Fab-Arm

Link to Group Project Page

This week's assignment is to design and build all the mechanical parts of a machine. Also this is group assignment and we decided to build a robotic arm based on an existing uArm. All the electronics part and automation is to be designed and build in upcoming weeks. We decided to call the project Fab-Arm as well.

The team members accompanying me for this project are

Renjith M s

Syedjunaid Ahmed

Jithesh Gopal

Rahul S rajan

Sachin Salim

Ajith Kumar m g

Sreejith Mohanan

Jim J seelan

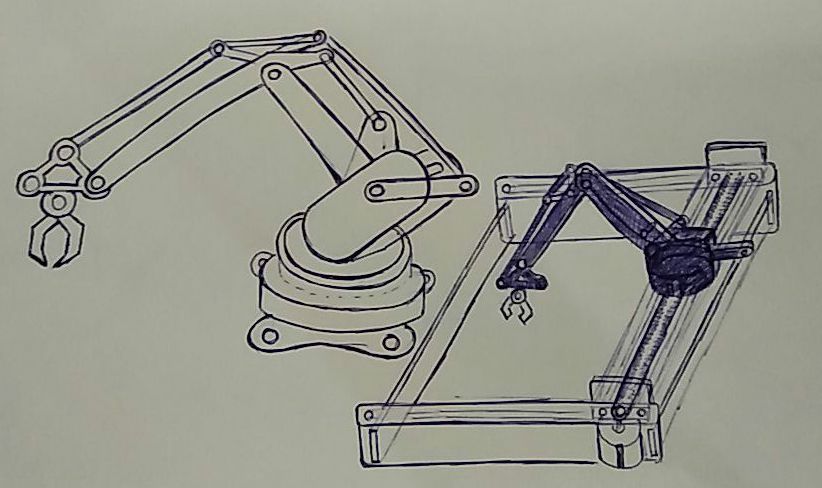

Basic sketch of the project

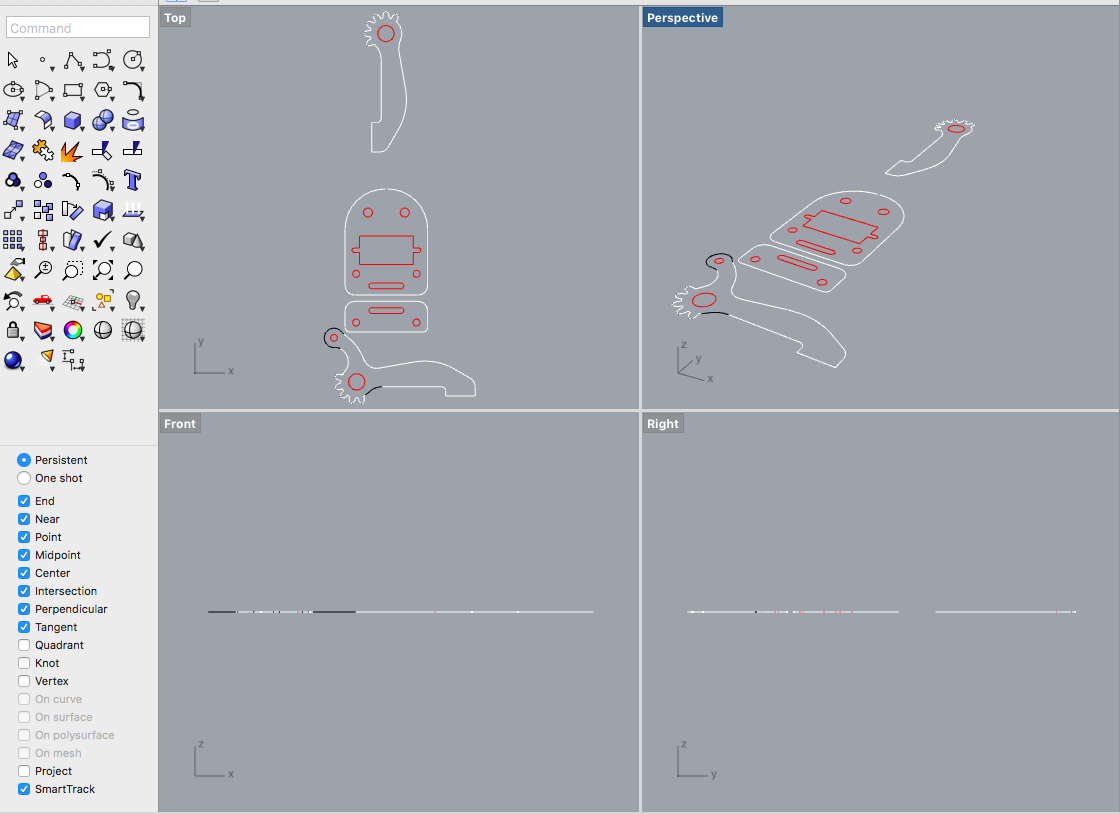

My involvement in this project is to design the end-effector and to assemble it.

