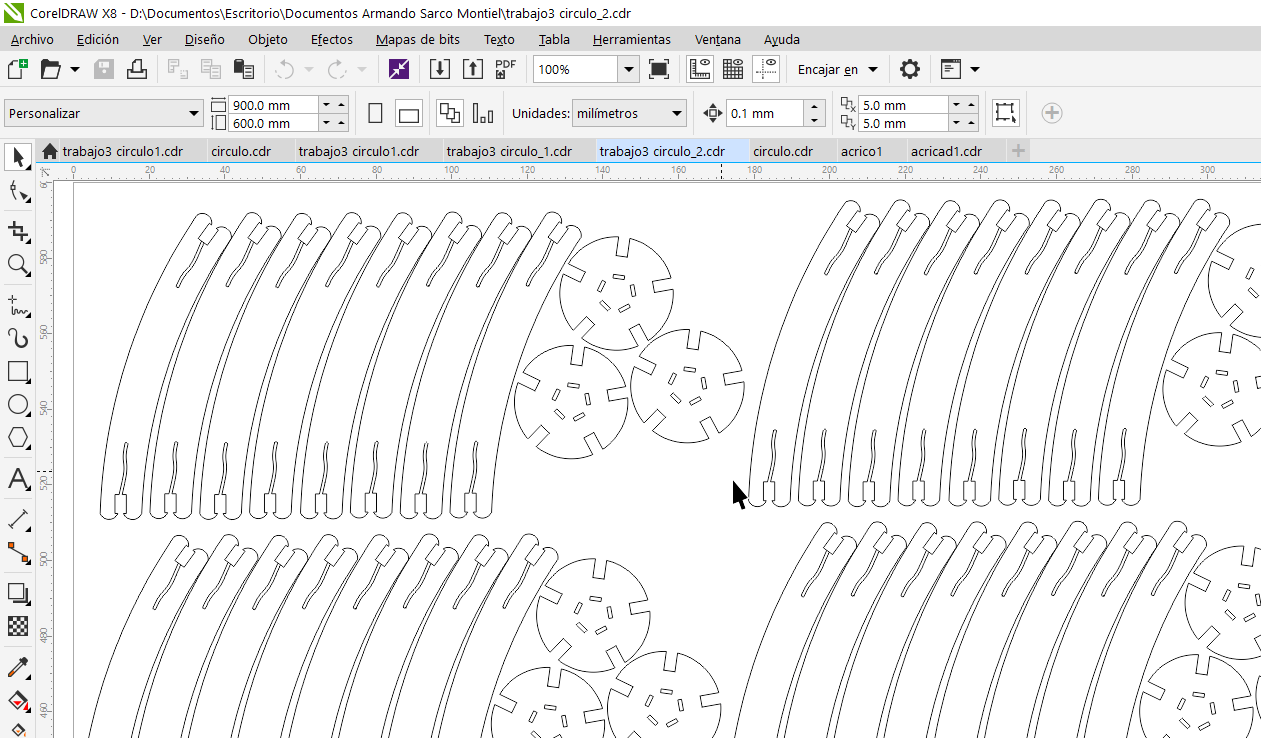

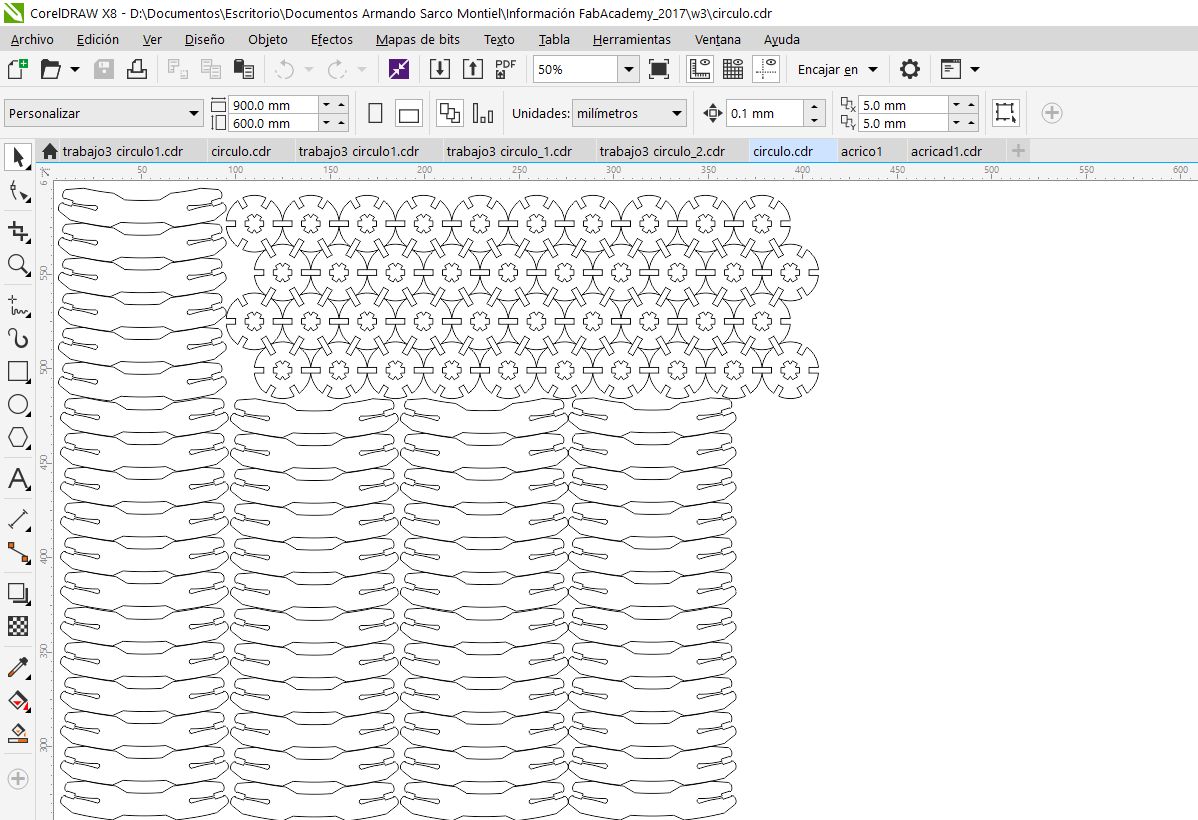

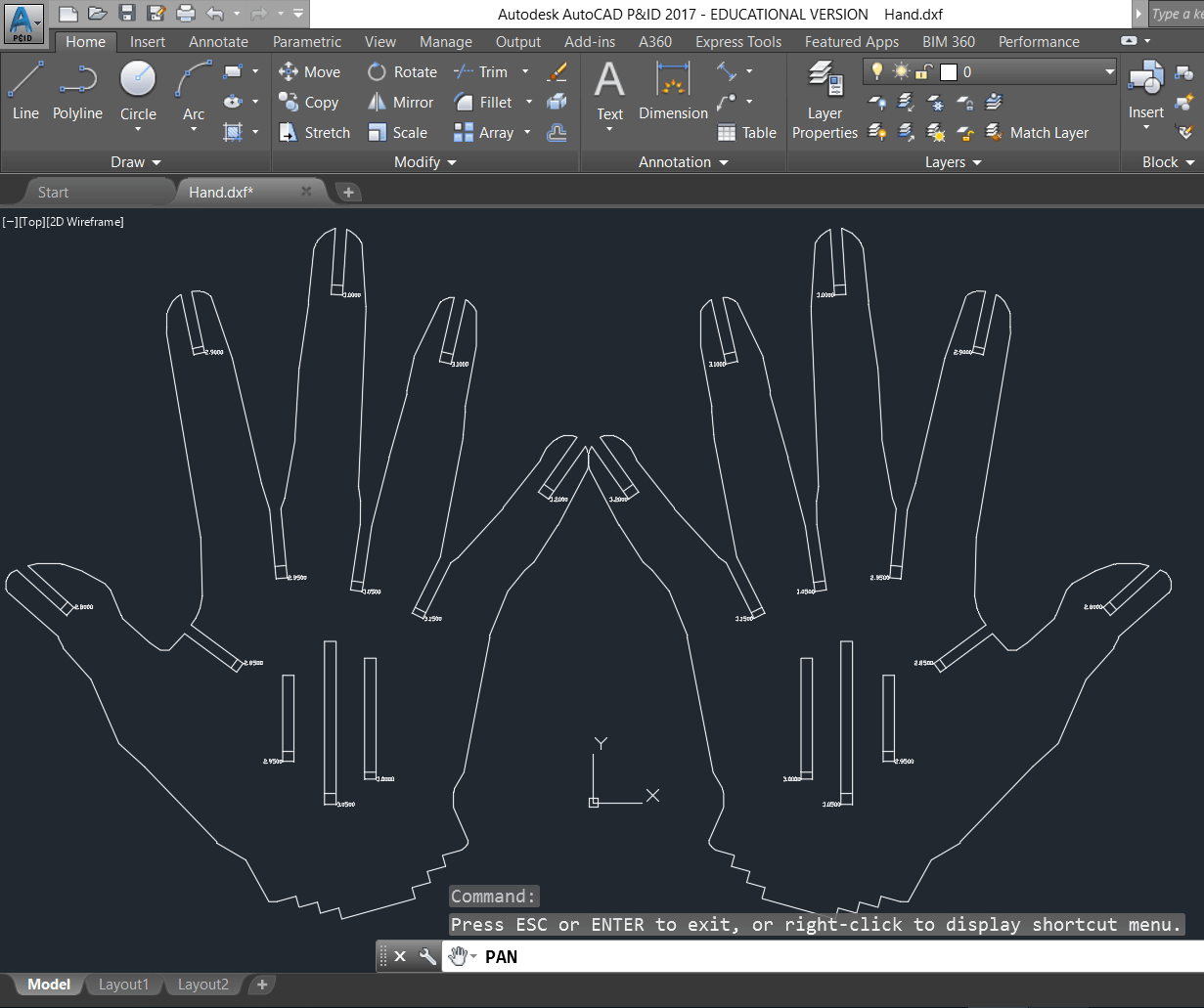

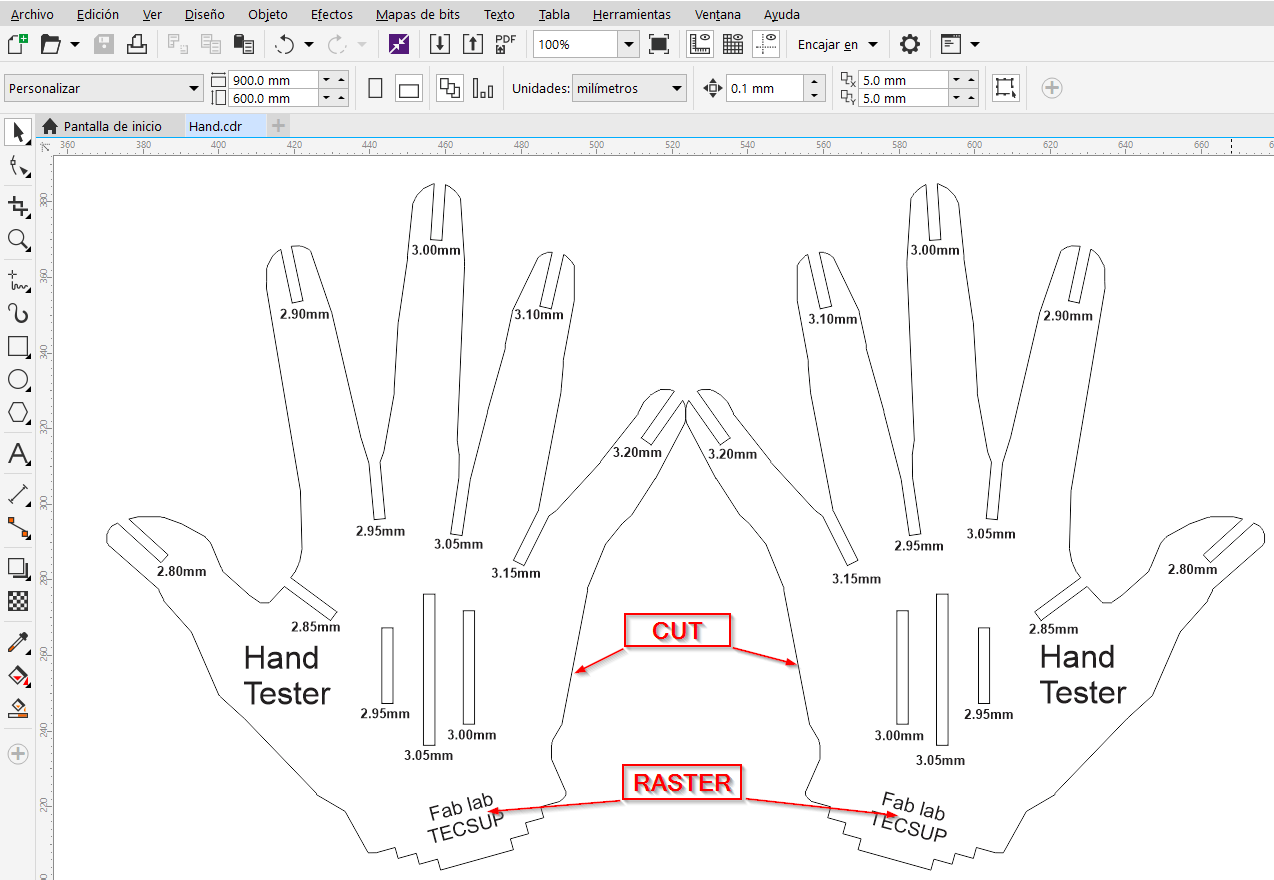

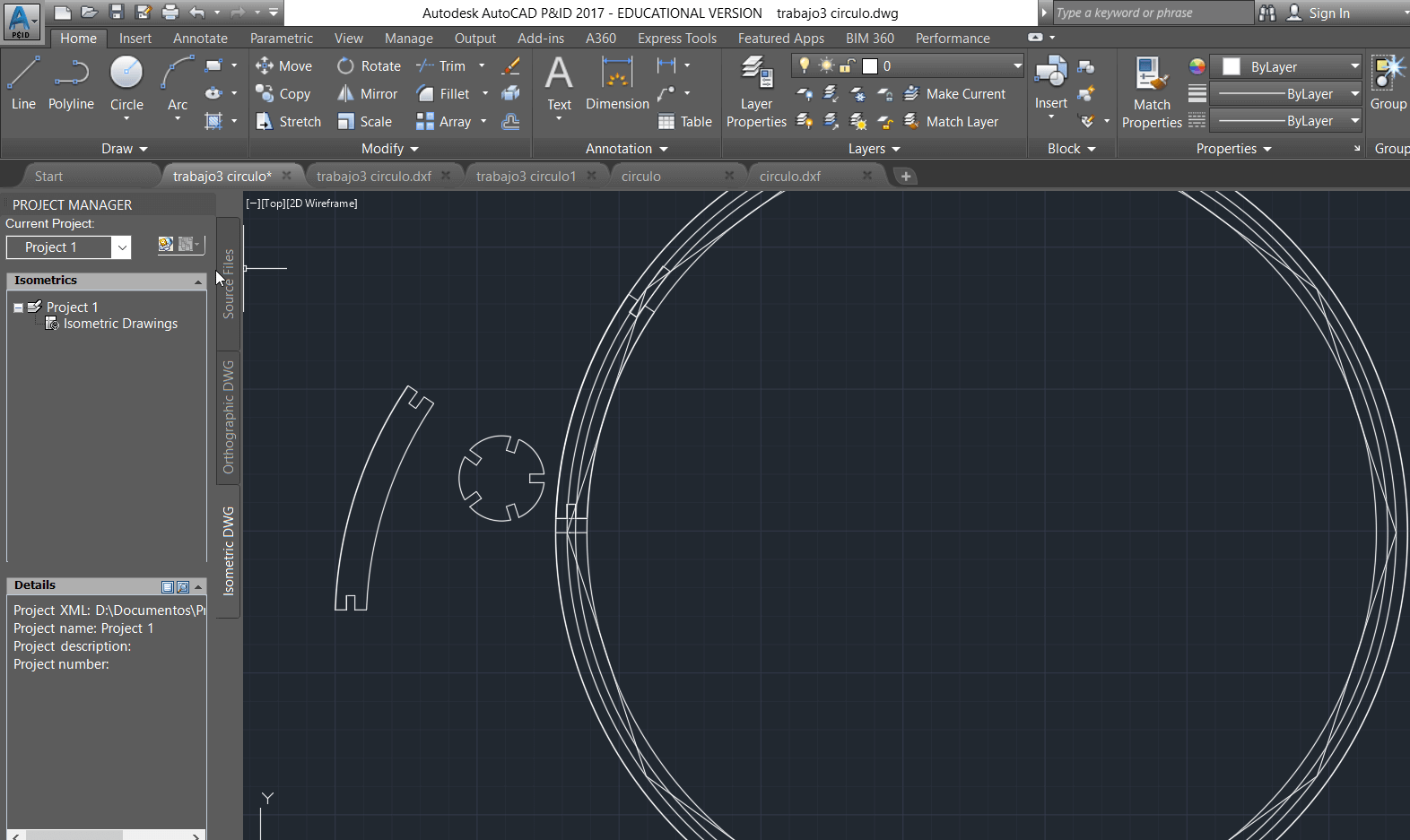

