FINAL PROJECT

Index

- My Final Project Introduction

- Design 2D : The Parametric Kite Patterns & Laser Testers.

- Design 3D : The Kite : Madrid version for flight with 10 to 20 km/h.

- Design 3D : Mechanisms. Caps and Connectors.

- Design : The Box for Electronics.

- The Budget : An Approximated BOM

- Technologies Involves I : LASER CUTTER MACHINE PROCESSES

- Technologies Involves II : 3D PRINTERS PROCESSES

- Technologies Involves III : MILLER MACHINE PROCESSES

- Technologies Involves IV : SEWING MACHINE PROCESSES

- Electronics : Design and Fabrication

- The Atmel 168P Datasheet : What i learned and Howe it Helped to me?

- Learning about Gas Sensors. Callibration.

- EPPROM Programs for store and read sensor data.

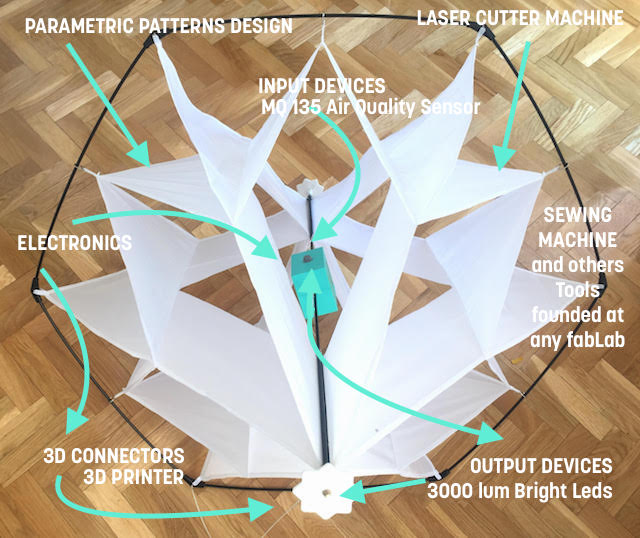

FAITO V.O1 : A FABABLE KITE FOR LEARN HOW TO RESPECT THE ENVIROMENT

Faito v.01 is a prototype develope during my Academy for learn How to fabricated Kites with the learns practice each week focussing on how to adapt the techniques and tools to kids.

Faito v.01 was designed as a part of research about Academy Tools suggested with the idea to use the more open Sources as possible an apply to my workshops when i finish.

Faito v.01 have the measures and weights ideal for have flights with Madrid´s wind forces so this was the idea for have something at the Final project presenattion but i designed inside "My Own Academy Spiral Nights" a second one with his parts for fly in the place i thought for first time, close to the Atlantic Sea.

Faito v.01 LEARN ME A LOT because i didn´t have experience at the design, fabrication or technologies used during the processes so EVERY MISTAKE was a lesson, every advance was a challenge, every processes opened other processes. I learned that now i have a Project for teh rest of my life if i want and I want

Faito v.01 should to have more sensors, should to be more complicated but it need as symply as possible for get the first interest of people who should to use it.

Faito v.01 is now a prototype which learned me how will to make the seconbd version, how not to make the same mistakes and probably have other news...

Faito v.01 have a mini-partner actually but still looking for more people or companies interested because the process learned to me how much will be your costs, Now I know the kite market and to what extent is it profitable to manufacture a kite in a fablab.

Faito v.01 as Neil´s mentioned at presentation is good for the class but both think that the second model can to have more input sensors studied during the Diploma i can´t to wait but i´m realistic Faito should to have more partners.

2D Y 3D DESIGN

The 2D design process started soon although a little blind since i had not yet advanced with my aerodynamic studies, on weight and trend in relation to other previous references which you can see at my

Looking for other possible projects with my instructor, some mentioned in my Intellectual property and Income´s assignment page : WEEK 18 about WHAT OTHERS DID? , we found that my prototype is currently commercialized so that being a design that existed it was necessary to demonstrate what is different in my kite in terms of design and what am i trying to improve with my process.

