Week03: computer-controlled cutting

Assignment

- group assignment: make lasercutter test part(s), varying cutting settings and slot dimensions

- individual assignment: cut something on the vinylcutter

design, make, and document a parametric press-fit construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways

group assignment

make lasercutter test part(s), varying cutting settings and slot dimensions

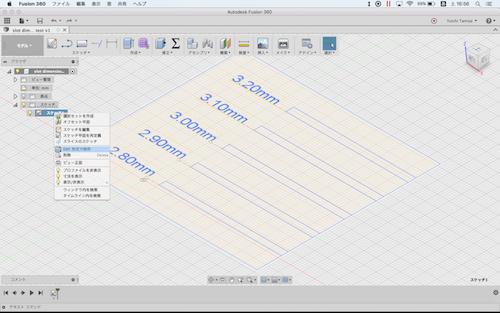

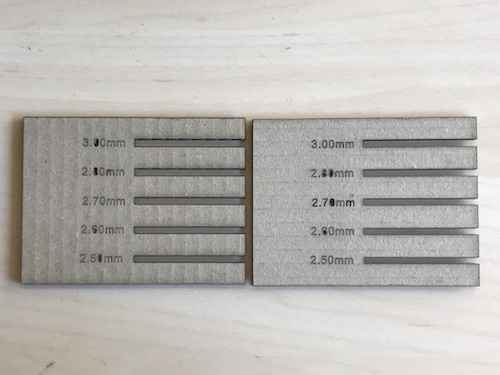

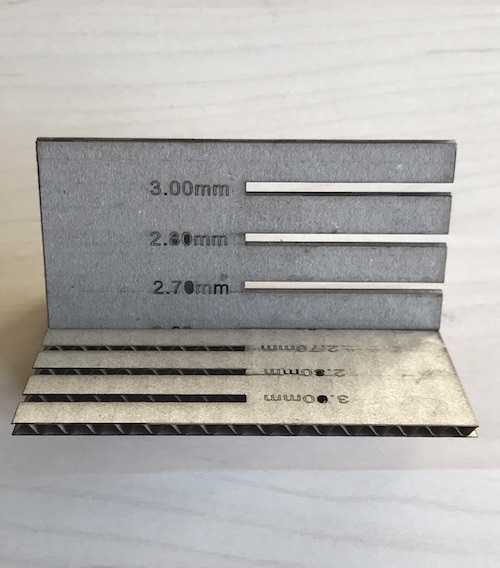

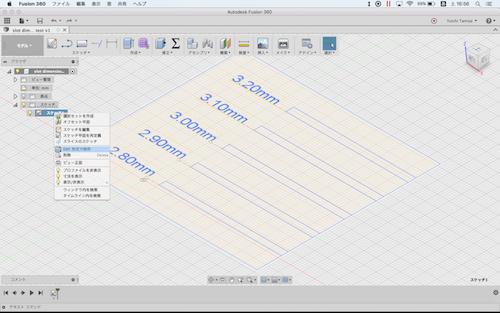

