Fourth Week Assignment:

Contents:

Requirement:

- Milling machine.

- Electronics components.

- Welding station.

- AVR Programmer.

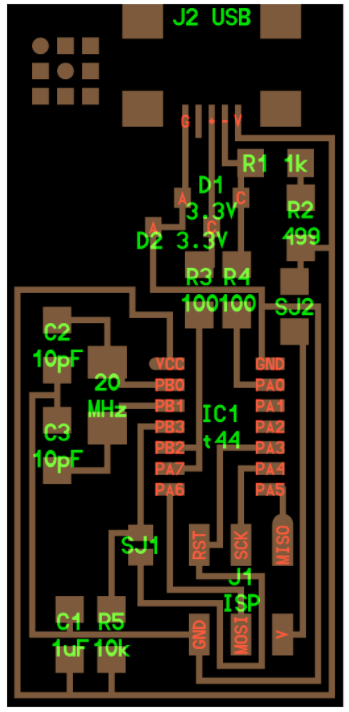

For this assignments I need to make a FabICSP, it is necessary to programming future board without AVR programmer

Almost I decide make two fabICSP, the firsth with an attiny 44 and the seconth with an attiny 45

PCB Fabrication

There are many ways to make a PCB Fabrication like using a milling machine, chemicals, etc. In this case I used milling technique

Milling machine

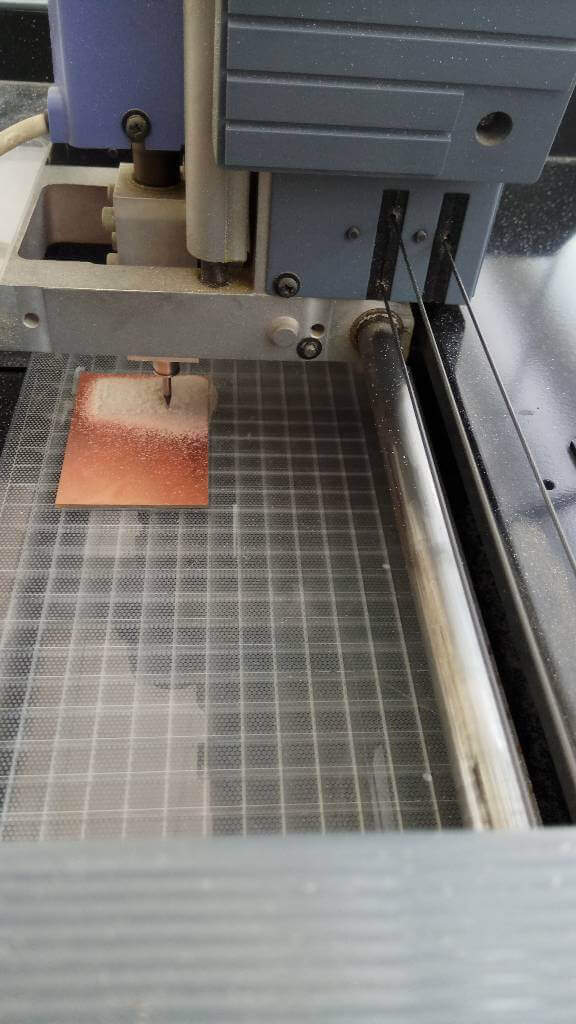

FabLab Tecsup has a ROLAND MODELA MDX-20, it is a good machine to make electronics board, 2D and 3D molding.

|

|

|---|

To make a PCB board are necessary some materials like:

- - Baquelita ( size depending of design circuit)

- - Double contact tape

- - A drill 1/64"