As I mentioned in my page FINAL PROJECT PROPOSAL : at WEEK 01

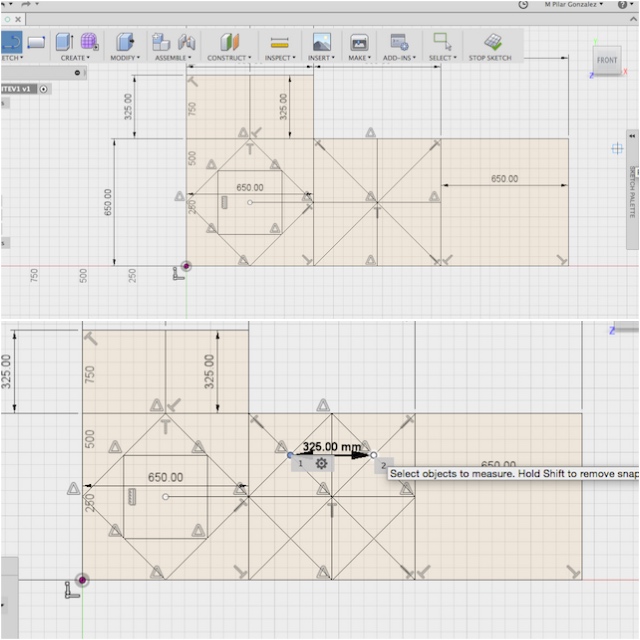

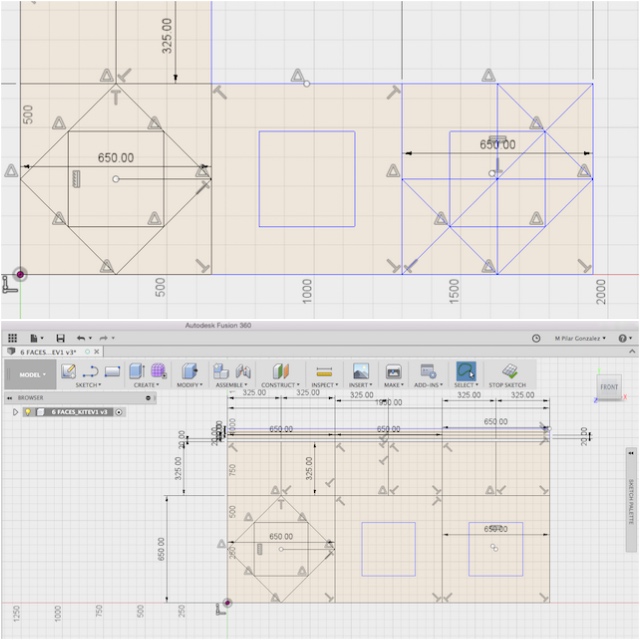

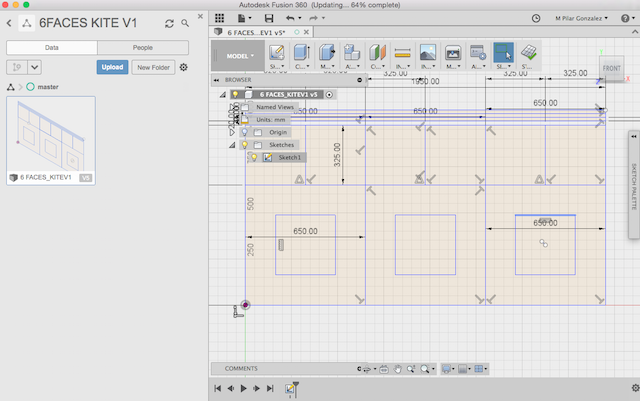

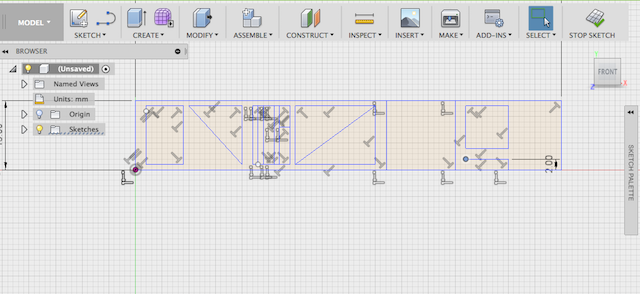

My initial idea was to design a kite that was easily designed with the tools proposed during my fabAcademy but always looking towards a practical future. That is why my design processes use different tools, both commercials and free.For my prototype and after several attempts, I used Fusion 360º in the 2D patterns design and laser testers, using the parametric functions of the program. This will allow to every one to modify the kite measurements in order to adapt the design to the size needs.

Clearly adore this design my intention when performing an equal is to demonstrate to what extent it is as I mentioned, easily designed by the tools that can be found in the fablab and to what extent the processes that are given in the academy could be fabricated some similar, with the less possible costs.

Another reason i wanted to design a kite like this is because its design after my research allowed me to know that it would be easily volatile with weak winds.Every conclusion in relation with the weight and wind now will be knowledges for make the properly kite and be happy flying it in front of the sea in future.

The 2D design process had several attempts that you can know more in my final roject process page at 2D design and 3D sections and in the weeks related at the :

2D DESIGN LEARNED TO ME: HOW TO MADE PARAMETRIC PATTERNS FOR KITES SO I GAINED HOW TO MAKE DIFFERENT MODELS CHANGIN SIZES EASY

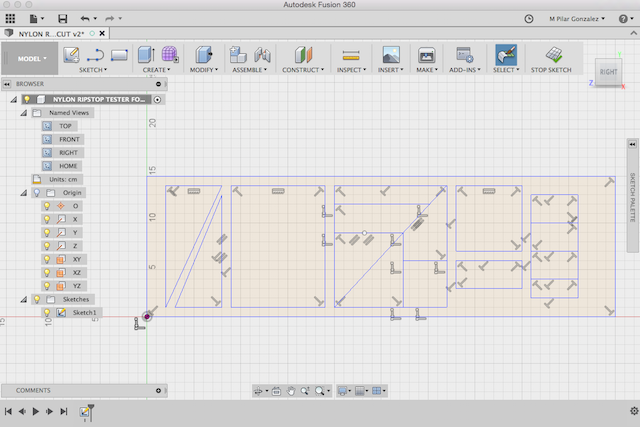

Faito can be designed with any 2D and 3D softwares Open Sources but i Used too : Fusion 360º, AutoCAD or Cinema 4D.

2D - PATTERNS Fusion 360º

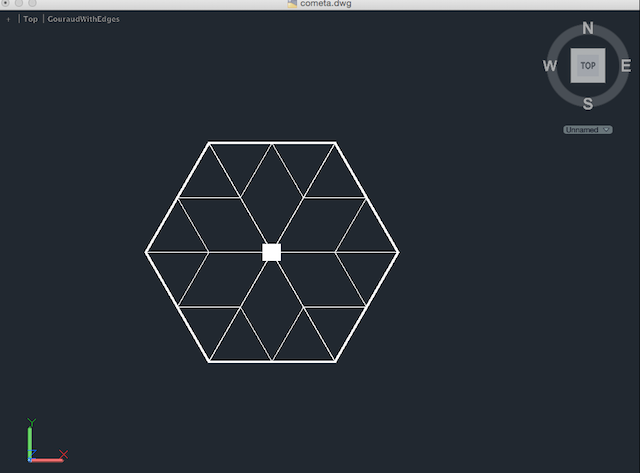

6 FACES (Madrid version): Parametric Design

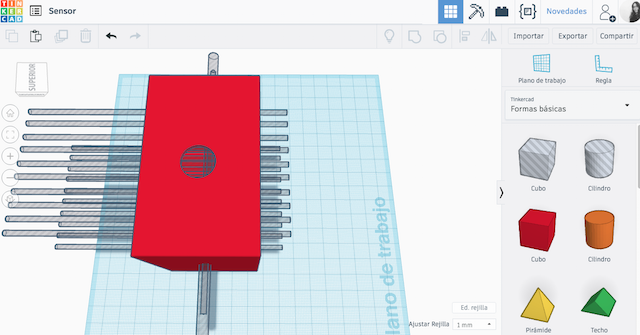

Now i know that my future students can make their patterns using different softwares as Open Sources (tinkerCAD), obviously depending the software used the design process involve one or another processes.

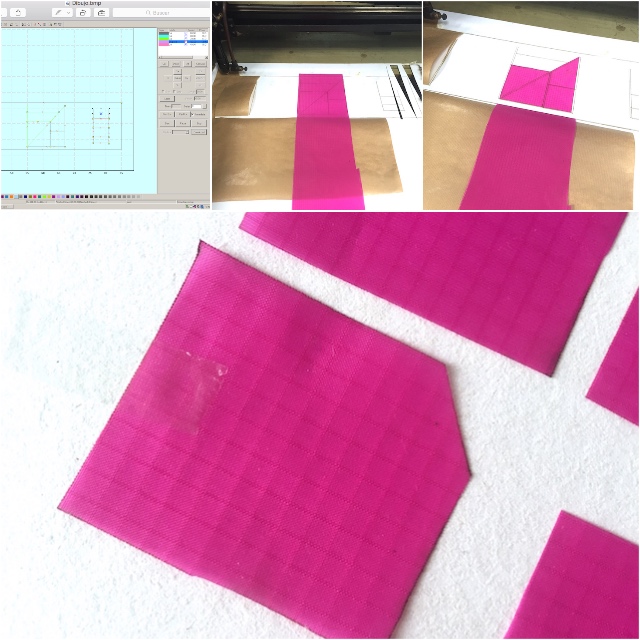

LASER TESTER DESIGNS:

One of the essential materials of the kite is the Nylon Ripstop fabric found in the Fab Academy inventory, but my kite should to be ultra - light so I decided to use Nylon Icarex. This material had not been cut before in our fablab. So I established a series of new parameters that will surely serve any student who needs it. You can know more about these testers by visiting the : Final Project Process Page

To make this tests on the fabric also made a series of random designs that served to make several testers of which you can know more in A random Design for set parameters at Laser Cutter Machine.

