Week 3 - Computer-Controlled Cutting

In the third week, our assignment is to make ourselves familiar with computer aided cutting. For this purpose, I will use the vinyl cutter and the laser cutter.

Vinyl cutter

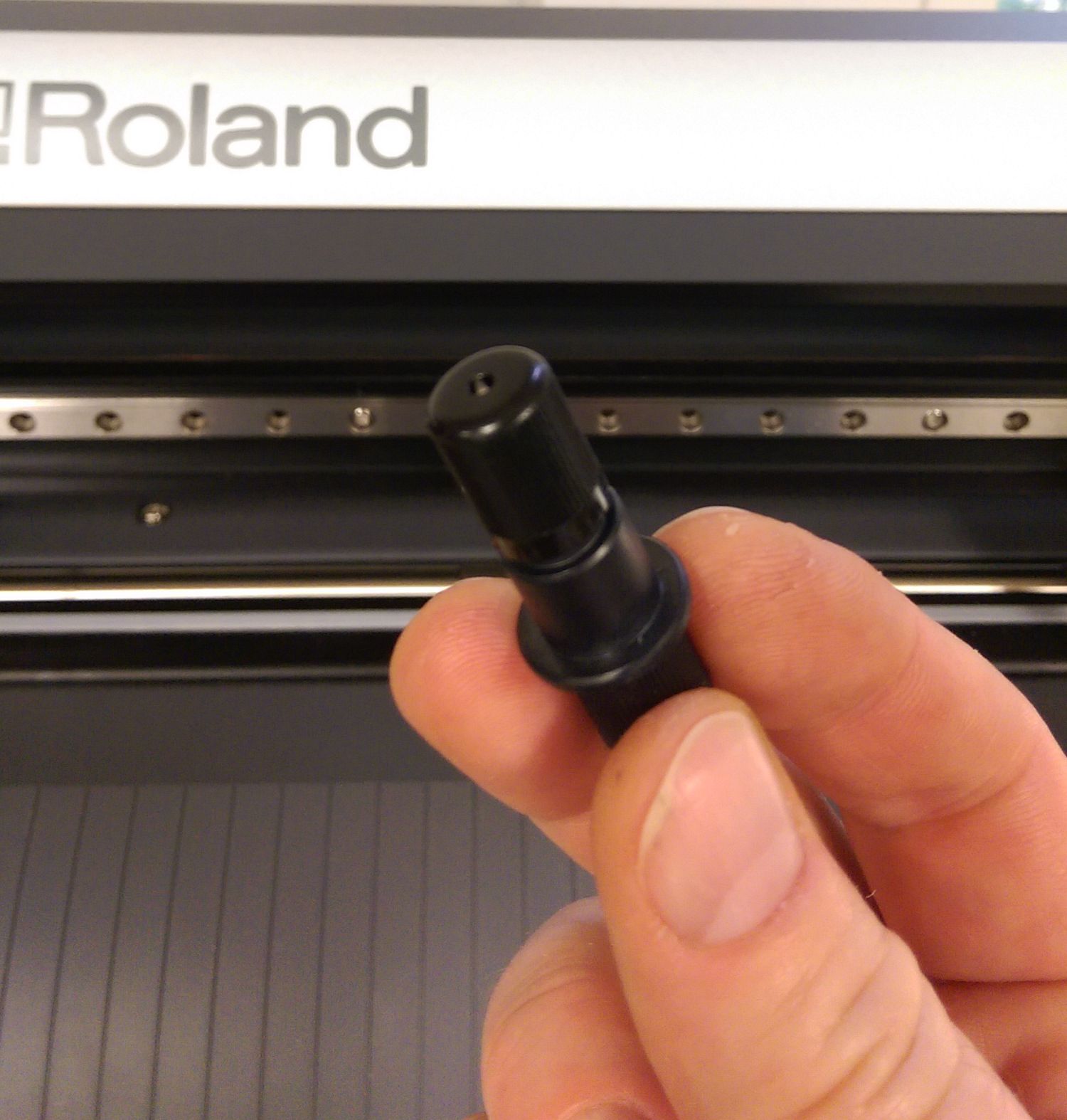

Our vinyl cutter is a Roland CAMM GX-24. You can cut rolls or sheets of various vinyl, tape, epoxy film and copper tape. Its is basically a knive, which is moved quickly over the vinyl. There are certain parameters, which you have to take into account to get better cut results. This is on the one hand side, the legth of the cutting knife, which is usually around 1 mm.