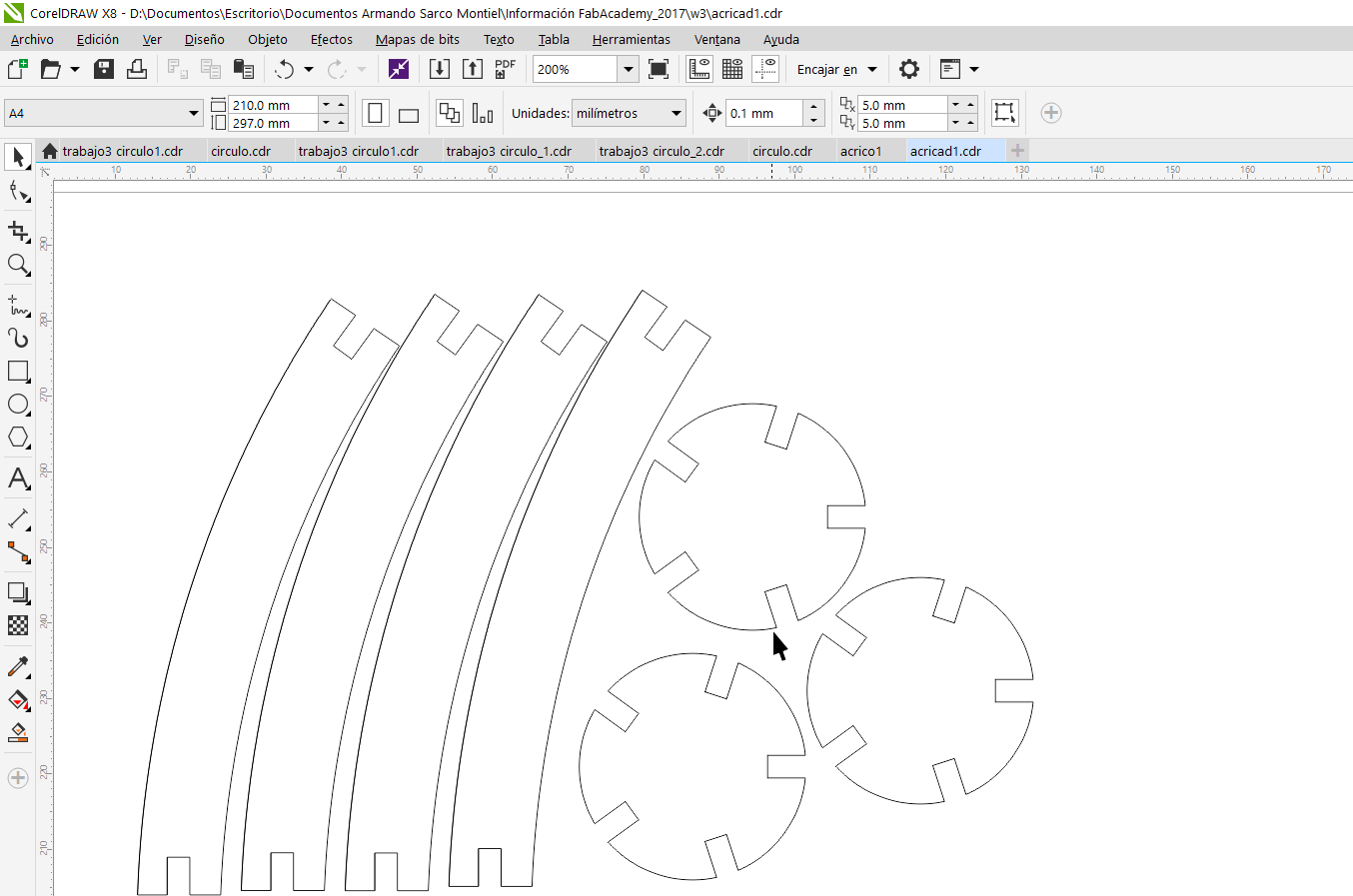

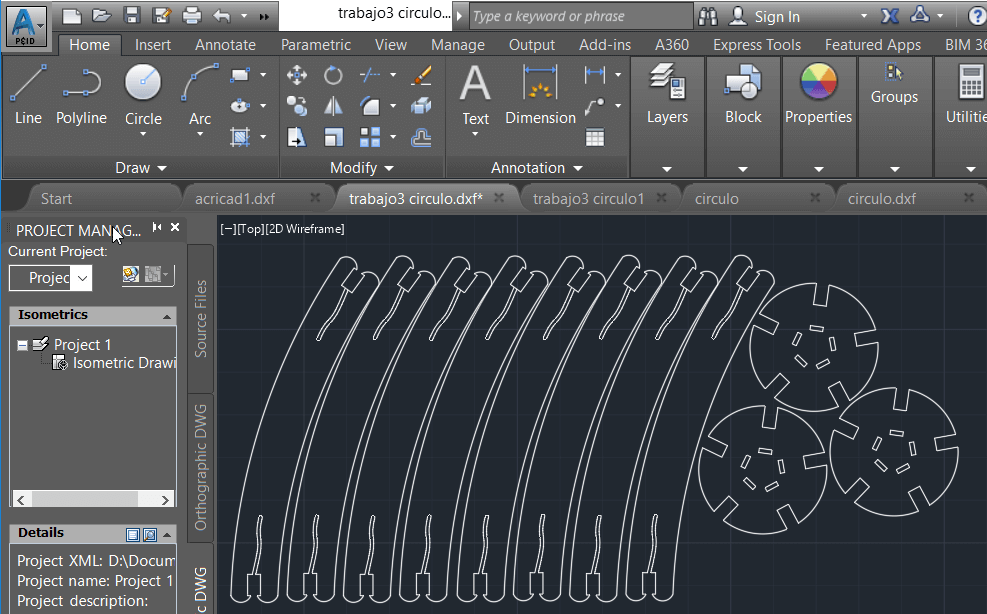

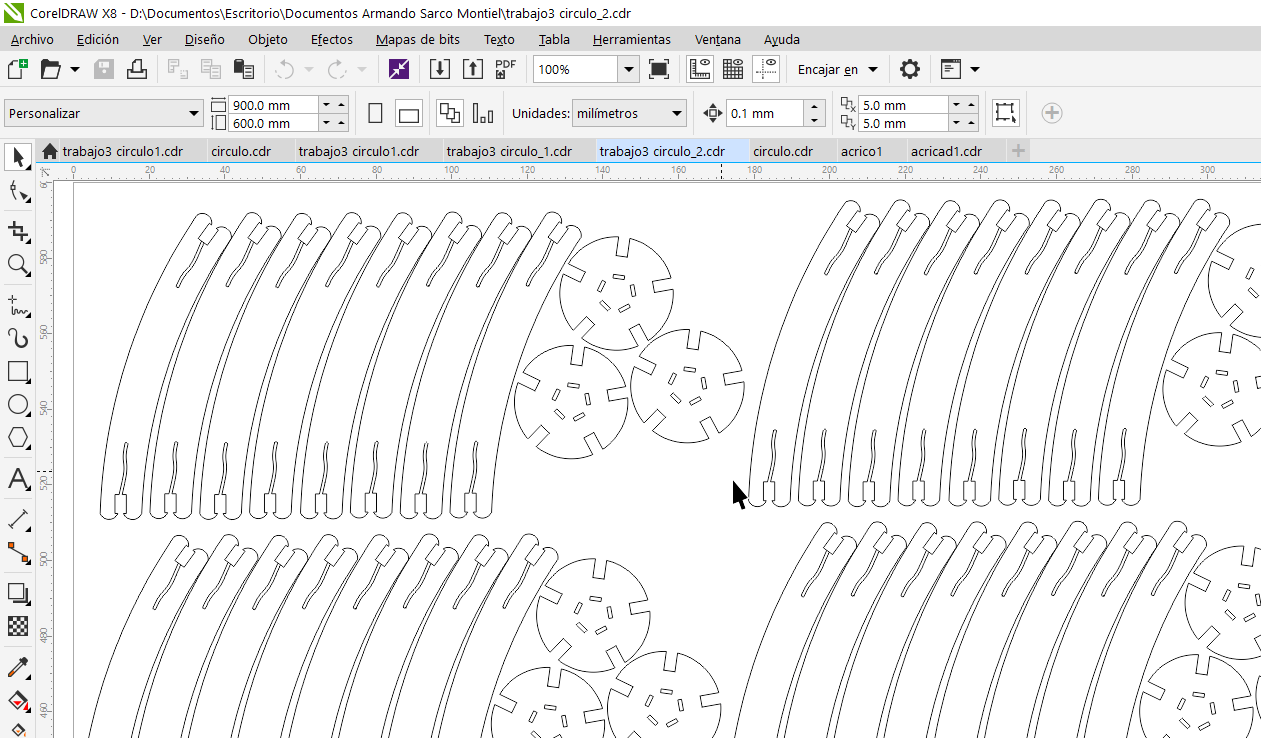

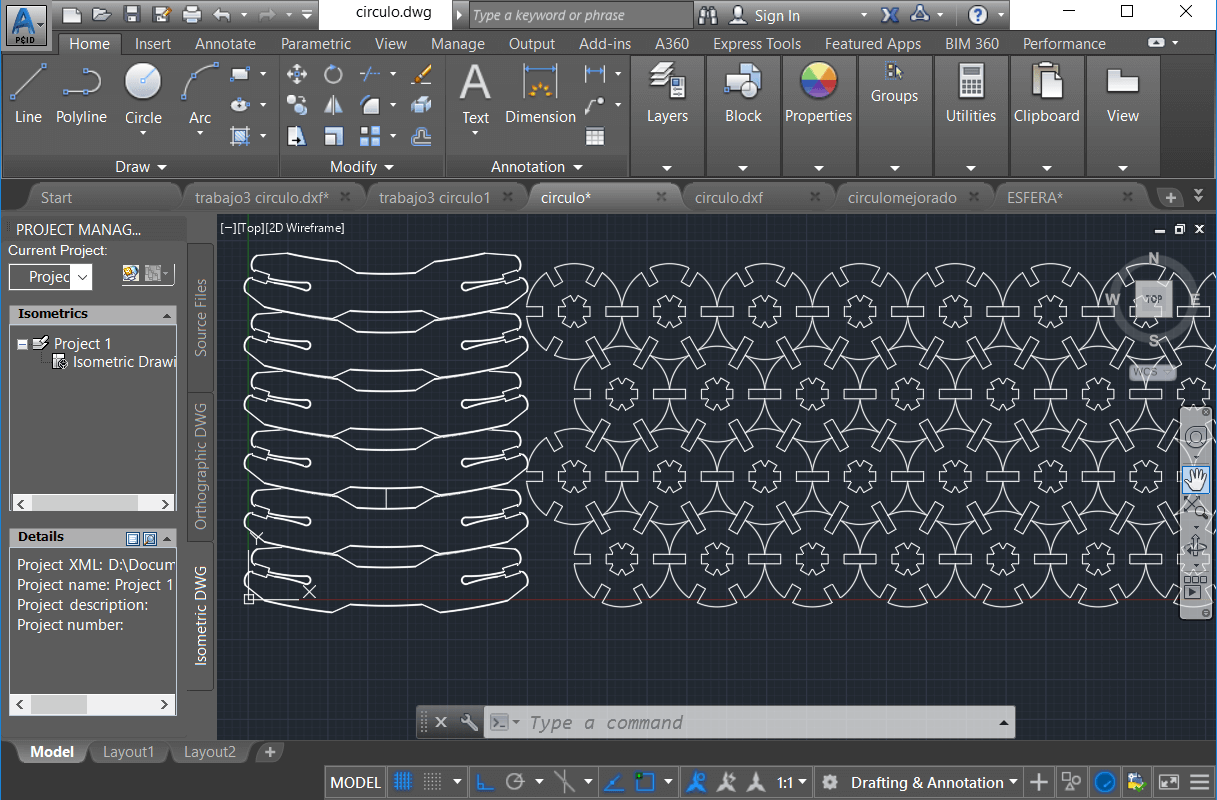

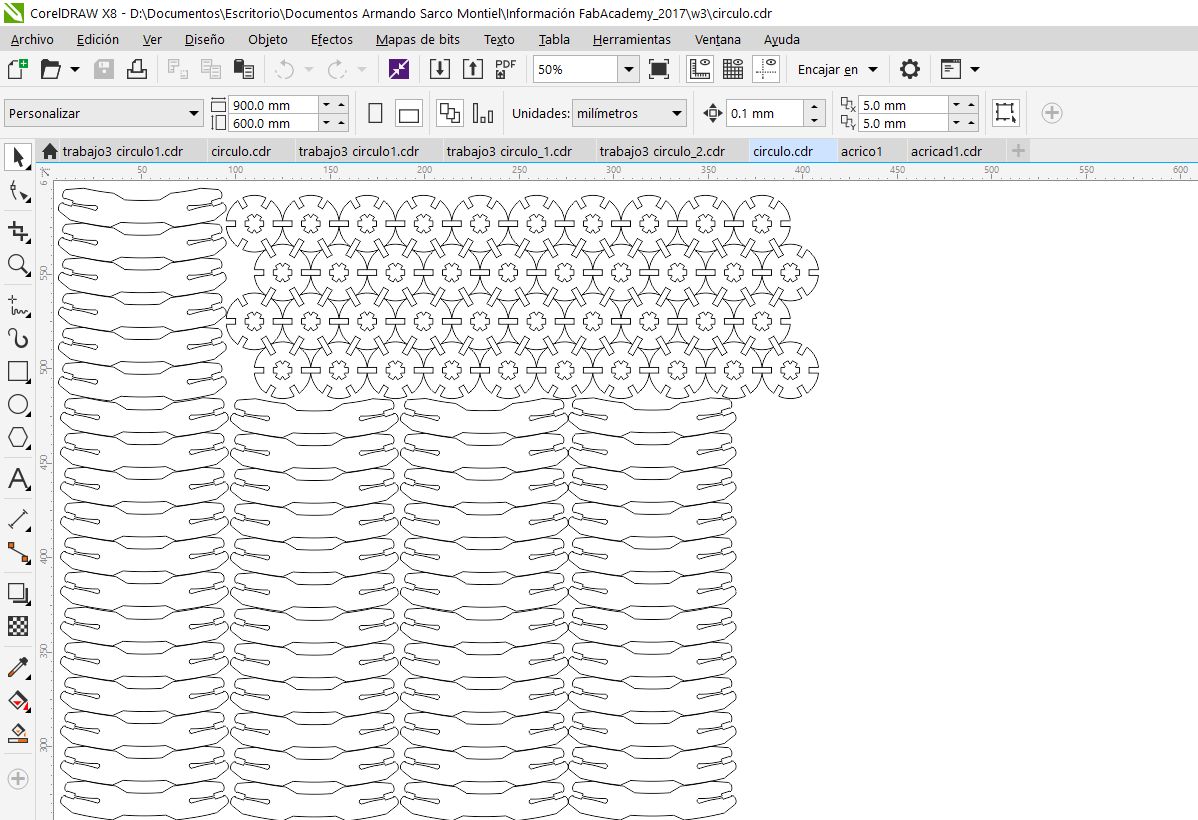

We design the hand tester in AutoCAD and export the archive in DXF format, because the laser cut machine works with Corel Draw, in Corel we have to define which parts are for cutting and which parts are to be rastered

