Week 9 - Mechanical design

This weeks assignement is the start into machines that makes machines so I will make a machine!

First the mechanical approach and later it will be electronically contolled.

This is a team assignement and I work together with the folks form incitefocus at the Fab Lab Detroit.

We will assemble several modular machines to one big machine. The goal is to have an automated mount for a

camera, which moves in x and y direction and is able to rotate. Our start is the linear

cardboard stage.

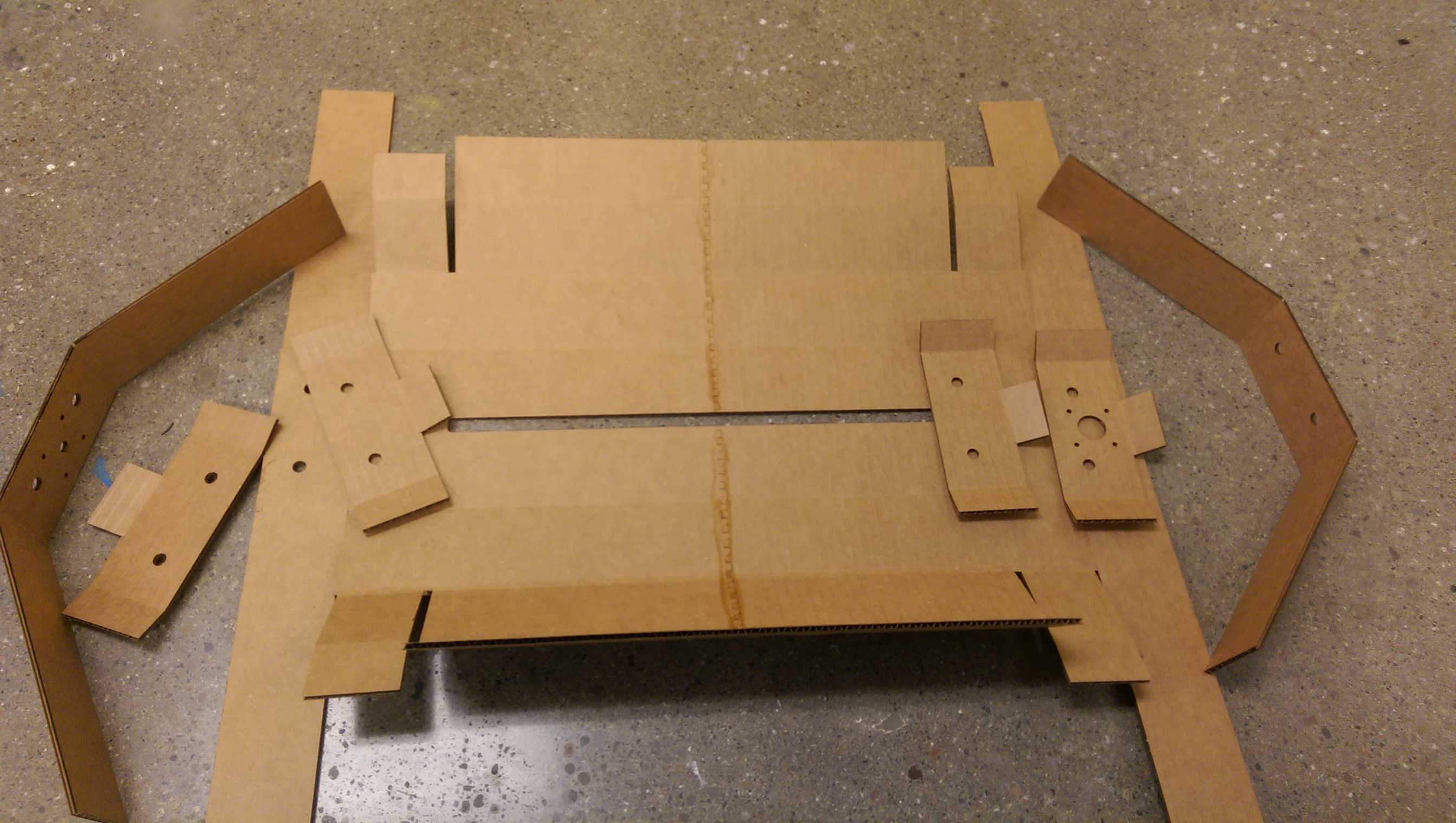

I used this

file

but since our Lab has a Epilog Fusion M2 75 W laser with a working plane of

20"x30", I needed to adapt the bigger piece. I have made a fit joint over the whole lenght and glued it together.