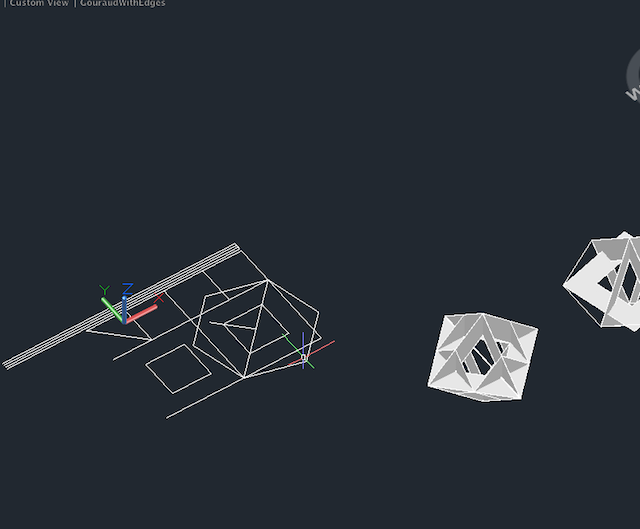

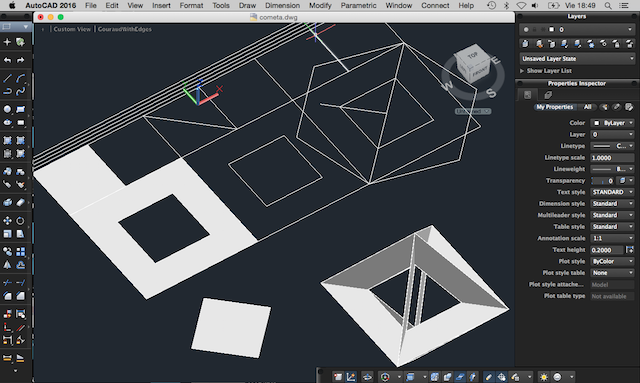

THE 3D´S KITE DESIGN

The design of the 3D kite does not have the dihedral connectors because when i made the design they were not yet finished. For the process I used the autoCAD tool since when exporting my .dxf with the patterns from Fusion 360º i had lost some lines. The model includes the 3D design of the box mentioned later and follow the process practiced during the Academy in weeks when i was trying with Cinema 4D.

3D KITE DESIGN LEARNED TO ME HOW TO SEW THE PATTERNS, HOW TO MEASURES NEW KITES, HOW TO MADE THE MAIN PARTS SO I GAINED HOW TO MAKE DIFFERENT KINDS OF CONNECTORS OR BOX FOR ASSEMBLED ELECTRONICS.

Faito v.01_ 6 FACES (Madrid version) AutoCad:

MECHANISM - PARTS :

