Assignment 13

26.4.2017

Topic: Input devices

Measure something: add a sensor to a microcontroller board that you

have designed and read it.

Learning outcomes:

Demonstrate workflows used in circuit board design and fabrication.

Implement and interpret programming protocols.

Have you:

Described your design and fabrication process using

words/images/screenshots.

Explained the programming process/es you used and how the

microcontroller datasheet helped you.

Explained problems and how you fixed them.

Included original design files and code.

A/D conversion (ADC)

Analog-to -digital conversion is totally new thing for me. I was

interested to study it and use it in my final project. For example,

Attiny44 has 10 bit resolution of ADC and 8 channels. As my final

project, I want measure two things, supply voltage (12 V) of my car

battery and temperature inside the car.

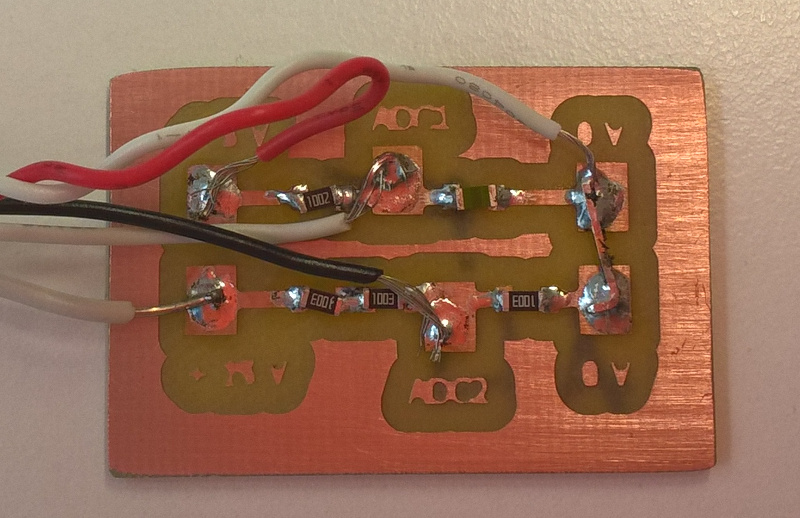

I designed a simple test board it include two voltage dividers: One

use 2x100k resistors to drop voltage from maximum 15 V to Attiny44's

measurable level 5 V on ADC pin and then 100k resistor from ADC pin

to ground. The second use 10k resistor from 5 V to ADC pin and from

there NTC thermistor to ground. NTC type is NAQ103B 375T10. Thus,

it's parameters are R25 10 kΩ and B (25/85) 3750. Bridge circuit

might be more accurate but voltage divider is enough in my use. I

detect only one limit temperature.