I used the standard lab UHAUL cardboard with 0.15" thickness. It works fine so far. Here are the two parts

1 and

2.

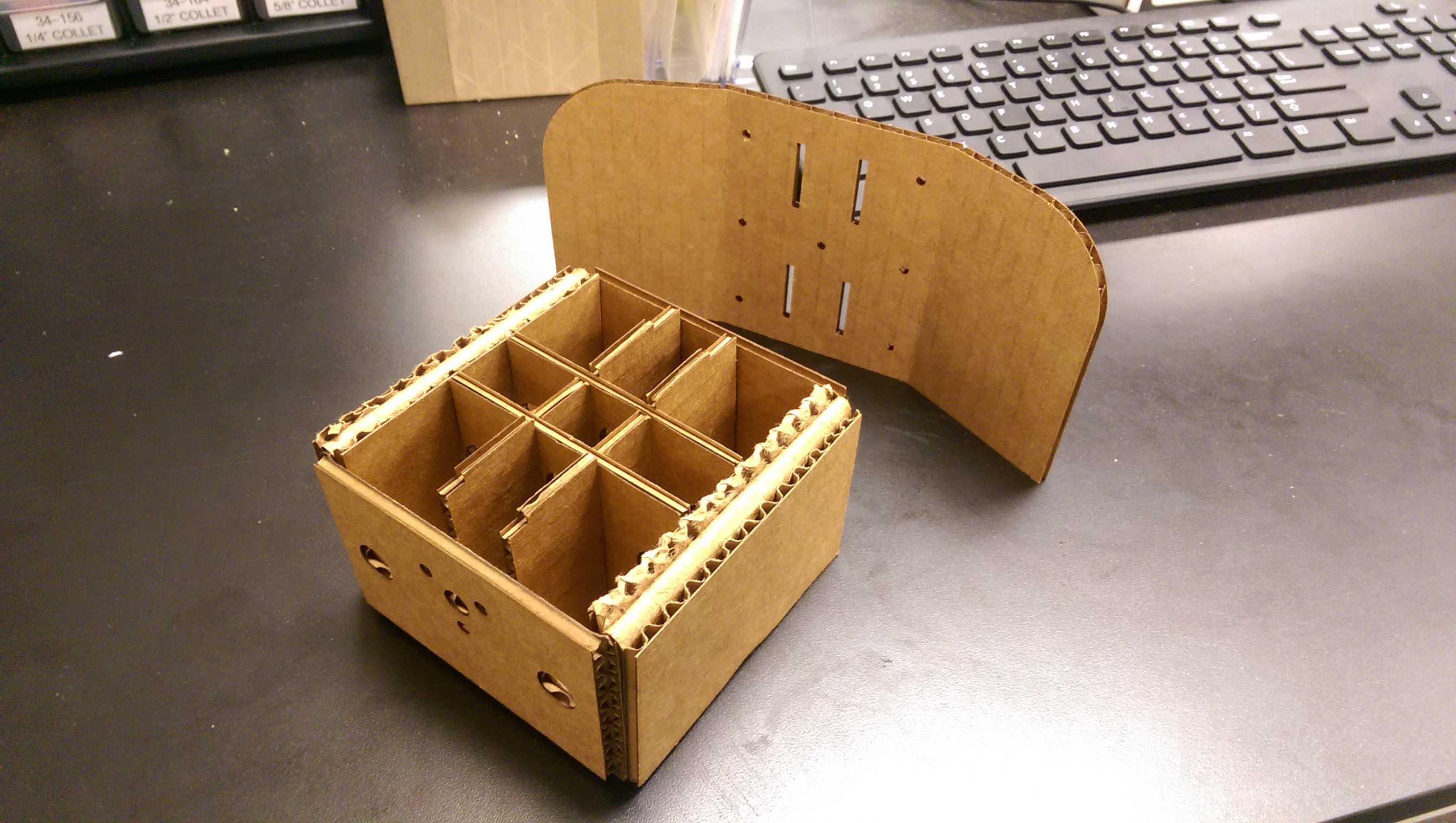

For the assembly I had the motor with the thread, the pvc washers, the aluminium rods and some screws to hold the motor and the thread in place.