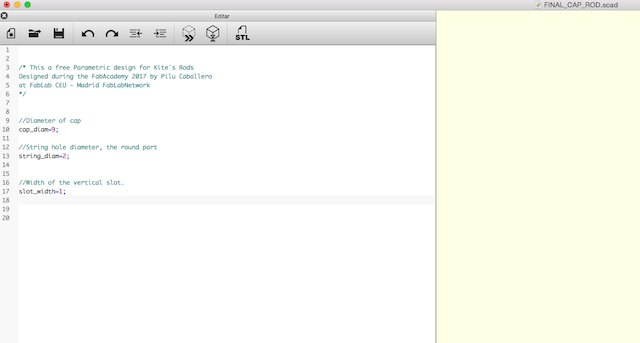

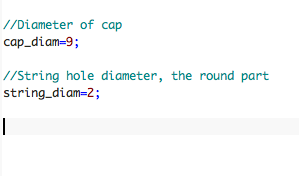

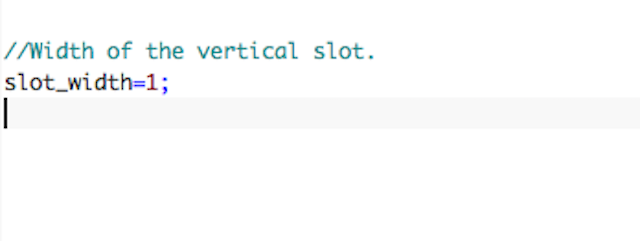

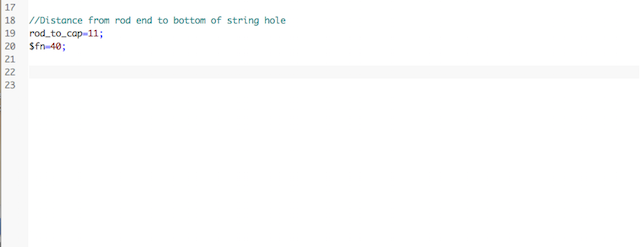

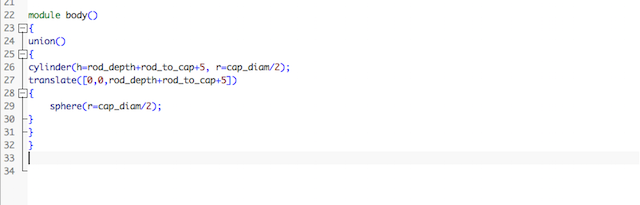

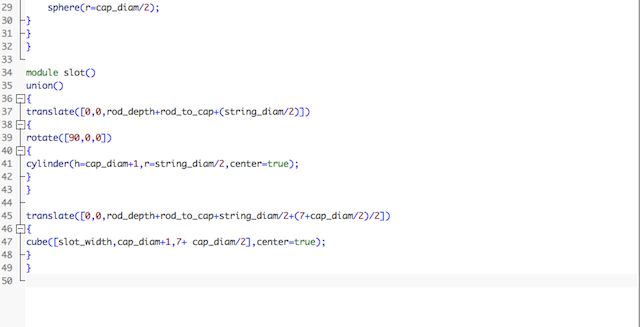

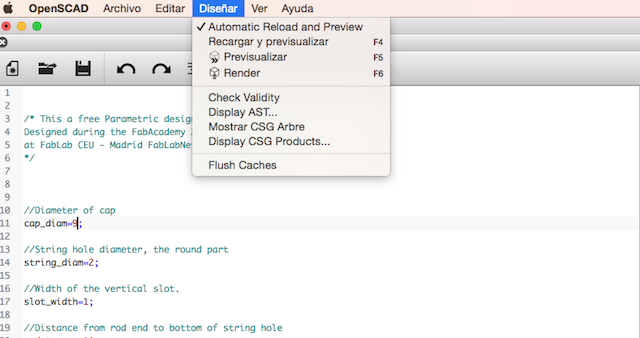

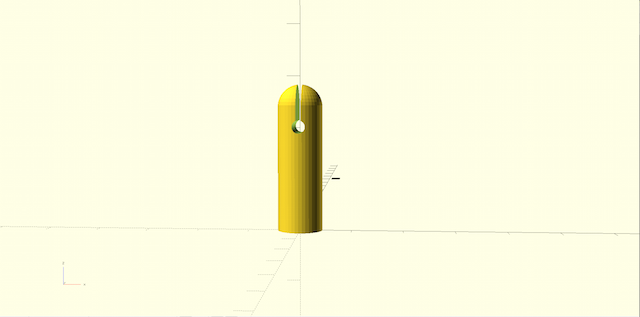

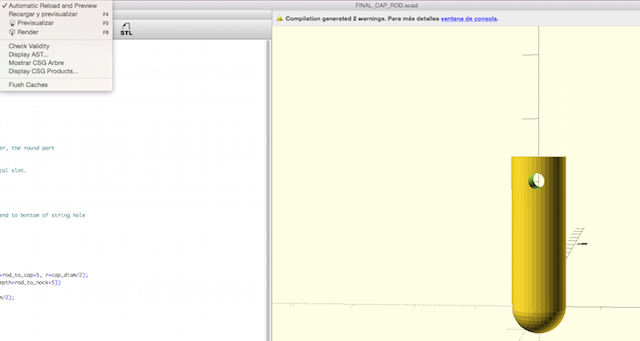

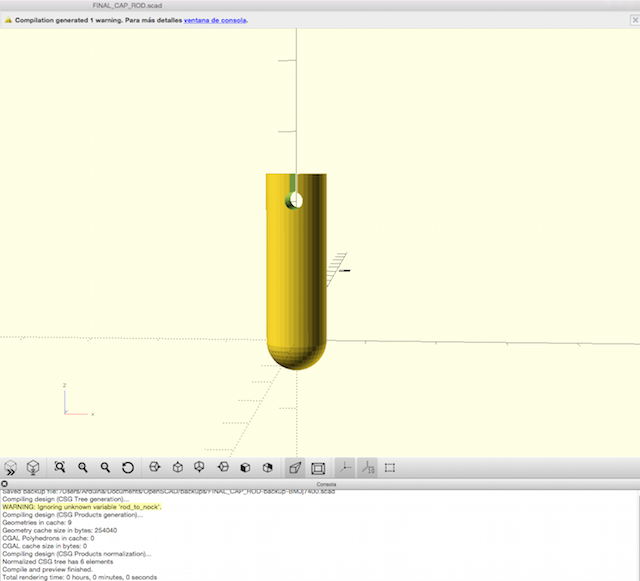

My prototype has essential mechanisms that work as connectors giving flexibility to carbon fiber tubes. These connectors are in the center rod and the sides. In the molding and casting week, I decided to begin a design for an 8mm rod that i could adapt by designing another part that would allow me to perform flights without integrating the electronics first so i designed a hub adapter with openScad :

CONNECTORS DESIGN LEARNED TO ME HOW TO MADE AN APPROPIATE MECHANISM FOR MADE THE FIBER CARBON TUBES MORE FLEXIBLES, USING BOOLEAN FUNCTIONS AND FOLLOWING SUBSTRACTIVE FOR EVERY PROCESSES SO I GAINED HOW TO MAKE DIFFERENT KINDS OF CONNECTORS.

CONNECTORS : Can be designed with Open Sources such as OpenScad, TinkerCad or commercials as Cinema 4D

Faito v.01_ 6 FACES (Madrid version):

Here are some pics about the process and the results of my models readies for print at the 3D Printer.

For now more about the design of the Diedro´s and the Start for Rod, you can go to this pages :