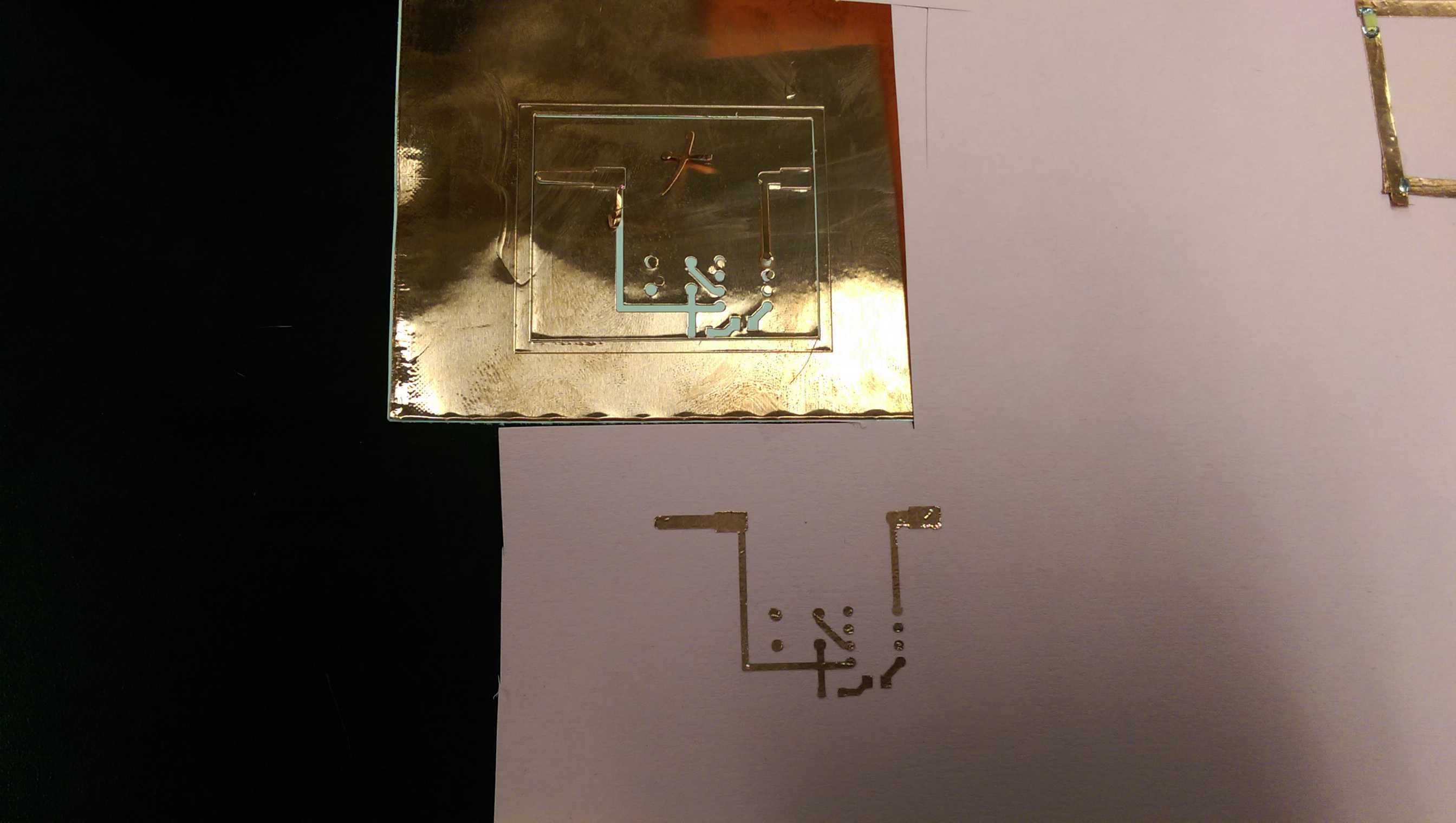

The other two important parameters are the cutting force, with that is the knife pushed on the material and the speed, whith that the knife is moved on the material. One has to take care of all of those parameters, regarding the material, what is beeing cut. The following pictures show some cute, I have made. The left one is a blue vinyl with the default settings Force: 80 gf and speed 20 cm/s.

In the left picture above, there is a little vinyl bat, which I made with the settings described. In the right picture is a circuit, which I cut out of copper foil with the settings in the following Link.

