FabAcademy2017 - Projects

Applications and Implications

May 24, 2017 - Week#17

What will it do?

I am making an intelligent robotic tracker that is able to do face and objects recognition & tracking, it is programmed to follow the certain object/face that the camera has captured. This will be used in different sectors like Security, Transport and Entertainment.

Who has done what beforehand?

Robots for that do face recognition & tracking are has been done beforehand, The person I know where I have even

got different help about installing OpenCV in my Raspberry Pi3, He is Adrian Rosebrock

Chief PyImageSearcher

What materials and components will be required?

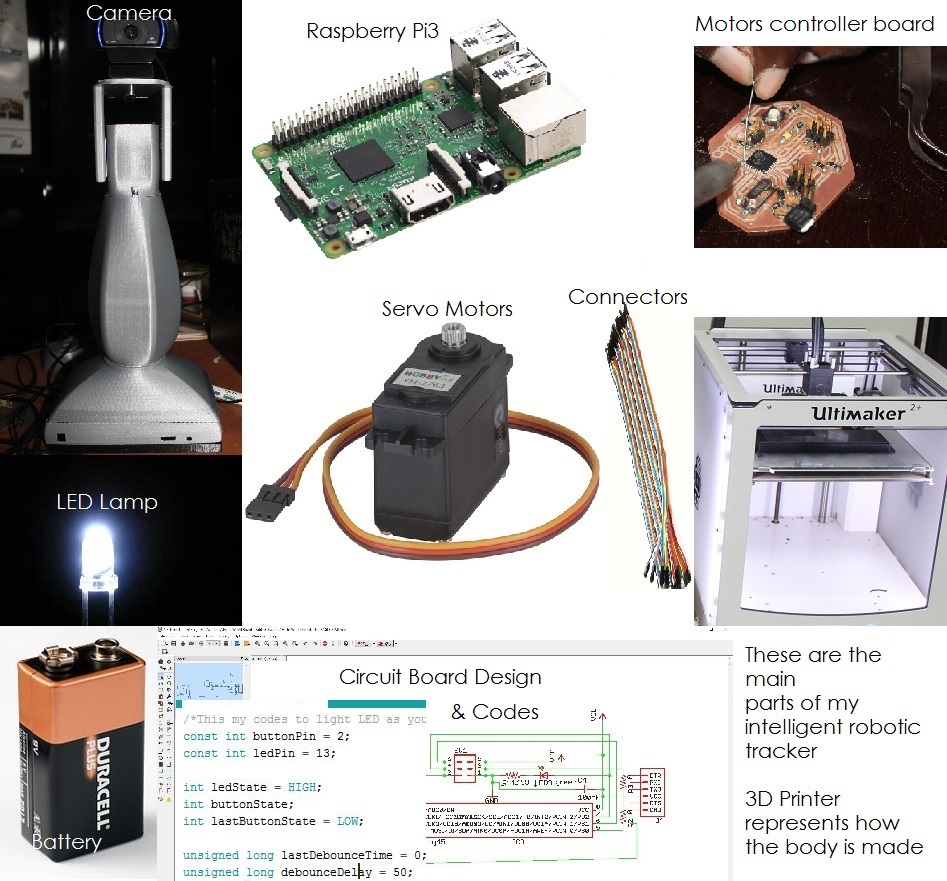

To be able to make my intelligent robotic tracker, it needs the following materials:

1. The Body: Made in composite or in plastic material printed with 3D printers.

2. Logitech HD 1080p WebCam: This serves as the computer vision.

3. Raspberry Pi3: I used this as a processor computer vision.

4. servo motor: To control rotation of the camera Right and Left, up and down.

6. Battery: Needed to supply power for motors and raspberry Pi3.

7. Motor Controller chip: This is designed to control the motors.

8. LED & Light Sensor: To enable automatic lighting system for the camera.

9. Wires: Connecting all the parts of the robot.

10.Display Device: To stream the video being recorded by the camera.

Where will they come from?

The mateials I used are all found in FabLabs, but also on the local market of any country those can be found there. Nothing i had to buy outside because we had every material I needed in our FabLab.

How much will it cost?

A Simple table to show the Bill of Materials for my Robot

| Item | Unit | Cost (USD) |

|---|---|---|

| Raspberry Pi3 | 1 | 39 |

| Servo Motor | 2 | 24 |

| Logitech HD 1080p Webcam | 1 | 59 |

| Baterry 9v | 2 | 17 |

| LED | 1 | 9 |

| Light sensor | 1 | 3 |

| Connectors | 1 | 10 |

| Total | - | 161 |

What parts and systems will be made?

I designed and 3D Printed my Robot's body in FabLab Rwanda. The motors controller was designed and programmed by me, The base is made in a mold which also made and the motors are hold in a box I made using lasercutter.

What processes will be used?

The processes to be used are: the 3D Printer to print the cover, Laser cutter also for the motor holder, The Shopbot to help in making a mold for the base of my Robot and CNC Milling Machine for circuit design and production.

What tasks need to be completed?

1. Designing all the parts of the Robotic tracker.

2. Printing them and assemble the parts and test them manually.

3. Adding all required materials to run the robot.

4. Design and Program the controller to start the Robot functions.

4. Test every part of the robotic tracker with the commands written.

What questions need to be answered?

Is the Robot able to track human face and follow him? Does it Rotate smoothly depending on the person's face movement?

After that, I will be looking whether my Robot can serve community using this face recognition and tracking tools.

what is the schedule?

The schedule for my project

| Calender | Activity |

|---|---|

| January 25, 2017 - March 01, 2017/td> | I first drafted a design for my Robotic Tracker and did final design with solidworks. I also designed some circuit boards that were required in that period |

| May 03, 2017 - June 07, 2017 | I did installations required, programming some parts of my robot adding input & output devices and testing the mechanical design of it to troubleshoot where necessary |

| May 03, 2017 - June 13, 2017 | Finally, the tasks to be done in the last period, are programming the controller and test the codes to see if they answer the above asked questions. |

How will it be evaluated?

The evaluation can only be done by checking the accuracy in face detection. and see how motors are responsive to the commands from the processor.