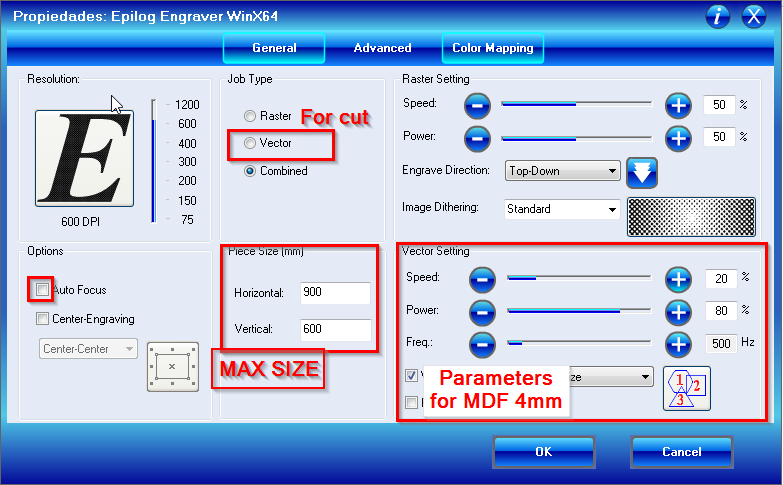

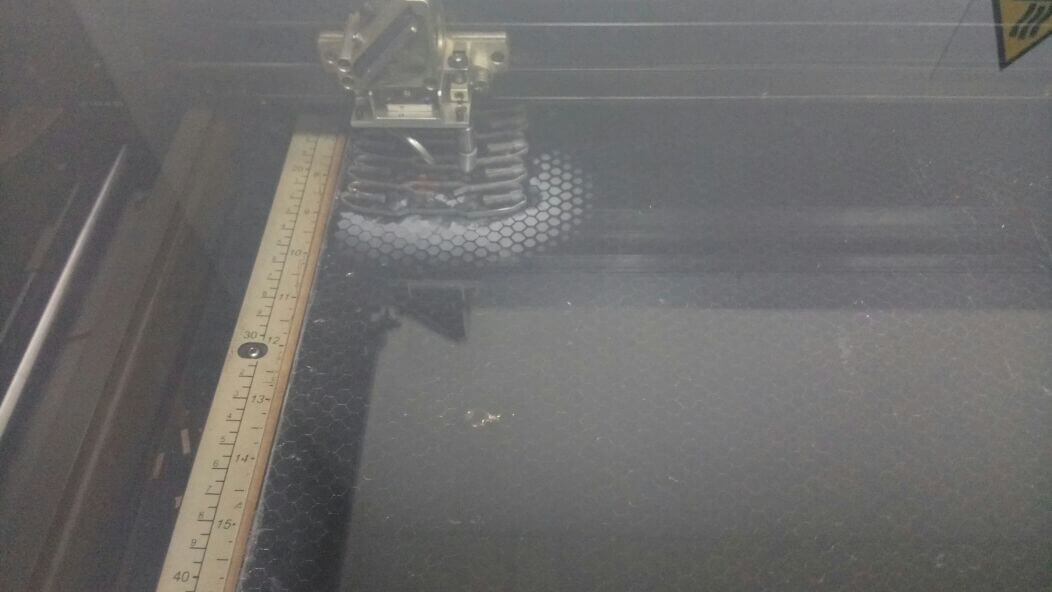

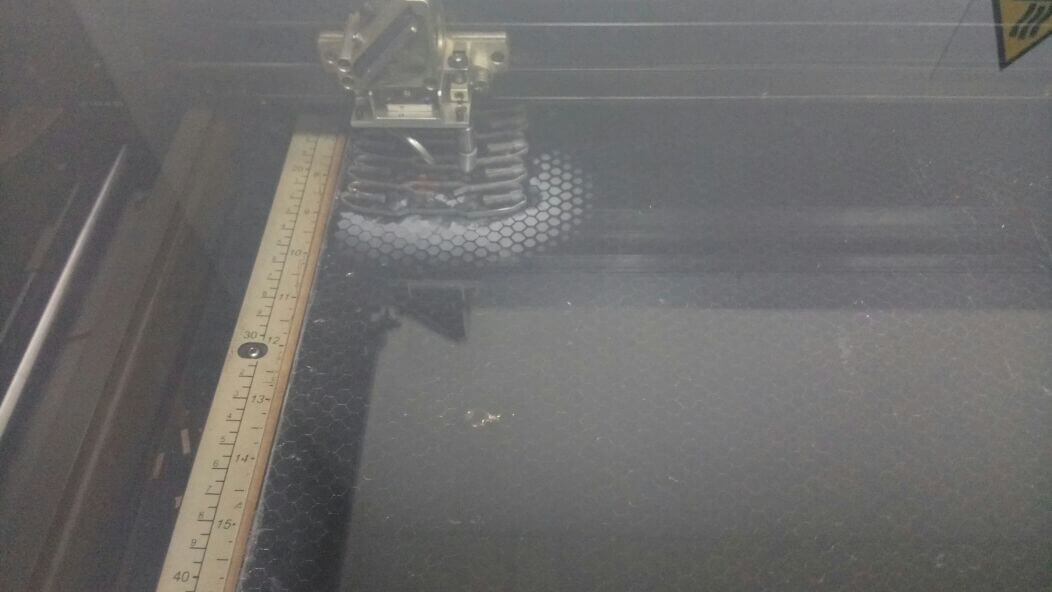

In Tecsup Fab Lab we have the Epilog legend 63EXT laser cutter, where we cut the hand tester that we design in group.

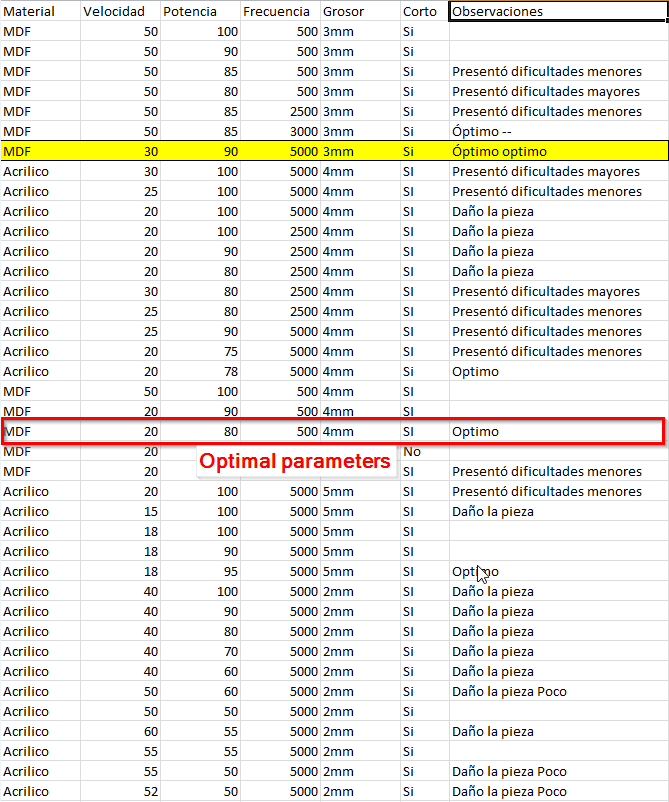

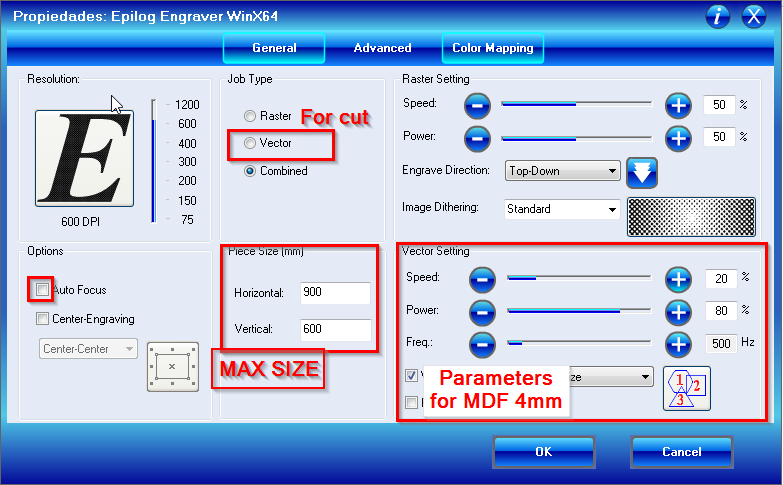

To do a good cut in the 4mm MDF material we have to choose the correct parameter in our "Epilog legend 36EXT laser cutter machine"

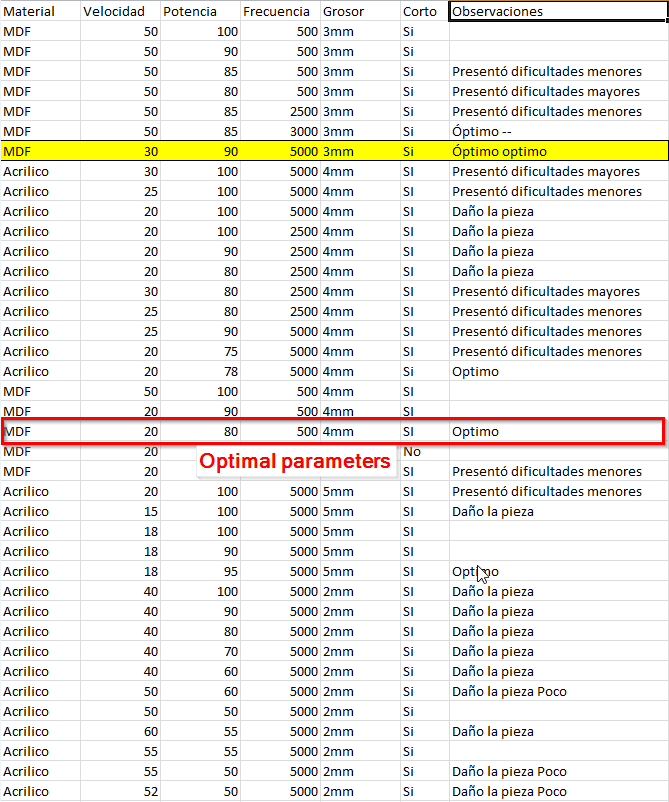

Fablab Tecsup has a long experience doing laser cut services, and they have a list with the optimal parameters to do a excellent cut.

