Introduction

This week the assignment was to design a 3D mold, machine it, and use it to cast parts.

Items used- Machinable wax

- Roland modela

- Instamold

- Hydrostone

- water

The design

The design i used can be found in the Fab academy archives.

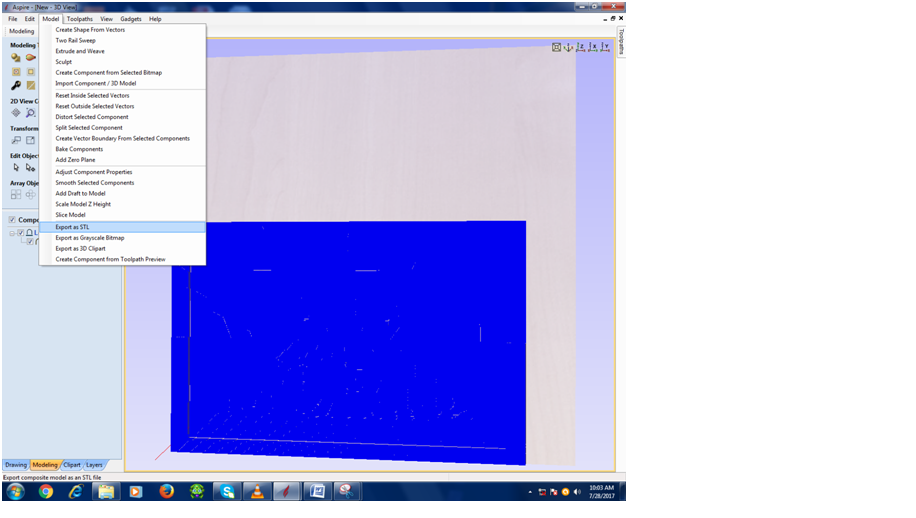

3D Modelling with Vectric Aspire

I enjoy modelling with Vectric aspire 8 since it has the capability to take a picture and transform it into a 3D model. I imported the hello world image and using modelling i was able to convert the mage into a 3D model and even alter the height and smoothness.

Since the software has a capability to convert the 3D model into an stl file i also generated an stl file and exported it.

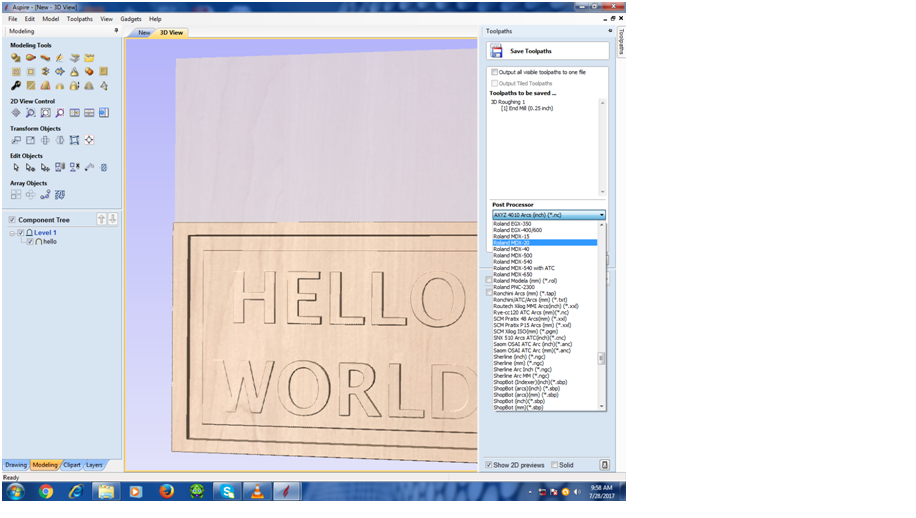

I then proceeded to generate toolpaths found on the right side of the window. I generated both a roughing and a finishing toolpath.