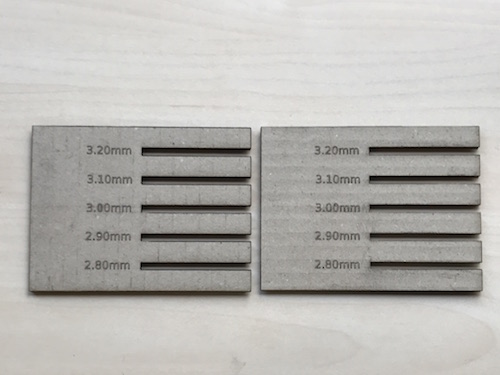

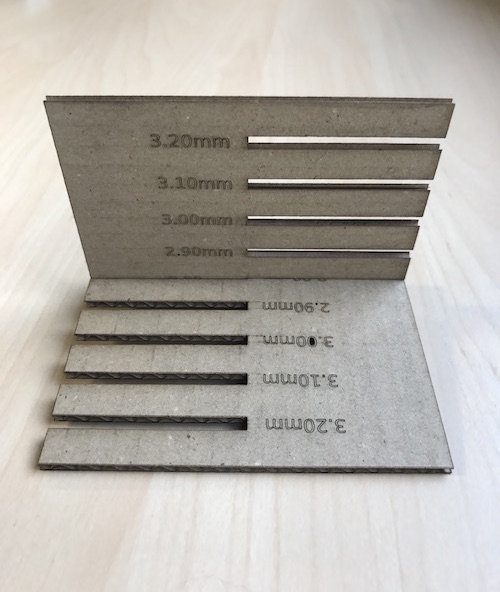

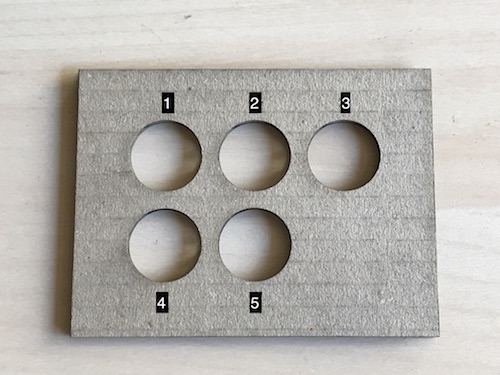

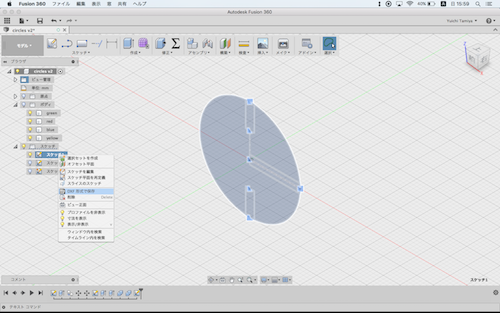

I made the slot dimensions sample board by fusion 360. My card board thickness is approximately 3mm. Test slot dimensions are 3.0 ± 0.2 mm.

Then export to DXF file.

download .f3d

download .dxf

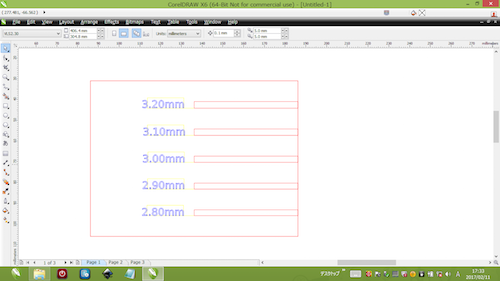

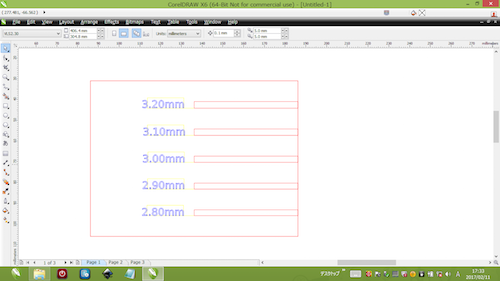

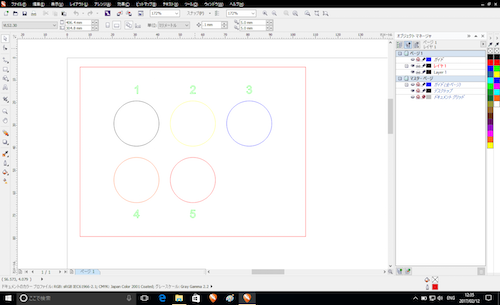

Open DXF file in CorelDRAW. Re-type the text which did not import correctly and set line color for laser cut.