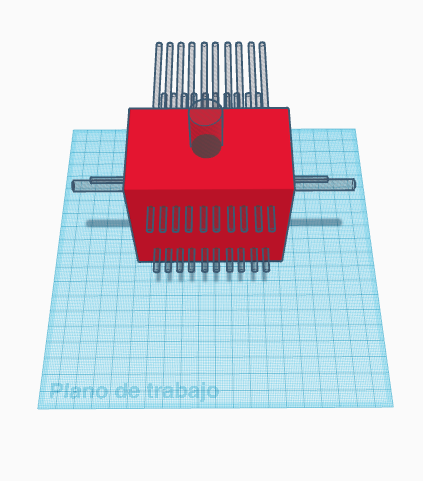

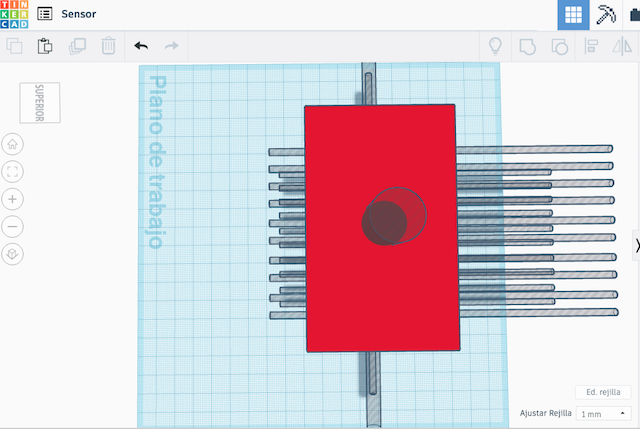

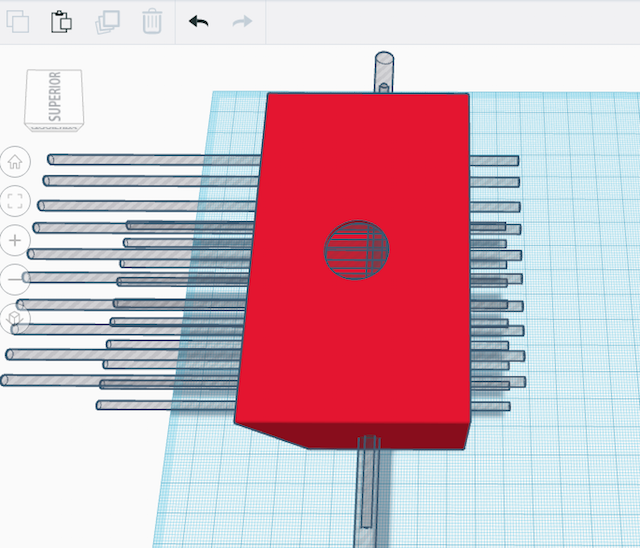

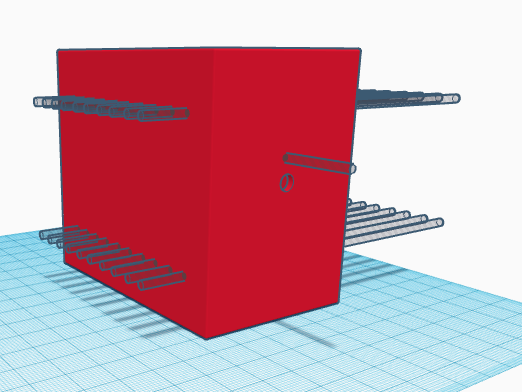

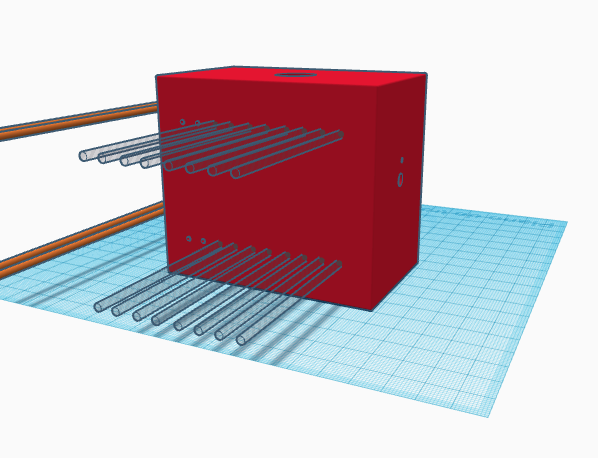

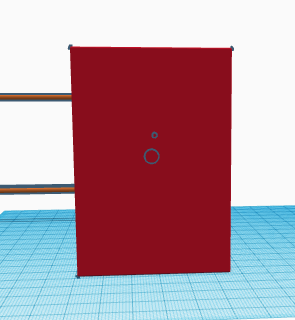

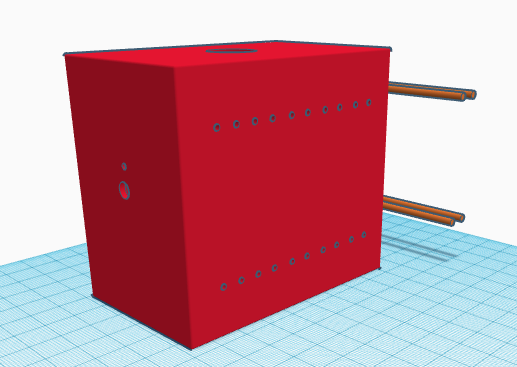

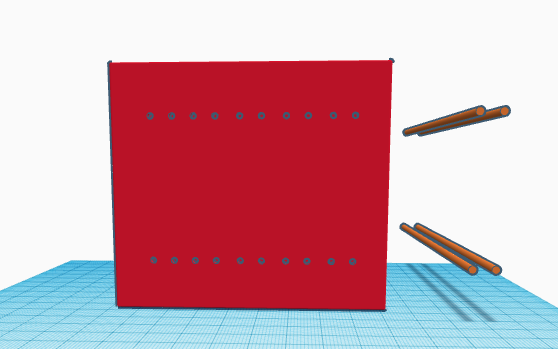

THE BOX FOR ELECTRONICS

The BOX The initial design of the Box that integrates the electronics in my prototype, was intended to be manufactured in the laser cutting machine with a light material such as balsa wood, (If you want to know more about this design processes just take a look the Interface and Applications WEEK

16) but for reasons of time i had to redesign a box that contemplated a minimum as weighth,very small and could be opened to show its interior. Rapid prototype that would need more than one attempt but that initially as my instructors would serve for the presentation. Also is an important part which can to be easyly designable by kids :

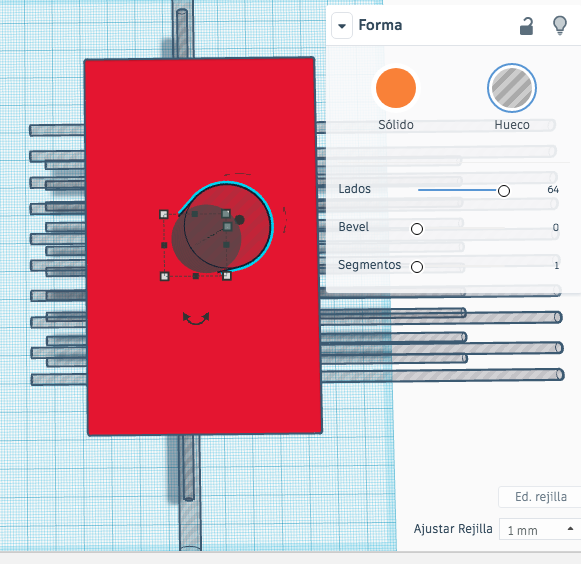

2nd ATTEMPT : The TinkerCAD attempt follow the addign and substractive techniques learned during the diploma is a basic design:

For make quick cut with basic design we can use any free software as fabnect :

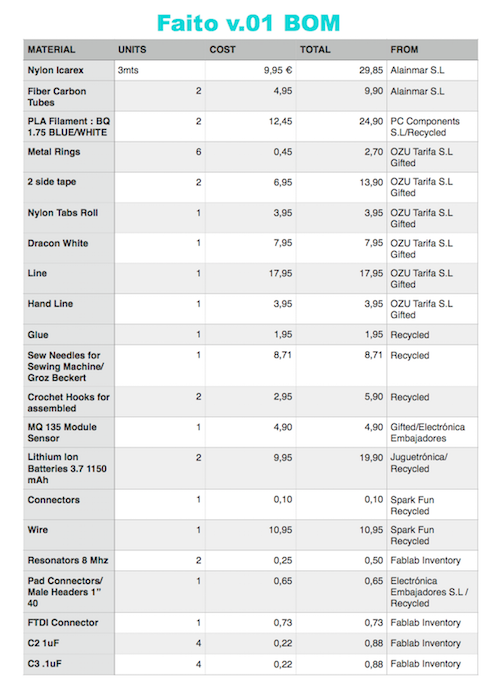

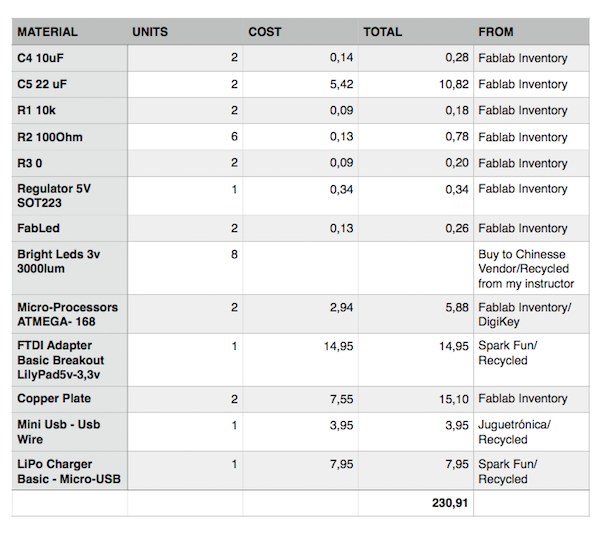

BOM : The bill of Materials

As i mentioned in the WEEK 17 the budget was reduce thanks to the support of a mini partner so here is the real if this opportunity didn´t to be able.

