FabAcademy2017 - Projects

Composites

May 03, 2017 - Week#14

Here is how I made my mould for composite making.

Most of the times I wondered how the planes stay in air while hauling heavy loads and with the plane itself being heavy.

But, finally I came to learn that the body of airplane is made by composites which make it light. I found it interesting

and I became interested to know how composites are made.

I made some files for machining from designs that I took from my final project.

I described below the way I made my composite.

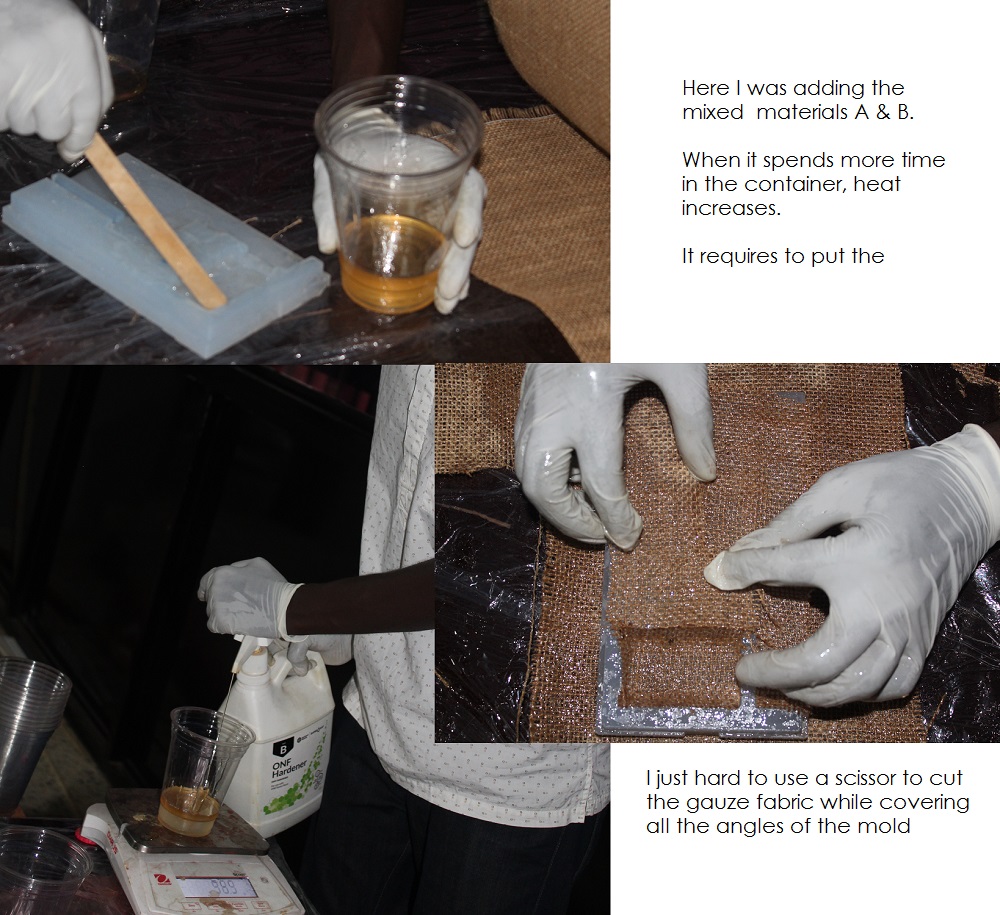

After making a mould, I had to put all the pieces together so that I start the process.

The Materials I used are; Epoxy and Hardener, to the ratio of 2:1 respectively, The mould is made out of rubber. I used gauze fabric as the cover to the body of the material, light plastic sheets, cotton, and a vacuum bag

1. I first mixed the Measure the amount of the Epoxy and Hardener to be used at the ratio of 2:1 as mentioned before.

2. I mixed them just to make sure they are well mixed. and In a short time I had to start putting that mixture to the material the time I delayed to

put the mixture to the material, it became hot and I didn't want that. I noticed it's a danger when to delay to remove it from the container.

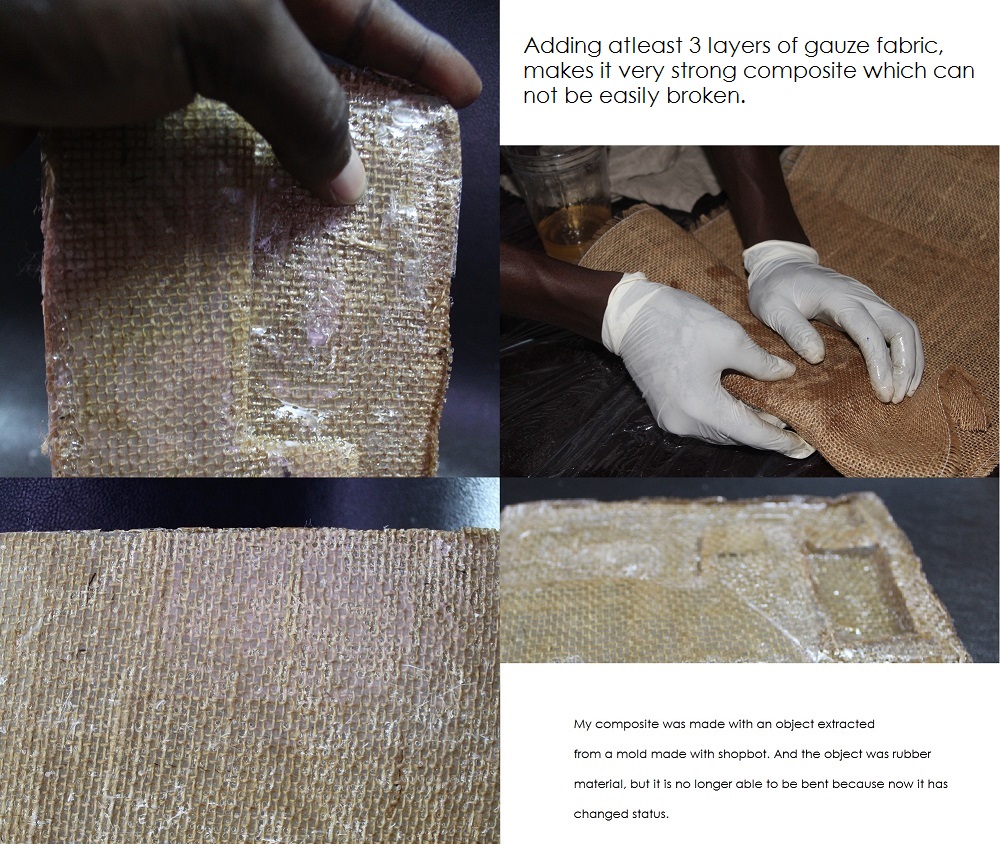

3. After putting the Epoxy and Hardener mixture to the material, I hard to cover my composite with the light plastic sheet and cotton before I pul the object in the vacuum bag.

4. I had to remove air into the plastic bag to make vacuum for the material to dry and become hard.

I listed below some problems and how I fixed them.

My mould had a lot of corners, and it was hard for me to put the gauze fabric in the mould, but later I decided

to take scissors and cut the gauze fabric according to the design of the mould.

Here is how I used Vacuum bag.

Below is my finished composite, normally rubber materials are very simple to bend but not after putting the Epoxy and Hardener mixture on the material. I waited for 24 Hours and composite was successfully cured.

I have Read and linked to the material safety data sheet (MSDS) and technical data sheet (TDS) for the resins that I have used.

Download the material safety data sheet (MSDS) and technical data sheet (TDS)

Below attached are original files of my 3D Mould Design.