download .cdr

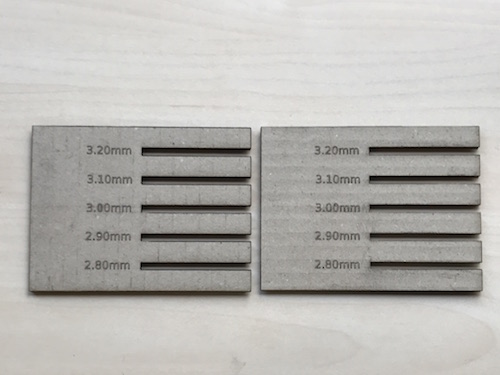

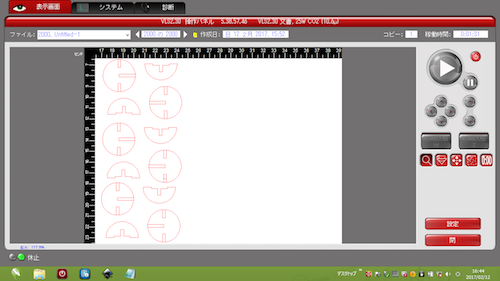

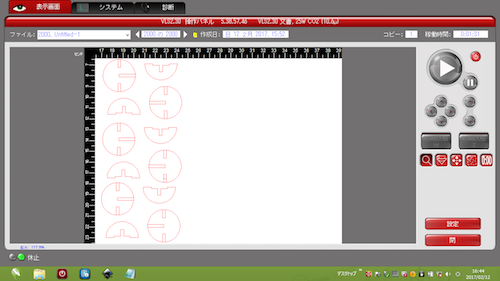

Send data to laser cutter's driver

Laser Cutter: Universal VLS 2.30

Material: approx. 3mm cardboard

| Parameter |

POWER(%) |

SPEED(%) |

PPI |

| Vector cut line(red) |

100 |

11 |

500 |

| Vector text(blue) |

13.5 |

24 |

500 |

| Vector (yellow) |

skip |

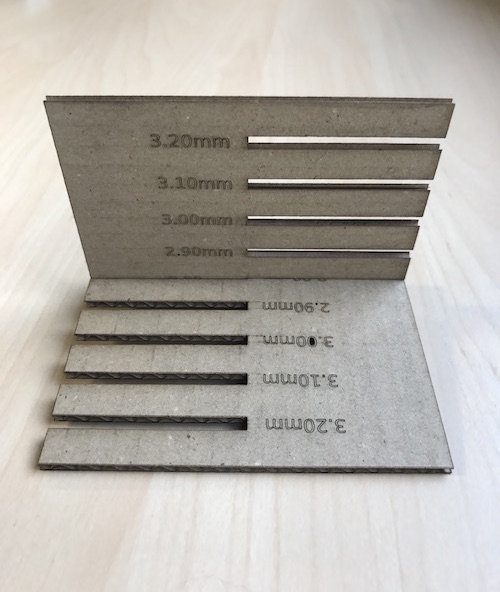

Slot dimensions 2.80mm fitted well, but may not be enough to keep other piece strong.

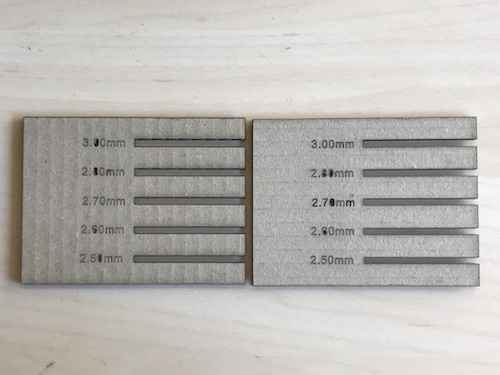

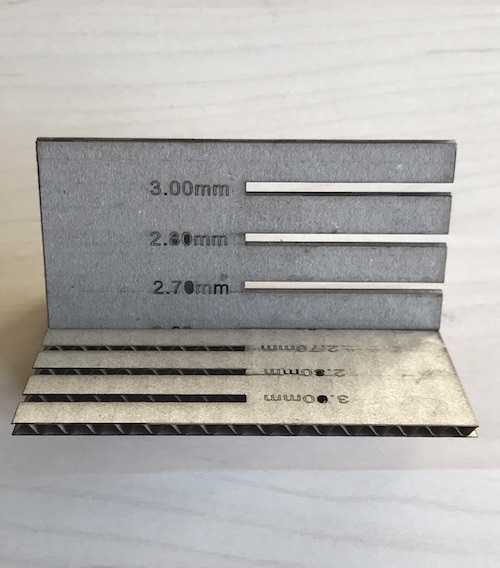

So, I made the narrow slot dimensions sample.

download .cdr

Slot dimensions 2.60mm is strongly fitted to hold each other.