I exported the toolpaths using the roland modela mdx20 postprocessor

You can download the toolpaths below

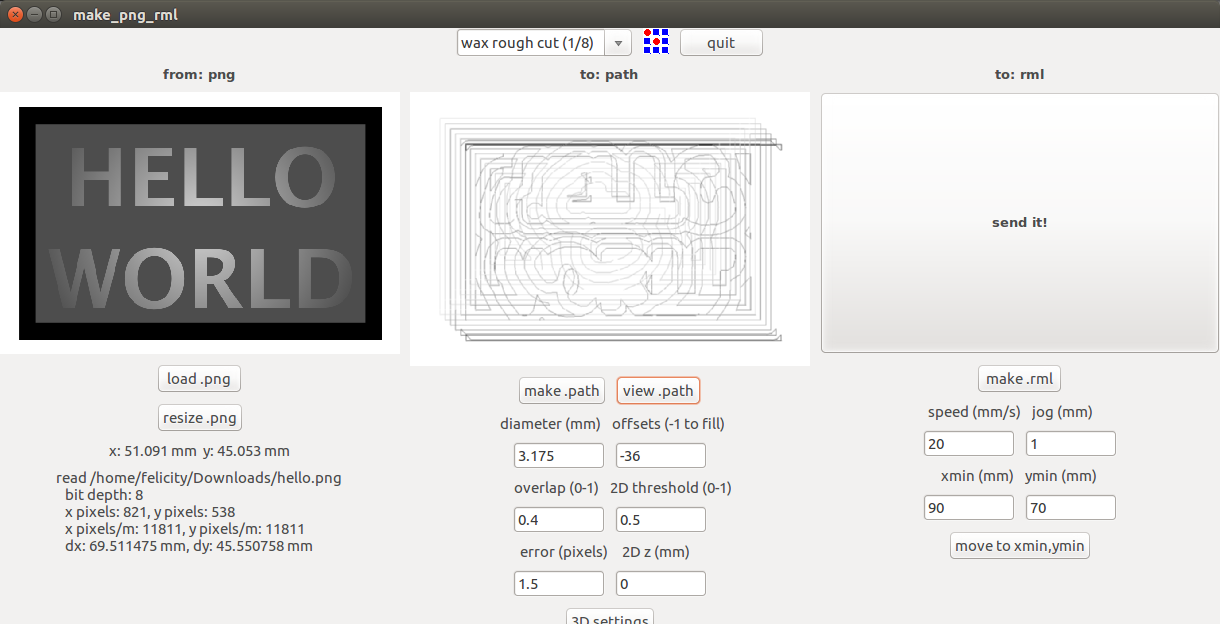

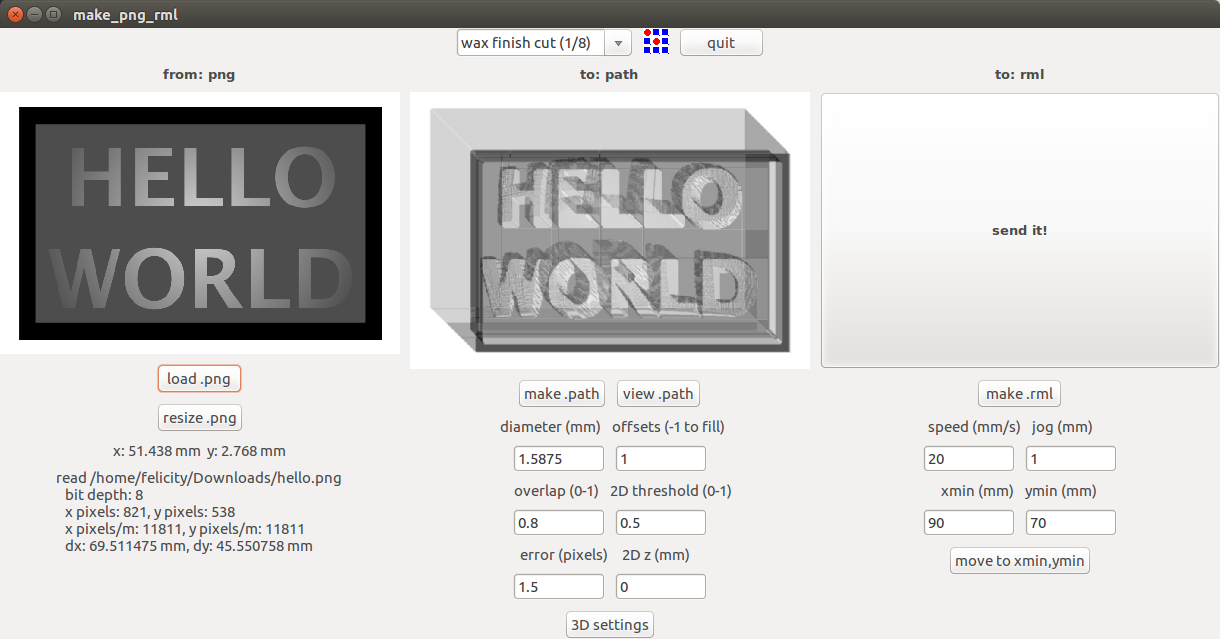

Fab modules

To do a rough cut i used a 1/8" tool and the following fab modules settings.

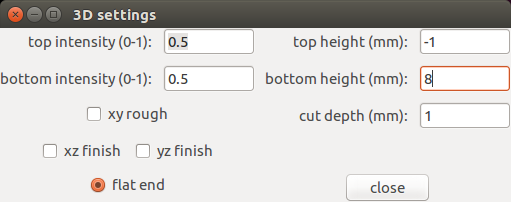

I also used the following 3D settings

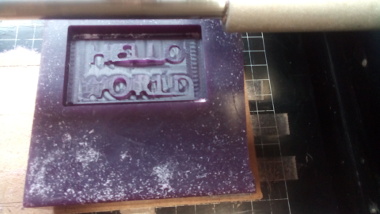

The rough cut results are shown below.

finish cut

for the finish cut i used a 1/16" tool wit the following fab modules settings

The mold 1/16"

Making the mold

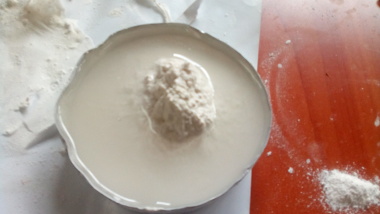

To make the mold i used instamold which is originally in powder form and is mixed with water in a 1:1 ratio.

instamold

making the mold

Depending on the liquidity of the mixture i had different outcomes. The firs one was too thick hence the mould was not well defined

The first mold was not very successful

after a few trials i finally got it right

Casting

The casting material available in our lab is hydrostone so i went ahead to use it. Just like the instamold the mixing ratio is 1:1. The mixture. The mixture take approximately an hour to dry up and is ready for removal.

