-Read the datasheet and the specfications of the materials used

-Mill a mold

-Follow the security norms of the resin

1. Find a sample to fabricate

http://scan.asso.insa-lyon.fr/tag/skate/

http://scan.asso.insa-lyon.fr/tag/skate/

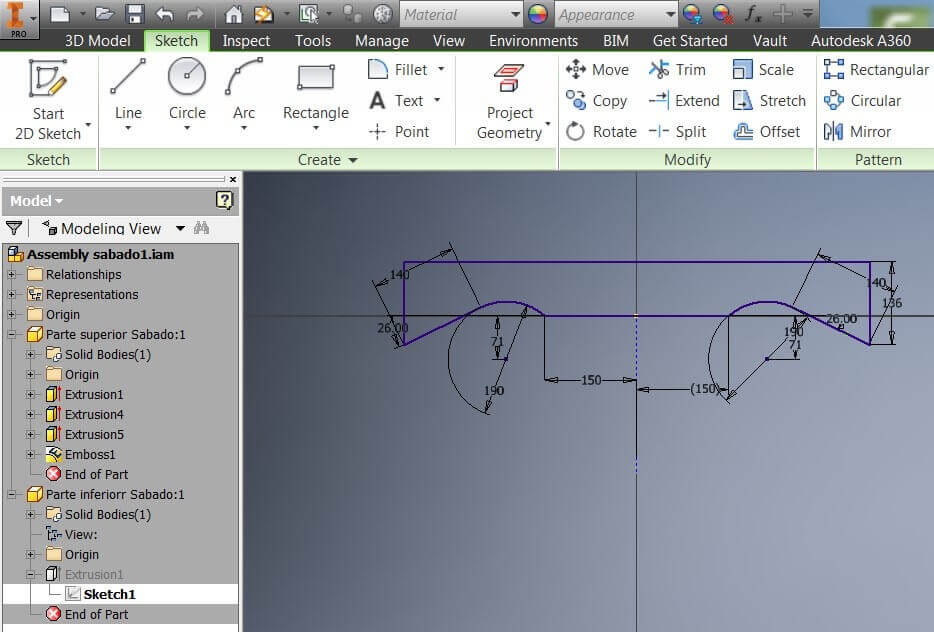

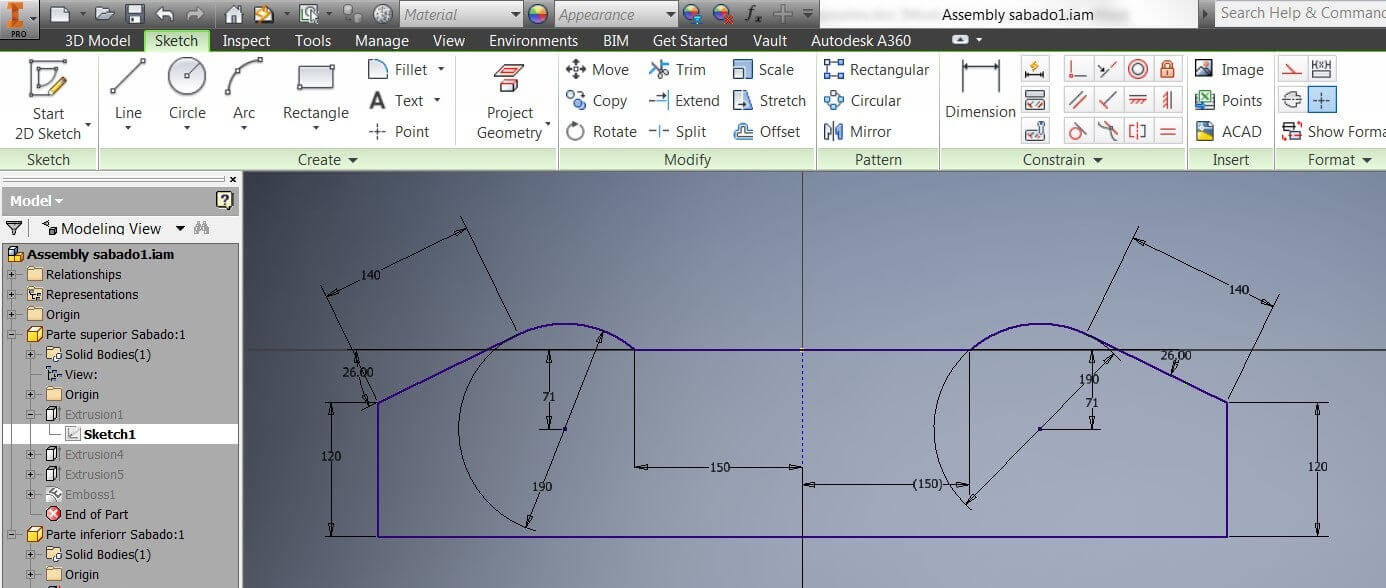

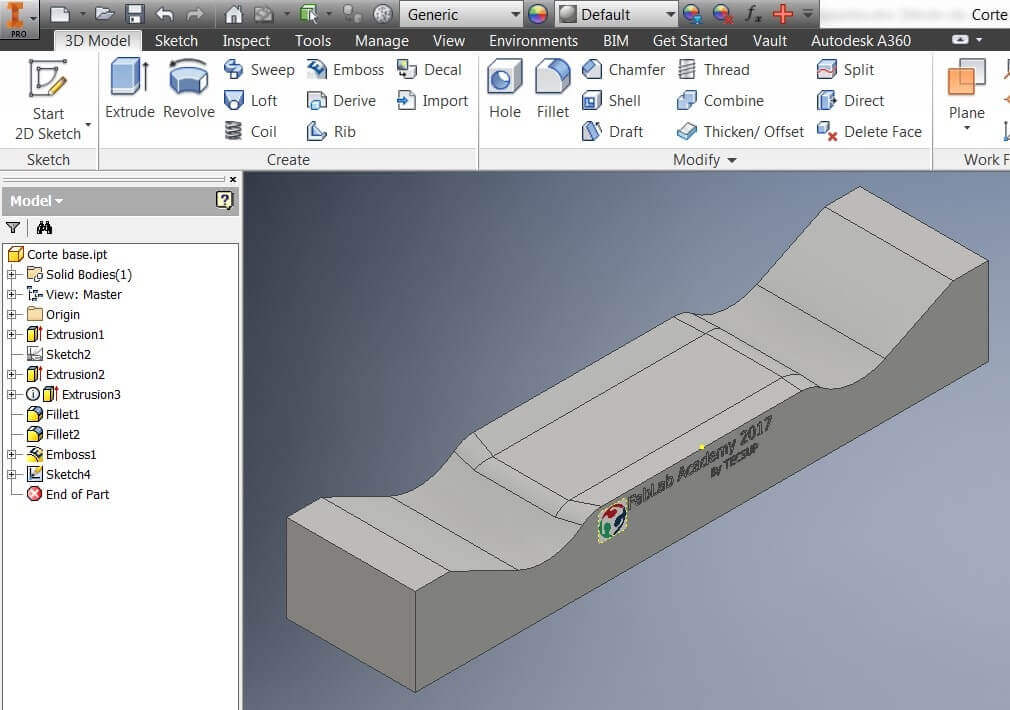

2. I designed a skate on inventor