|

|

|---|

|

|---|

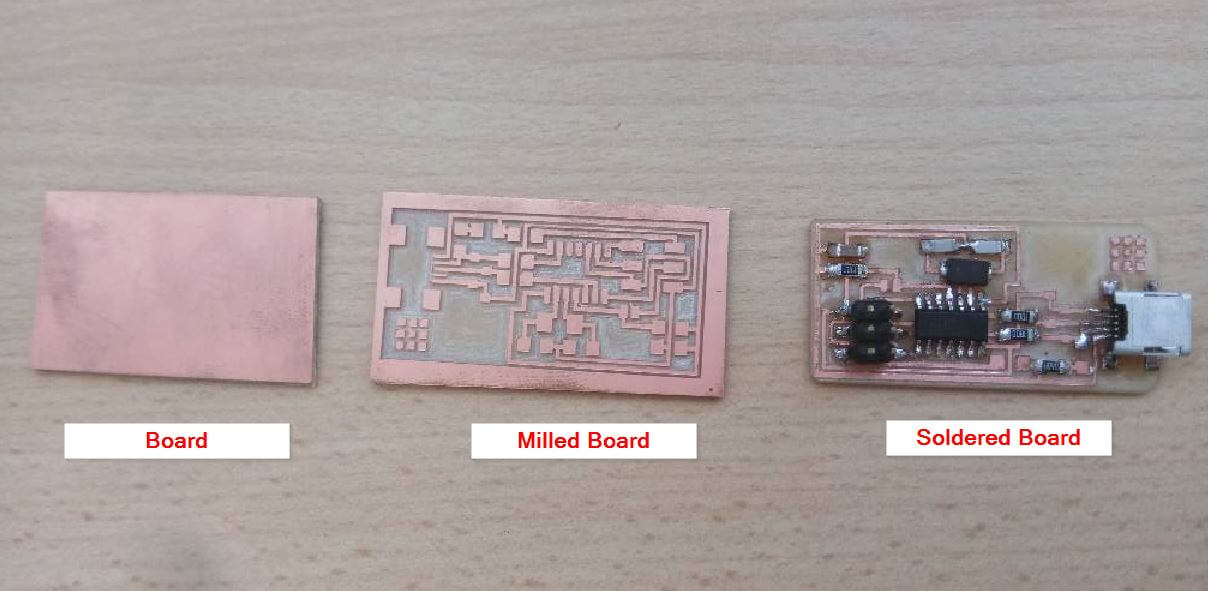

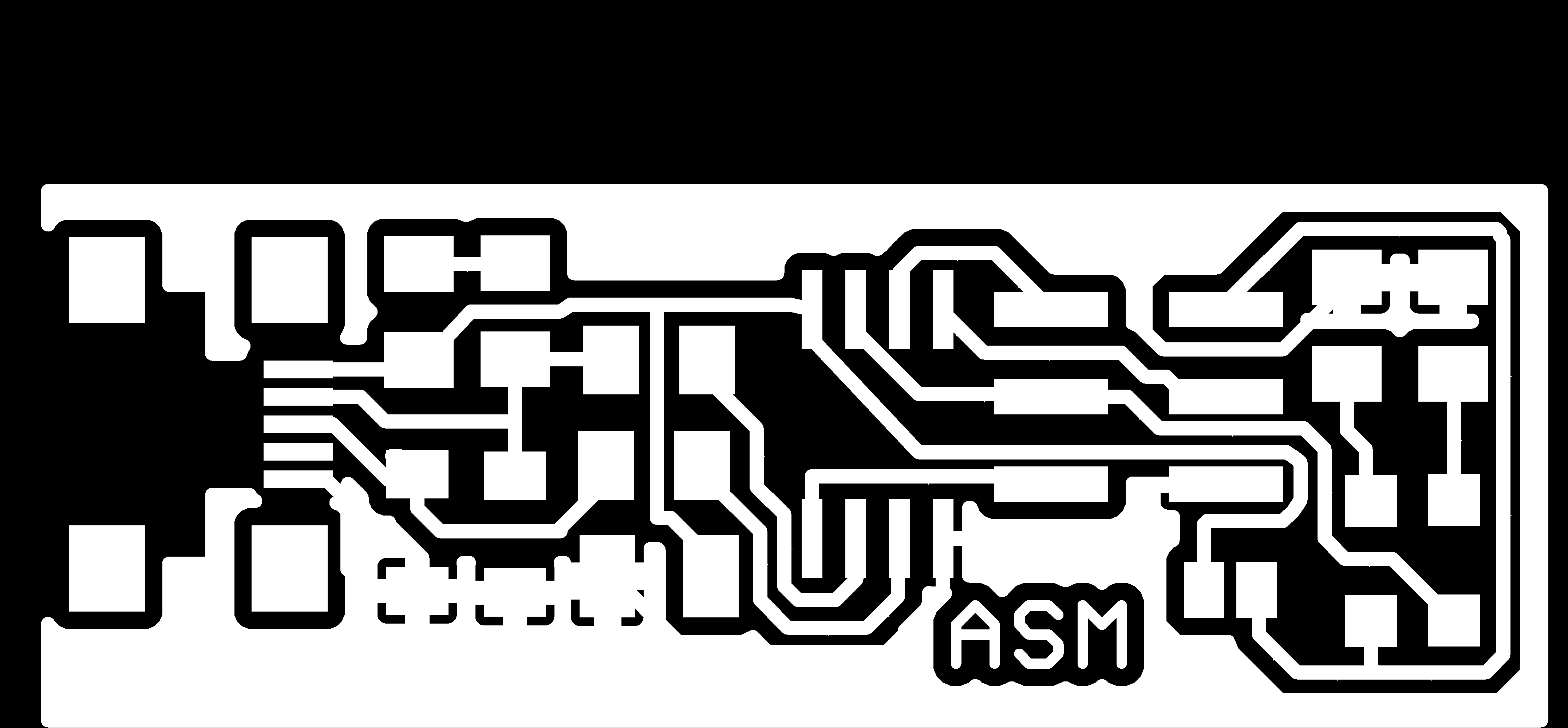

The first step is use a the PCB Provided by Neil

|

|---|