The casting media

Mixing the media with water

casting

Removing the cast object

Outcome

The final cast object

Working with stl files

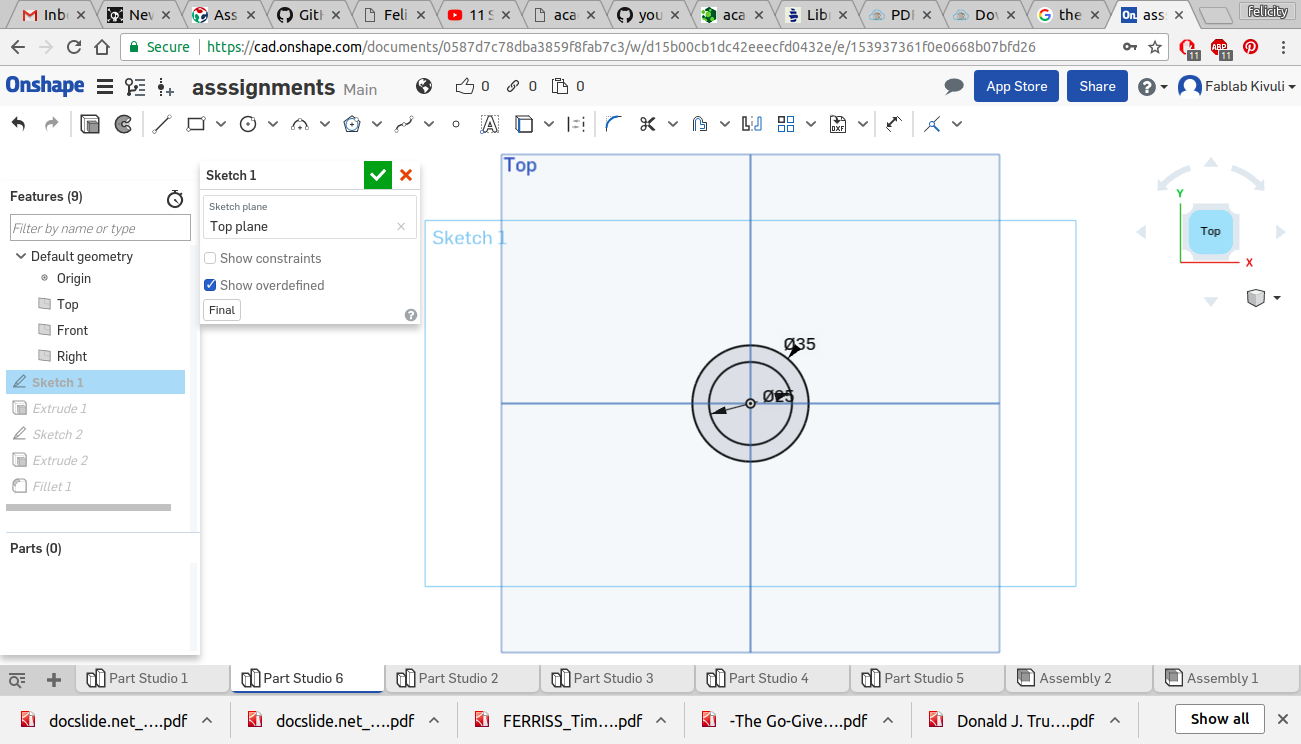