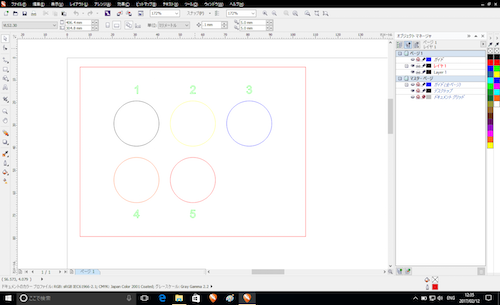

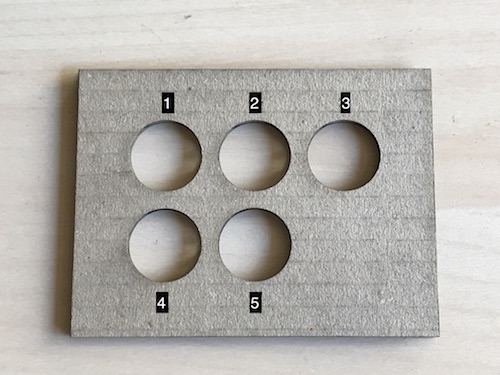

Vector cut line (red) parameter made much soot, so I try to find better soot less parameter.

download .cdr

No.5 Red is the same as cut line of slot dimensions sample.

I tried some faster speed and less PPI.

| Parameter |

POWER(%) |

SPEED(%) |

PPI |

| 1 |

black |

100 |

20 |

400 |

| 2 |

yellow |

100 |

17 |

400 |

| 3 |

blue |

100 |

17 |

500 |

| 4 |

orange |

100 |

11 |

300 |

| 5 |

red |

100 |

11 |

500 |

All circles are cut. No.1 was very less soot. So I will use this parameter to make press-fit kit.

individual assignment

cut something on the vinylcutter

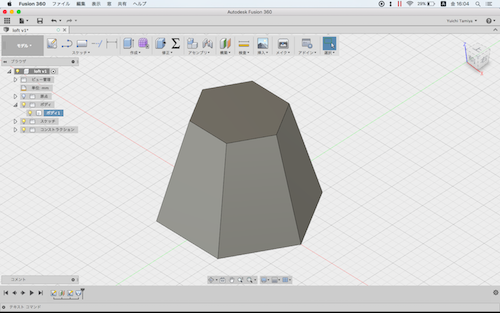

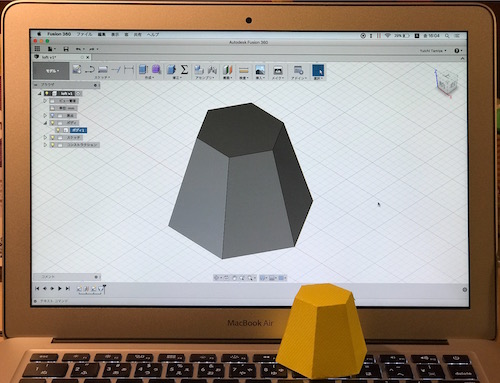

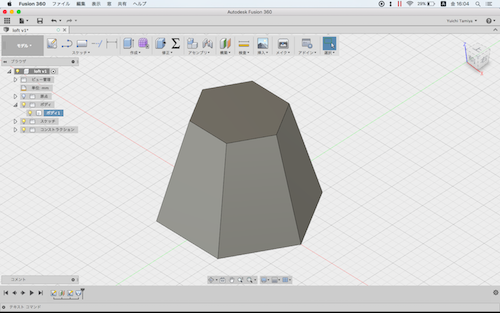

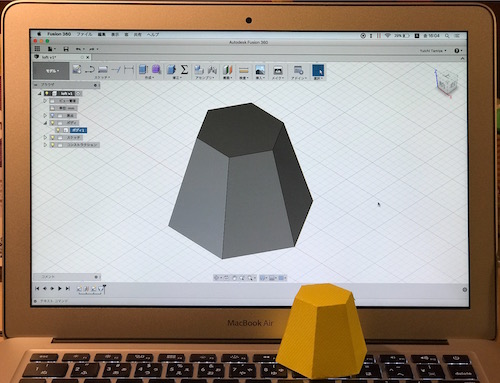

I made a simple STL object by Fusion 360.