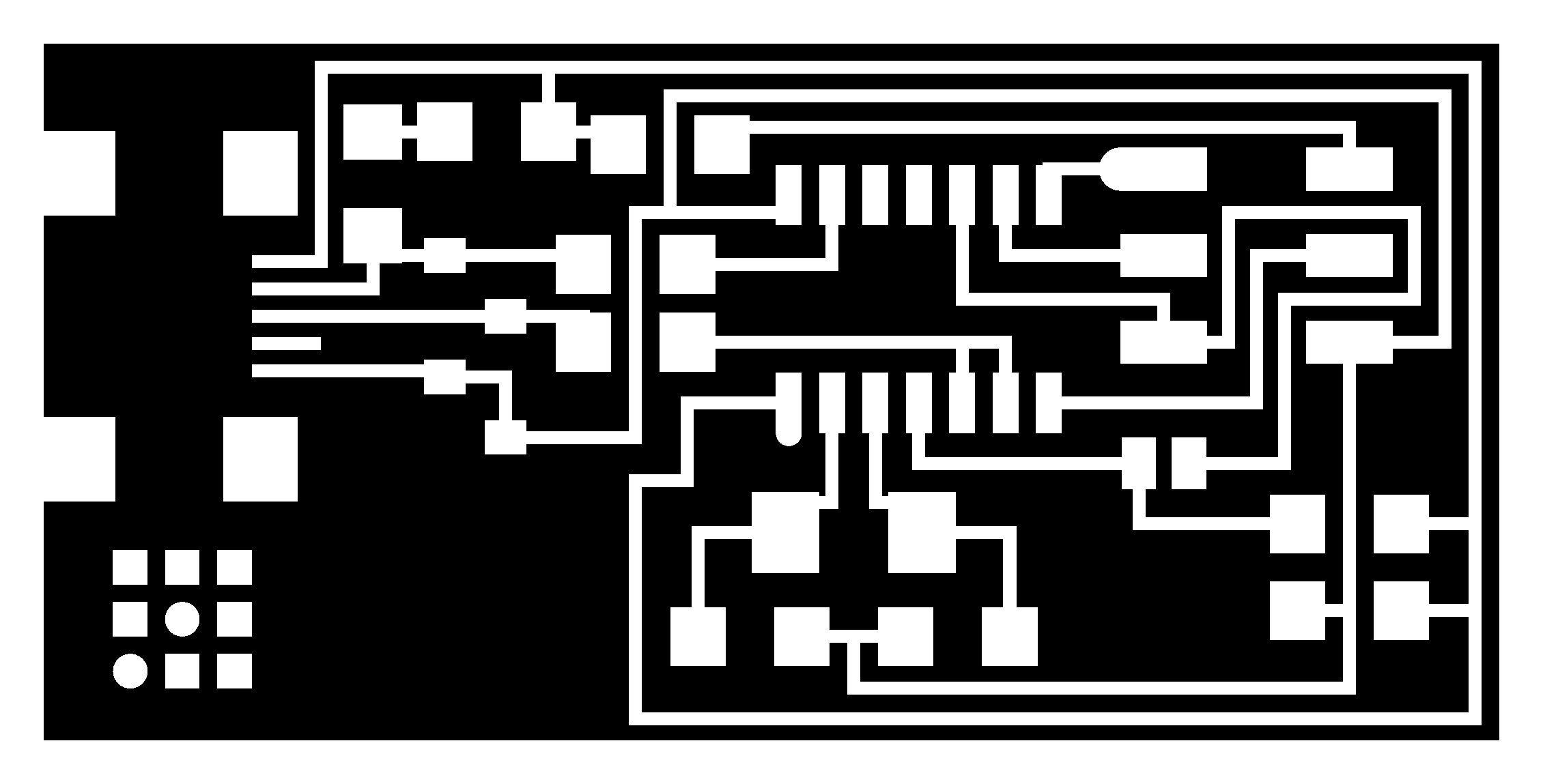

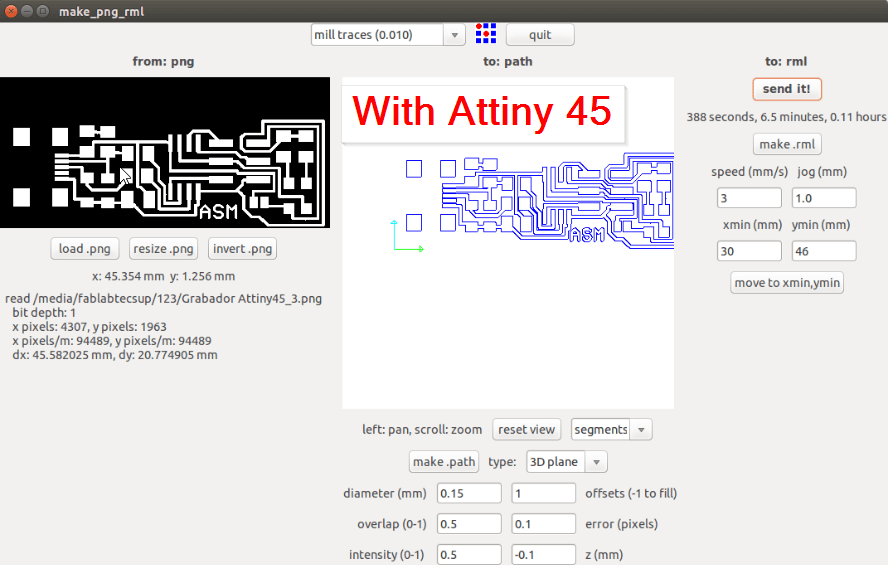

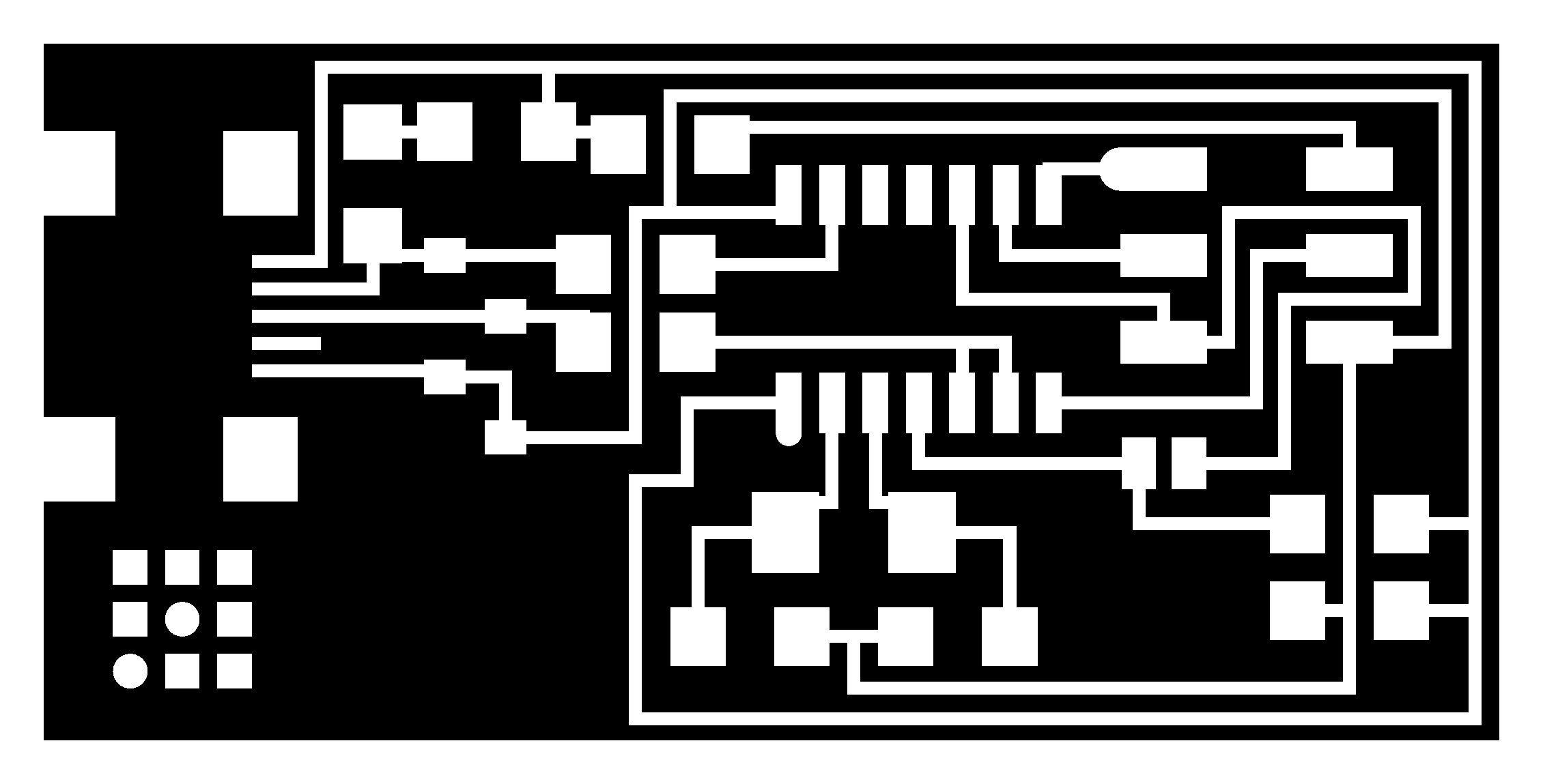

Them is necesary use a high resolution image(Black and white) where only you can see layers, something like that, So that the Modela can recognize the tracks and convert them into coordinates so that milling maching can mill .