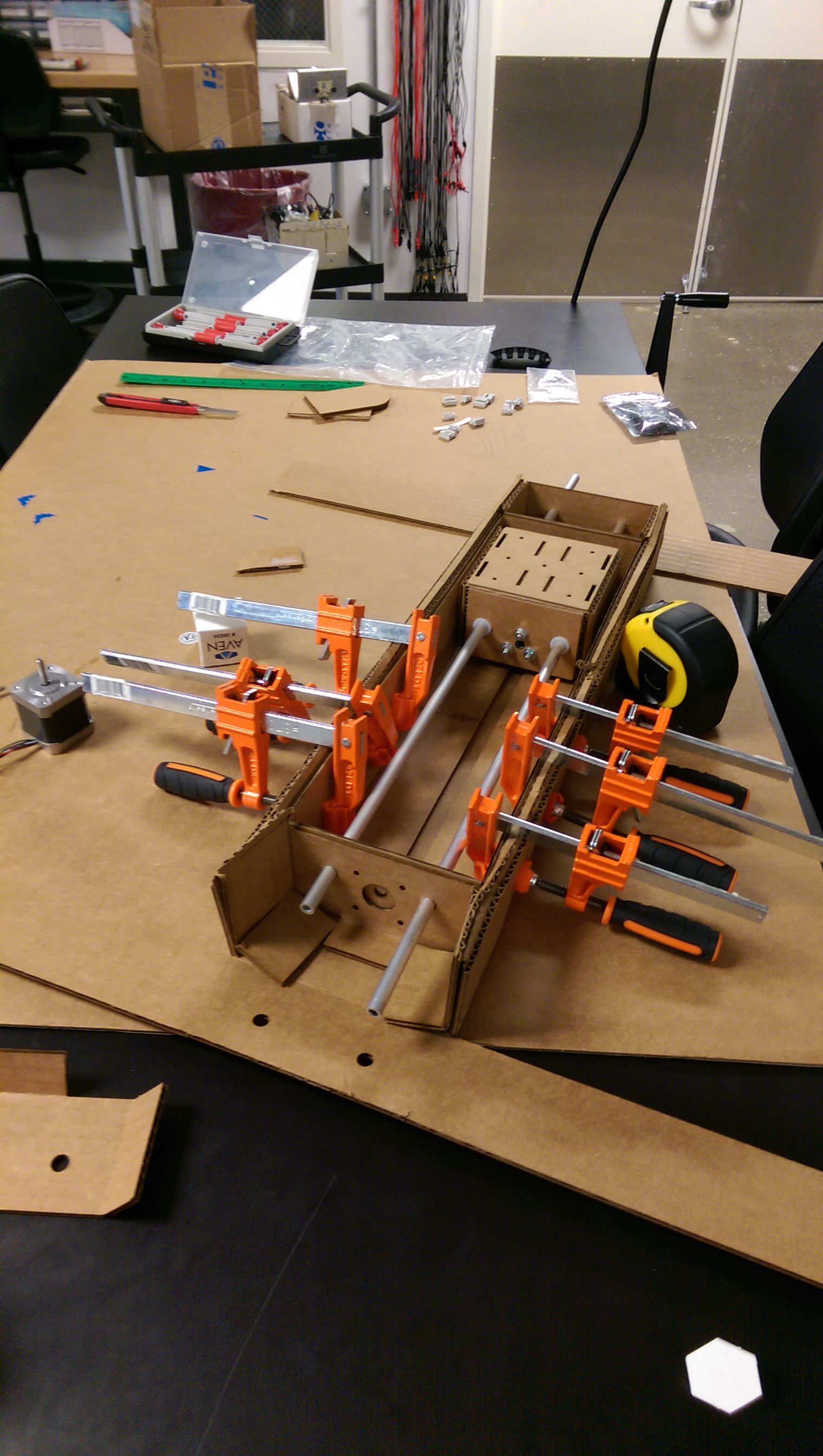

The next step was the assembly of the whole piece. To get a good binding, I clamped the sides.