Vinyl cut

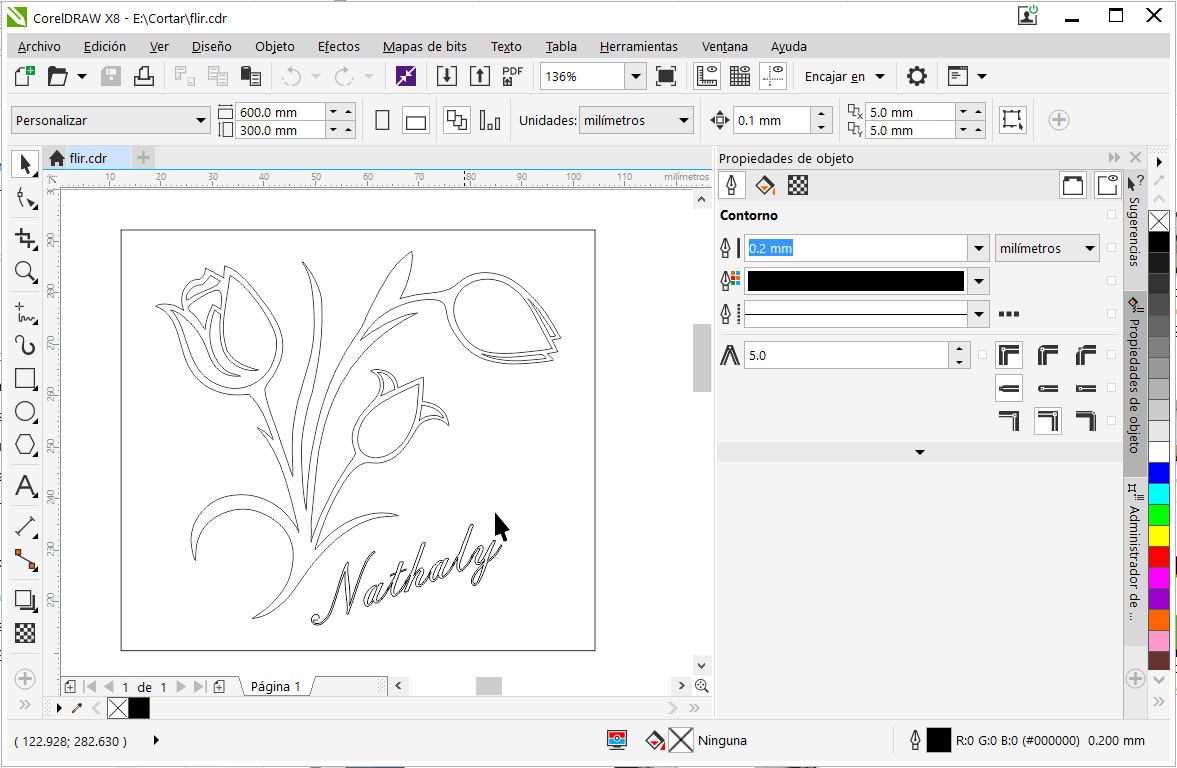

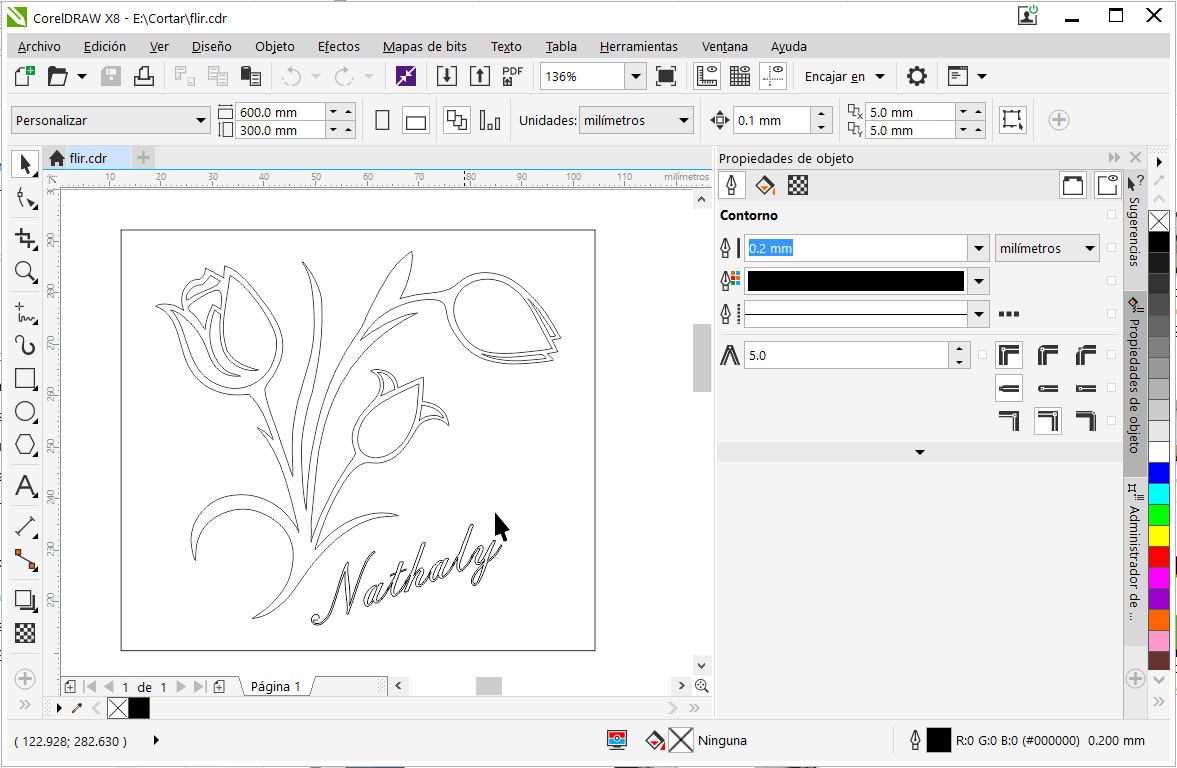

For this work I decided to make the vinyl cut of a tulipan, for which I chose an image and then vectorize in Corel Draw.

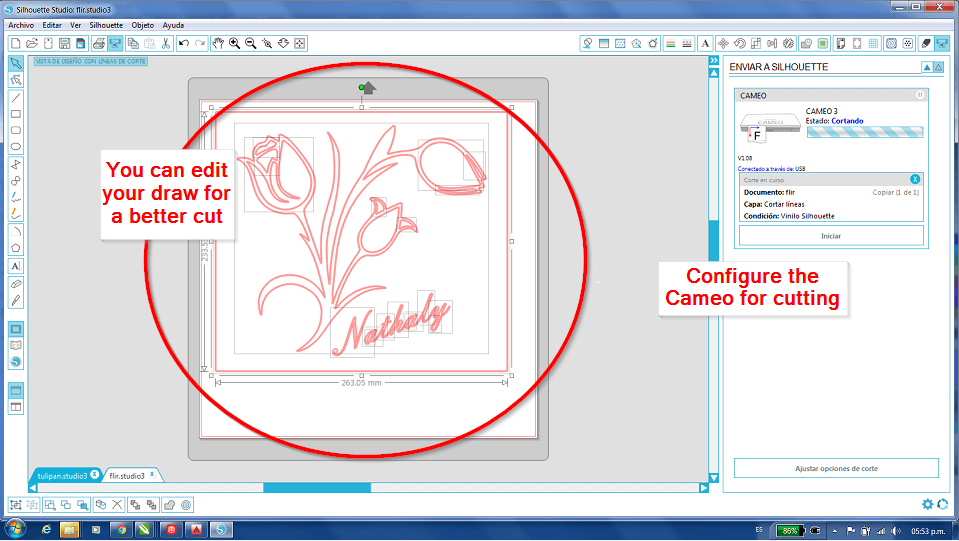

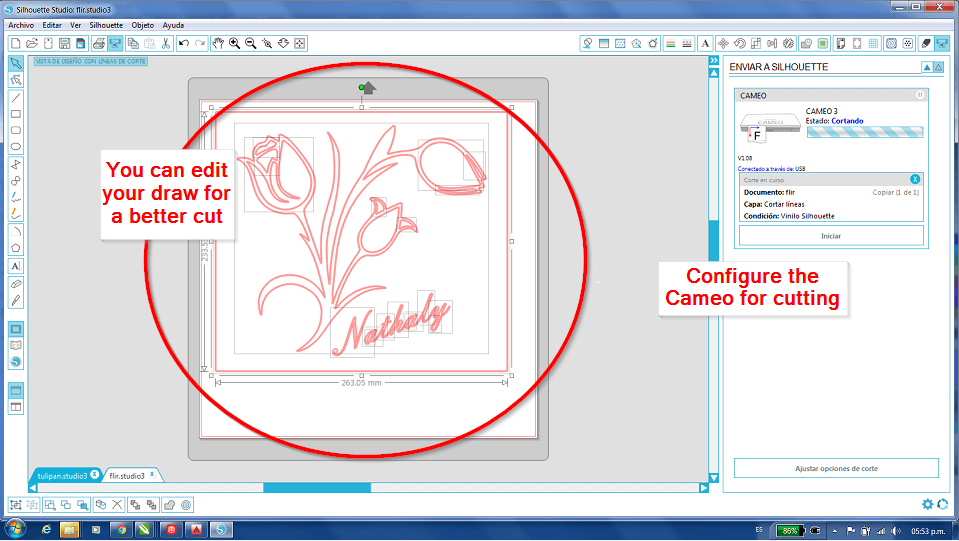

In our Fablab we have the Silhouette Cameo 3 machine

After vectoring in Corel Draw, I export the file in DXF format, so that it can be opened with the application of the cameo, and then be cut.

The first step to do the cut, is set up the cut parameters

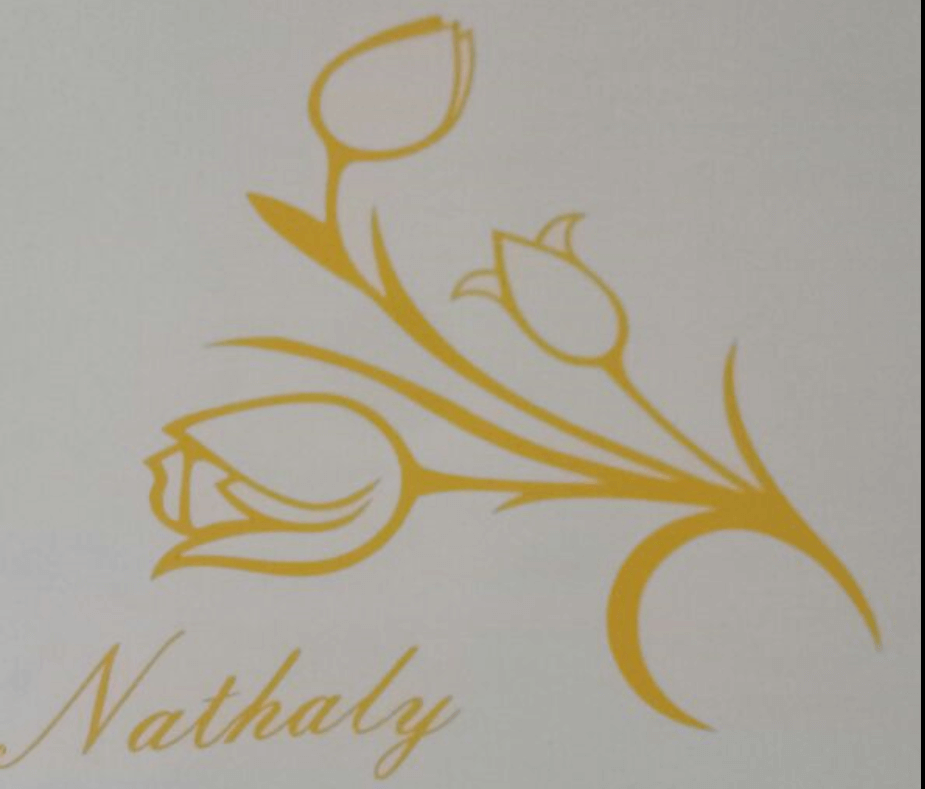

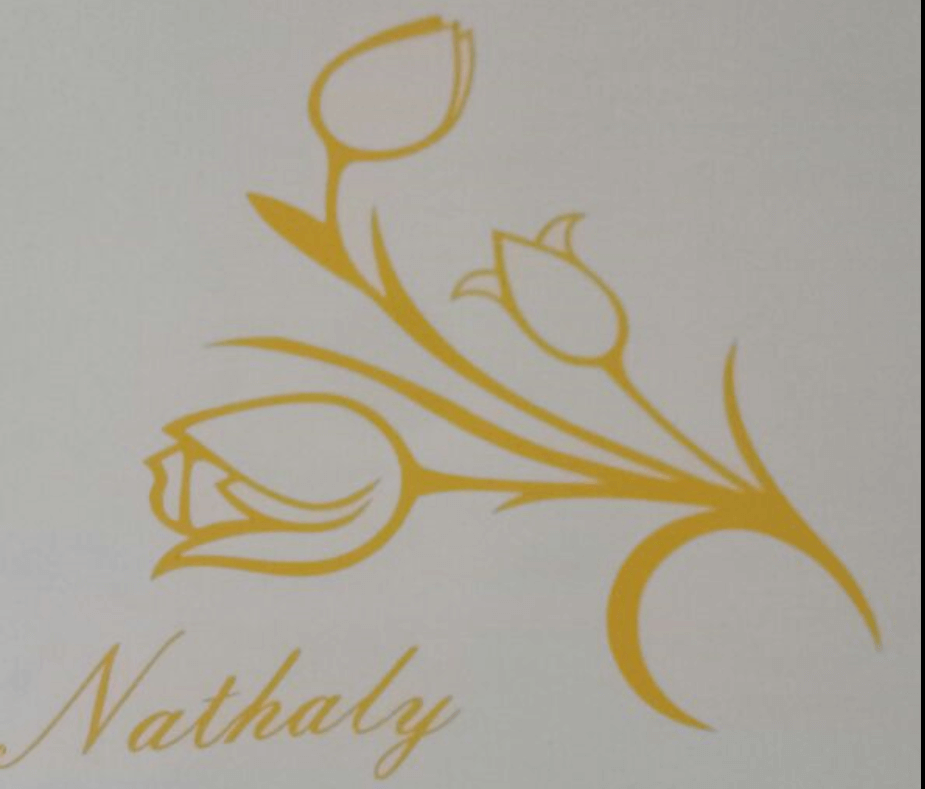

Finally I gave the vinyl cut to my wife.