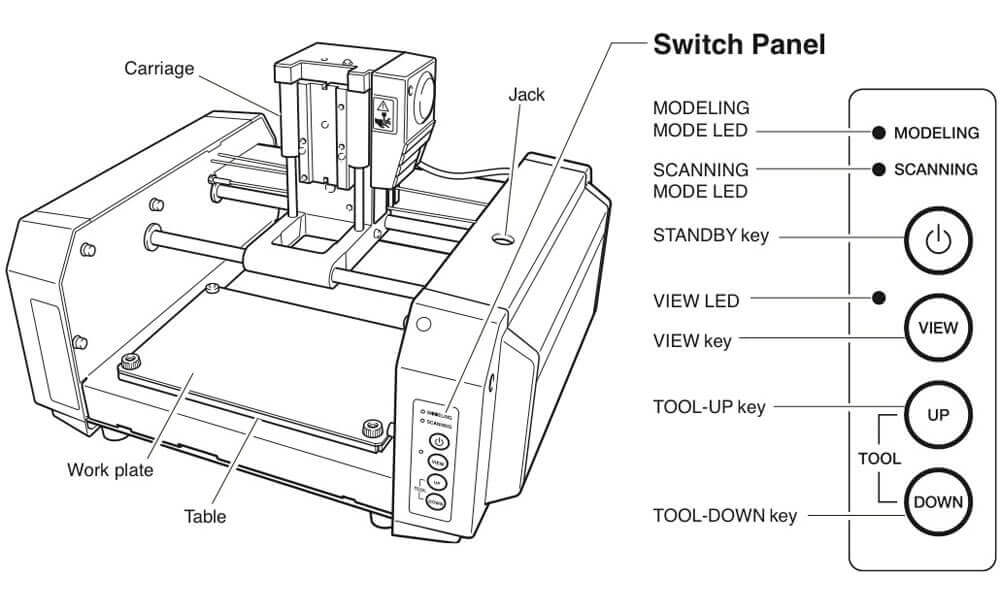

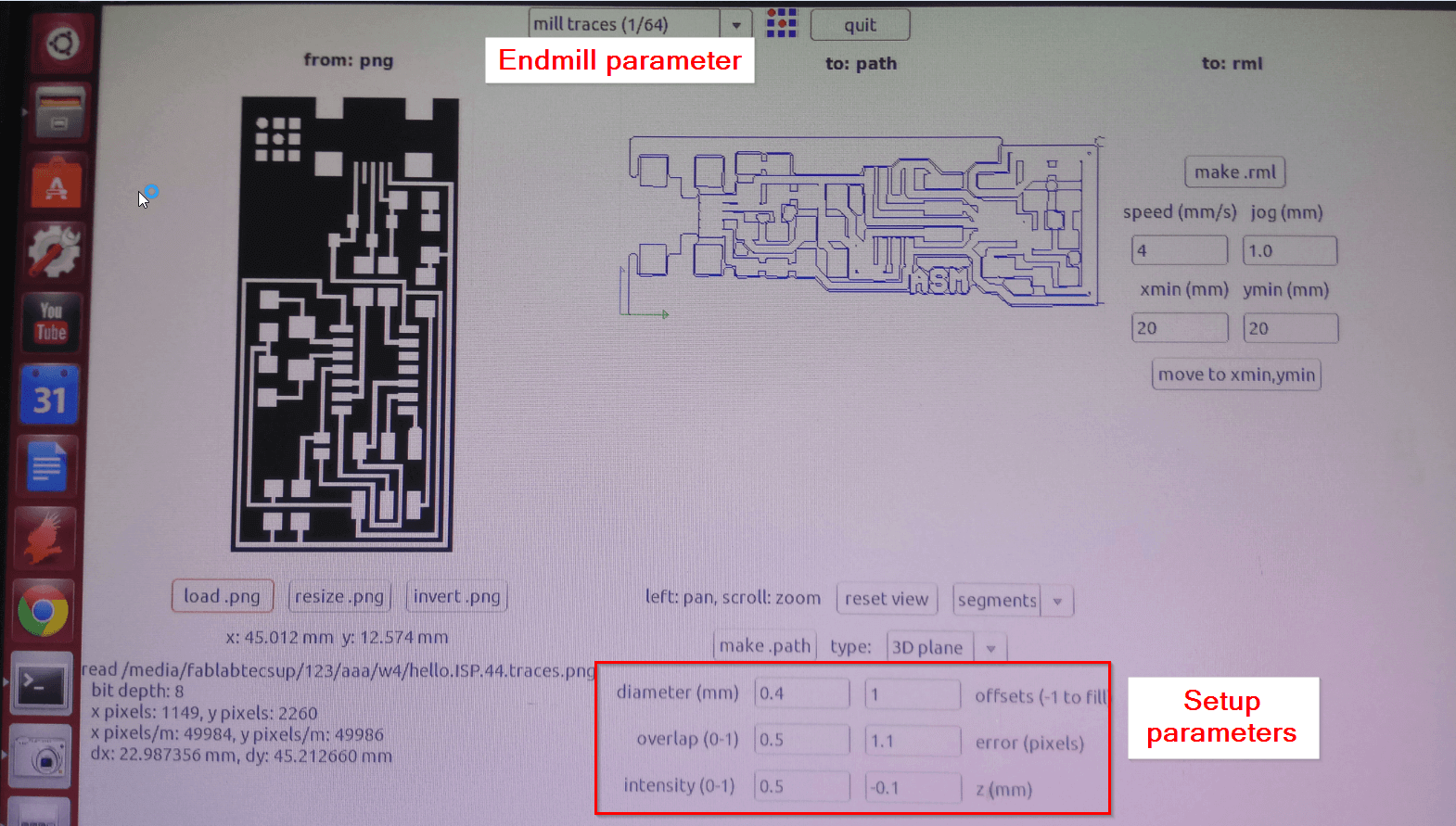

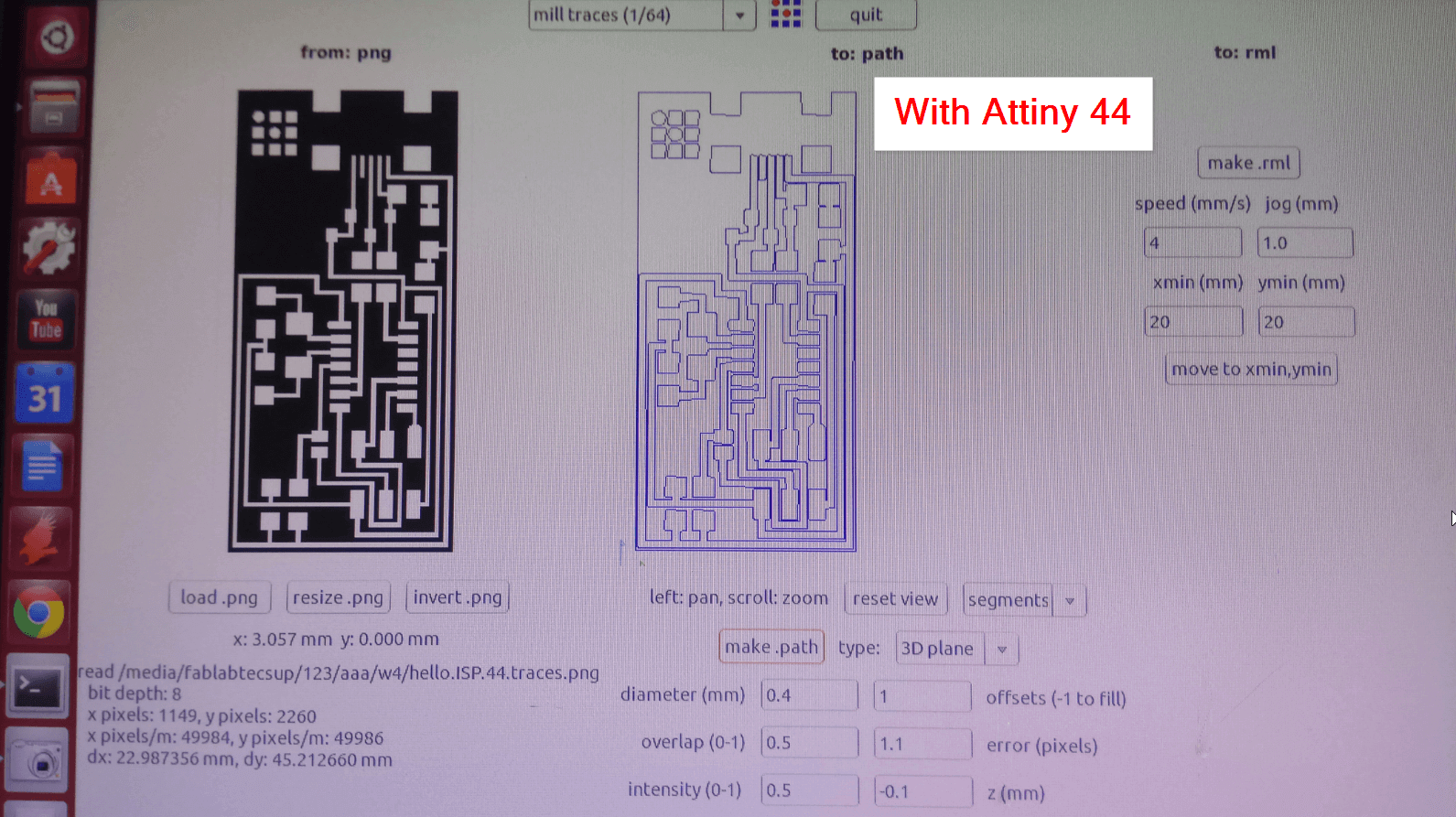

The second step is configure the CNC modela milling machine to do a good board

Now I have to wait to the milling machine do their job |

|---|

|

|

|---|