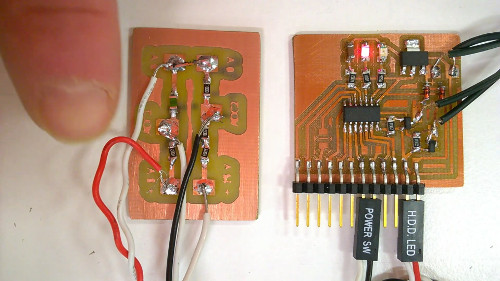

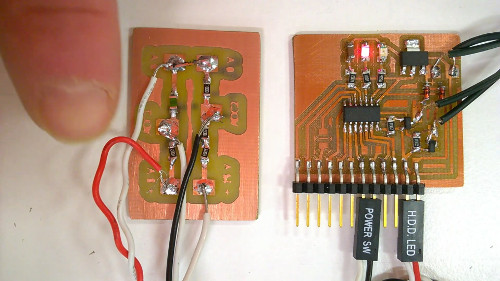

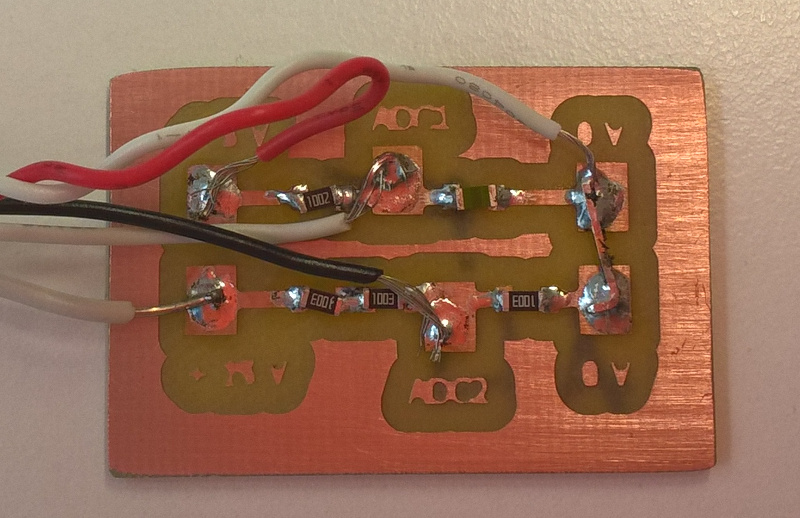

I milled this PCB board and put components and wires in place. I

measured some basic tests to test the board and understand it's

working. Voltage on ADC pin decreases when temperature increases.

Wires in top side:

Wires in top side:

Red: +5 V

White: 0 V

Wires in bottom side:

White: +12 V

Black: ADC 2, voltage

White wire in middle: ADC 1, temperature

I designed the board so that I can connect it to the output board I

made as Assignment 10. Similarly

maybe, I need input device connected to main board in my final

project. I wrote some code for it. I got some help from page:

https://www.marcelpost.com/wiki/index.php/ATtiny85_ADC. ATTINY44

data sheet advices that by default, the successive approximation

circuitry requires an input clock frequency between 50 kHz and 200

kHz to get maximum resolution.

I can select ADC channel by MUX values. ADMUX = 000011b changes it

as pin PA3/ADC3.

Prescaler is here 64, therefore sample rate is about 15 kHz for 1

MHz clock. Prescaler should be 16 for 62.5 kHz

sample rate.

I used here 8 bit ADC, therefore the maximum ADC value was 255.

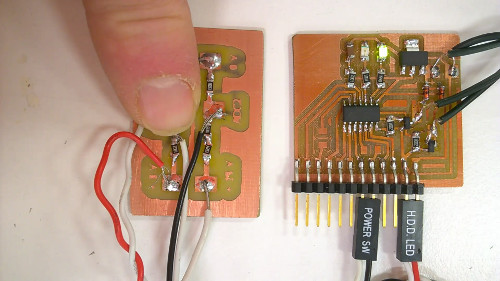

If the ADC value is less than 128, the green led lights and if it is

more the red led lights.

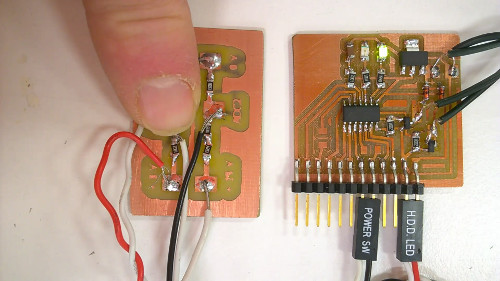

Then, I made a finger test. My finger warmed the NTC and led color

changes from red to green.

