Final Project

It is hard, to think of a final project yet, since I have so much to do but sine I am always anxious to gain a little more

comfort, I will make a Bootie Dryer. After surfing, I can put my wet booties on it and shorten the dry time. Especially, in

shadow places and during the night. The result, nice dry booties on the next morning and no hard feelings regarding a cold wet

bootie experience, when going surfing again.

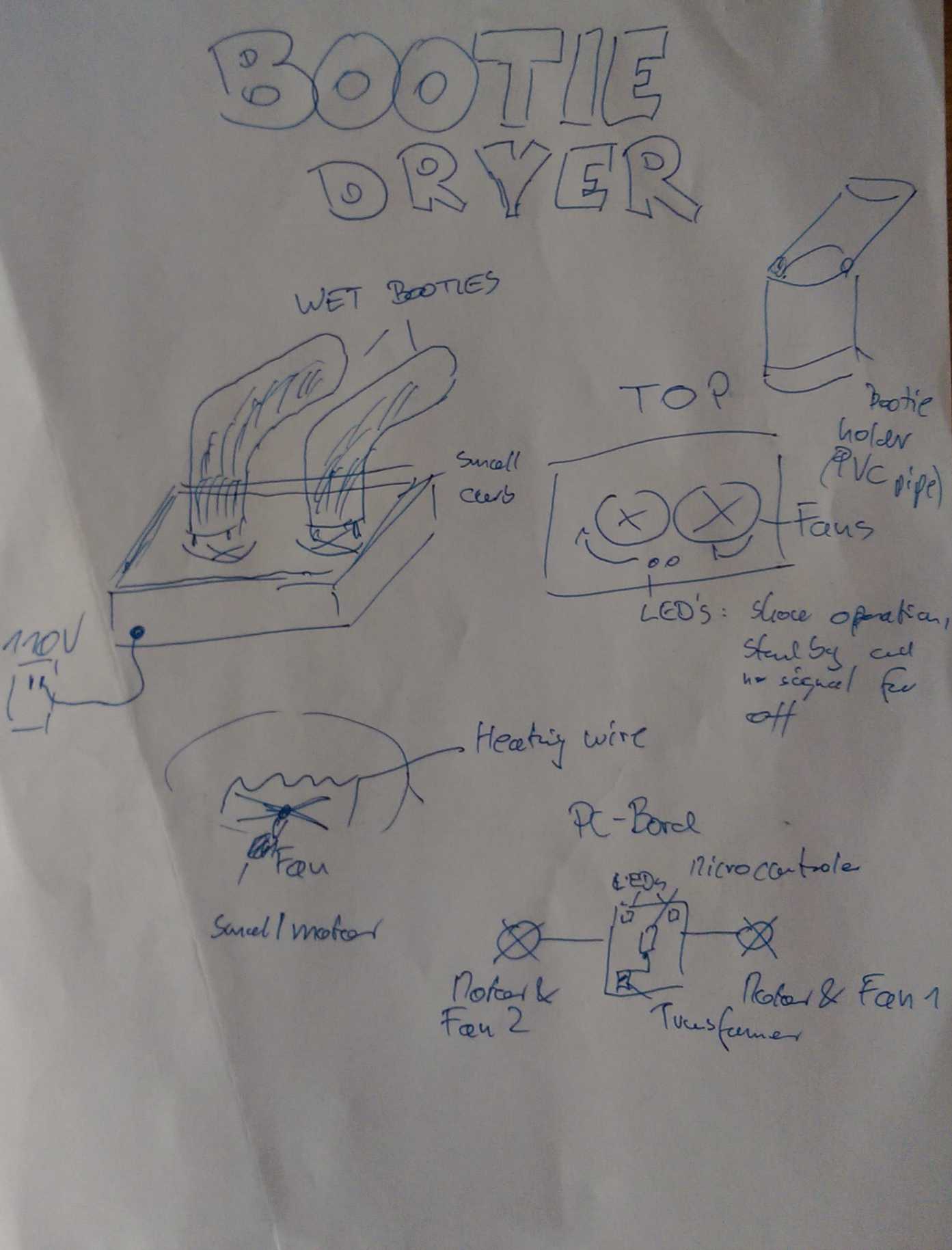

First priority is the time frame. I split my project into several modules, to use the lab space and equipment in a reasonable and efficient way. This project allows me to combine the skill of several lectures: 3D design and 3D printing, 2D design, composites, electronics design and microcontroller programming. The housing of the dryer, I will make with plywood, which I will cut with the laser. To make it waterproof, I will cover the surface with fiberglass and epoxy. As holders for the booties, I will use PVC pipes from a hardware store. To combine them with the housing, I will make a 3D printed connecting piece. Inside the housing is the whole electronics. Since I will plug it in the wall, I need a transformer. With a microcontroller I will control two motors, to blow air into the bootie holders. The air, I want to heat with some wire setup. I need to dig in the web for ways to do that. The temperature and some LEDs for the status of the dryer, I will control with the microcontroller as well. That is my idea so far, I will add more with the time. For the intrigued reader: If you have some comments or feedback, please shoot me an email (see contact tab).

What will my final project be like

To describe my Booty Dryer I will break it down into several points.

What will it do

The pupose of my Booty Dryer is to dry my booties after surfing. I will put them on the holders and switch on the fans and the heating device. I will make the whole housing waterproof to avoid any damages to the electronics inside.Who's done what beforehand

There are already severeal commercial varaiations of this on the market for around 50 Dollars. There are also several DIY versions, which are less sophisticated. My version will be simple but effective and costs less.What materials and components will be required?