TECHNOLOGIES INVOLVES : FABRICATION

For the manufacture of the prototype i have used various tools such as Laser Cutting machine, 3D Printers, Milling machine and Sewing machine each of these technologies involves the knowledge acquired during each week but as i had new processes a can to learn new ones.

TECHNOLOGIES USED DURING THE DEVELOPE LEARNED TO ME HOW TO PRACTICE THE NEW SKILLS AT THE MACHINES LEARNED DURING THE DIPLOMA. HOW TIME I CAN TO SPENT IF EVERY THING GO WELL?

LASER CUTTER MACHINES: This technology made precise my patterns fastly for sew without problems. I had the opportunity to try some kinds of models of Laser Machine at differents FabLabs such our fablab, the IED Fablab and Sevilla Fablab during my greatings visits there.

At the manufacturing process on the laser cutting machine, made several testers. After the study and practices with different materials such as paper, cotton fabrics, nylon ripstop and nylon icarex for several weeks, finally i got the appropriate parameters to make a clean cut without burns or stains and perform my fabrics properly.

To cut my patterns i had the opportunity to visit the FabLab of the Institution where i work (IED FabLab) and that i had not been able to visit until the moment. They was really interested in my processes so after i commented all parameters used in the CEU Laser Machine, we was ready for Cut my patterns with success. Now they have in their library parameters new ones for new materials.

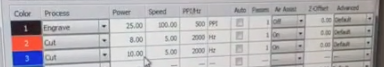

This was the parameters used at Fablab CEU testers commented noticed proper as the last one.

| POWER | SPEED | CORNER POWER |

|---|---|---|

| 60 | 20 | 12 |

| 80 | 16 | 14 |

| 70 | 14 | 11 |

| 40 | 18 | 16 |

The settings for cut the patterns at the IED were something differents because the materials for this time was ICAREX :

| POWER | SPEED | CORNER POWER |

|---|---|---|

| 10.00 | 5.00 | 2000 Hz |

3D PRINTERS MACHINES : Made Mechanisms described at Design section.

3D PRINTERS USE LEARNED TO ME HOW TO FAST I CAN MADE PRECISE AND REPEATED TASK, HOW I MUST TO SIMPLY THE DESIGNS,TOLERANCES FOR don´t MISS MATERIAL, NEW FILAMENTS...

FAITO v.01: 3D Printer Processes from Pilu Caballero on Vimeo.

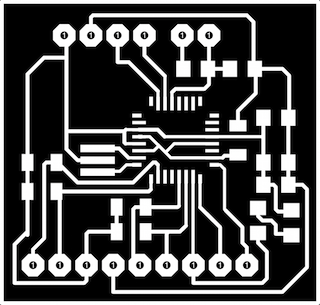

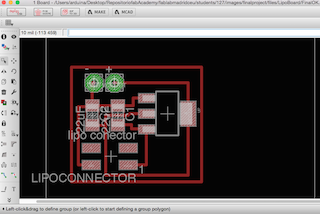

MILLING MACHINE : I used the Modela described during the Academy for mill the boards. The design processes are described below.

THE MILLING MACHINE USE LEARNED TO ME HOW TO BE CAREFULL WITH THE PROCESSES, HOW TO USE FABMODULES OR FABMODS,COMMUNICATIONS PROTOCOLOS,MEASURES FOR DESIGN, MILLS,HEADERS, HOW TO BE CAREFUL...IT´S MY FAVOURITE!

Faito v.01 : Electronics Processes from Pilu Caballero on Vimeo.

SEWING MACHINE: Here are some pics about the sewing process:

ELECTRONICS : Turn Faito to an interactive Kite

THE ELECTRONICS LEARNED TO ME HOW TO USE POWER REGULATORS FOR ION LITHIUM BATTERY SUPPLIES, HOW TO READ DATASHEET, HOW TO USE CAPACITORS RECOMENDDED, HOW TO USE A DIFFICULT SENSOR, HOW TO USE 3000 LUM 3V BRIGHT LEDS, HOW TO DESIGN MASTERS AND SLAVES. HOW TO DESIGN THE BOARDS FOR THE NEXT MODELS.

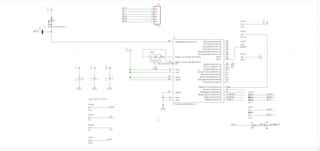

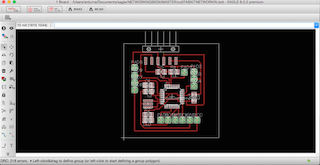

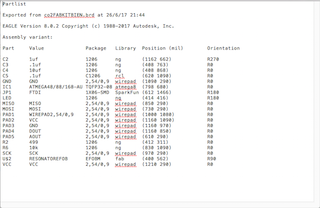

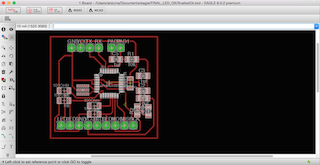

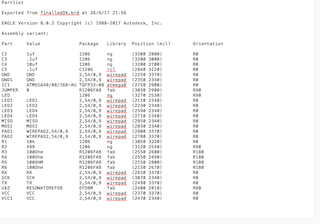

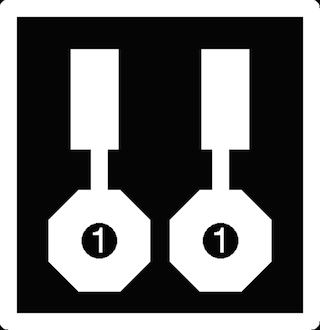

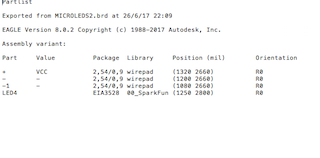

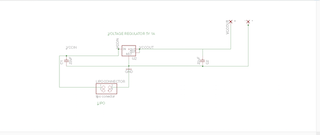

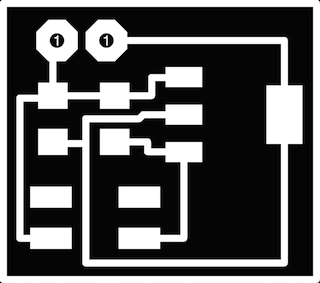

Faito v.01 have some boards inside designed with Eagle following the processes learned during the Academy :