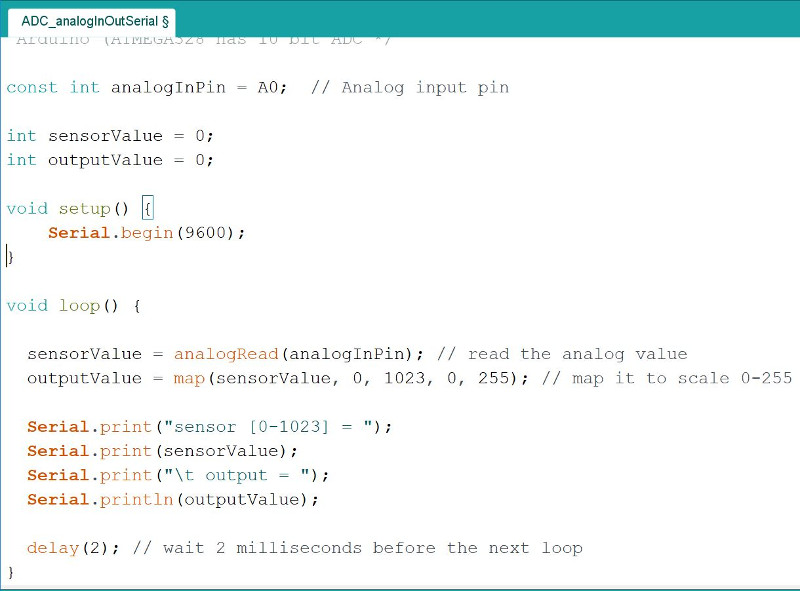

I tested my board with Arduino also. It has also 10 bit ADC. This

simple program reads ADC pin and print it out.

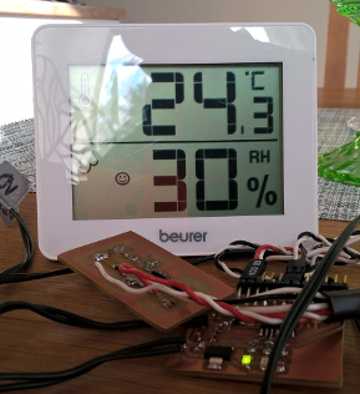

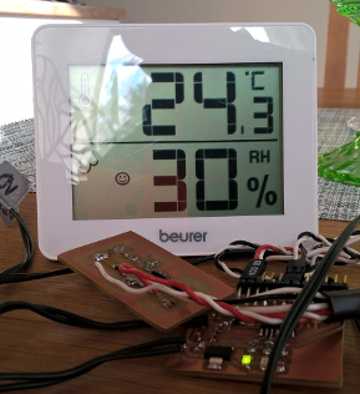

Room temperature at 24.3 °C gives ADC value 128 at scale 0-255.

Voltage level is 2.57 V. Outside temperature at 2.4 °C gives

ADC value 179 at scale 0-255. Voltage level is 3.54 V.

Warming sauna temperature at 42 °C gives ADC value 95 at scale

0-255. Voltage level is 1.88 V.

