Since the beginning of FabAcademy I was interested in working with sensors.

My initial idea, described here remains a project I would like to work on, but I felt I couldn't deliver it the way I wanted in the amound of time left to complete my final project.

For my final, I decided to insist on the idea of multiple inputs, this time used for controling a parameter which I always wanted to work with: sound.

What will it do?

I will make a sound control interface, which will bear several sensor inputs. I am willing to interface with SuperCollider in order to produce sound. I intend to try out as many different input as I can in the time I have, and be inventive with the design of the interface. My goal is to develop a decent, functional object, while learning as many things as possible from the project itself.

Who's done what beforehand?

There are several projects I've seen on the internet which combine physical sensor interfaces with sound and light output.

Here is a list of my inspiration sources:

- Julian's Project: Penny Organ - How Music Works

- Introduction to the Mouse Theremin project https://versal.com/learn/1vmfne/lessons/1

- Drawing the Electric Synth

- Sketching Electronics -- Arduino Piano code

- Lilytronica by Aphroditi Psarra

Commercial Products:

- Theremini®

- Seaboard GRAND

What materials and components will be required?

Electronic components

Arduino programmable board // ATmega 32u4 micro-controller

mini-USB Output

12 Buttons

a Switch

2 Potentiometers

a Light sensor

Copper foil with adhesive backing for capacitive sensing

~15 feedback LEDs

Device // Casing

Clear Acrylic Sheet, white(2mm) and transparent(5mm)

Filament // Filaflex

Screws and Nuts

Where will they come from?

I will fabricate on my own all the things I 'm using for my project. The small electronic components as well as the materials I'm using for my prototype are already in the inventory of the FabLab.

How much will it cost?

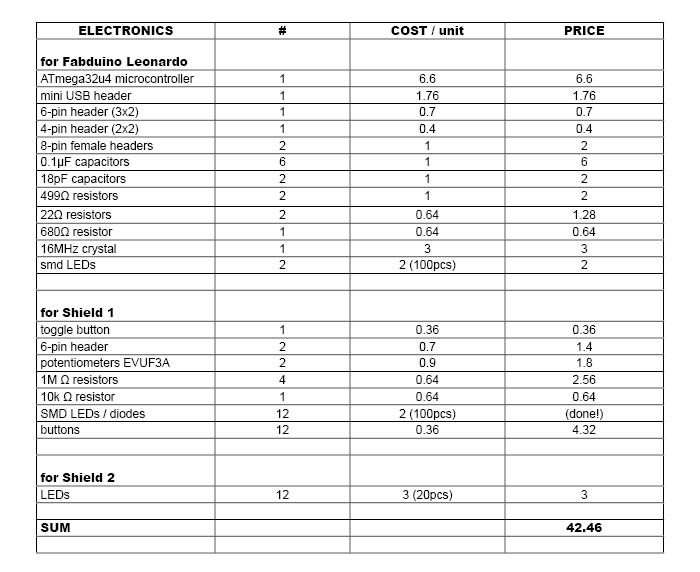

This is a low cost project in terms of electronic components.

Here is the list of the components used for my board and shields. The prices may vary according to the vendor. The prices stated can be found on Digikey and e-bay.

The major costs of the material I' ll be using is the Plexiglass and the Filaflex.

For my final prototype I used a piece of 200x200x5mm of transparent plexiglass and 2 pieces of 200x200x2mm of white acrylic.

The price of sheet of 1000x1000x5mm Plexiglass like the one I used is around 30€, depending on the vendor. The price reduces with smaller material thickness and from Plexi to Acrylic.

The cost of the GREENFFX ELASTIC FILAMENT (Filaflex) I used is 35,90€ for 500g.

What parts and systems will be made?

Electronics:

-A new Fabduino Leonardo -- I was planning to use my Circulino (FabLeo) for my final project, but some traces of the female headers proke and it became too difficult to prototype with it.

-A shield on which to plug all the sensors

-A shield for a multiplexed key matrix using LED diodes and plugging in series feedback LEDs.

-The object // device

What processes will be used?

-Electronics design - Roland milling

-Vinyl Cutting

-3D Printing

What tasks need to be completed?

I already had my fabbed arduino, but for practical reasons I will do it again.

I will use the logic of my LED array (output week), but instead of charlieplexing, I will use multiplexing (2x6, 8 pins) for my keyboard and feedback LEDs.

I will make a copper foil vinyl cut and extensive laser cutting with acrylic and Plexi.

What questions need to be answered?

I will have to decide on:

-Which sensors give better results when mapping their inputs and combining them with sound programming

-The architecture of my object and its electronics, so that it can be easily fabricated / reproduced

-what more will I be able to do with it, in a "universal controller" concept, apart from sound control

What is the schedule?

I am planning to spend equal amounds of time on electronics and fabbrication and less time on programming.

After designing my second FabLeo - Sounduino, I made a 10-Day TO DO list including the following tasks:

Day 1:

-Prototype the sensors

--decide on pins to use

--write & check input code

--prototype button matrix

Day 2:

-Design shield with sensors, according to microcontroller board

--mill, solder board

Day 3:

-Design object 3D

--prototype 3D printed parts

--prepare files for trial laser cutting for insides // supports

Day 4:

-Write code for Synth in SuperCollider, decide on sounds / Osscillators, fix communication with Ardiuno IDE

Day 5:

-Prepare files for final object (laser cutting and 3D printing)

Day 6:

-Fabricate final object

Day 7:

-Assemble parts with electronics, sensors

Day 8:

-Program altogether

Day 9:

-Make Video

Day 10:

-Design Presentation Slide

[**The schedule I made was extremely tight, but I had already rethought on most of the tasks I would have to complete.

The problems I faced and delayed me by two days, but I knew in advance that the tasks I'd planned for the last two days needed significantly less time.]

Here is a picture of the things I have to do, written on a list

How will it be evaluated?

Personally I have set two goals for this project:

1/ learn as much as I can about inputs

2/ make it work!

In this, the following were my priorities:

- learn how to interface with Arduino IDE and SuperCollider

- design a fancy kit and fit all the electronics inside

- make sound!