download .f3d

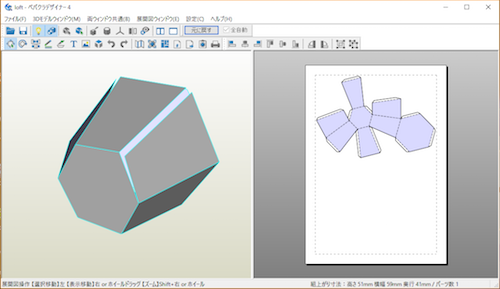

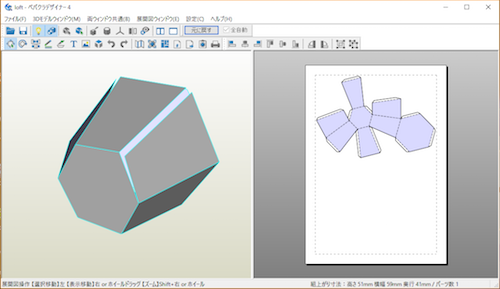

Import STL file to Pepakura and make it flat.

download .pdo

Then, export to DXF fire.

download .dxf

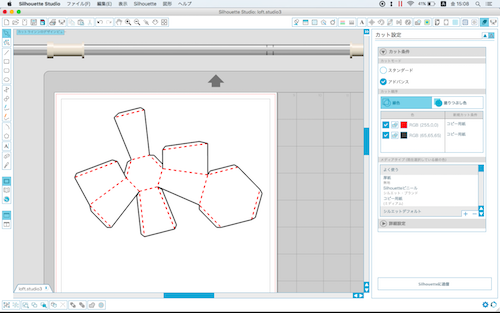

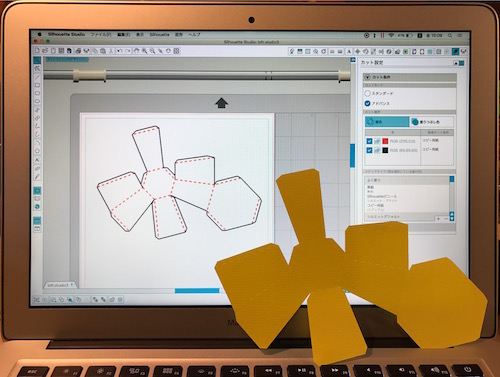

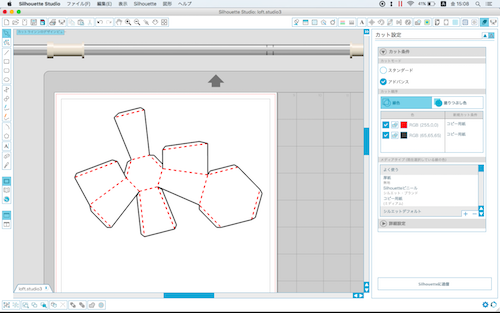

Import the DXF file to Silhouette Studio

download .studio3

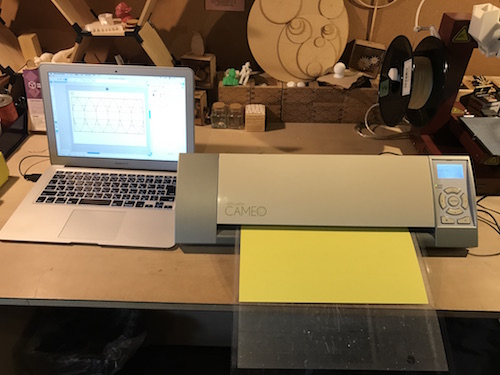

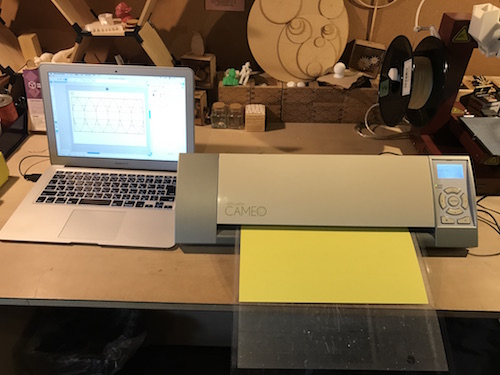

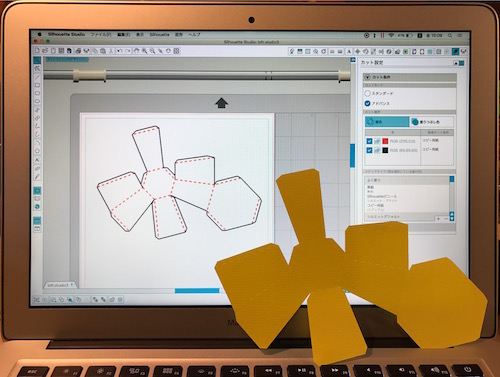

Cut by Silhouette CAMEO

Then fold....

Paper Cutter is very useful tool to cut thin material. I almost think Paper Cutter is older style than Laser Cutter in any ways, but it is not correct. Paper Cutter is still one of the choices in digital fabrication.