1. A Master Board with an Input : MQ 135 Sensor described at my Final Project Page

2. An Slave with Outputs : Bright leds 3v / 3000 lm

3. Tiny boards for assembled for 3000 Lum 3v Bright Leds

3. A Board for Power Supply : Voltage regulator for Lithium Ion Batteries connected in Parallel.

DESIGN

MASTER

Designed at Networking and Communications Assignment :

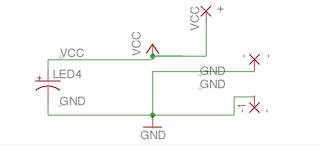

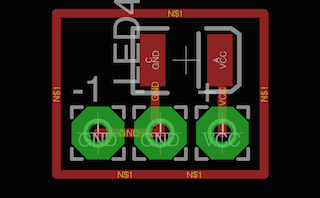

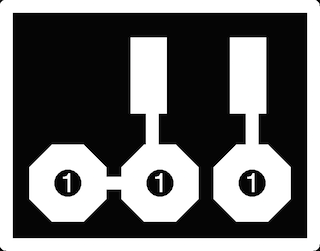

SLAVE and HIS TINY BOARDS

The leds are assembled at the kite so here are the tiny boards for them :

The board for the array :

During the Project development week i also designed the tiny boards for the Receive Board and the Power Supply board.

Boards for each led attached :

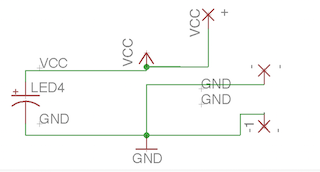

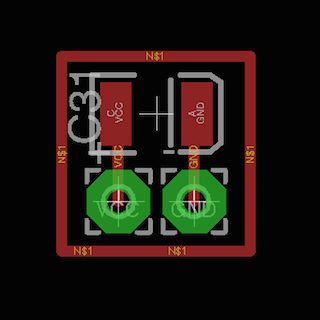

POWER SUPPLY

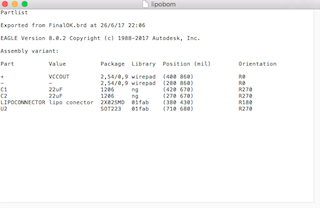

I connected 2 Lipo Power Supllies 3,7v 1150 mA each one, so i decided design a Lipo Board with a 5V Voltage Regulator from the fablab inventory :

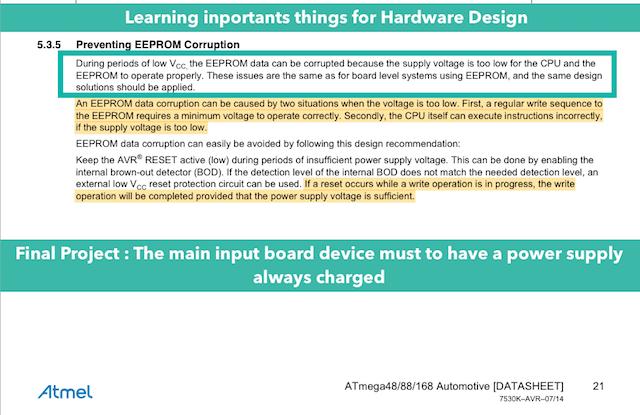

THE ATMEL 168P DATASHEET: THINGS I LEARNED AND HOW IT HELPED TO ME?

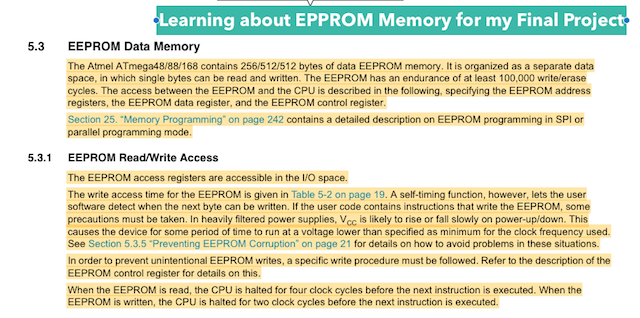

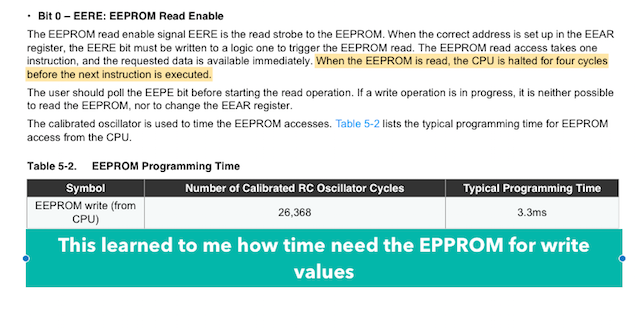

I learned a lot during the Diploma reading this Datasheet used in other assignments such as : Output Devices, Input Devices, Networking and Communications and Interface and Applications so for this part, i extxracted some simply things that helped to me a lot with the final programs for store the sensor values at EPPROM MEMORY.

And here you can to navigate beetwen his three hundreds pages where i was making my anotations in parts used during the Diploma at Input Devices Assignment, Output Devices and Interface week.

PROGRAMING : Interface Pollution Data Values for use to Teach and Learn HOW TO RESPECT THE ENVIRONMENT

Faito v.01: Programing Processes from Pilu Caballero on Vimeo.

THE PROGRAMING LEARNED TO ME HOW TO MADE A BASIC NETWORKING, HOW TO READ SENSOR VALUES, HOW TO USE APROPIATE VALUES FOR SEND TO SLAVES, HOW TO USE TEH DATASHEET FOR CODE, HOW CAN TO BE PROGRAMMED BY KIDS AND OPENED THE PROCESS FOR STORE DATA VALUES WITH THE USE TO EPROM MEMORY.

INPUT DEVICES send information data to OUTPUT DEVICES for Flash Bright Leds described at Electronics section.

