Making an Assebly Kit

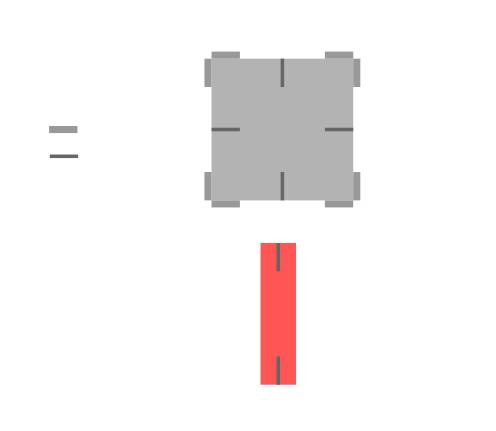

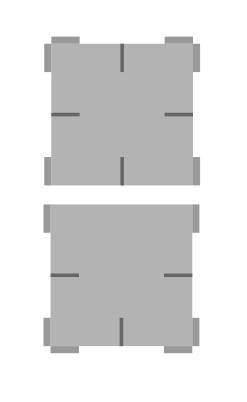

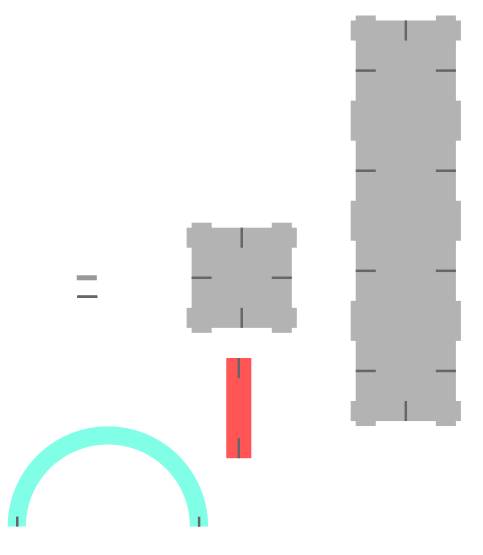

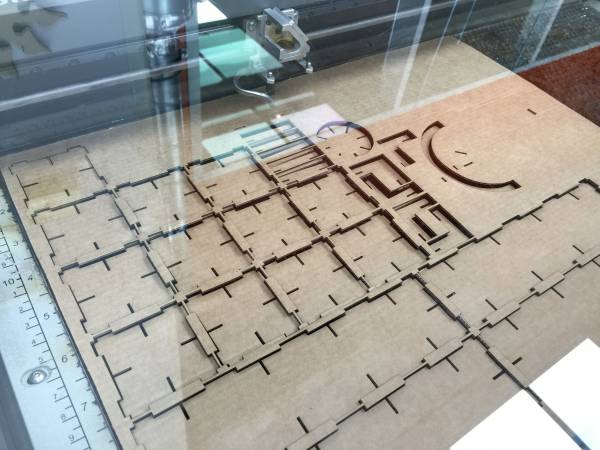

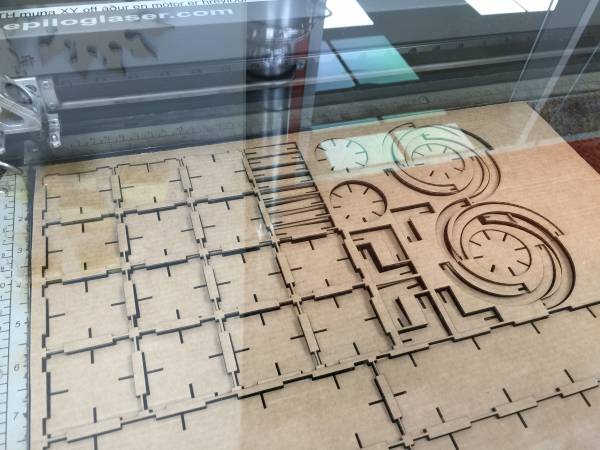

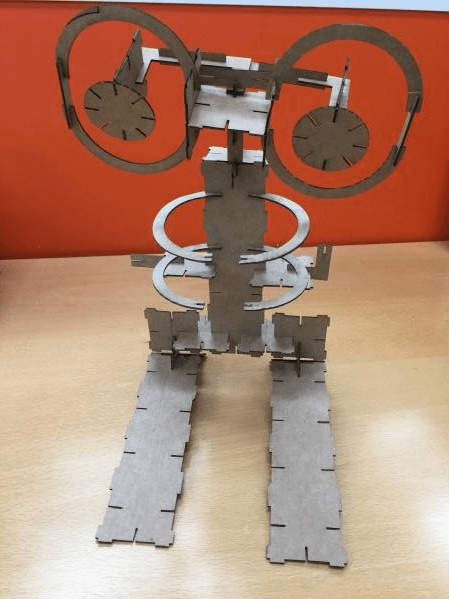

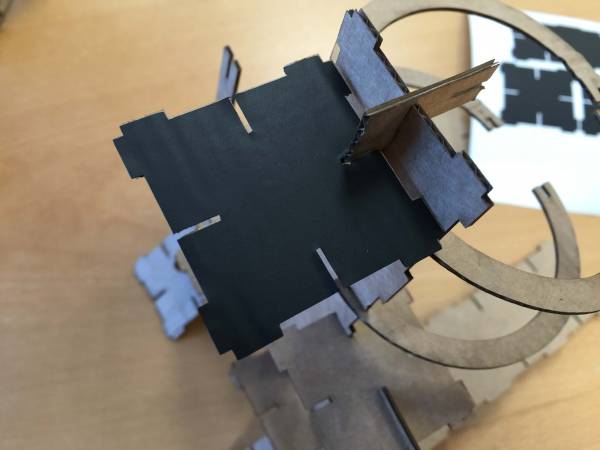

This week I made an assembly kit with a laser cutter and a cardboard. I wanted to make something that reminded me of legos, something simple, straight forward and fun, with it’s limitations but some that you could work around.