Laser cutter

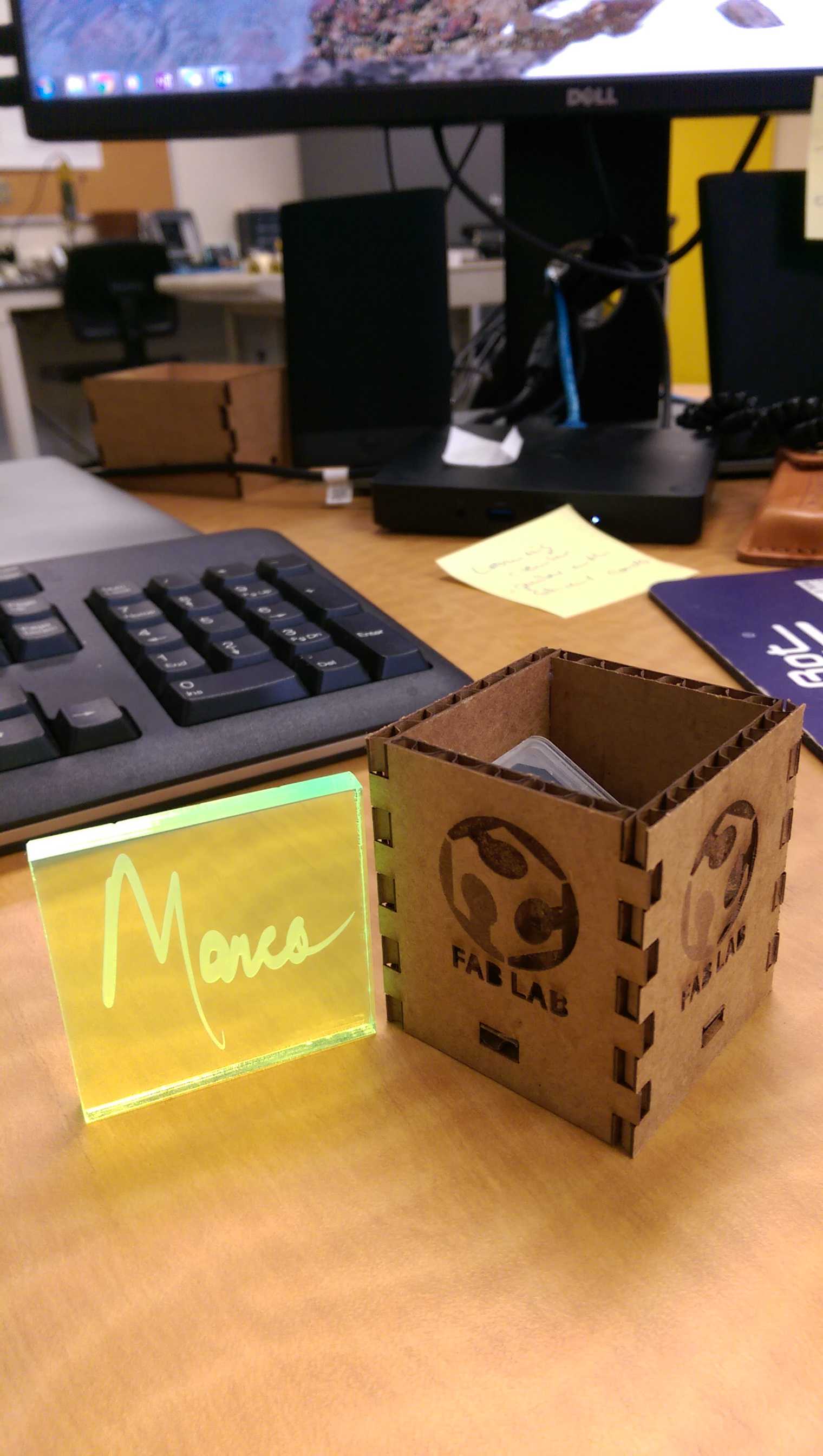

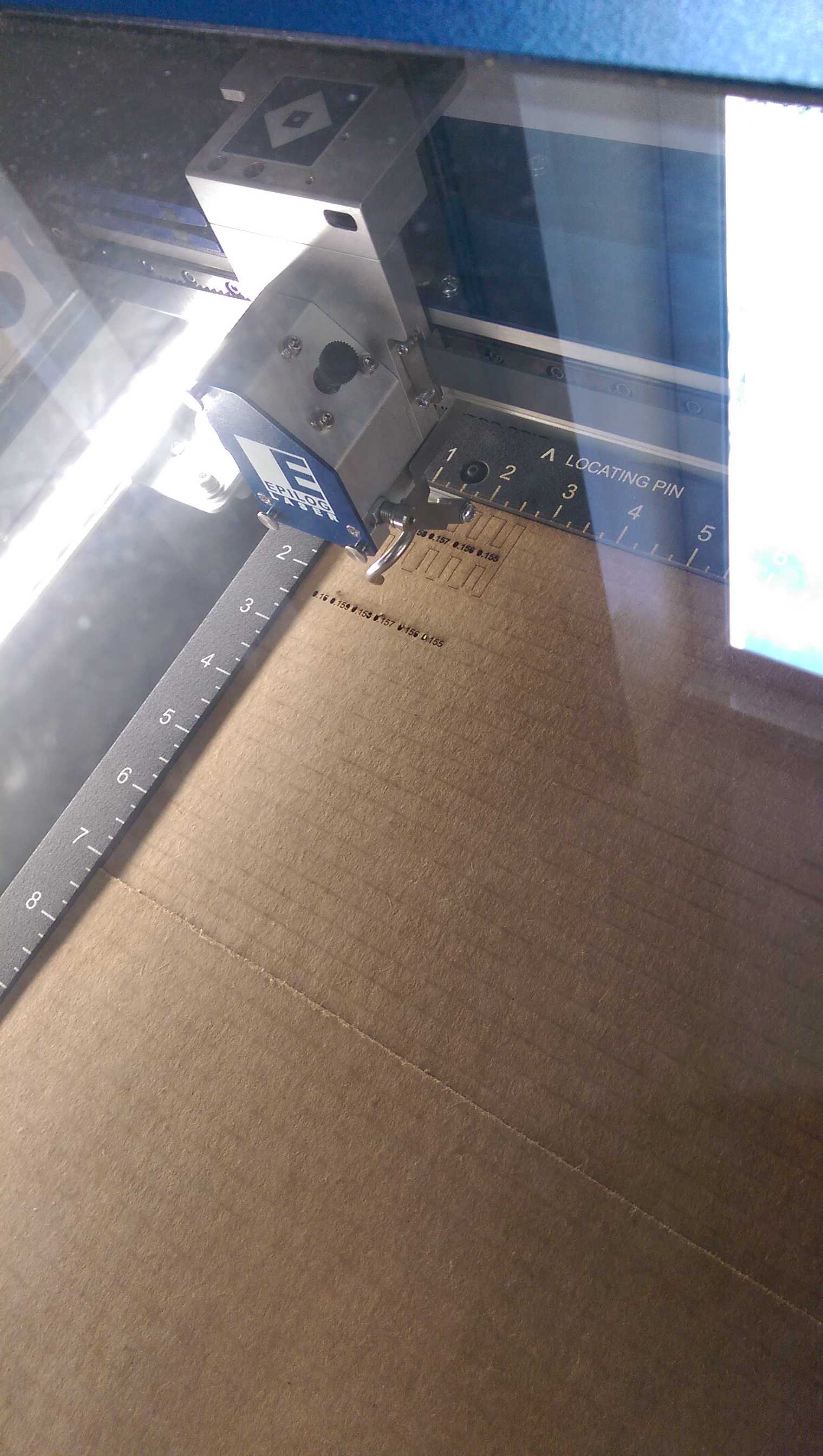

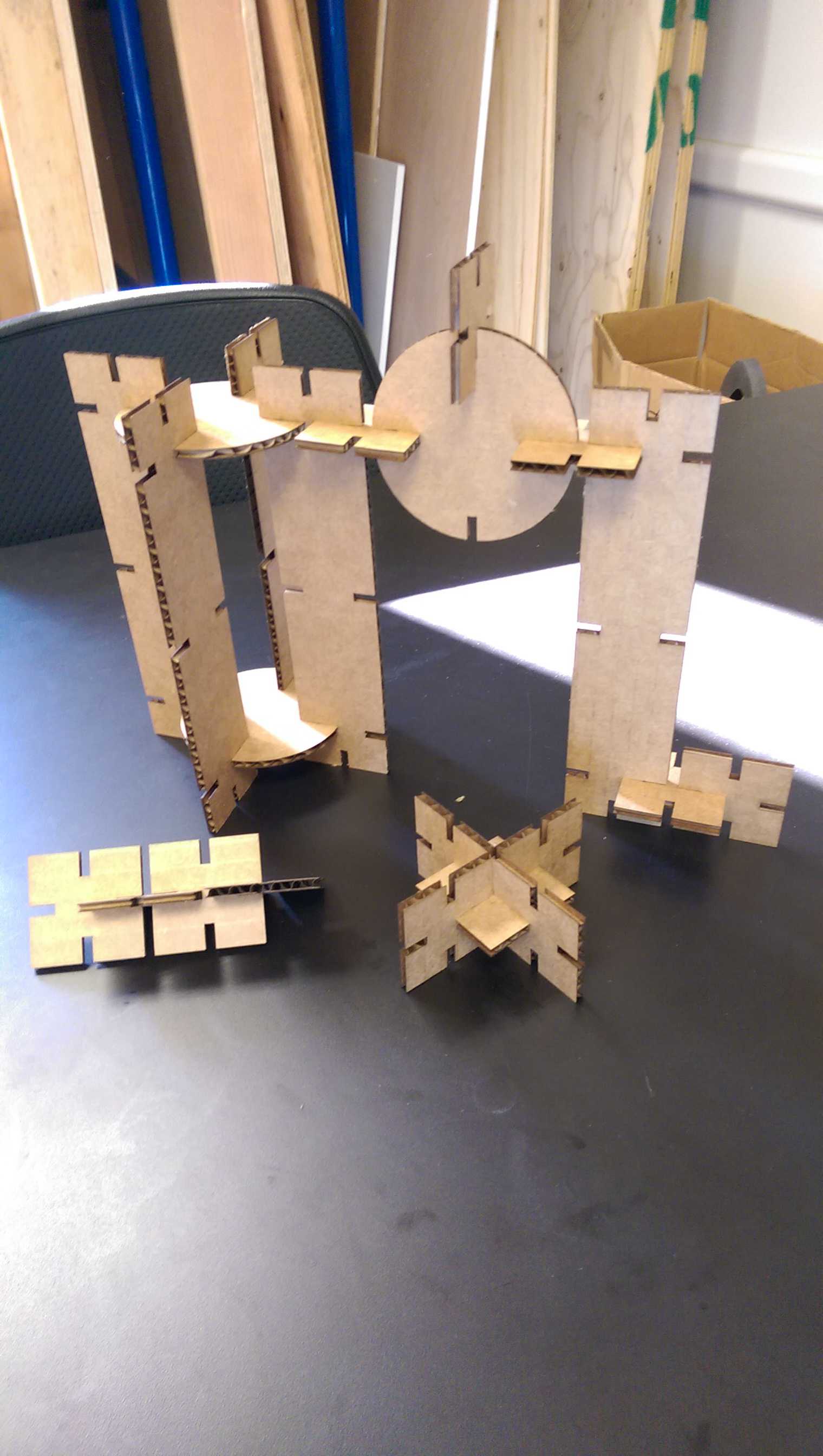

Our Fab Lab is equpped with an Epilog Fusion M2 CO2-Laser with an output power of 75 W. Here you can see some part, which I did during my time here in the lab to make myself familiar with the machine. The left piece is from one of my students, who participated the first class on Rapid Prototyping here.