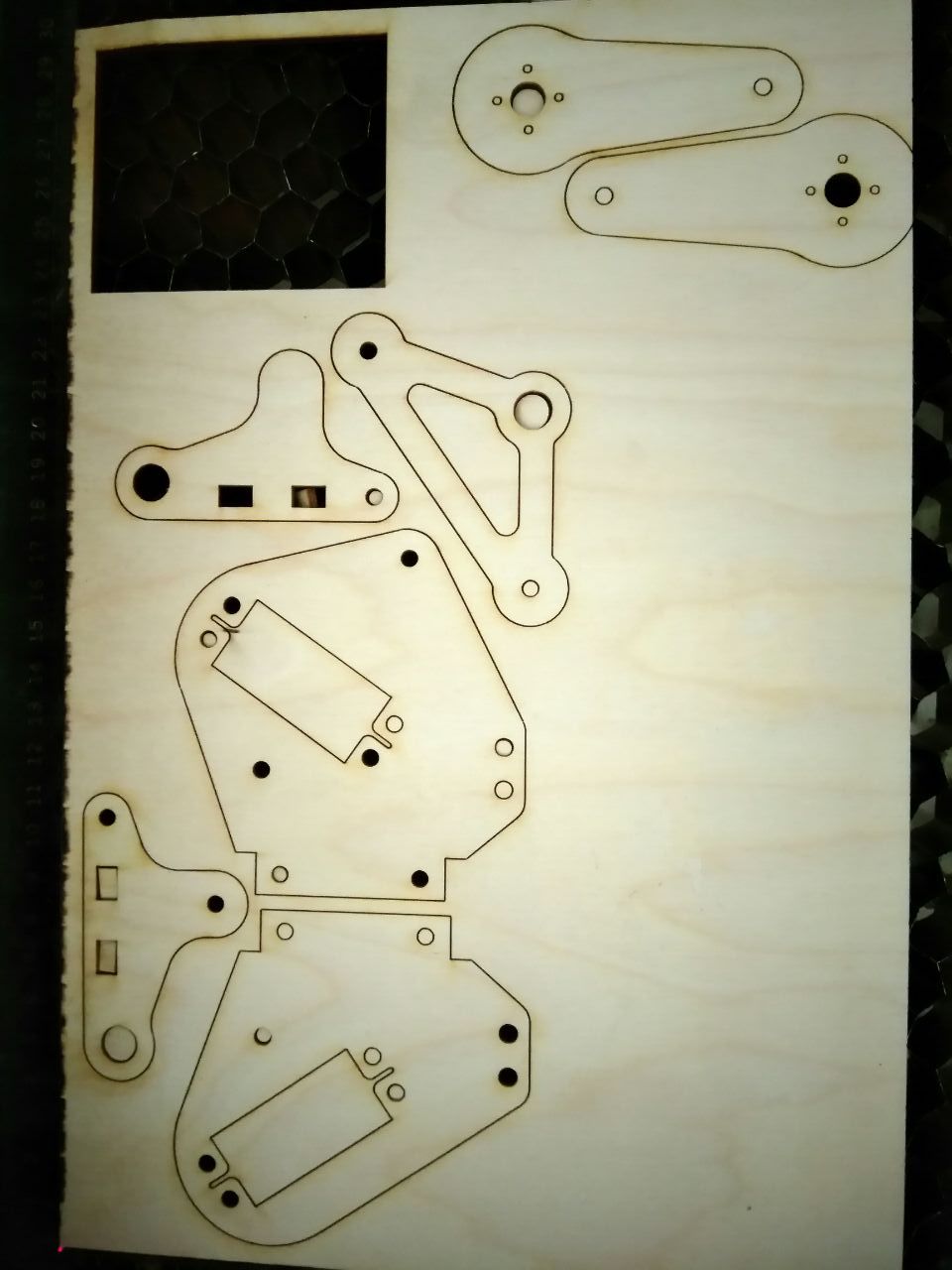

Cutting and Assembling the parts

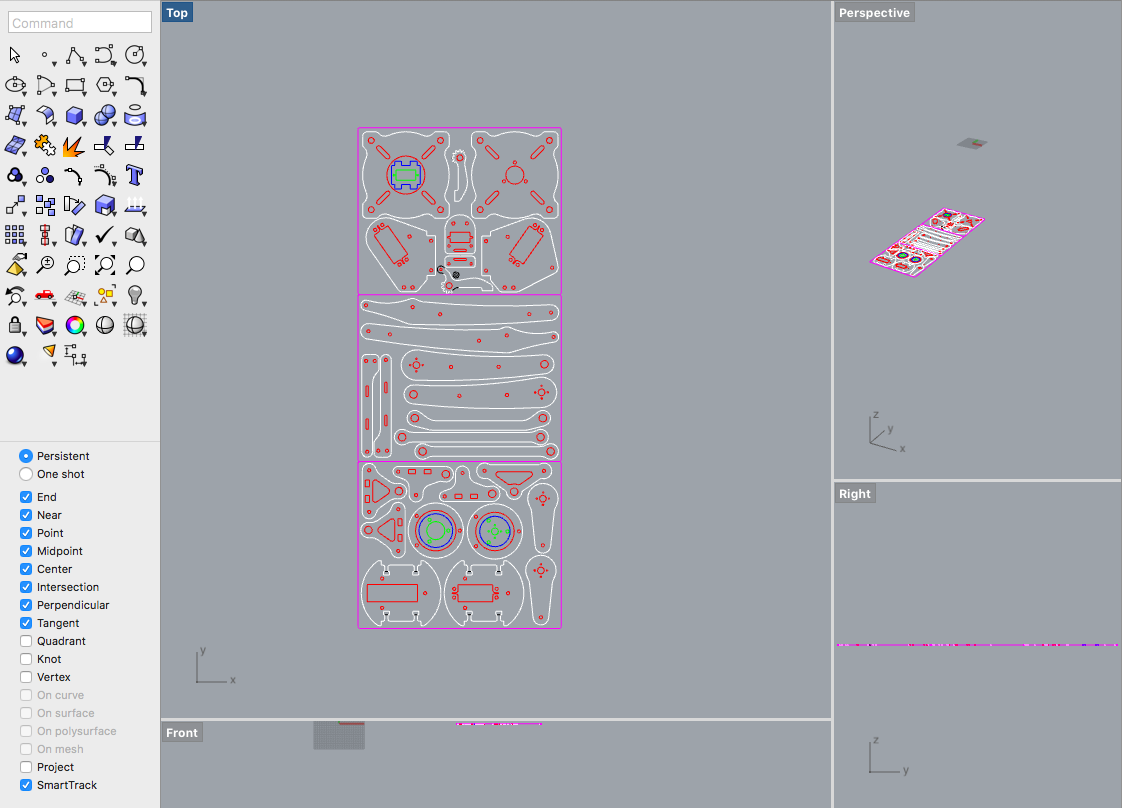

We got the design parts from this link. We laser cut the parts.

When we assembled the Fab Arm and the end effector.

Testing out robotic arm

We used arduino to test and control the servo motors.

Drawing a line repeatedly

The Detailed documentation and codes for the arduino are written here

Challenges faced

Eventhough we had the design files, we could not acquire all the parts for assembling, so we had to 3D print some spacers. Ajith designed the spacers and we used it for assembling.

This is the spacer I created using craftwood.

Also we did not have the desired servo motors. We intended to cut our designs on 6mm acrylic but since the servos at our disposal would not work properly with heavier acrylic, we moved to 4mm craft wood. We also did not get flange bearings for assembling from the local market.

Future upgrades

We also decided to scale the arm which will force us to redesign the component parts and have to use stepper motor with gears for movements for arms because the servo motors would not work properly with the increase in load when scaled. Also we need to add Guide Rail.