I will use 6 mm plywood, fiberglass and epoxy for the chassis and 2 inch PVC pipes for the holders. The connection wood-PVC I will 3D print, probably PLA. The electronics will contain an Attiny 44A SSU, two DC motors and voltage regulators or transistors. As power soure I want to use the grid and an transformer to get at least 9V supply voltage for the board. The board I will design, mill and solder myself. Several cables, resistors and some LED's as function indicators.Where will they come from

The largest part of the materials will be outof the Fab Lab inventory. There are various vendors for that. The plywood, PVC, fiberglass and epoxy from home depot. The electronics from DigiKey or Jameco.How much will it cost

My plan is to drop the costs significant under 50 Dollars. I am envisaging something around 30 Dollars, which is my first guess.What parts and systems will be made

I will make a chassis of plywood, covered with fiberglass and epoxy. I will 3D-print the connctiosn for the PVC pipes and teh rotors for the air flow. I will make a circuit board to control the motors and the heater and to deliver power to this components. I will have sveral lights to show the operation status.What processes will be used

I will use 3D design with tinkercad or Solidworks, depending on the complexity od the parts. I already have a design for a rotor, which I can modify for the airstream. I will use PLA or ABS to make the connections and the rotors. I will use 2D design in Corel Draw to make the chassis and cut the parts with the laser cutter. I will then cover the housing with fiberglass and epoxy. For the design of the circuit board I will use Eagle and to cut it, the SRM-20 mill. To mount the electronics, I will use a soldering iron.What tasks need to be completed

Design and manufature the chassis, mount and install th PVC pipes, design and manufature the board and finally putting all togehter.What questions need to be answered

I will answer this, asthe questions appear. Firast I will start with the design and manufacturing of the chassis. The most challenging ap[pears to me for now the programming of the microcontroller. What drives me at the moment are the following questions.-

Is there enought time to do all this?

How to install the heating? Just a wire?

What is the proper ratio of airflow and heat, to get the booties dry? Guessing the ammount of water, which can be dried in a certain time intervall.

Due to the evaporation of the water in the booties, there will be condensation of the water due to the heat, needed for this process. have to think of a way,. to avoid water flowing back in the PVC pipes and endangering my electronics.