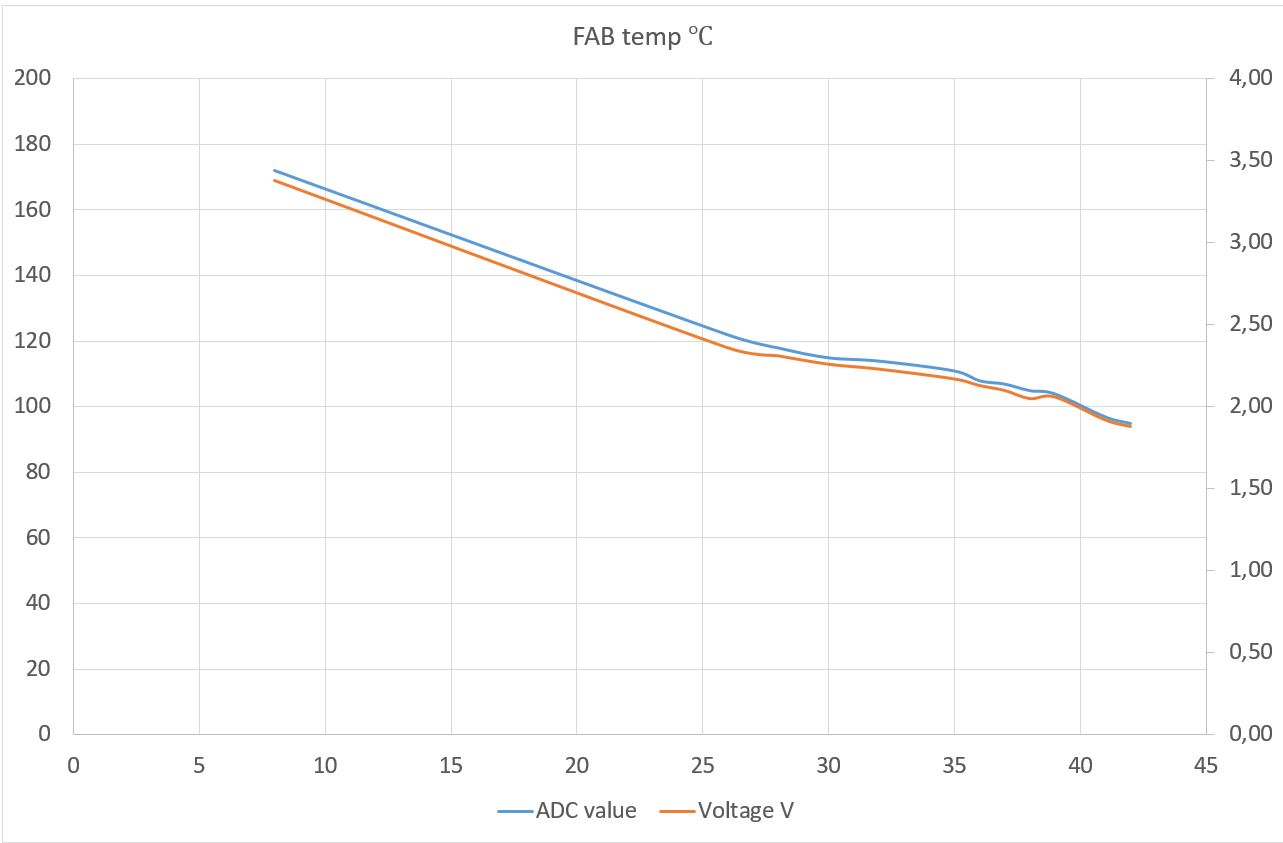

Further, I measured following data. Temperature (down) increased

from +8 °C to +42 °C. I documented Adc values (left) and voltages

(right). The reference voltage was set to VCC, 5.04 V.

Thus, ADC value decreases when temperature increases as planned. The

curve is very linear from temperature 8 °C to 26 °C, because I

measured only two temperatures there. Between 26 and 42 °C I

measured values as 1 to 2 °C steps.

I want measure two channels as my final project and I wrote

following code for it.