Parametric press-fit construction

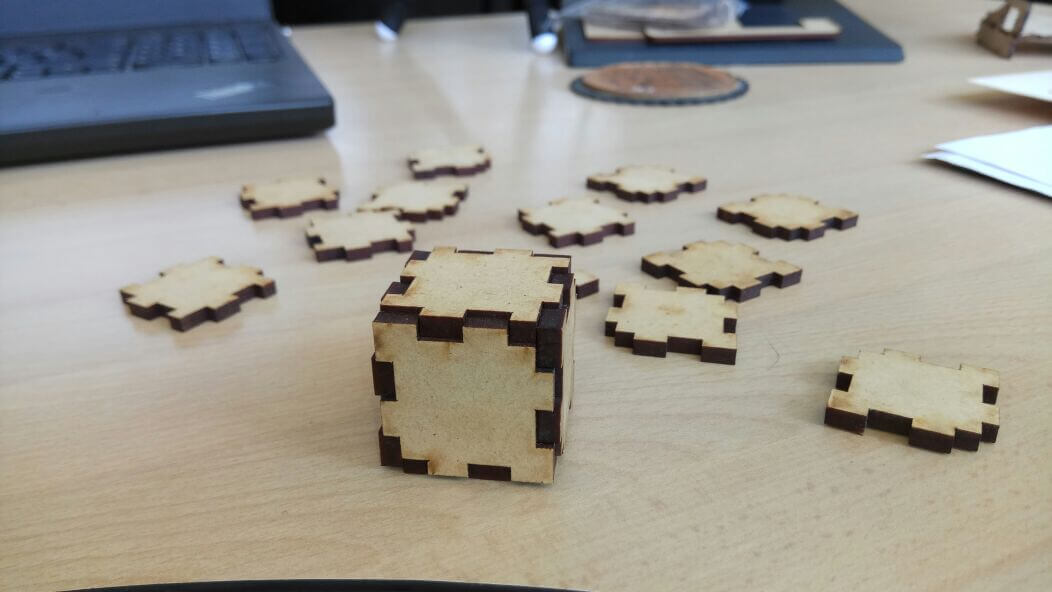

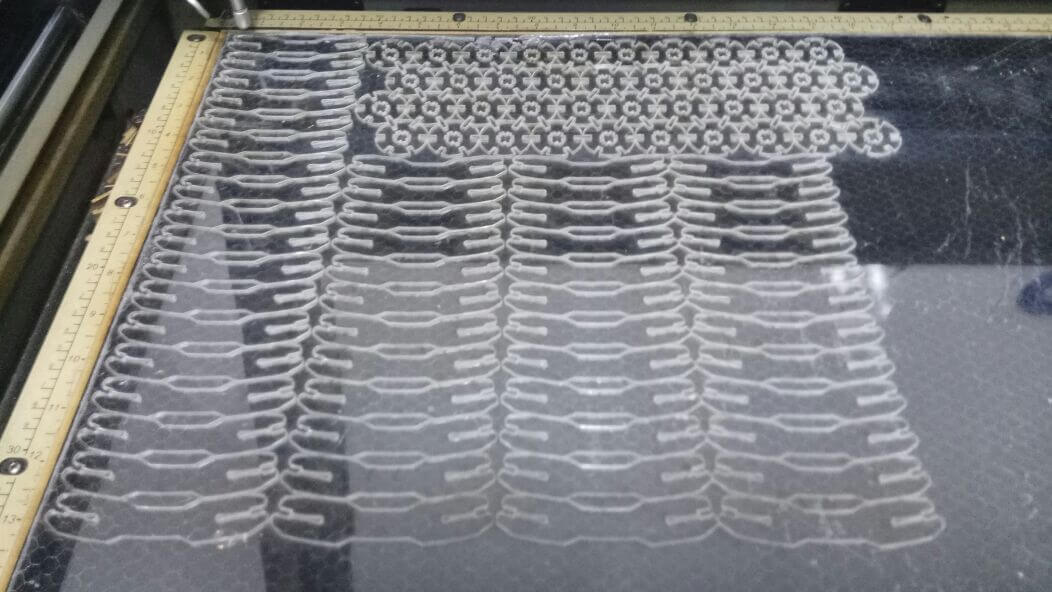

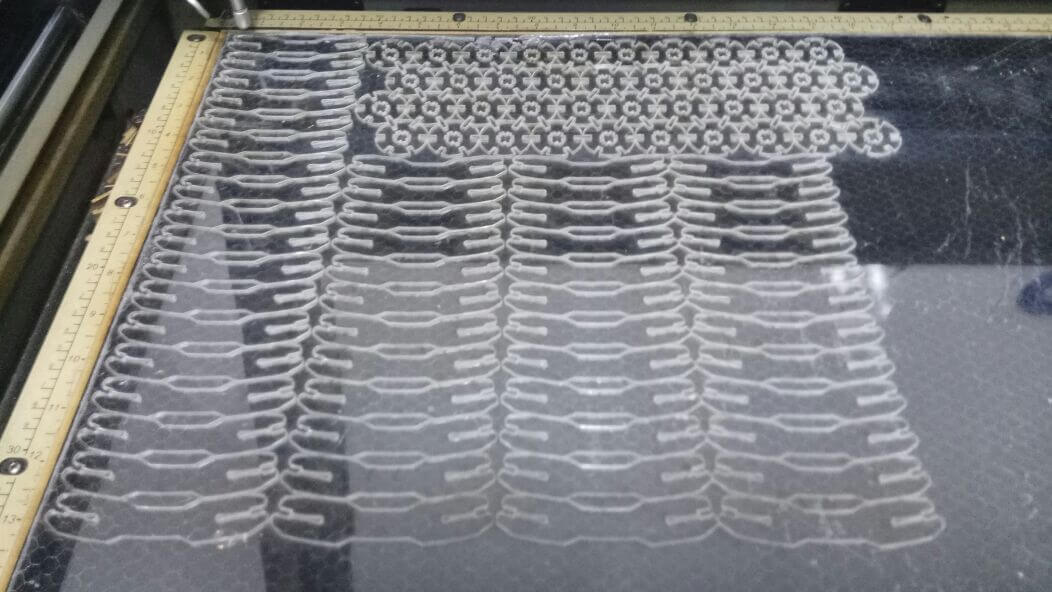

In this assignment I decided to design and implement two parametric press-fit kit, one in MDF of 3mm and other in acrylic of 3mm to do some comparations.