So i had this Programing Files :

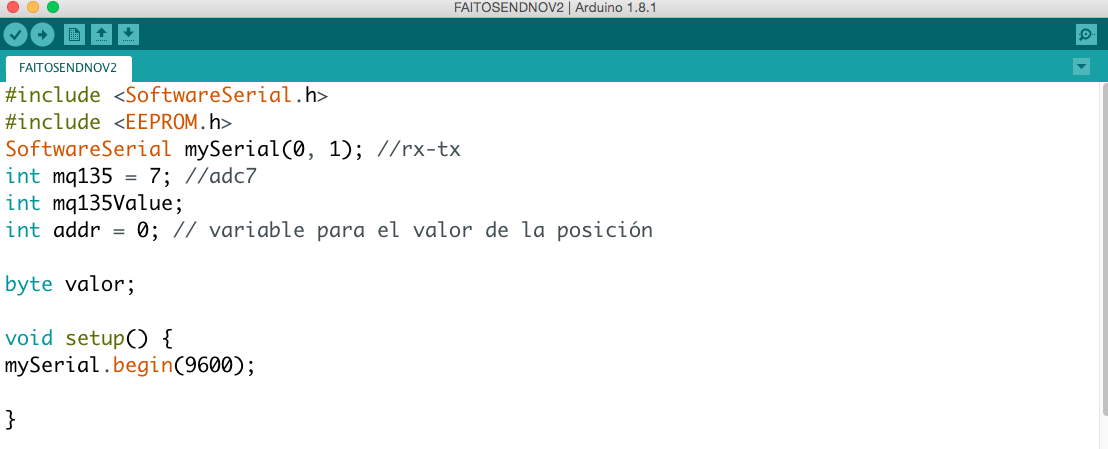

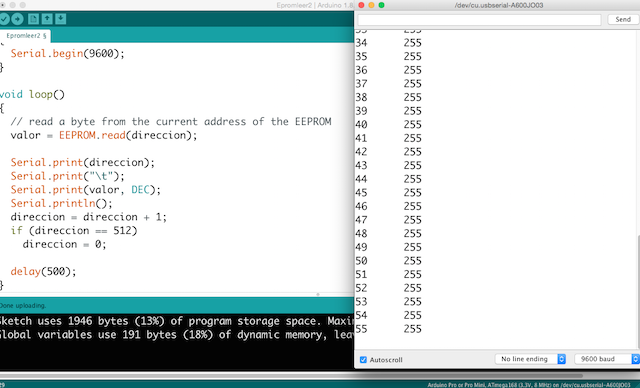

Faito Kite as i mentioned store data from the sensor during the flight so for this i use EPPROM memory from my processor for write there them and read when the kite stop his flights. For that i programmed some codes for send and receive the values trought the boards and another for read the values at my computer.

The micro-processor on any AVR based board has EEPROM: memory whose values are kept when the board is turned off (like a tiny hard drive). This library enables you to read and write those bytes. As i learned trought the Datasheet, my processor have 512 bytes on memory so the capability is limited.

The main functions used were :

EEPROM Read : Read the EEPROM and send its values to the computer troght monitor serial.

EEPROM Write : Stores values from an analog input to the EEPROM.

EEPROM Update : Stores values read from A0 into EEPROM, writing the value only if different, to increase EEPROM life.

Another library used of, course was software serial described before.

So here are the programms worked :

FAITO SEND AND WRITE AT EPPROM MEMORY

#include < SoftwareSerial.h>

#include <EPPROM.h>

SoftwareSerial mySerial(0, 1); //rx-tx

int mq135 = 7; //adc7

int mq135Value;

int addr = 0; // variable para el valor de la posición

byte valor;

void setup() {

mySerial.begin(9600);

}

void loop() {

int mq135Value = analogRead(mq135)/4;

EEPROM.write(addr, mq135Value);

EEPROM.update(addr, mq135Value);

mySerial.write(mq135Value);

Serial.print(mq135Value);

addr = addr + 1;

if (addr == EEPROM.length()) {

addr = 0;

}

delay(100);

}

As you can see i divided the Input Sensor value by 4 for have the data in bytes for store at the EPPROM memory.

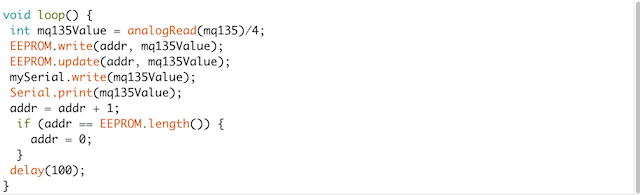

FAITO RECEIVE AND ACTIVATE LEDS

With this progamm the led board detect if the datas incoming from serial all availables and turn ON the array leds according an input i had previously studing the sensor.

#include <SoftwareSerial.h> SoftwareSerial mySerial(0,1); int input; int ledPin1 = 5; int ledPin2 = 6; int ledPin3 = 9; int ledPin4 = 10; int brightness; void setup() { mySerial.begin(9600); } void loop() { if (Serial.available()>0){ input=Serial.read(); if (input <'75'){ digitalWrite(ledPin1, HIGH); //Si el valor de input es 1, se enciende el led digitalWrite(ledPin2, HIGH); //Si el valor de input es 1, se enciende el led digitalWrite(ledPin3, HIGH); //Si el valor de input es 1, se enciende el led digitalWrite(ledPin4, HIGH); //Si el valor de input es 1, se enciende el led } else { digitalWrite(ledPin1, LOW); //Si el valor de input es diferente de 1, se apaga el LED digitalWrite(ledPin2, LOW); //Si el valor de input es diferente de 1, se apaga el LED digitalWrite(ledPin3, LOW); //Si el valor de input es diferente de 1, se apaga el LED digitalWrite(ledPin4, LOW); //Si el valor de input es diferente de 1, se apaga el LED } } }

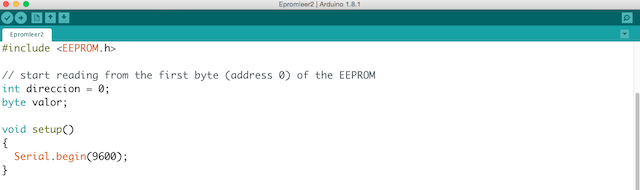

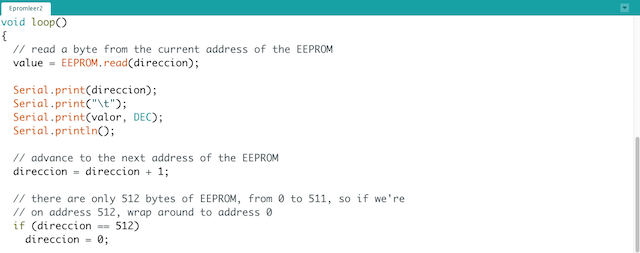

EPPROM READ DATA BYTES

This the program for read the data stored during the flights which print at monitor serial the data incoming from the sensor in bytes.

#include <EEPROM.h> // begin reading from the first byte (address 0) of the EEPROM int direccion = 0; byte valor; void setup(){ Serial.begin(9600); } void loop(){ // read a byte from the current address of the EEPROM value = EEPROM.read(direccion); Serial.print(direccion); Serial.print("\t"); Serial.print(valor, DEC); Serial.println(); // advance to the next address of the EEPROM direccion = direccion + 1; // there are only 512 bytes of EEPROM, from 0 to 511, so if we're // on address 512, wrap around to address 0 if (direccion == 512) direccion = 0; delay(500); }

LICENSE

Faito v.01 have a Creative Commons License explained at my Intellectual Property Page :