Demonstrate workflows

used in circuit board design and fabrication.

Implement and interpret programming protocols.

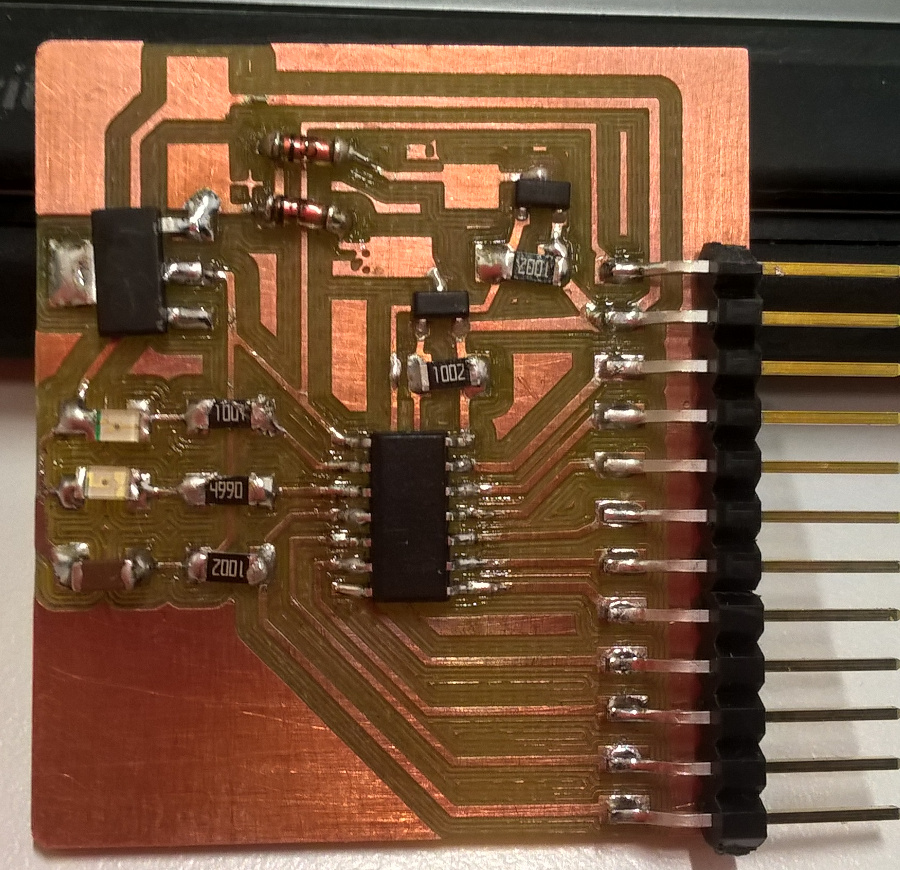

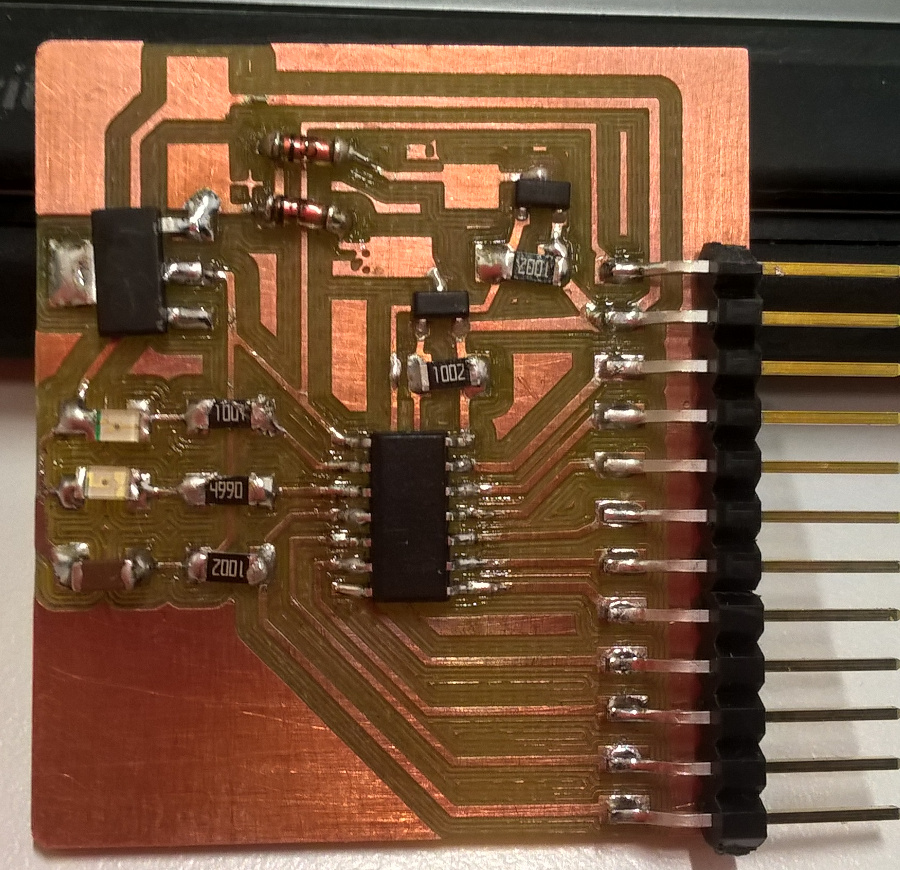

Now I have chance to work with my final project. I need control

board for one DC motor and one relay. The motor rotates only to

one direction. I made schematics and board plan by Eagle.

