Contents:

1. Introduction

In a travel by Germany, I could see how the Delta robots works in the factories, I was delighted with its performance, and I started to think how I will controlled it ,

and the most important how i will teach this concepts to my students, was in that moment that I decided build my own Delta robot,

and learn how to controlled it, and the Fab Academy was the perfect solution to my doubts.

For this project I need to reinforce my knowledge in mechanics because this is my Weak point, my motivation for this project is my fascination by mechatronic devices, especially robotics.

2. Define and planning the project

2.1 Scope of the project

My project consists of the develop, design, build and control a Delta robot, which will be used for pick and place, for example if we want to order several products

in a box that will then be transported, this Delta robot has to be low cost with the posibilty to be replicated.

The project is also oriented to the development of the knowledge of modeling and control of this type of mechanisms

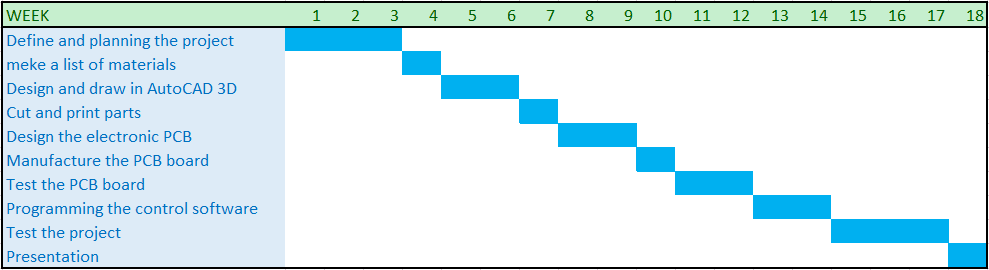

2.2 Schedule

To have more order in the project I am proposing the following schedule.

2.3 material's list

To build my Delta robot I going to need the following materials

- 1 Acrylic 8mm

- 1 Acrylic 5mm

- 1 MDF 18.5mm

- 3 Stepper motor

- 3 A4988 Driver

- 3 Bearing 12x42x20

- 1 Switching source

- 1 vacuum pump

- 1 Vacuum Cup

- 1 Solenoid valve Mini

- 1 T 3 Way

- 20 Bolts M3 of 8, 12, 20mm

3.project development

3.1 Development of the mechanical part

To begin defining the concept of the mechanical part develoment, I start making a sketch of what the physical Delta robot would be

Mechanism design

I started my mechanical design on blackboard

After I did the design in Autocad, I had some problems with my first design in Autocad 3D, because I thought make the superior base on a 3D printer but my design was so big for it.

For this reason I decided use acrylic for the base.

To the framework, I decided use MDF of 18.5mm

For the couplings I decided print it in the Stratasys Object 30 Prime

For the forearm I used 3.4mm steel rods

Finally I made and assembling the mechanical structure

3.2 Development of the electronic part

I design a Power module to control my stepper motors, for this I used eagle software.

I used my fabduino that i made in the assignment of output device, and I connected with the power stage, to control the stepper motors