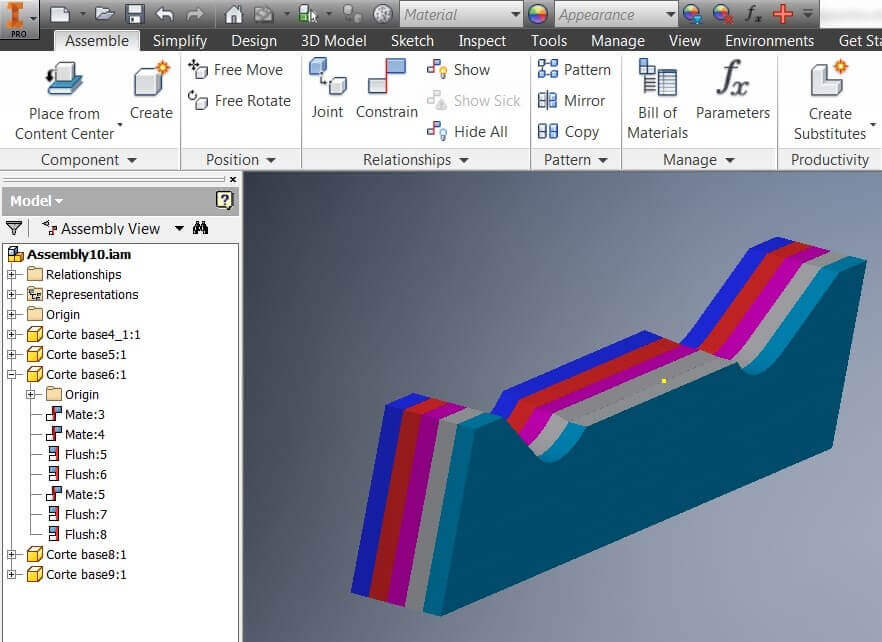

3. Then you design the assembly

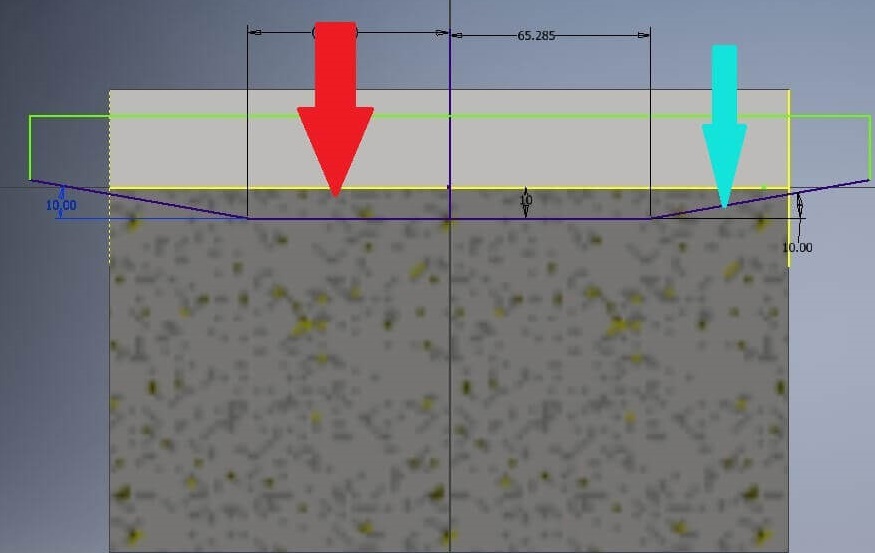

4. After that, you mill your .dxf files on the shopbot

5. Do the joints on the top and bottom using nails and glue

6. After that I rectified the surface and the angle using a KUNZMANN machine

7. Verify the angle using a goniometer

8. I also did the finishing using the polisher machine