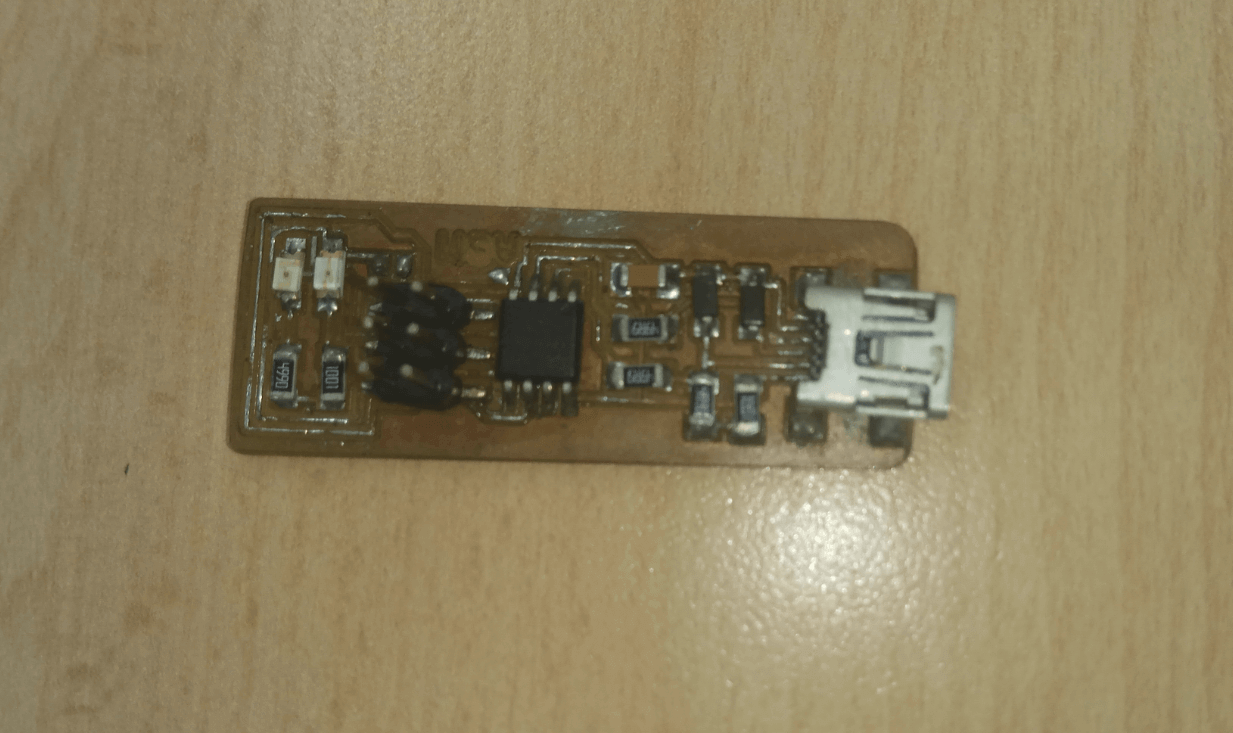

PCB Welding

Is important to have all componets that are necessary for this circuit.

Components:

- - x1 Mini-USB-Shield

- - X2 Resistor 1k ohm

- - X2 Resistor 499 ohm

- - X2 Resistor 49 ohm

- - X1 Condensador 100nF

- - X2 LED's (green - red)