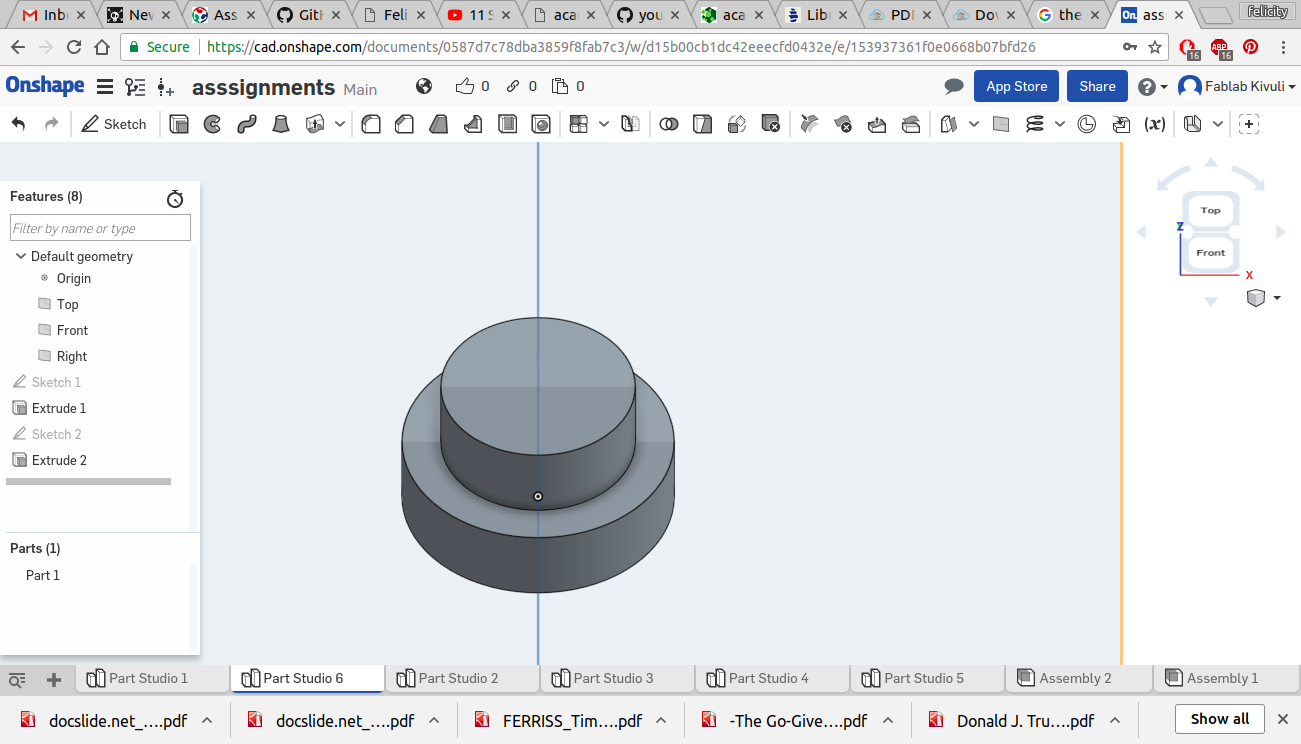

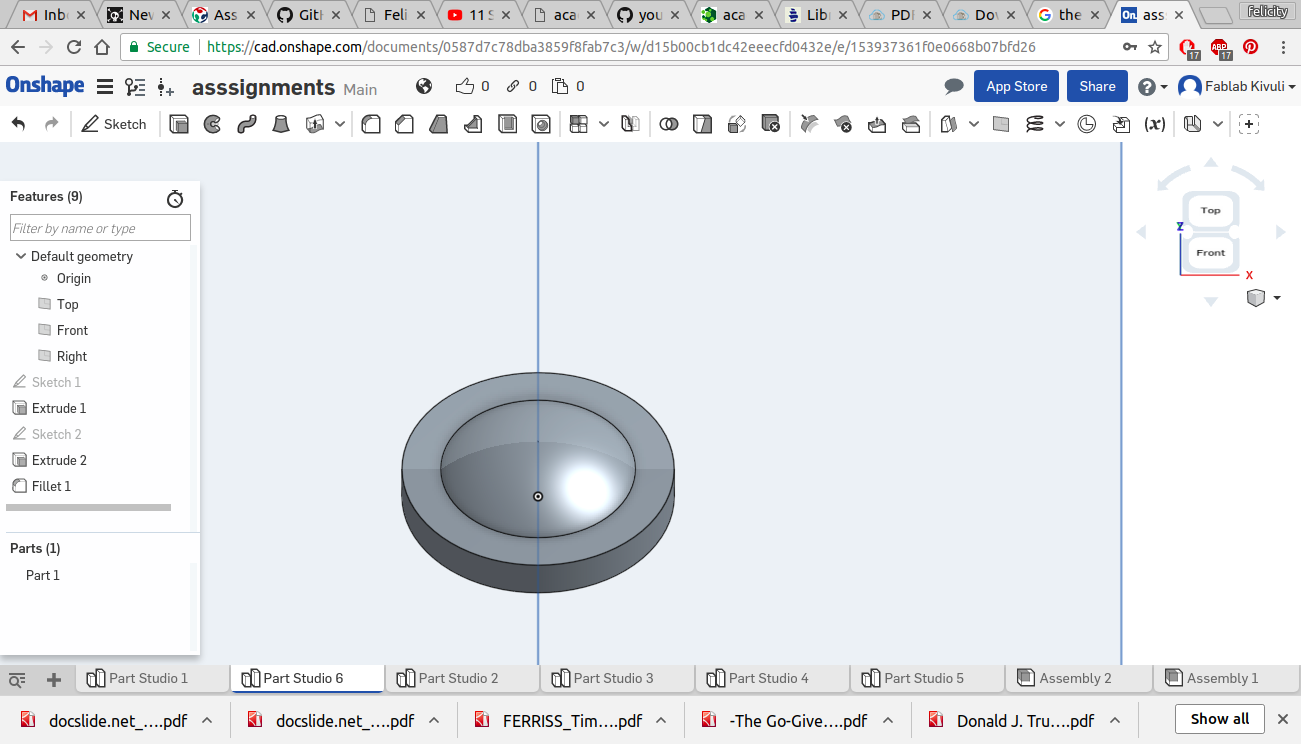

I furthet went on to try to work with stl files. I began by designing a model in onshape as shown