9. Cut the extra material

-Is the most used material

-Almost every skate is made on maple

-Maple is cheap, resistant and kind of flexible

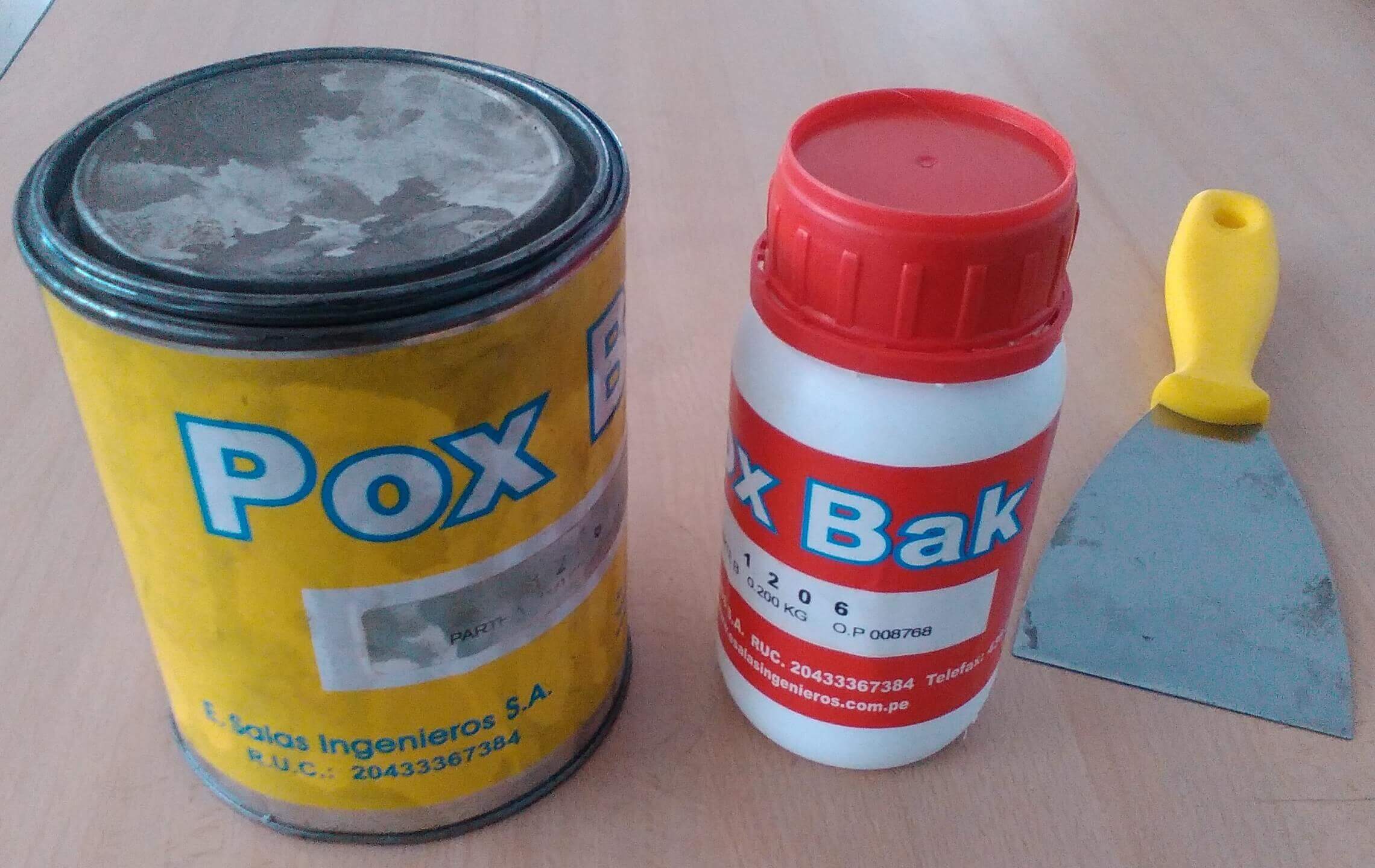

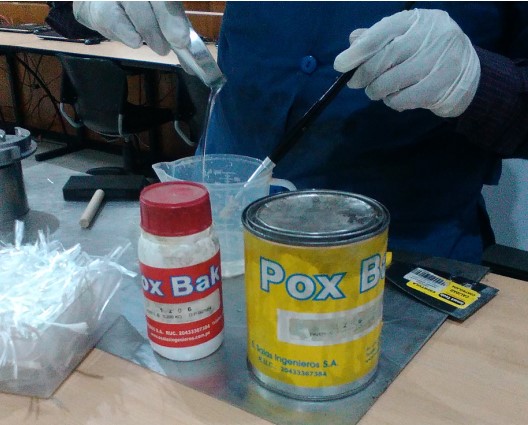

10. Mix the resin following the manufacturer recommendations

Archivos de la resina

Archivos de la resina

11. After cleaning the surface, apply the resin layer by layer