MDF material

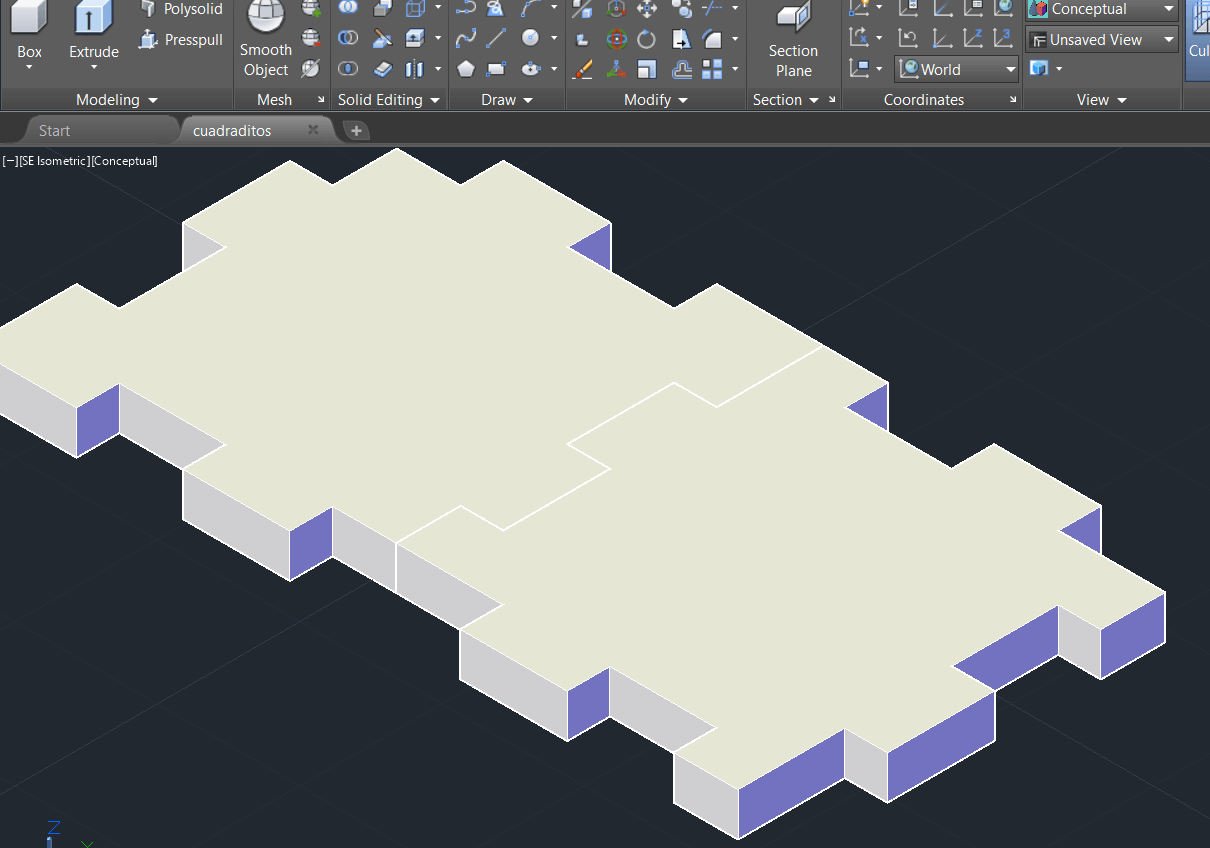

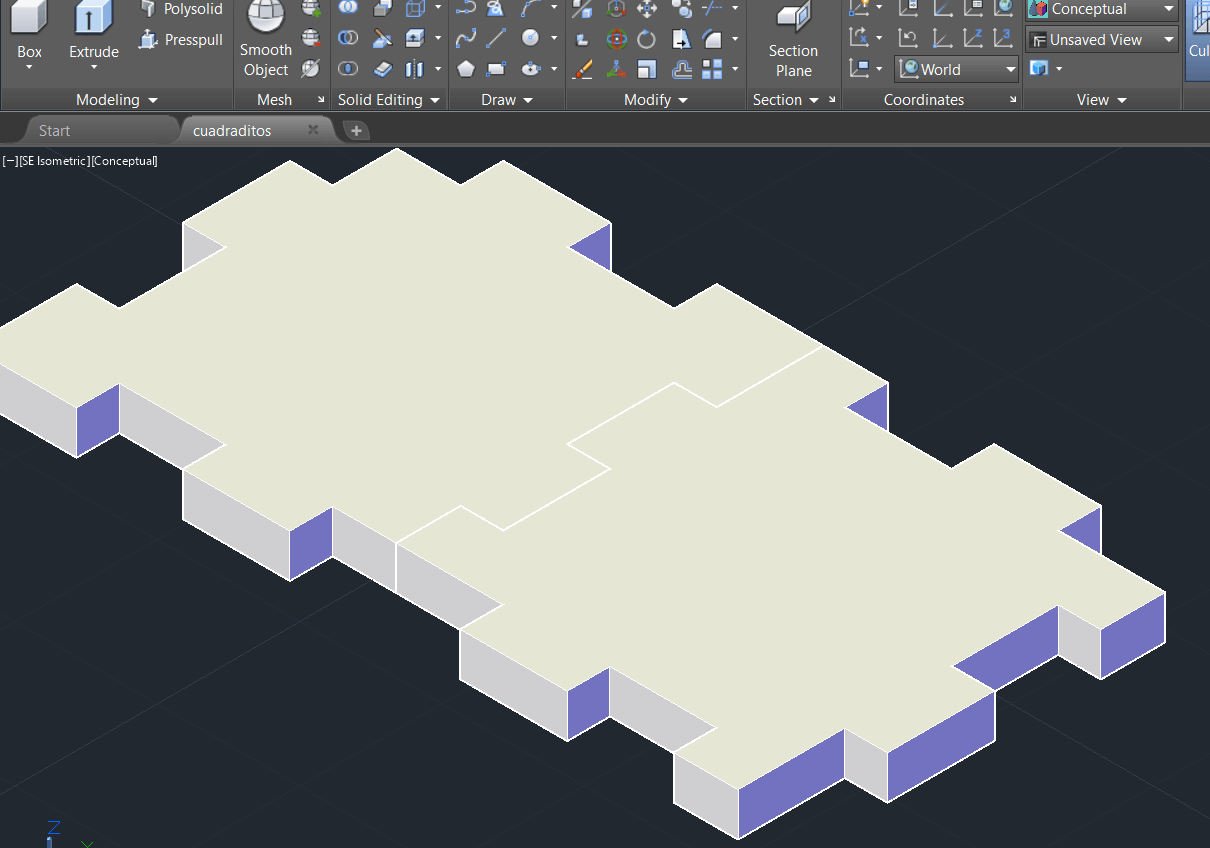

First I design my prototype in AutoCAD 3D for the MDF material, was easy take measurements because i used my hand tester, that I did in the last assignment. at last I use the laser cut to obtain my pieces.