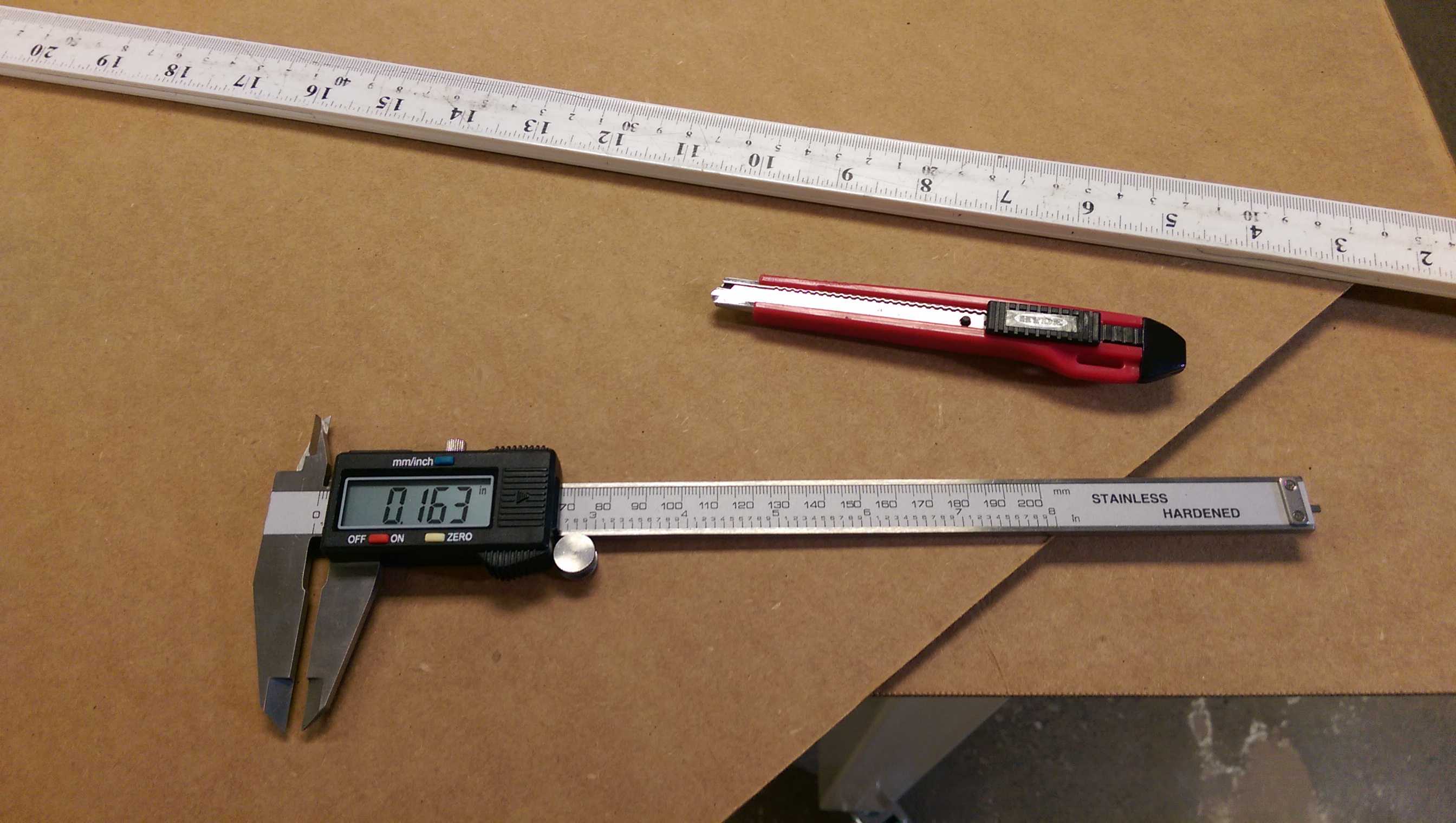

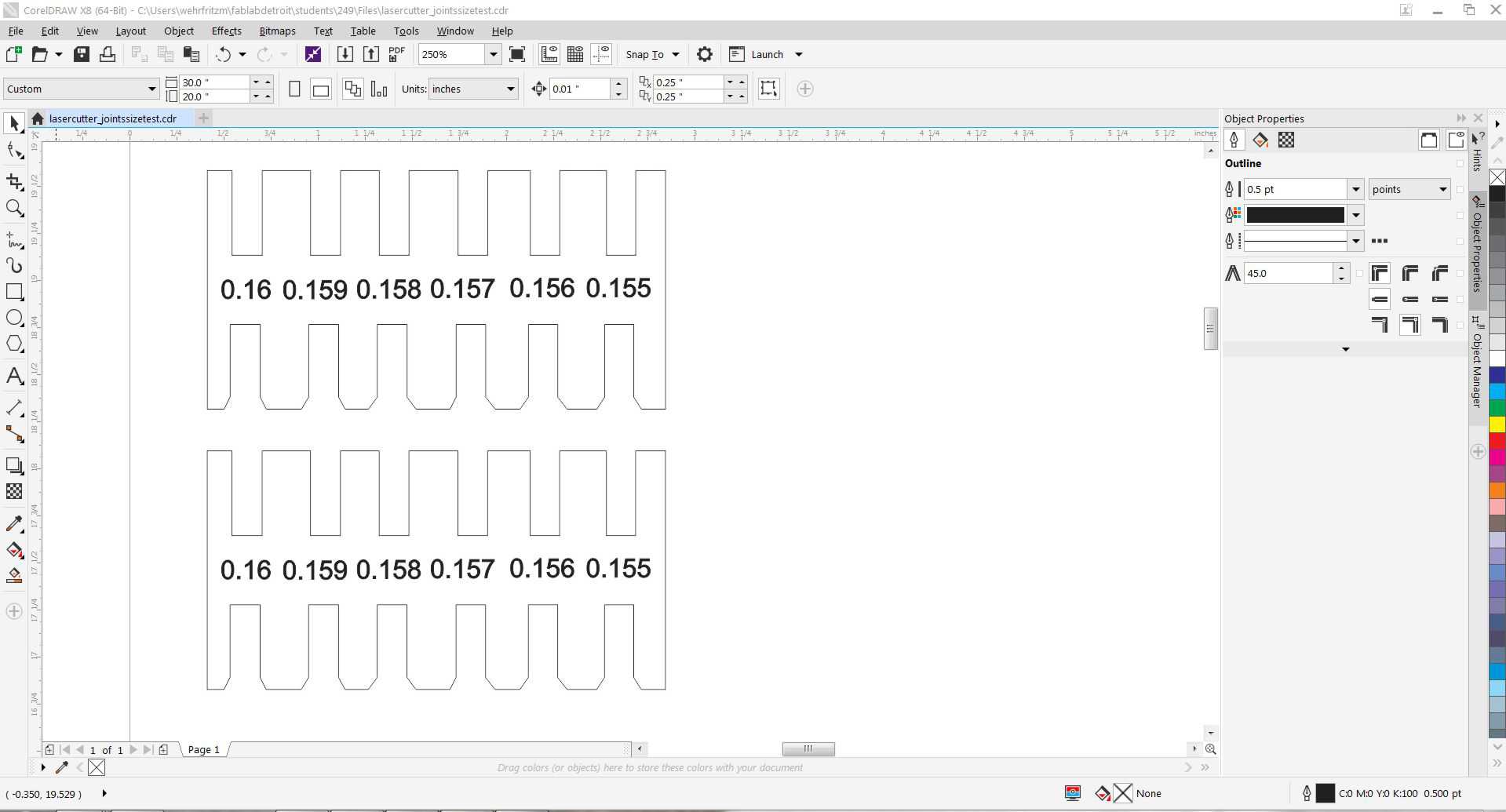

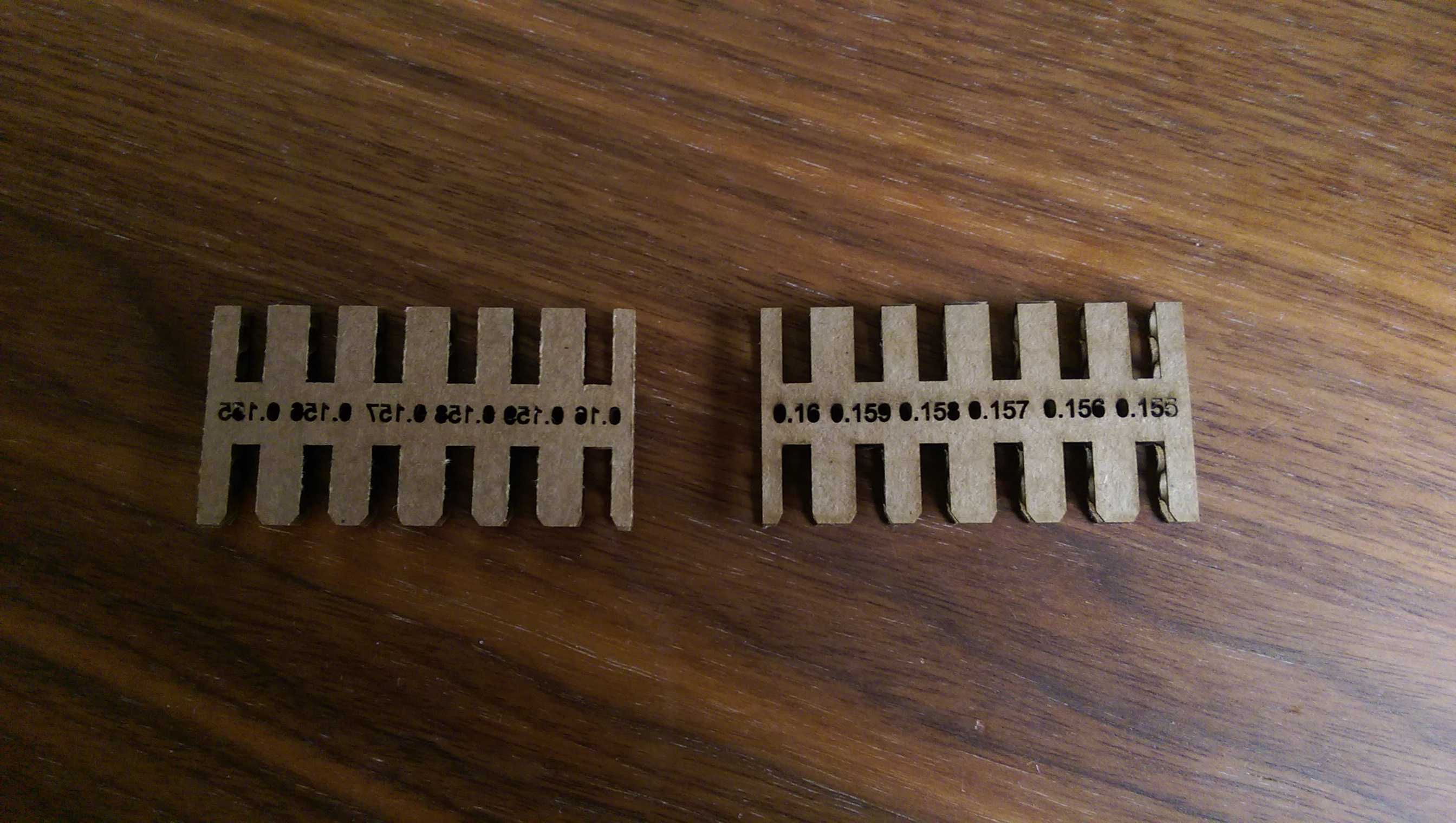

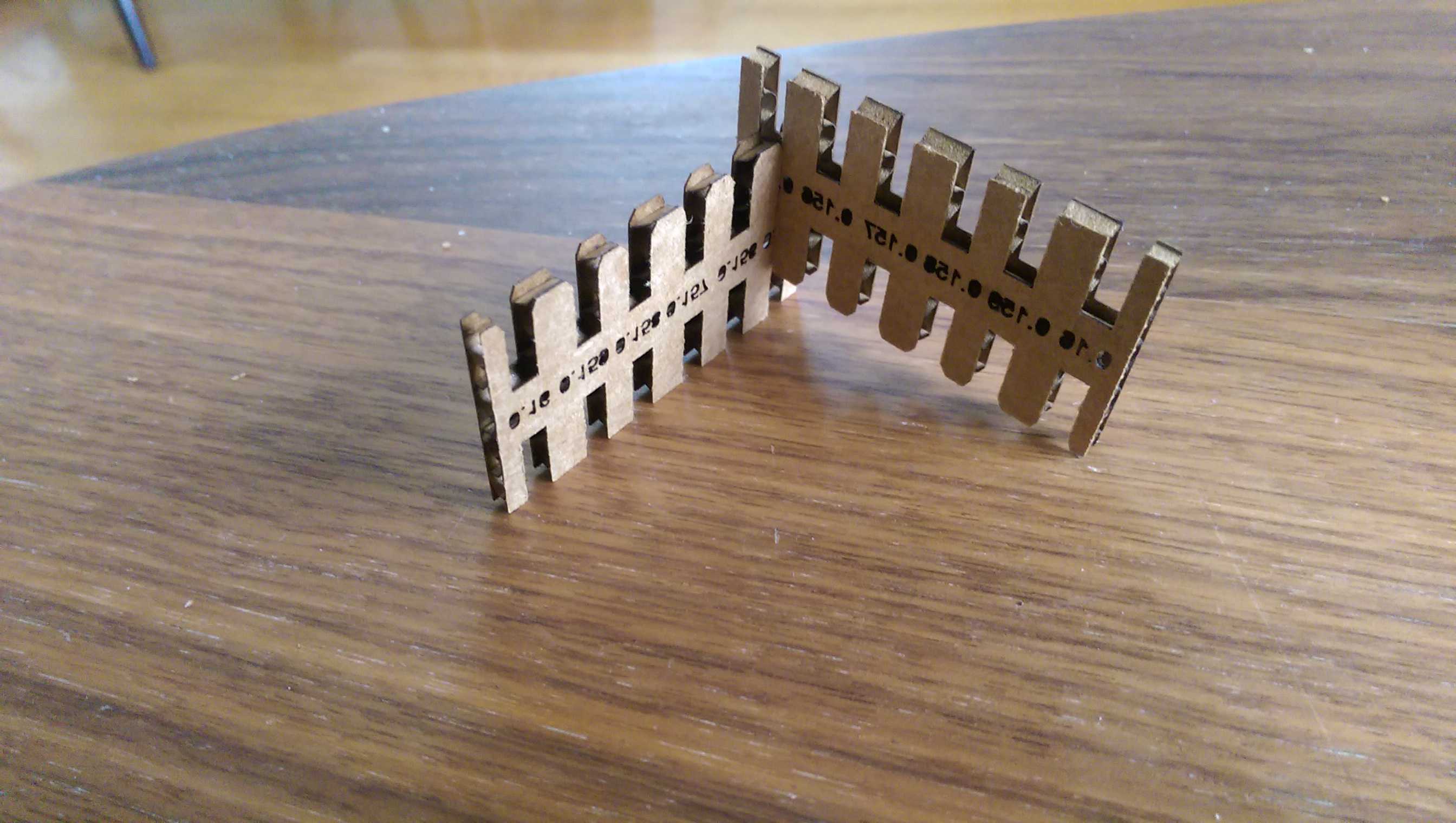

For the designing I am using Corel Draw. It is recommended by Epilog and to my extend it is fairly easy to use. To find the proper size for the fit joints, I did a test cut. I wanted to use cardboard because we have plenty of it in the Lab. First I measured the thickness and designed a test shape, to play with the width of the cut and to use champfer.