12. Fix it on the table

Since I used dry plywood, it broke

I added more triplay, but wet

13. Before the test I added sandpaper

14. The skate test

15. Final presentation of the skate

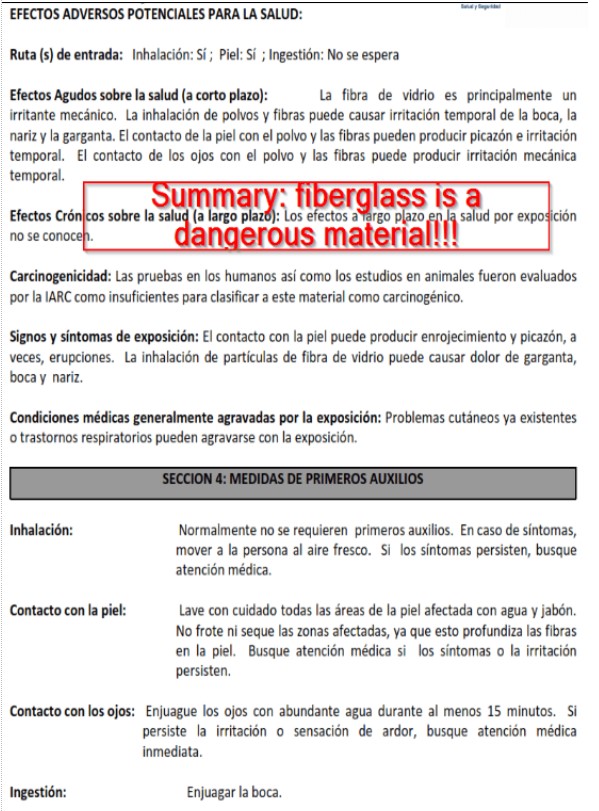

We have to be very careful, to use some dangerous products, that is why we have to read your safety data sheet to avoid injury.