- - x2 diode

- - x1 Attiny 45

To soldering it is necessary to have good practice and precision

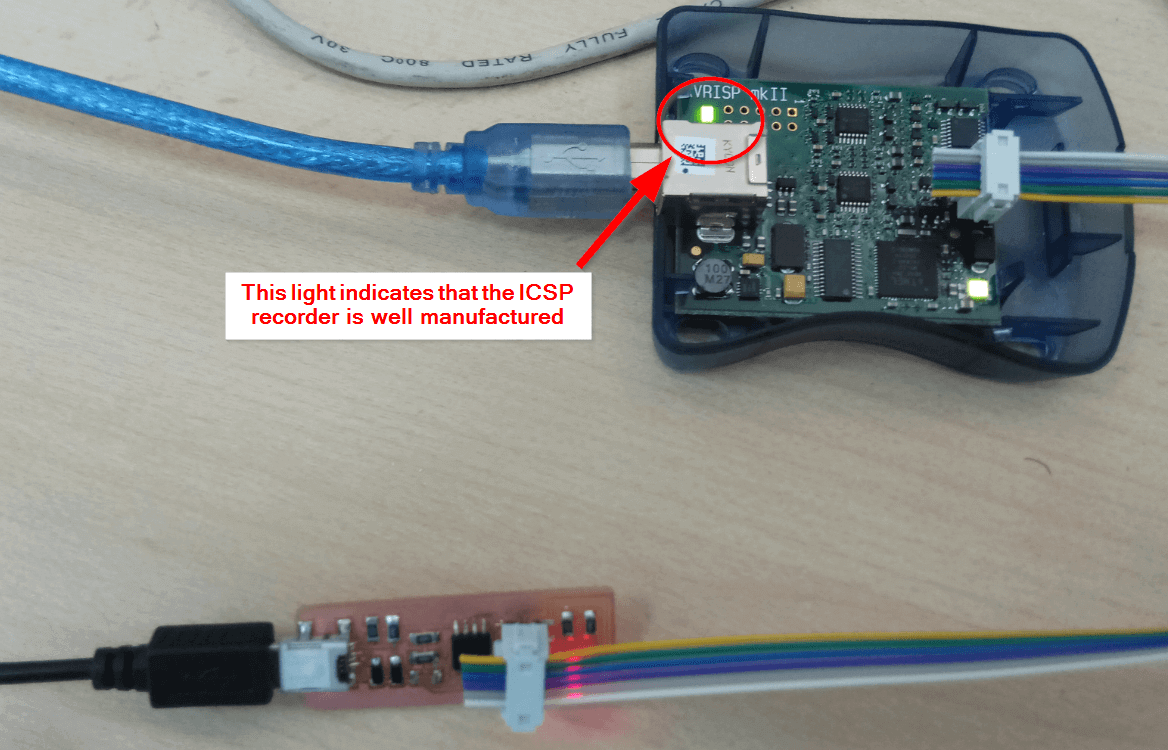

PCB Testing

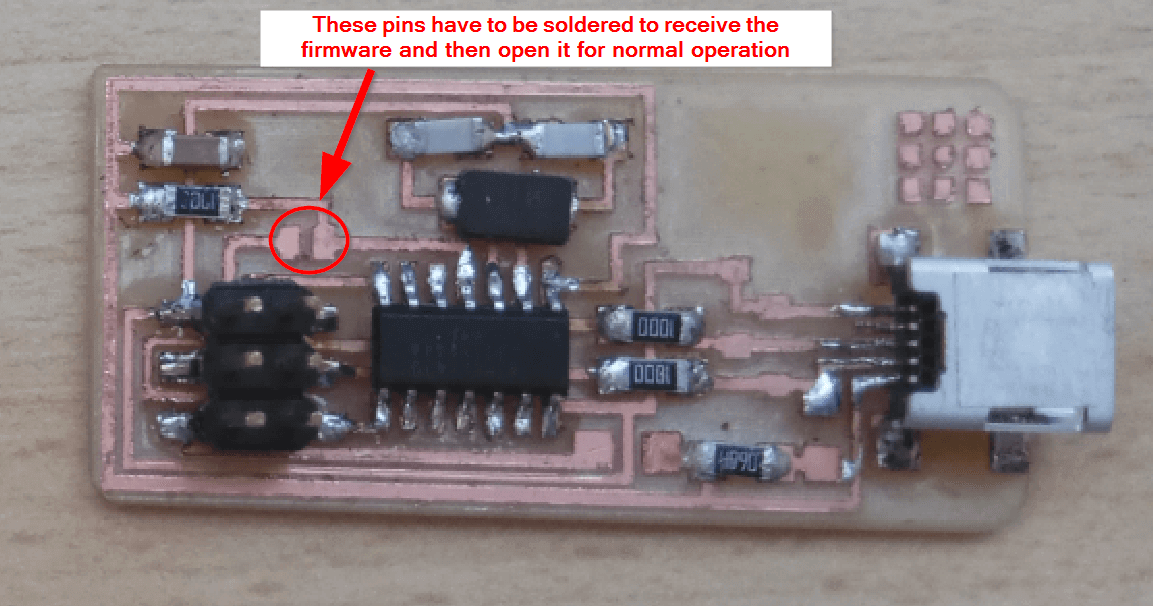

To testing our PCB is necessary use an AVR programmer, to load the firmware into the microcontroller this only once

PCB Programming

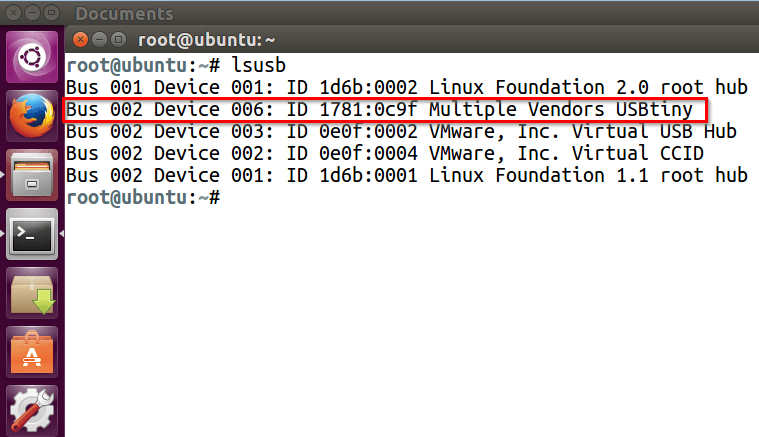

To test your fabICSP is necesary to conect to the PC to confirm that this acknowledge the USB port