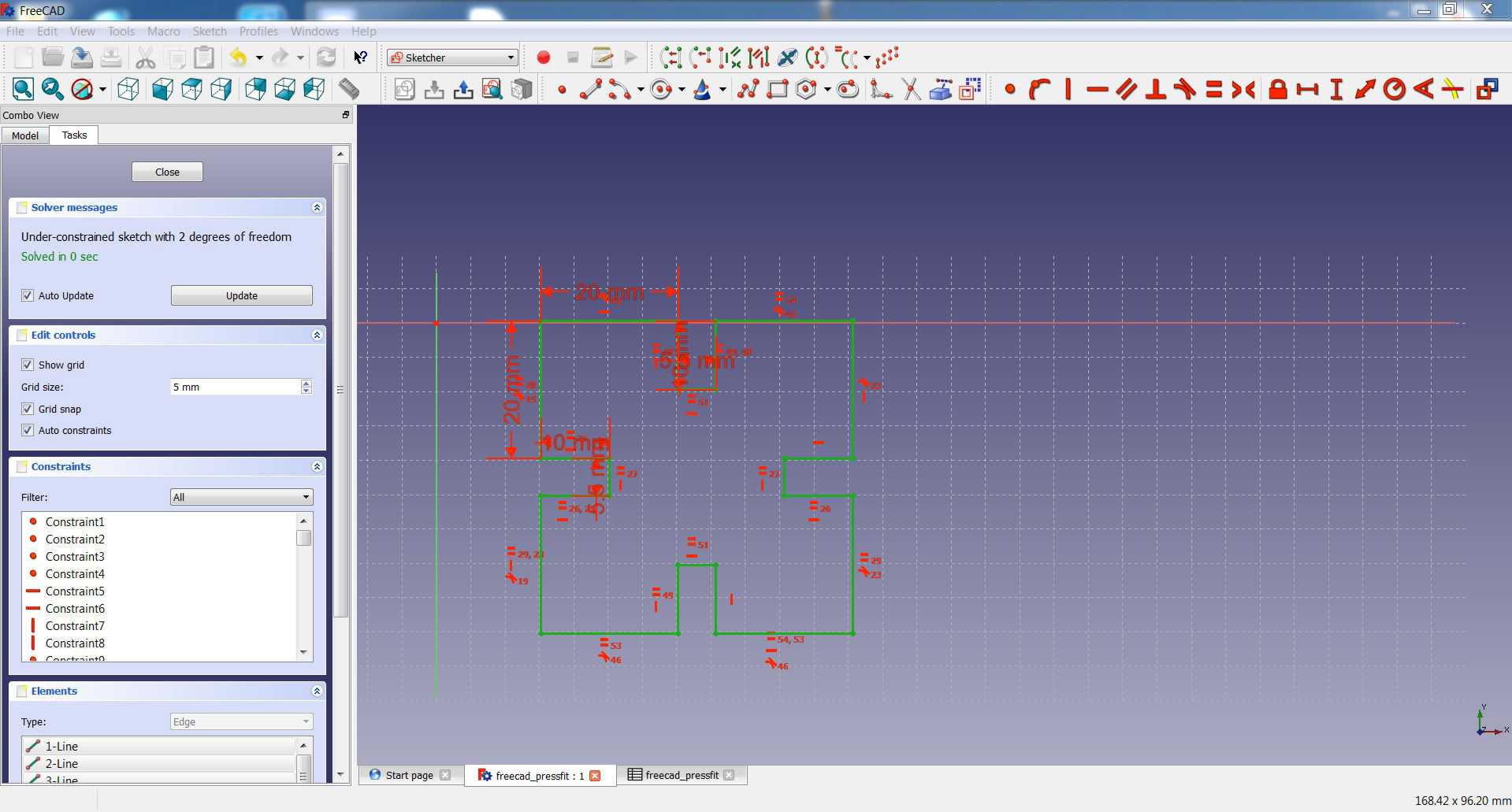

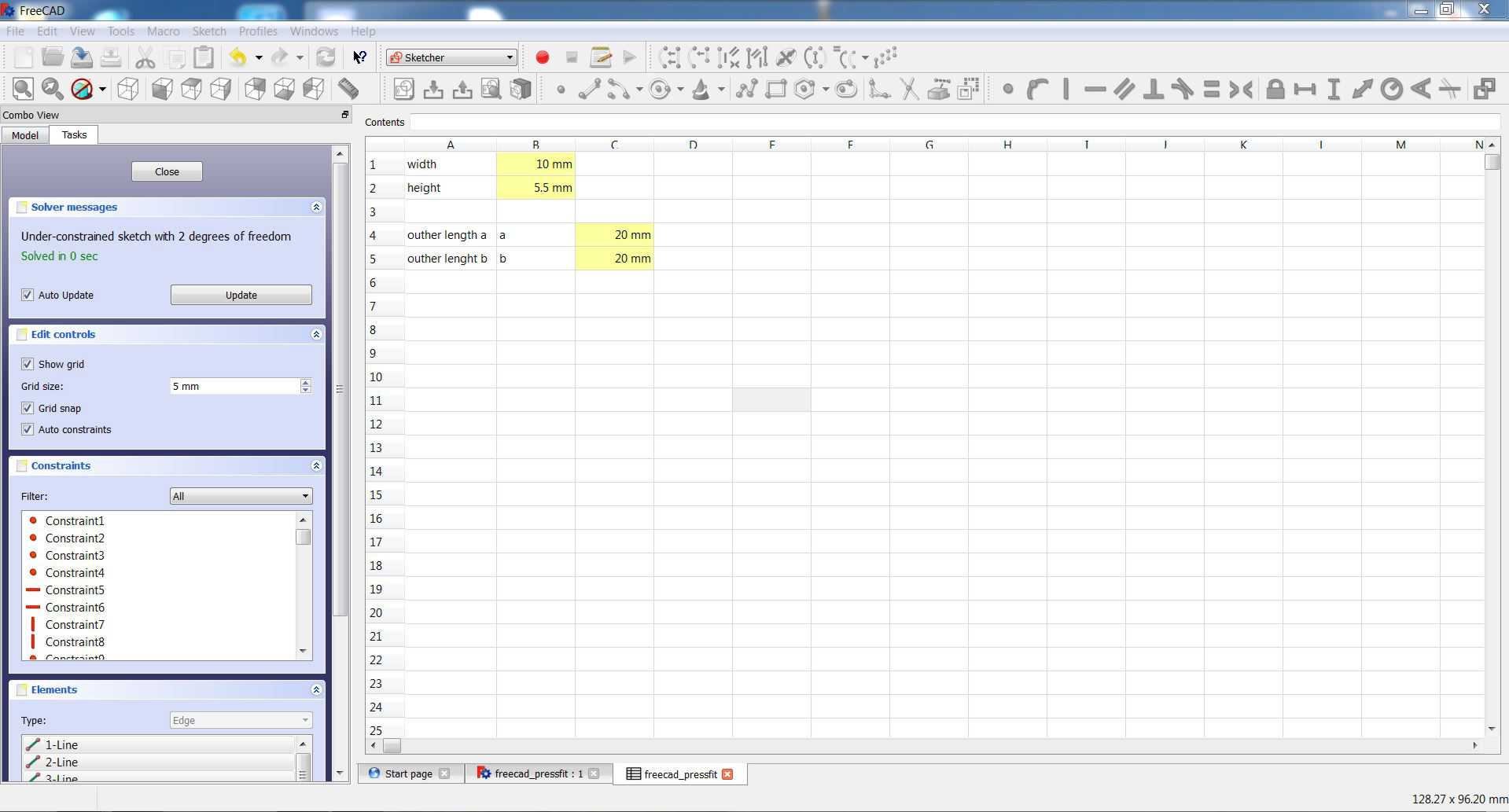

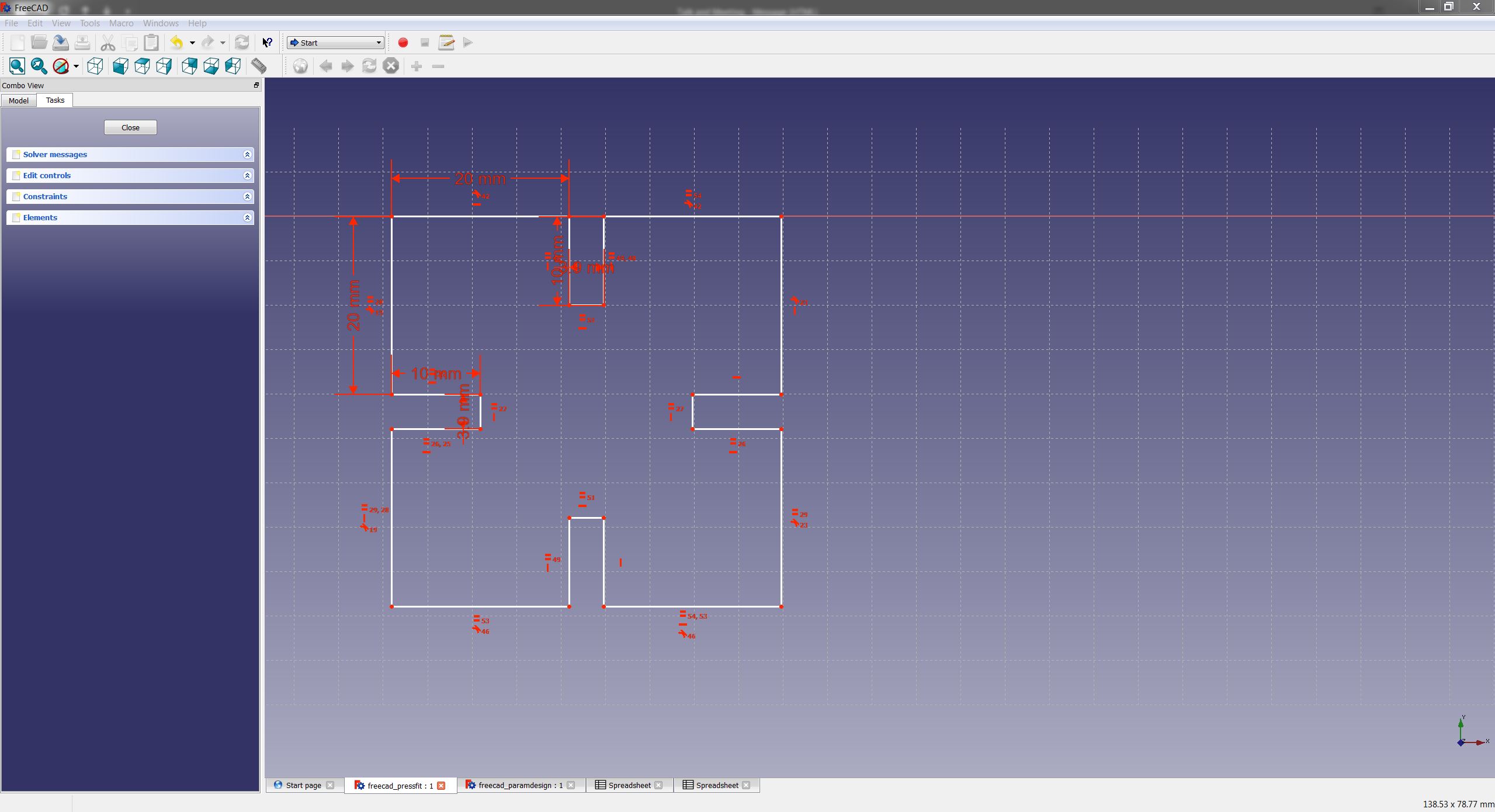