// FAB_ADC02.c This code is edited by Yrjo L. for Attiny44 use

2.5.2017

// ====================================

//

ATtiny44

ISP

//

VCC--+ o

+--GND

MISO---+5V

// GREEN LED PB0

--+ +--PA0

M2 SCK

---MOSI

// RED LED PB1

--+ +--PA1

M1 RST

---GND

THIS IS

NOT THE FINAL CODE FOR FINAL PROJECT

//

RESET

--+ +--PA2 ADC2

//

INT0 PB2 --+ +--PA3 ADC3

TEMP

//

PA7 --+ +--SCK ADC4

V-MEA

//

MOSI --+--------+--MISO

// ====================================

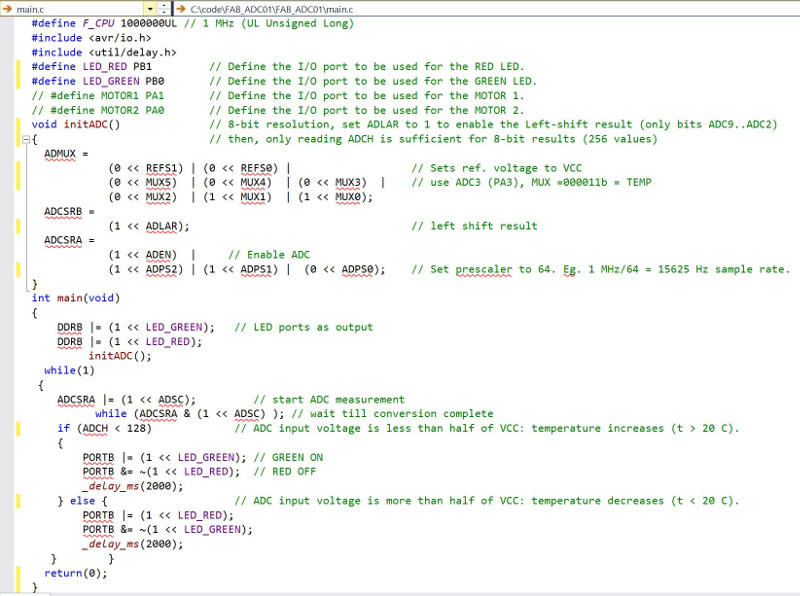

#define F_CPU 1000000UL // 1 MHz (UL Unsigned

Long)

#include <avr/io.h>

#include <util/delay.h>

#define LED_RED PB1

// Define the I/O port to be

used for the RED LED.

#define LED_GREEN PB0 // Define the I/O port to

be used for the GREEN LED.

// #define MOTOR1 PA1 //

Define the I/O port to be used for the MOTOR 1.

// #define MOTOR2 PA0 //

Define the I/O port to be used for the MOTOR 2.

void initADC()

// 8-bit resolution, set ADLAR to 1 to enable the Left-shift

result (only bits ADC9..ADC2)

{

// then, only reading

ADCH is sufficient for 8-bit results (256 values)

ADCSRB = (1 <<

ADLAR);

// left

shift result

ADCSRA = (1 << ADEN)

| // Enable ADC

(1 << ADPS2);

// Set prescaler to 16. Eg. 1

MHz/16 = 62.5 Hz sample rate.

}

int main(void)

{

int Mtemp;

int Mvolt;

DDRB |= (1 << LED_GREEN);

// LED ports as output

DDRB |= (1 << LED_RED);

initADC();

while(1) {

ADMUX = (1 << MUX1) | (1

<< MUX0); // use ADC3 (PA3), MUX

=000011b = TEMP

ADMUX &= ~(1 <<

MUX2);

// not use ADC4 (PA4) MUX =000100b = VOLTAGE

ADCSRA |= (1 <<

ADSC);

// start

ADC measurement =TEMP

while (ADCSRA & (1

<< ADSC) );

// wait till conversion complete

Mtemp = ADCH;

_delay_ms(2000);

ADMUX &= ~(1 << MUX1) & ~(1

<< MUX0); // not use ADC3 (PA3), MUX =000011b = TEMP

ADMUX = (1 << MUX2);

// use ADC4 (PA4) MUX =000100b

= VOLTAGE

ADCSRA |= (1 <<

ADSC);

//

start ADC measurement =VOLTAGE

while (ADCSRA & (1

<< ADSC) );

// wait till conversion

complete

Mvolt = ADCH;

if (Mtemp < 128 || Mvolt < 200)

// if temperature > 20C or

voltage < 12V then pump and blower stop

{

PORTB |= (1 <<

LED_GREEN); // pump & blower stop

PORTB &= ~(1 << LED_RED);

_delay_ms(2000);

} else {

// if temperature < 20C and voltage >

12V then pump and blower work

PORTB |= (1 <<

LED_RED); // pump & blower

start

PORTB &= ~(1 <<

LED_GREEN);

_delay_ms(2000);

}

} return(0);

}

It works as expected. If temperature is more than 20 °C or battery

voltage is lower than 12 V, then the pump and blower stops and GREEN

led lights. Battery voltage level 11.8 V refers to ADC value >

200 and then ADC voltage level is 3.91 V. Voltage level 11.7 V

switches RED led on. It refers to to ADC value of < 200 and then

ADC voltage level is 3.88 V. Those limits are ideal, however. ADC

value of 138 might suit better for temperature limit 20 °C.