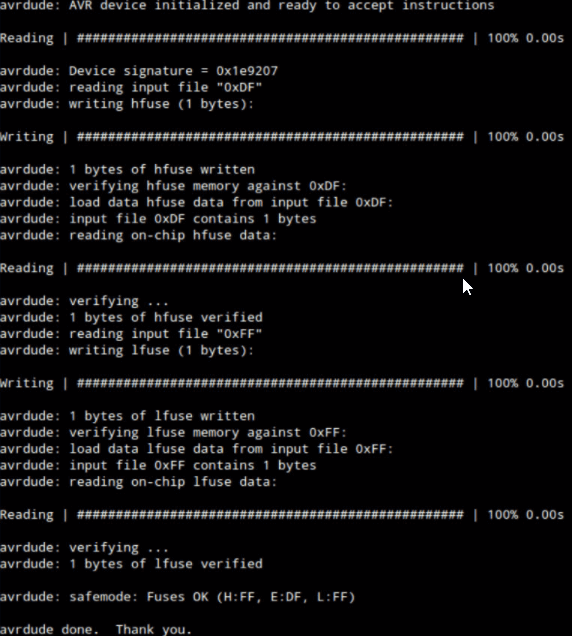

Finally I configure the fuses and download the firnware

|

|---|

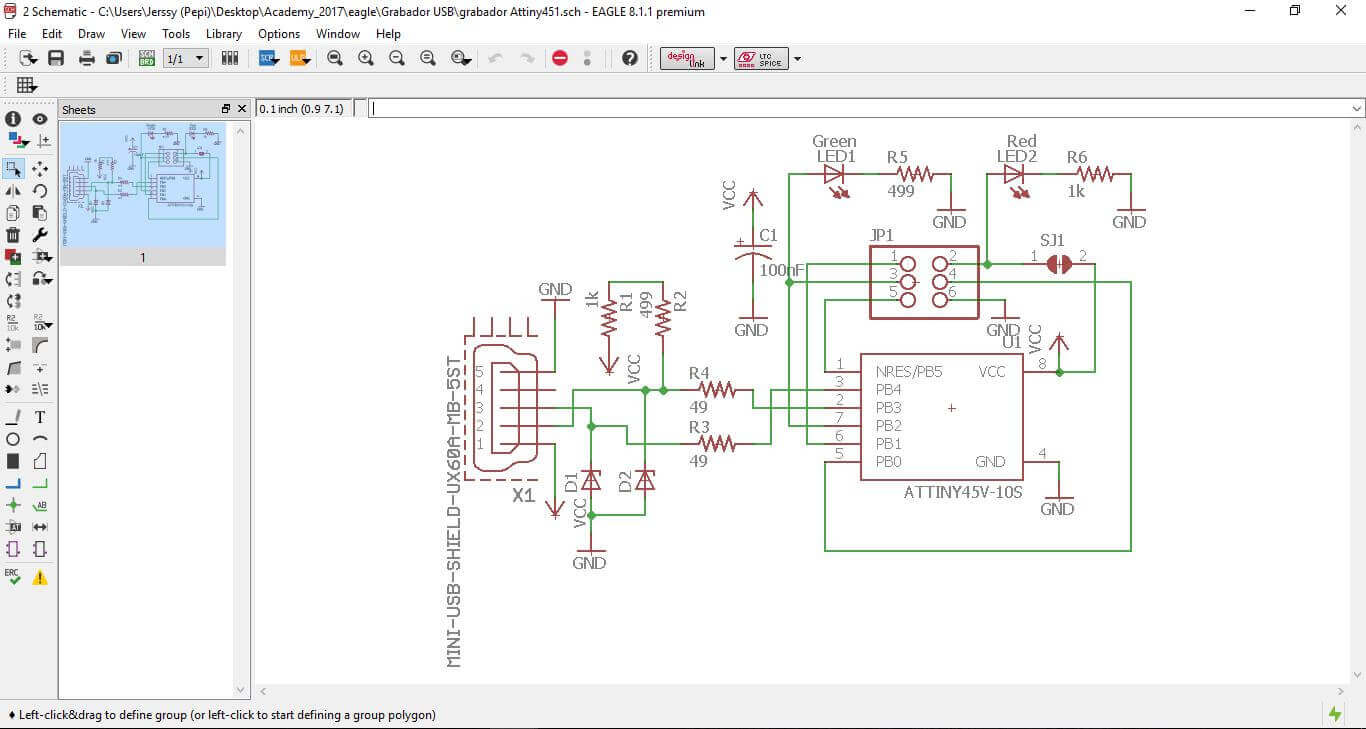

Designing my own FabICSP with Attiny45

For this assignment i decided do my own FabICSP design using the attiny45 and the PCB design software eagle to design my circuit, the schematic for this design is the follow:

|

|---|

|

|---|

Now I going to show you some differences between my two boards

|

|

|---|

|

|

|---|

Areas for improvement

- I have to practice enough to achieve a good soldering point

- Prior knowledge of electronics is required

- I Needed Good knowledge of the parameters of the Modela milling machine

Selft evaluation

- What worked:

- I design in eagle and weld my PCB with success, because I have some previous experience

- What did not work:

- I couldn't tried my FabICSP over Windows

- Things to improve:

- Program the FabICSP over Windows operating system