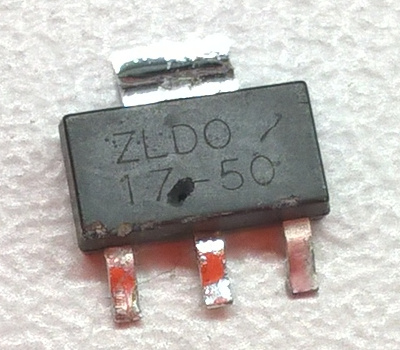

My solution uses 12 V operating voltage from my car. It is

lowered to 5 V for Attiny44 use by regulator ZLDO17-50.

Attiny44 includes 12 I/O pins and it is enough for my application.

Also, I simplified my board by using in-circuit clock.

A motor and a relay are controlled by two N-MOSFETs, type NDS355ANCT.

They have maximum properties of 30 V and 1.7 A. These mosfets are

so tiny, that how they can handle such a voltages and currents?

Further, they are protected by diodes from reverse spike

voltages. This may occur when I stop powering of the motor or any

coil. A reverse voltage, up to several hundred volts and only a

few microseconds, spikes back and kill my mosfet.

I use BAV103 diodes. They reverse voltage is 200 V and

forward continuous current 250 mA. And, they need 10K

pull-down resistors. I made big connector plates to 12V control

wires I could solder there. I drew them directly to board by Rect

drawing tool of Eagle board editor.

All other connections are handled by 1x12 pin header. Other

components are familiar from earlier assignments. RED led is

connected to PB1 and GREEN led to PB0. Even, there were familiar

components I needed data sheets to check features. And, the new

components took familiar by reading data sheets.

I could control also speed of motor as described in page:

http://bildr.org/2012/03/rfp30n06le-arduino/. Then, I must connect

motor control to pin PA5, PA6, PA7 or PB2. However, I use pins PA0

and PA1 for these controls. Pin PB2 can be used as interrupt

(INT0) and wake-up purposes.

And, PA2, PA3 or PA7 can be used for analog-to-digital conversion

(ADC) purposes. Hence, they can be used for temperature and

battery voltage measurements. Minimum voltage level could be

detected by certain Zener diode also.

Here, I tested also Antti's idea for PCB milling. I didn't use

Gimp, but exported PNG files directly from Eagle. Purple lines

in the picture represent outlines. I created a new layer and drew

0.8 mm rectangular outlines around my plan, zoomed the window to

fit all and located they to the left side of window.

I exported traces without outlines first, changed the background

color to white and exported then only outlines.

I soldered the microcontroller and mosfets by reflow oven and

other components by hand. Then, I found a mistake, the

microcontroller was upside down. What next? Antti explained that I

can took it out by hot air blower. Some other components dropped

also. I soldered they again, now by hand! Jari helped me a

lot.

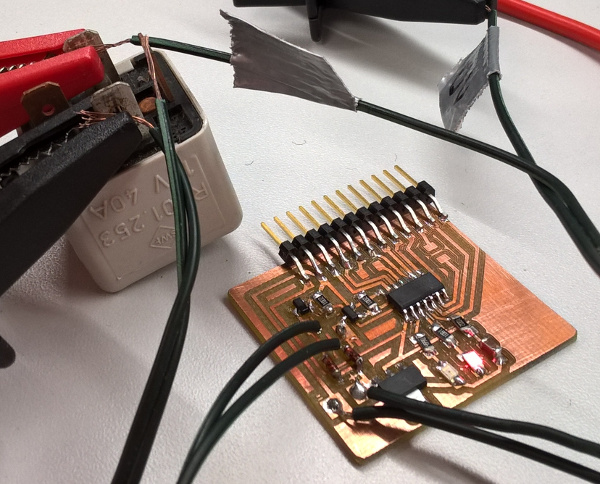

Important new components are mosfets and the regulator. I tested

my board by simple program, that blinks the led. Also, I tested

the regulator by 12 V voltage and it powered my board as designed.

I done also a program, which starts and stops the motor and the

relay, as well as blinks the leds similarly.

The fabrication and programming processes were very similar as in

assignments 6 and 8.

Board schematic: FABcamper.sch

Board layout: FABcamper.brd

Png files: FABcamper011.png and FABcamper022.png

Control code: Motorrelay_main.c

I tested my board and connected it to 12 V power source. It

worked. Then, I connected also a relay from my old car to it. And,

it worked well again. Leds blinked and the relay sounded klik

klik.

The second minor damage I made was a

small hole in the regulator. I used battery charger, when I tested

my board at home.

The second minor damage I made was a

small hole in the regulator. I used battery charger, when I tested

my board at home. When I worked with Assignment 13, I found error in my

code MotorRelay_main.c. Leds were connected in different order in

my second board as compared to first one. I corrected this to the

code MotorRelay_main.c and documentation here.