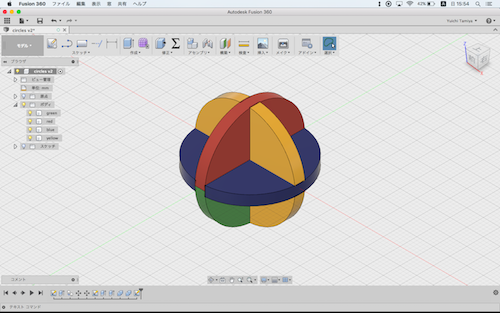

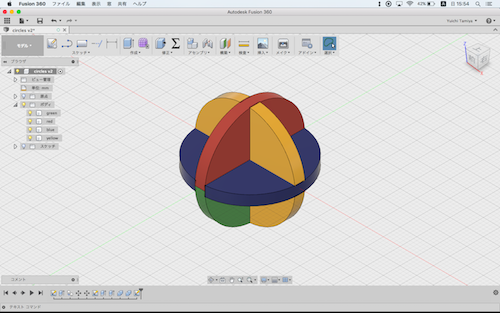

design, make, and document a parametric press-fit construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways

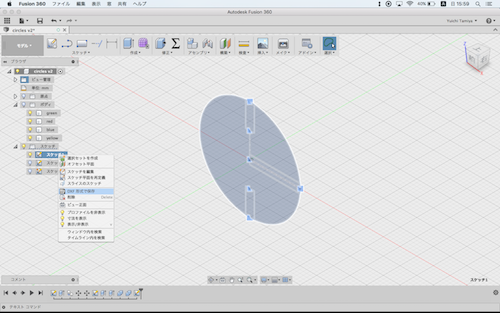

Design 3D model by fusion 360

download .f3d

Then export DXF file from each sketch

download .dxf

download .dxf

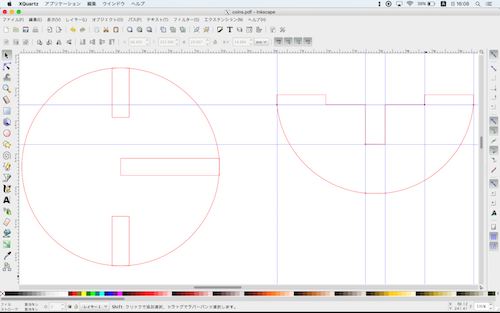

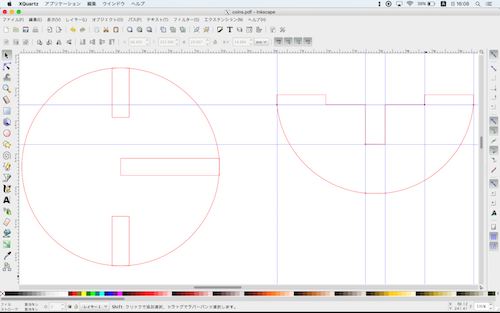

Import DXF files to inkscape, then adjust lines and set line color for laser cut

Import to CorelDRAW and send to Laser Cutter driver

download .cdr

Then cut

Assemble one unit

Assemble in multiple ways