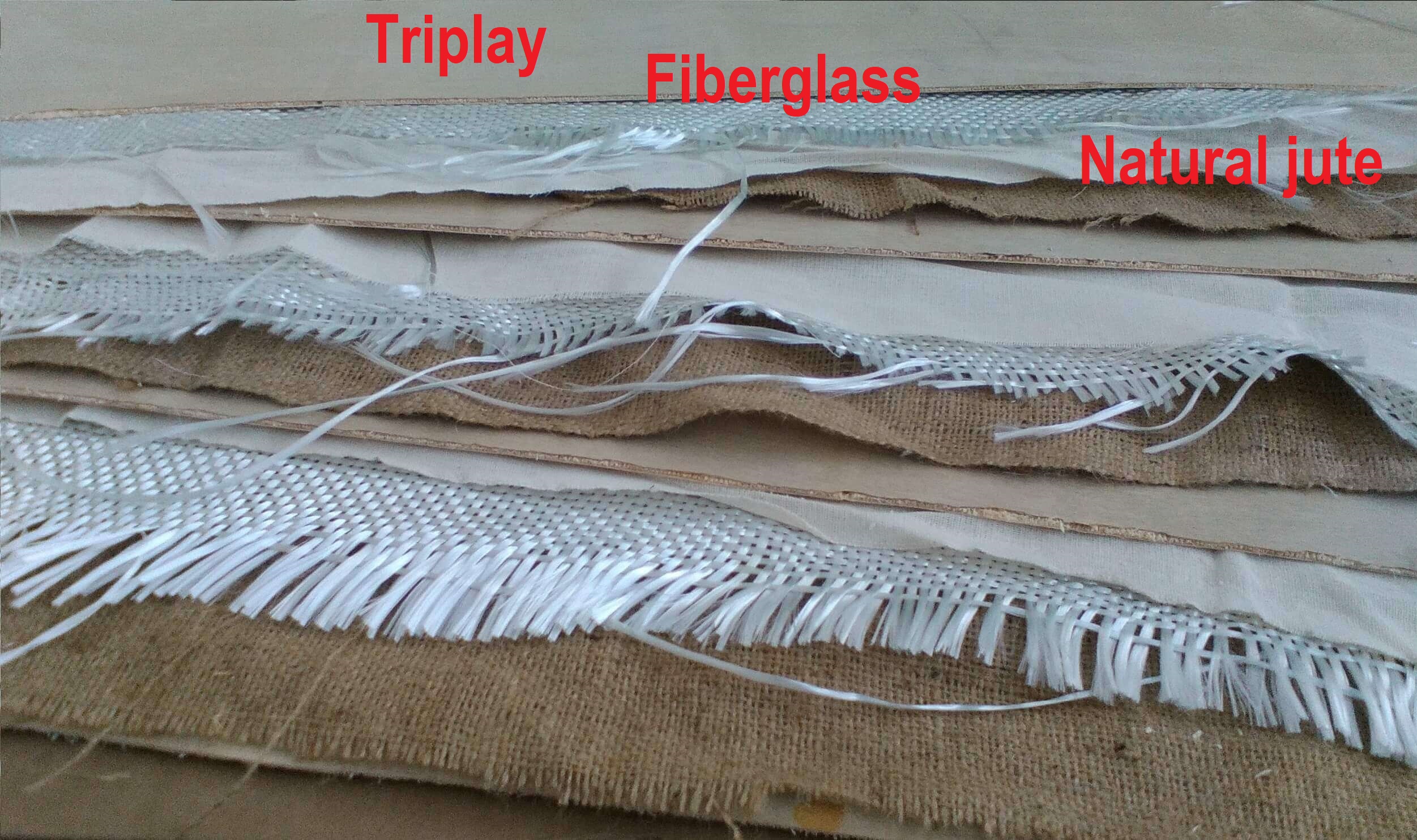

For this task I will use fiberglass and resin, and these materials are hazardous to health, for more information you can read their data sheets located in the download section.

Fiber glass

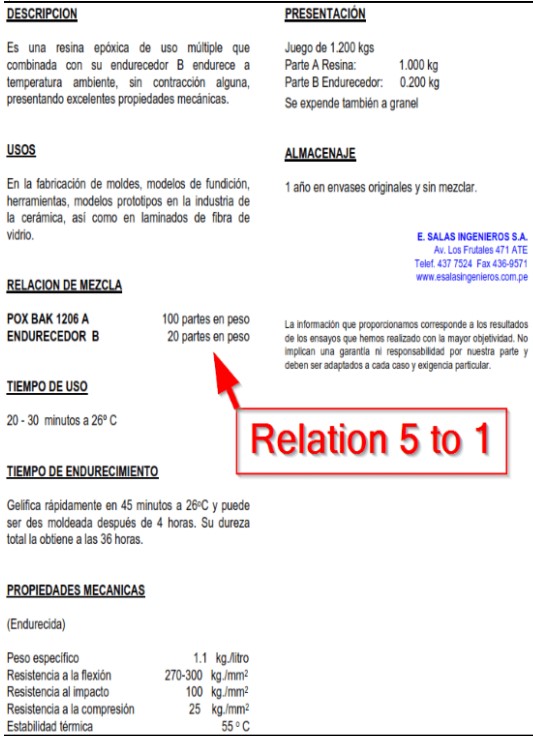

Resin

2 Use a sponge to apply the release agent (car wax) applying approximately 2 times, drying time between the past and the next 5 minutes.

3 Preparing the mixture ratio according to the manufacturer's recommendation follows the 5 to 1 ratio.

4 Apply the first resin pass after mixing, each pass between 10 minutes of drying

5 After 30 minutes, place the fiberglass and help with a thin brush over the resin on the mask

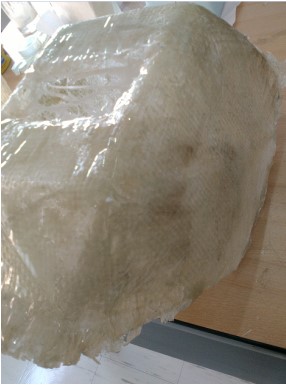

6 After placing 2 layers of fiberglass and resin, let stand 10 minutes to place plastic bag and vacuum cleaner, which allowed me to remove the air and plastic to adhere to the mask with fiber and resin.

7 After 8 hours of drying in the environment remove the plastic and observe the roughness and the finish that gives it more shine.

Perform the first fiberglass test with resin on the mask but without using the plastic bag at the end, having as an error with respect to roughness and some fibers at the ends were left standing and this creates problems to give the final finish.

Perform the second fiberglass test with resin on the mask but now if you use the plastic bag, having to minimize scratches. In the edges is generated radius for easy removal and give the final finish of the welding mask.

-Follow the security norms to work with epoxy resin

-Follow the security norms to work with fiberglass

-You need a matrix

-Do the test in order to verify if there are problems