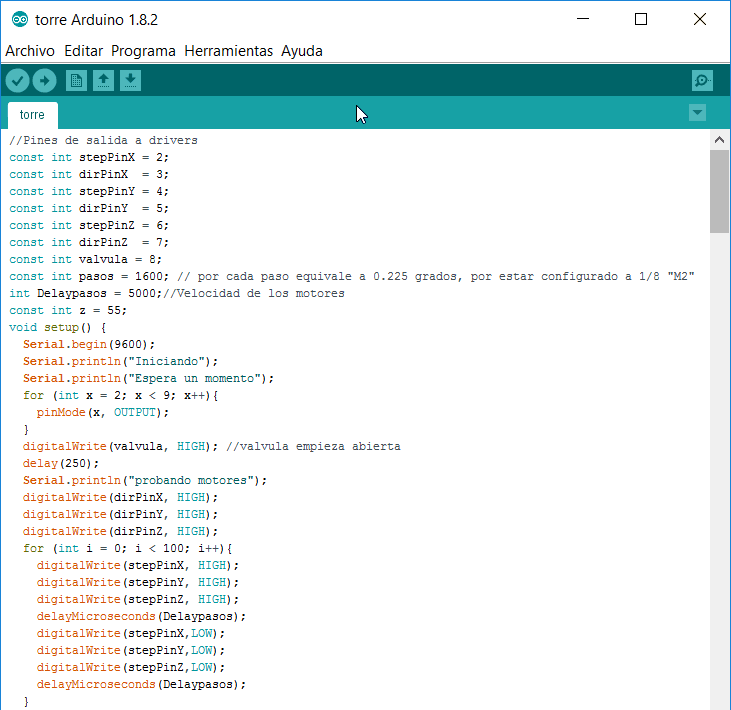

3.3 Development of programming

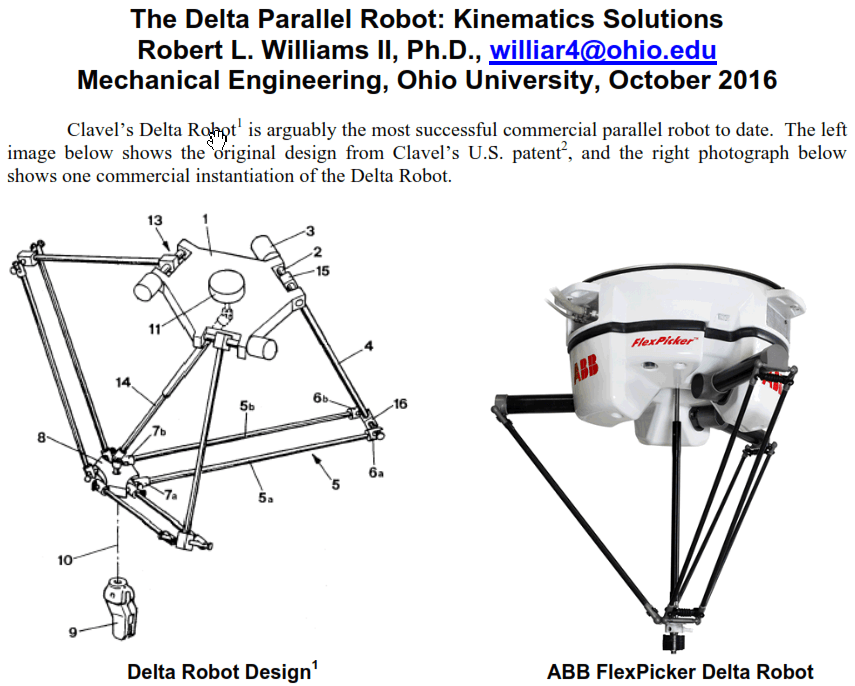

In the beginning I thought use "C" language over Ubuntu, but was more easy use the Arduino IDE, because has a lot of information in the web, the other problem was do the mathematical model, to controll the Delta Robot, Happily I found a paper "The Delta Parallel Robot: Kinematics Solutions Robert L. Williams II, Ph.D., Mechanical Engineering, Ohio University, October 2016" with how to do this but this was complex and i had to simplifie to use with the Fabduino microprocesor ATmega328p.

Finally I implemented a program to build a tower

4.Testing

At last I did some test with the Delta robot

5. Self evaluation

- What worked:

- I designed, Built and controlled my delta robot with success

- What did not work:

- My Delta robot have some problems with the homing position, because this task is in mode manual, and for this reason loses accuracy.

- The ATmega328 processor of Arduino is not enough to achieve a good control of the three axes of the Delta robot

- Things to improve:

- Implement a homing positión with limit switches.

- Do the motor coupling in metal to avoid errors in the movements

- Use a processor more power like the ATMega2560