2D sketch

extruding

filleted model

The model can be found in this link here

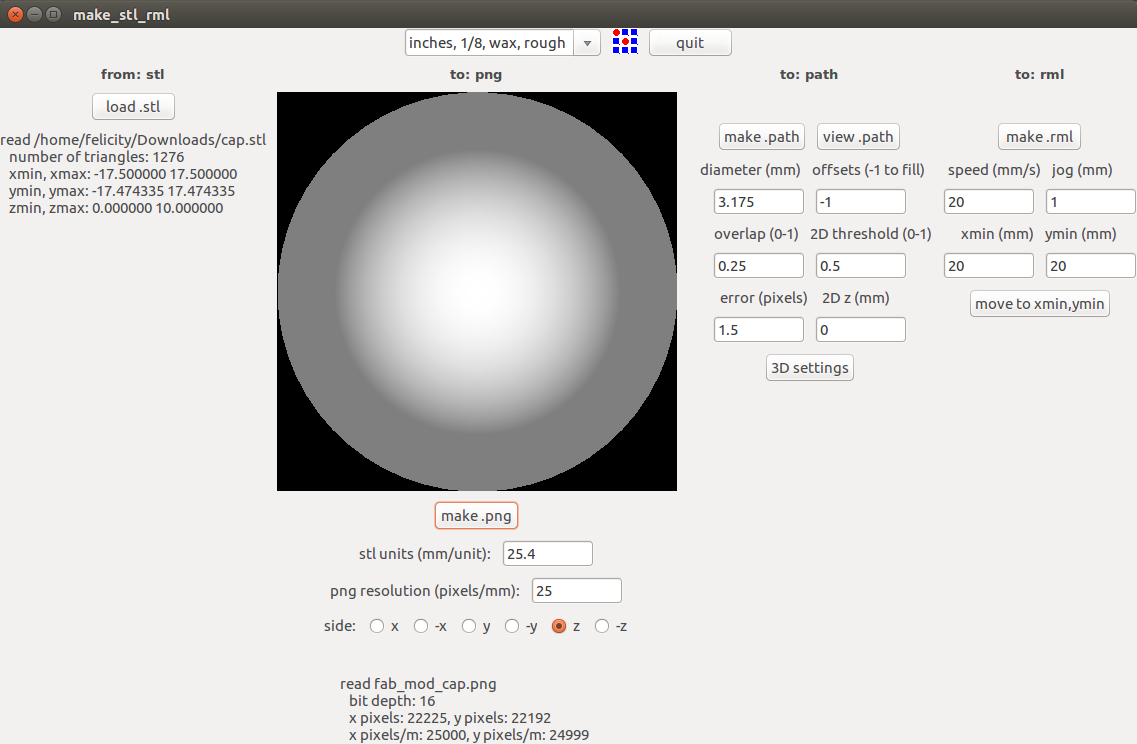

I then exported the stl file and imported it into the fab modules to convert it to a png image

Fab modules

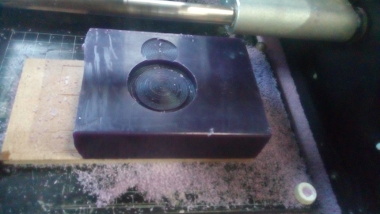

On sending to the modela the following were the results

Roughing

finish

I then went ahead to the mould making stage

mixing

mould making

The outcome of the moulding process is seen below

mould

Then i went on to cast with hydrostone casting media

Casting

The final outcome is as shown

Outcome