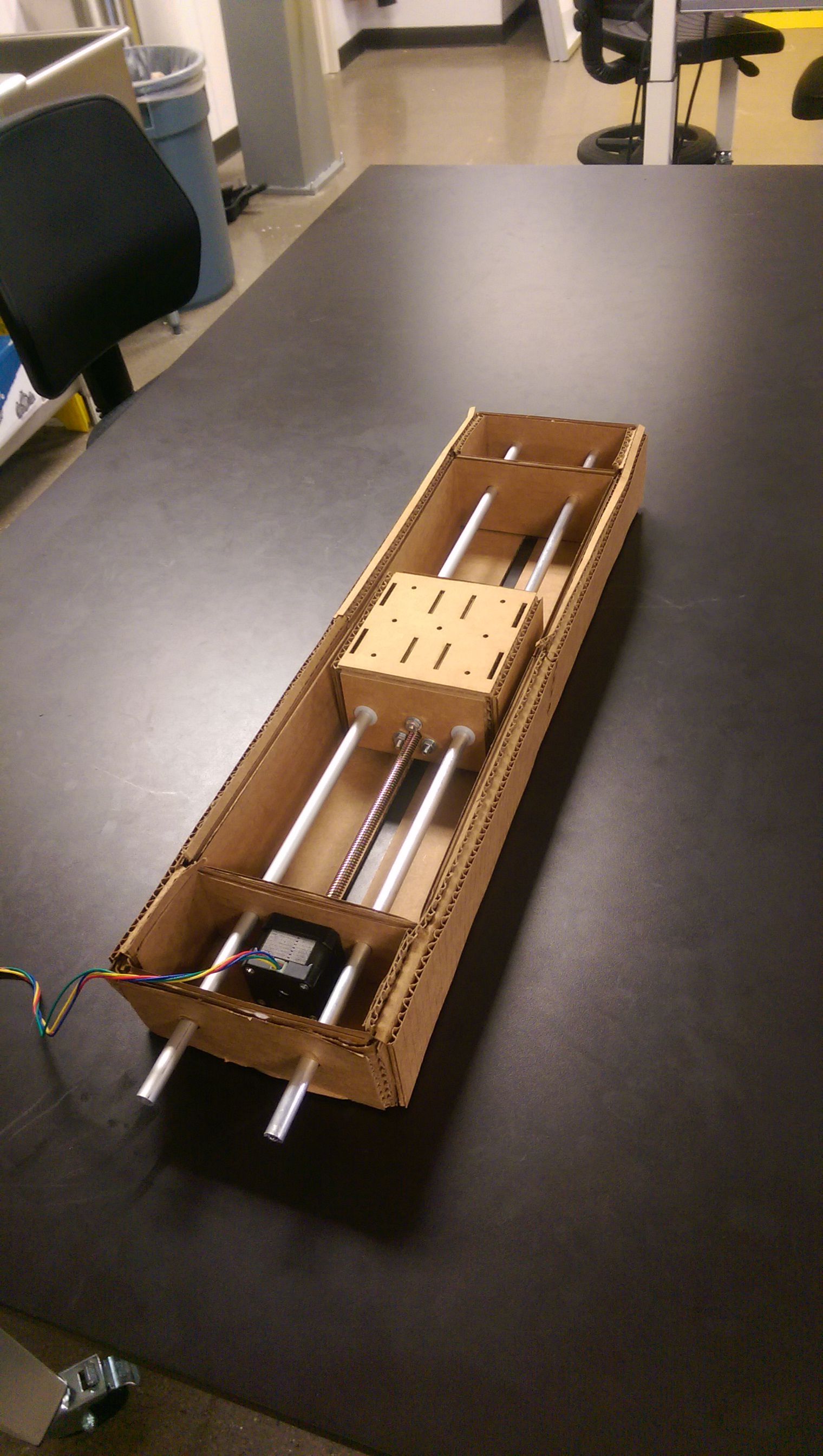

And step by step I finished the linear cardboardstage.

The control of the motor is done by the gestalt node board.

Sorry for the video beeing rotated.