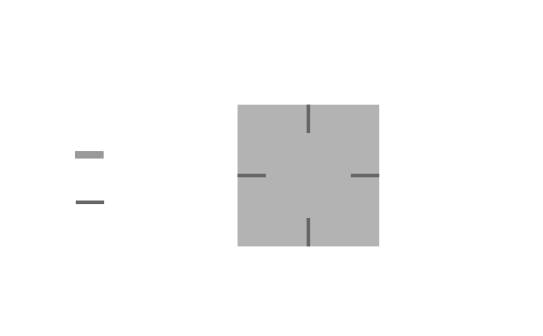

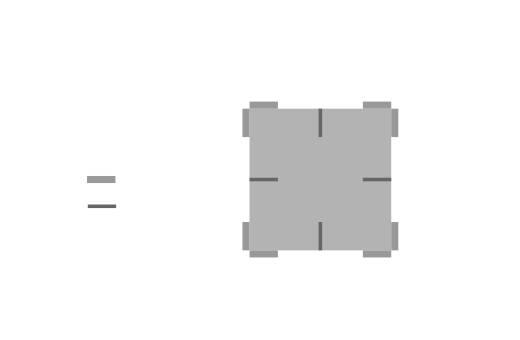

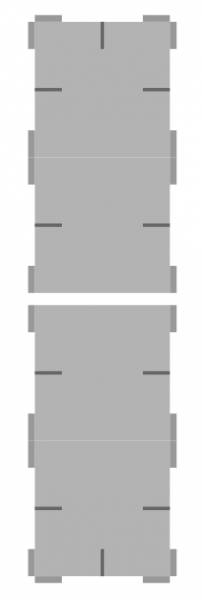

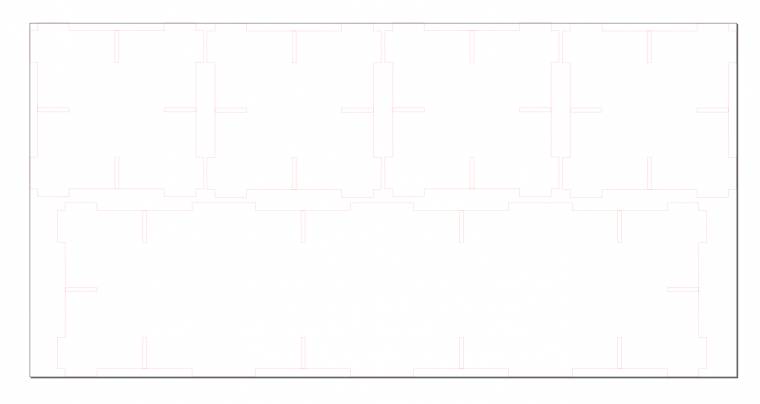

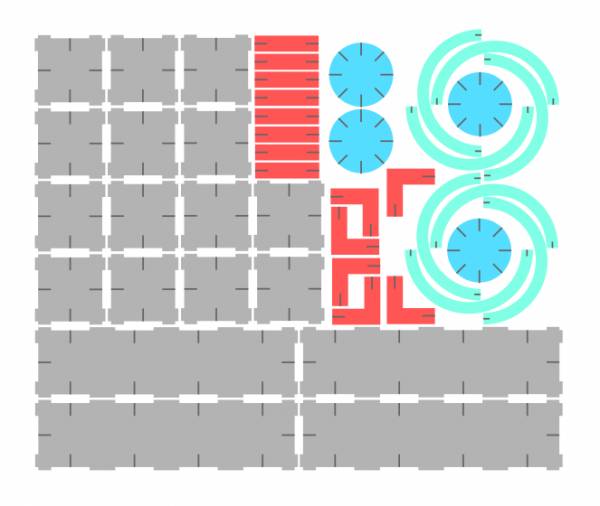

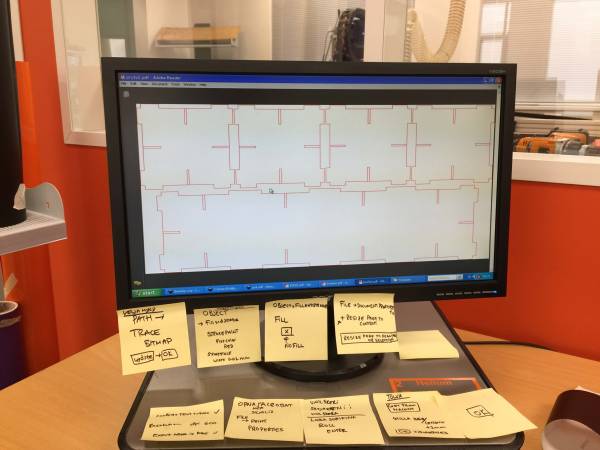

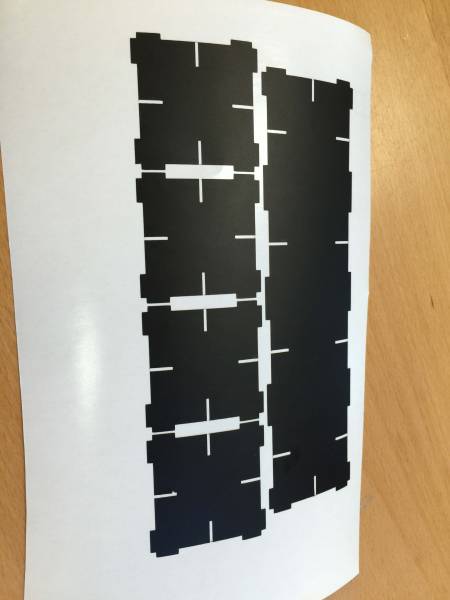

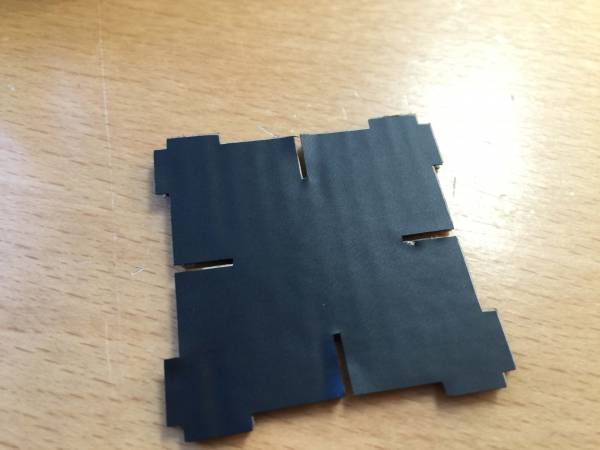

Starting in inkscape I made a square (40x40mm) and a rectangle (1x8mm) to make the cutouts in the square. I first made a master cutout that I made all the clones with, where if you change it in any way, the changes would apply to every clone.I made another master rectangle, which wasn’t a cutout but a addon knob to be able to assemble the kit in many other different ways. One thing to note I discovered that to unify clones with another object you need to unclone them first.

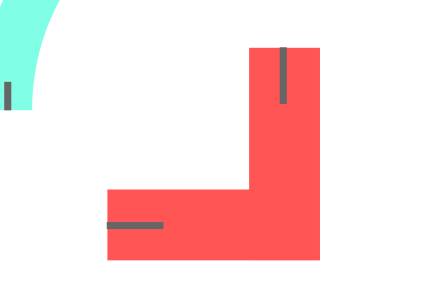

I wanted this to be my main building block and have it work the same way no matter what way you turned it, but that would create a small problem where the knobs would sometimes interfere with each other hence the limitations.