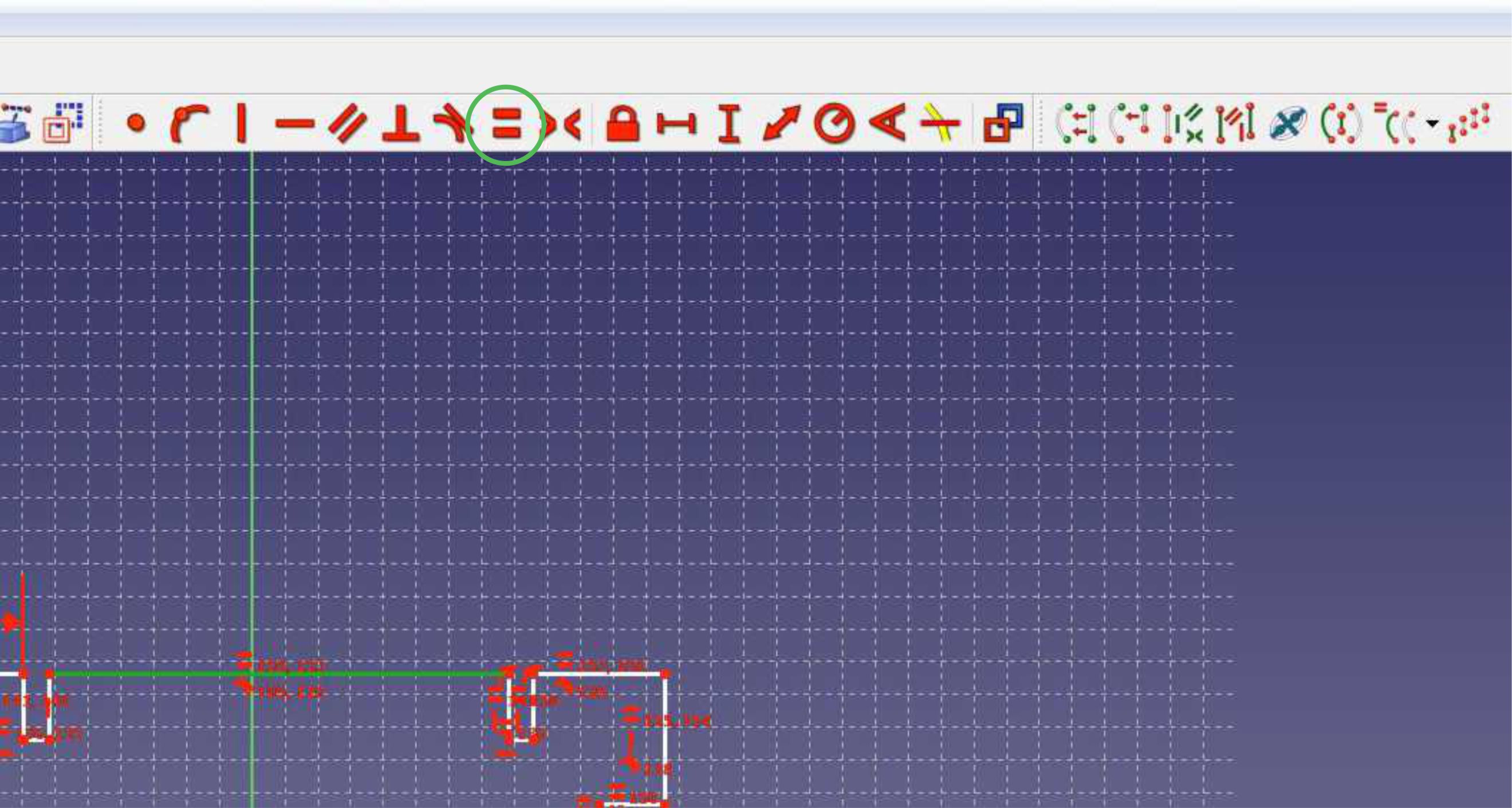

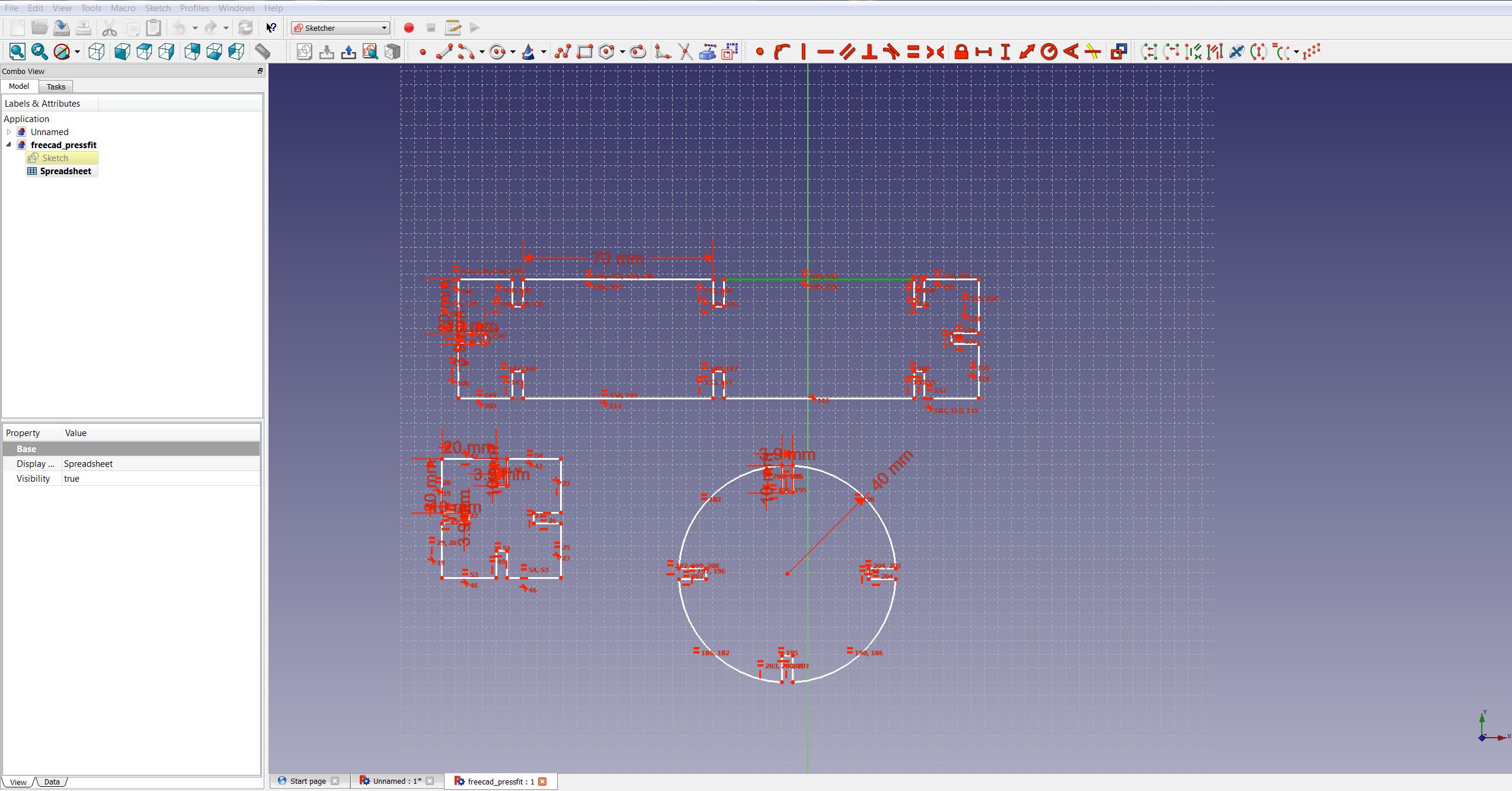

As a next step, I started to play around with FreeCad and the parametric design.

And here it is, my press fit joints kit.

Go to top