Exercise 12

Molding and Casting

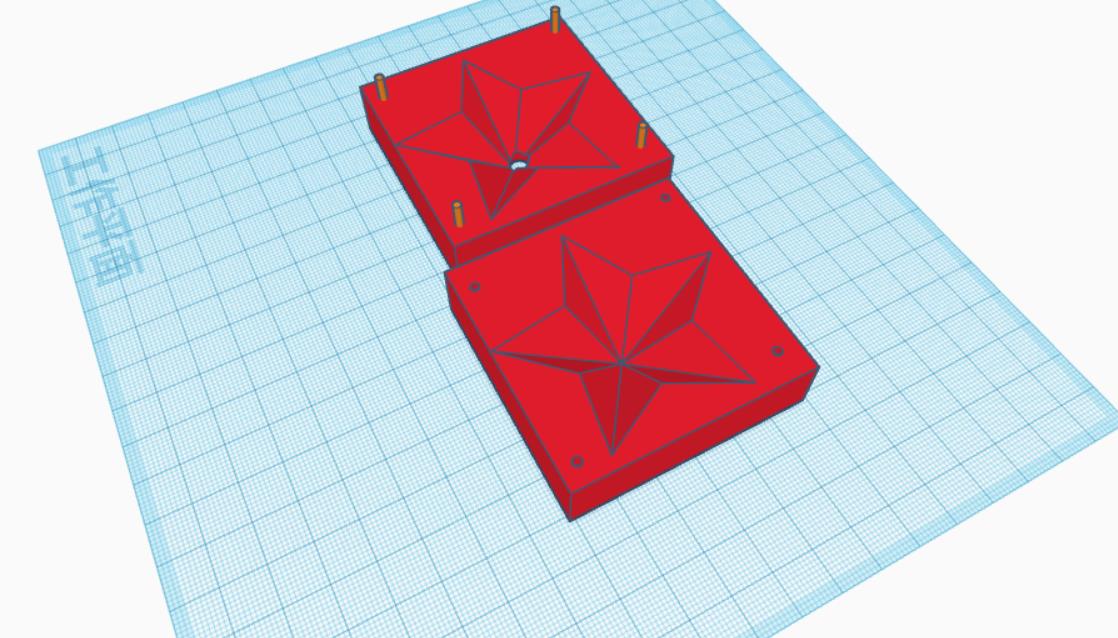

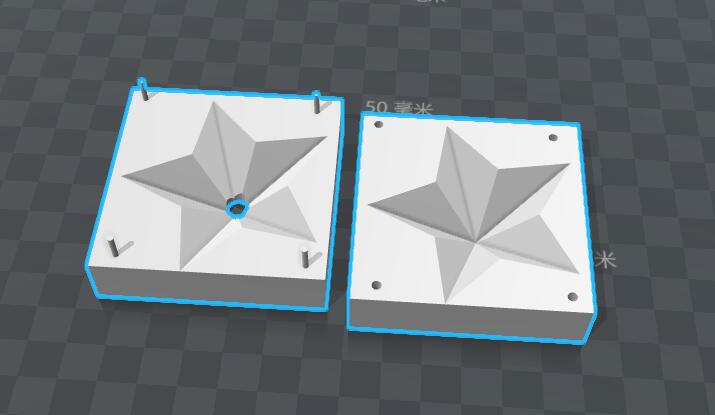

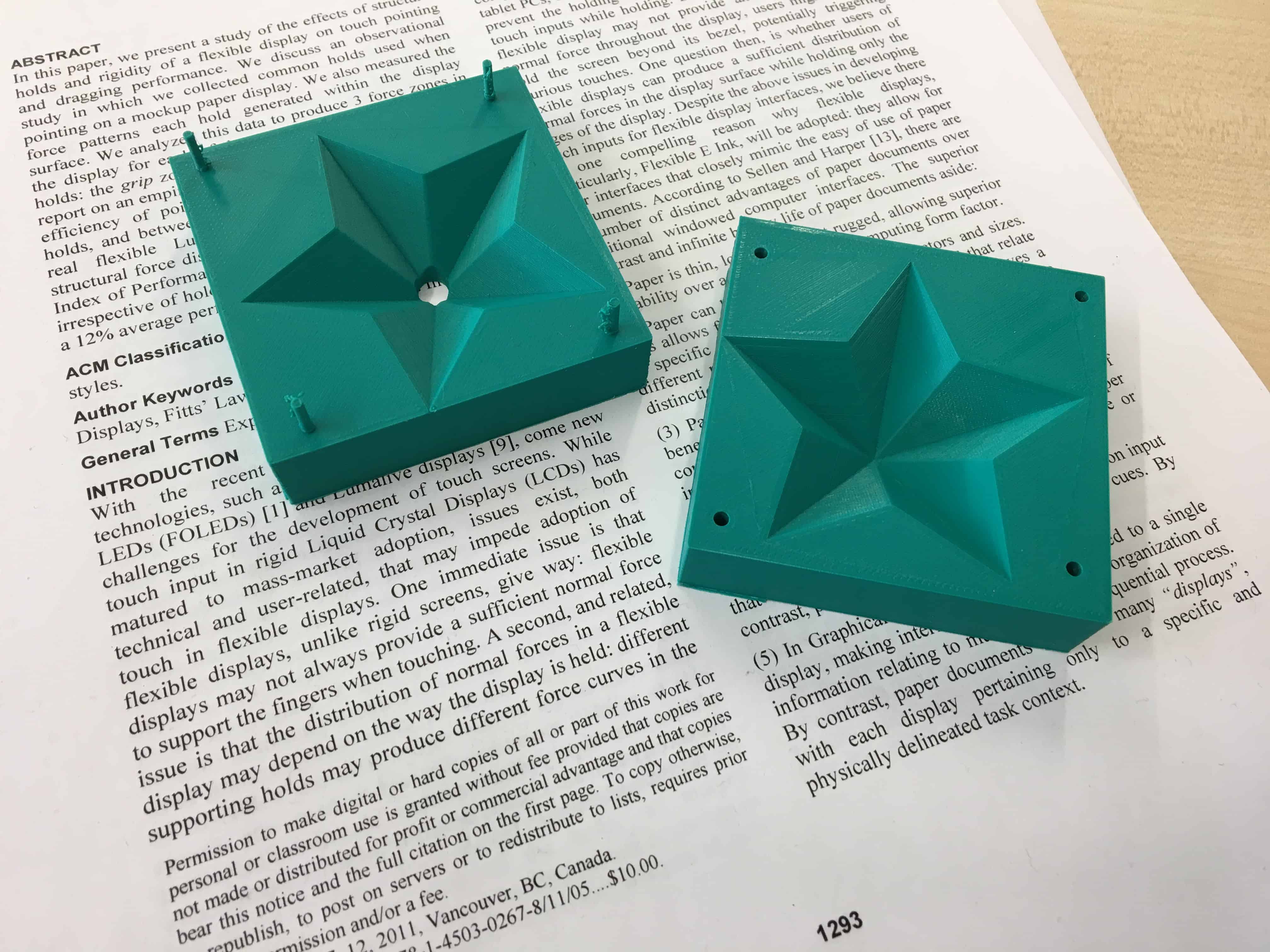

Create the Cast

I used tinkercad to create the cast by saving it in STL file. Then I used 3D printer to print it.

I tried to make a star

Wax Casting

Things I needed to wax casting

- Regular Wax pallets

- Red Wax for coloring

- Essential Oils for smell

Steps:

1. Set up a waterbath for the glass container

2. Put wax pallets in glass container and heat it up to about 60 Degree Celcius. I do this in order to melting point of wax.

3. Add red wax to the glass container for coloring

4. Wait for wax to melt

5. Prepare Mold by sealing openings of the mold with tape

6. Pour wax into mold with a funnel.

7. Wait for wax to cure

Concrete casting

Things I needed to concrete casting

- Silicone Mold

- Fine Concrete

- Water

- Plastic Containers

- Wood sticks to mix the concrete with water

- Scale for measuring the amount of water and concrete

- Respiratory Mask

- Gloves

The ratio of water and conncrete is 1 : 4. Normally, it needs 2-4 Days to cure

Steps:

1. Put corrcet amount of Water and concrete into plastic container by using the scale

2. Mix water and concrete until the mixture is smooth

3. Pour mixture into silicone mold

4. Wait for concrete to cure

Finally, I made a star wax candle and a lovely bear.