Project Development

My first idea was a walking handrail. In the first few weeks I was searching for how it would look like and how it would move, what kind of movement it would perform.

These drawings below were made in the second week computer-aided design, checking out the movement performance on the wall in Photoshop and Gimp.

Then creating a rotation movement in Fusion360 and trying out gear constructions in Inkscape:

In computer-controlled cutting I was interested in to find out how I can produce a light structure through substraktive methods, in combination with first: flexibility and second: stiffness despite of minimum of material usage.

The3D scanning was about how I can print a light structure through additive methods ind combination with stiffness despite of minimum of material usage.

Computer-controlled machining I utilized for experimenting light structures that transform stiff material in flexibel one.

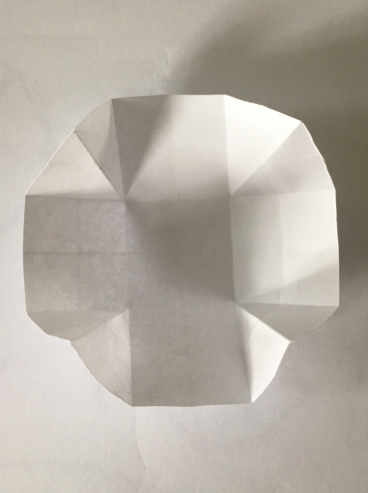

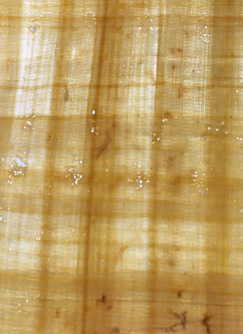

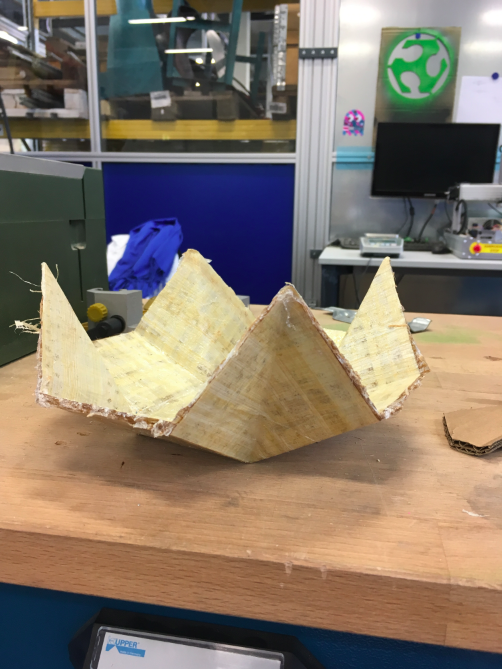

In composites I tried another light weight structure: foldings I used papyrus leaves and jute to create a natural based architectural light weight structure with a lasercutter. I did some strength tests.

During our electronic and programming weeks I´ve tried to find out solutions for the problems and tasks I was going to be faced in my final.

In output devices week I was trying to find out how to controll a motor not only in Arduino but especially in C. As I am very much interested in the architecture of microchips I wanted and want to learn how to program them on the lowest level as possible. Finding out the register address in Atmels Datasheets to switch on a pin was very interesting for me. I´ve looked up in online tutorials for assembler language to understand how a chip is working, and then I started to learn C language, nearly everyday I was learning C from books or online tutorials. With the help of one of these tutorials I found out how to find the right addresses in Datasheets, how to calculate and programm the angles the motor has to perform.

//main.c ATmega328 Program

#include <avr/io.h>

#include <util/delay.h>

#define F_CPU 16000000

#define BUTTON_PRESSED (PINC & (1<<PC6))

// check for button press

typedef unsigned char BYTE;

typedef unsigned short WORD;

int main (void) {

// declare PB1 as output pin.

//This is where the motor is connected

DDRB = (1 << PB1);

TCCR1A |= 1<<WGM11 | 1<<COM1A1 | 1<<COM1A0;

TCCR1B |= 1<<WGM12 | 1<<WGM13 | 1<<CS10;

ICR1 =19999;

// main loop

while (1) {

OCR1A = ICR1 - 800; //18000

_delay_ms(100);

OCR1A = ICR1 - 1600; //18000

_delay_ms(100);

OCR1A = ICR1 - 2600; //18000

_delay_ms(100);

OCR1A = ICR1 - 1600; //18000

_delay_ms(100);

}

}

In Input Devices week I thought about a communikation between two boards via light. One pcb in each foot and an acrylic pole as communication channel. But it is also possible to you use it as a general input instead of a start button for example.

In Networking and Communications I thought about having at least two boards, one in each foot, but at the end I thought this networking principle makes more sense for more then two feeds for example a snake style robot or octopus robot, with one master and for each leg or joint one small board. This is something I would like to develop after my railbot.