Acrylic material

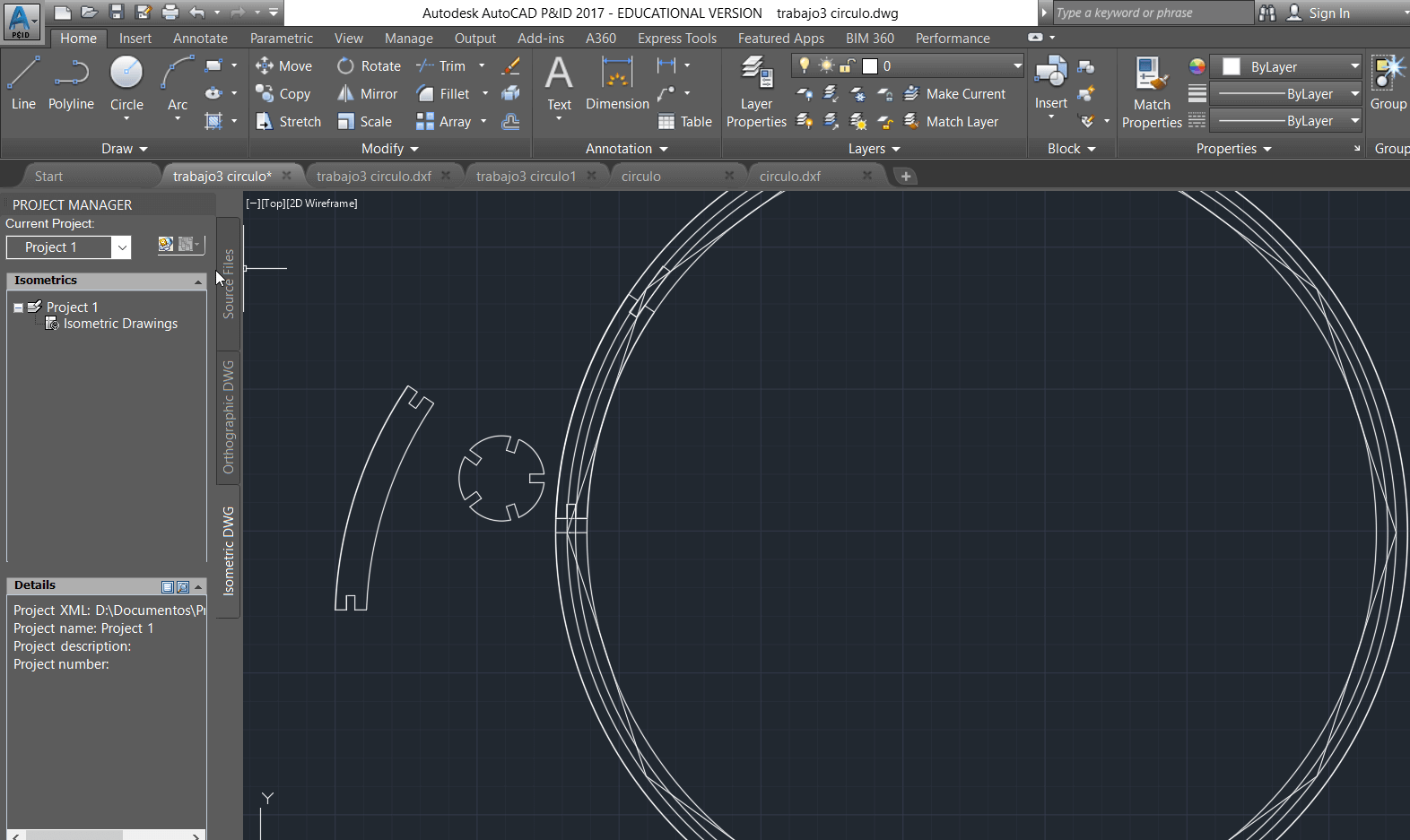

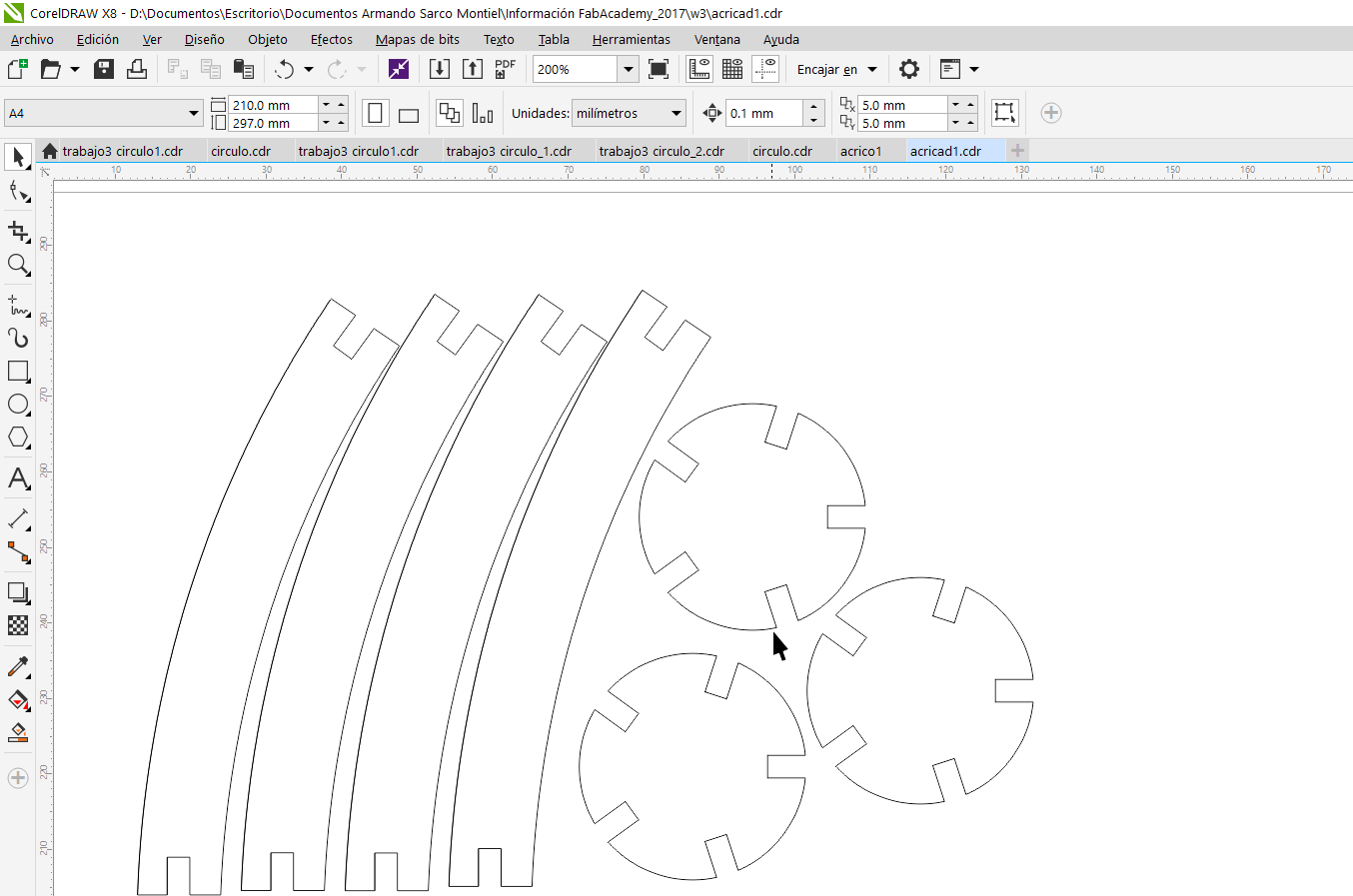

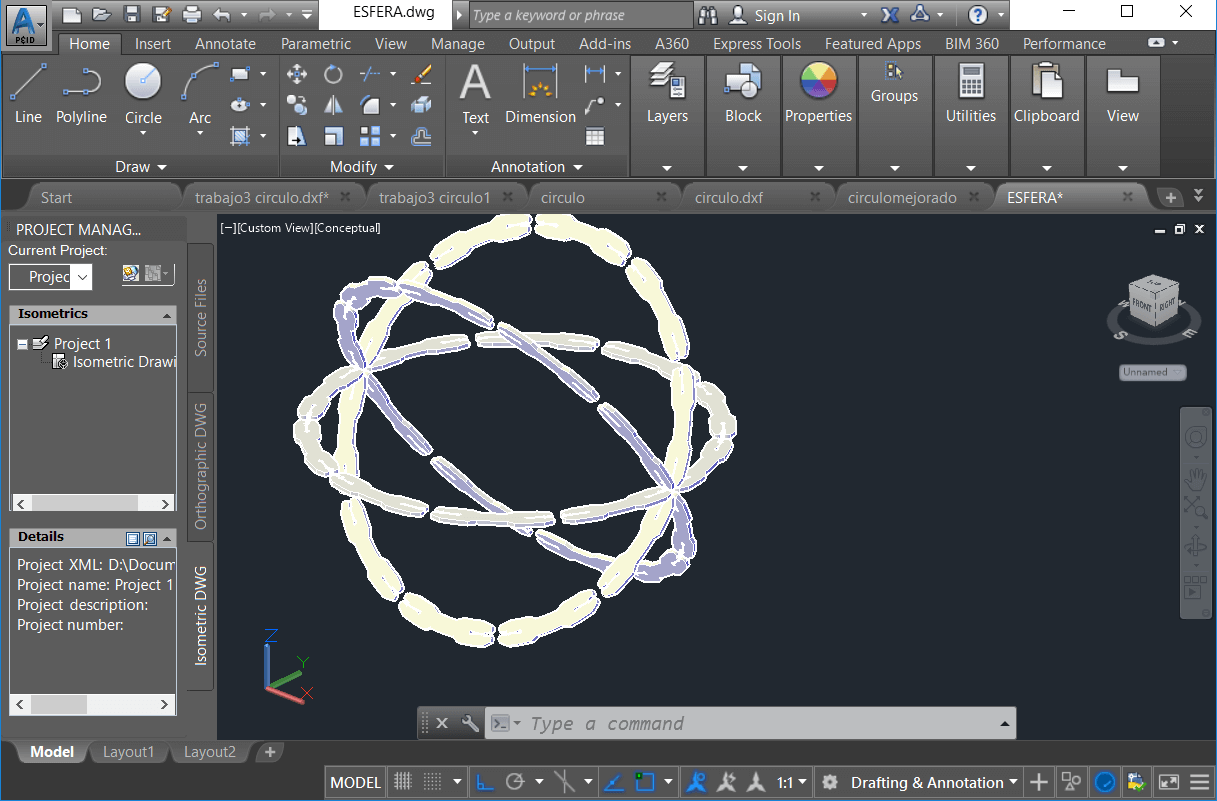

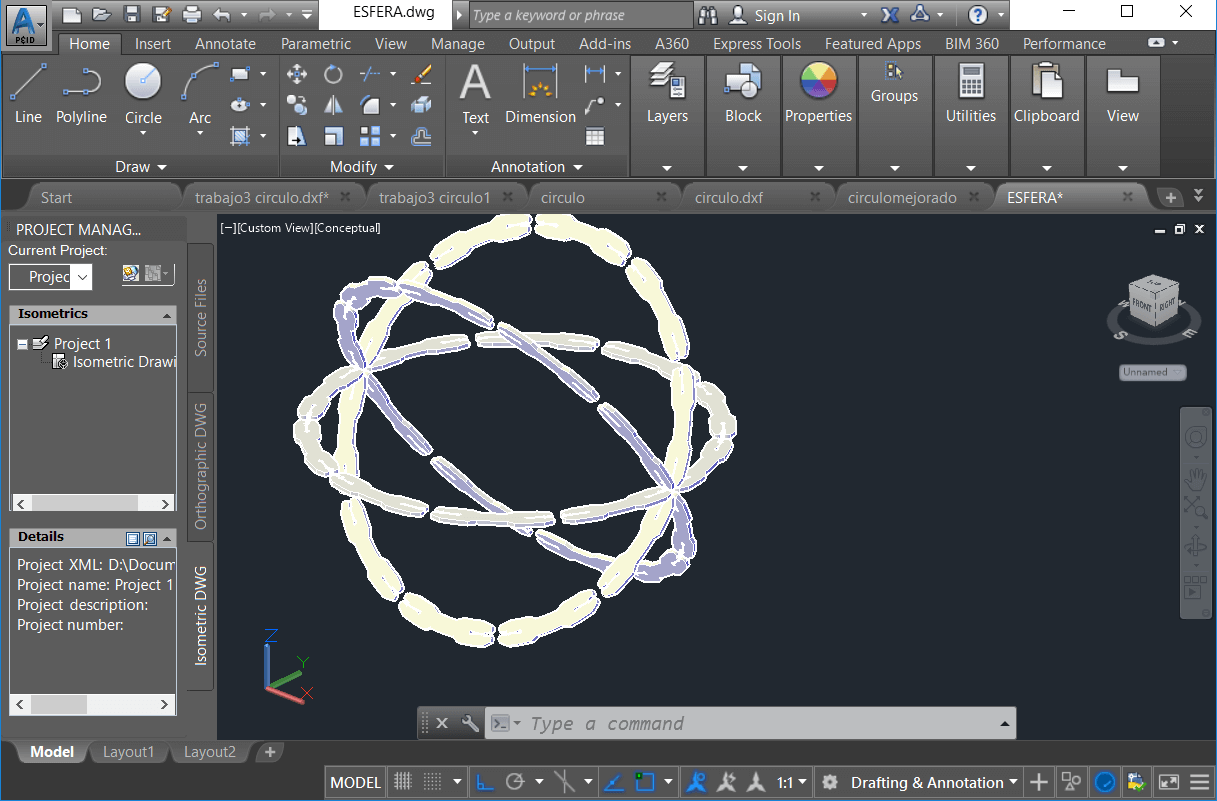

For my prototype in acrylic, I decide do a sphere with similar parts but in my first design I had a trouble with the width of the acrylic, since the material are very irregular, and the press-fit dont works well. .

I decided to do an improve to my design, to ensure that the fit does not come off. But I had another trouble, because the acrylic its brittle and I broke many pieces.

Finally I did a last improve and at last I can saw the light.

Selft evaluation

- What worked:

- With the joint tester (our hand-tester), was easy to do good press-fit kits.

- What did not work:

- was very difficult to do a good press-fit in acrylic material, because in Perú the Acrylic manufacturers makes an irregular product, and this affects the final result in despite of making a good design.

- Things to improve:

- Always select the right material at the time of making a cut. Take into account the width of the light cut, of the laser cutter machine.

File download

In FabLab Tecsup we have a great work group:

- Armando Sarco Montiel

- Diego Santa Cruz Meoño

- David Maita Franco

- Jhon Irwin Lozano Meza

- Juan Diego Ernesto Cerrón salcedo

- Ingrid Midori Nuñez Yamaguchi

For this group assignment, we decide to do literally a hand tester to prove different sizes of press fits, we take as material of reference 3mm MDF.

We design the hand tester in AutoCAD and export the archive in DXF format, because the laser cut machine works with Corel Draw, in Corel we have to define which parts are for cutting and which parts are to be rastered

|

|

|---|

In Tecsup Fab Lab we have the Epilog legend 63EXT laser cutter, where we cut the hand tester that we design in group.

|

|

|---|---|

|

|

To do a good cut in the 4mm MDF material we have to choose the correct parameter in our "Epilog legend 36EXT laser cutter machine"

Fablab Tecsup has a long experience doing laser cut services, and they have a list with the optimal parameters to do a excellent cut.

Vinyl cut

For this work I decided to make the vinyl cut of a tulipan, for which I chose an image and then vectorize in Corel Draw.

|

|

|---|

In our Fablab we have the Silhouette Cameo 3 machine

After vectoring in Corel Draw, I export the file in DXF format, so that it can be opened with the application of the cameo, and then be cut.

The first step to do the cut, is set up the cut parameters

Finally I gave the vinyl cut to my wife.

Parametric press-fit construction

In this assignment I decided to design and implement two parametric press-fit kit, one in MDF of 3mm and other in acrylic of 3mm to do some comparations.

MDF material

First I design my prototype in AutoCAD 3D for the MDF material, was easy take measurements because i used my hand tester, that I did in the last assignment. at last I use the laser cut to obtain my pieces.

|

|

|---|

Acrylic material

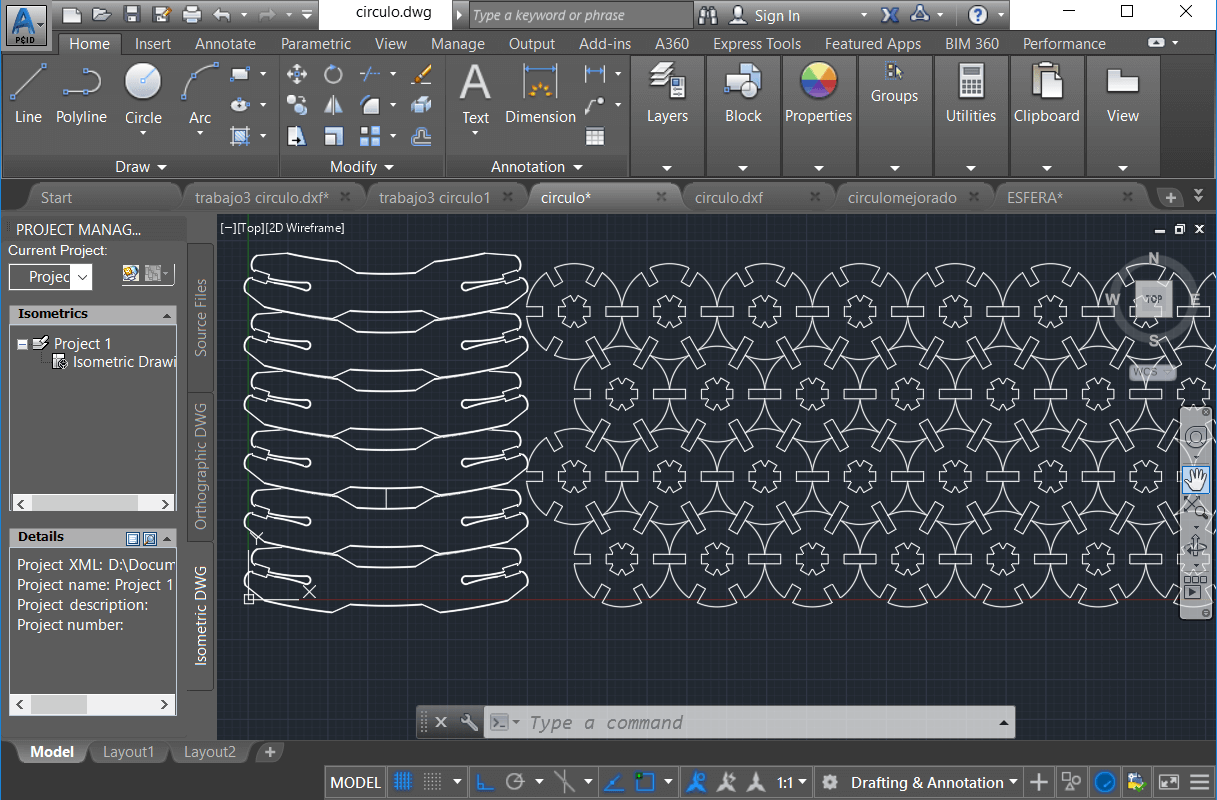

For my prototype in acrylic, I decide do a sphere with similar parts but in my first design I had a trouble with the width of the acrylic, since the material are very irregular, and the press-fit dont works well. .

|

|

|---|

I decided to do an improve to my design, to ensure that the fit does not come off. But I had another trouble, because the acrylic its brittle and I broke many pieces.

|

|

|---|---|

|

|

Finally I did a last improve and at last I can saw the light.

|

|

|---|---|

|

|

|

|

Selft evaluation

- What worked:

- With the joint tester (our hand-tester), was easy to do good press-fit kits.

- What did not work:

- was very difficult to do a good press-fit in acrylic material, because in Perú the Acrylic manufacturers makes an irregular product, and this affects the final result in despite of making a good design.

- Things to improve:

- Always select the right material at the time of making a cut. Take into account the width of the light cut, of the laser cutter machine.