ADMUX = 000011b changes pin PA3/ADC3 and ADMUX = 00100b changes pin

PA4/ADC4 as the ADC channel.

Prescaler is here 16, therefore sample rate is 62.5 kHz for 1 MHz

clock as recommended in data sheet.

Motors 1 and 2 are not yet coded anymore here.

Design files: NTC+15V.sch and CTN+15V.brd.

Code: FAB_ADC02_main.c.

Board as png file: NTC+15VTRC.png.

As replacement of a output file I tested drive outlines by manual

control.

Post-registered note:

Later, I made similar voltage dividers for my final project use. Node_F1

board measures temperature and MainB_F1 voltage.

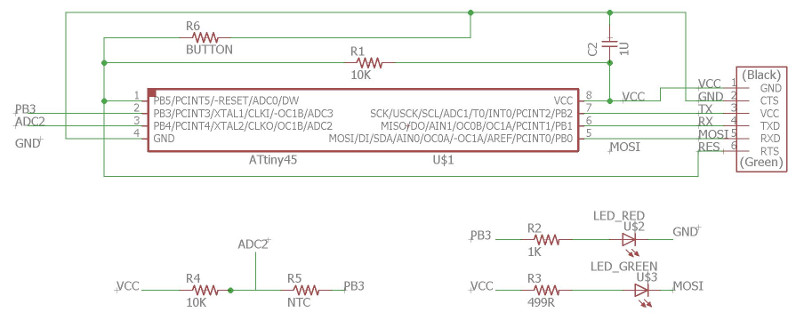

Node_F1

During assignment 15,

networking and communication, I made a board for communication but

also for testing of temperature measurement (ADC), user interface

and serial communication together. My original ADC code needed some

modifications to work also in Attiny45. One difference

exists as ADLAR set in ADMUX |register for attiny45 and ADCSRB

register for Attiny44.

Further, pin PB3 control both the RED led and ADC measurement

/ADC2). When it is 1, led lights, and when it is 0, temperature

measurement circuit grounds via PB3 and starts. Green led is

controlled by pin PB0. I added also a button to test RESET pin

feature.

This schematic is for Node_F1.

I must change pins TX and RX that I can use direct cable between

units.

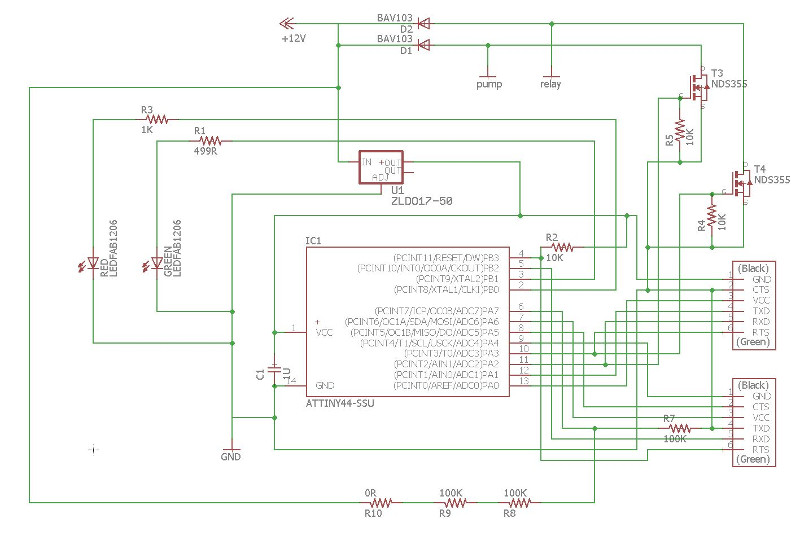

MainB_F1

As well as during final project

I made MainB_F1 board as a evolution of boards made during

assignment 10 and 13. It is presented below and includes voltage

measurement by ADC (ADC7).

This schematic is for MainB_F1.

Boards as png files: fabnode_track02.png

and FABcamper21.png.

Wires in top side:

Wires in top side: