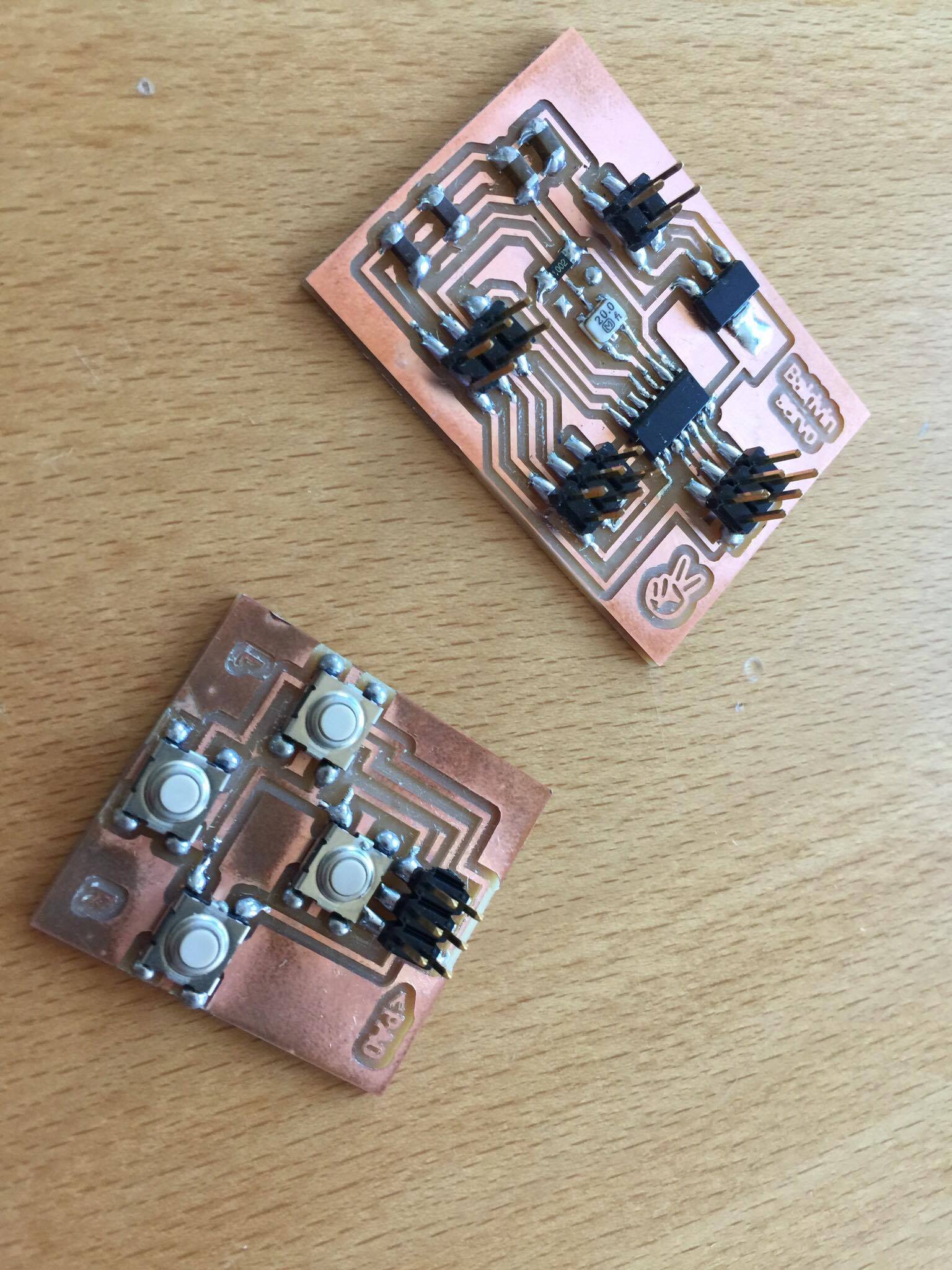

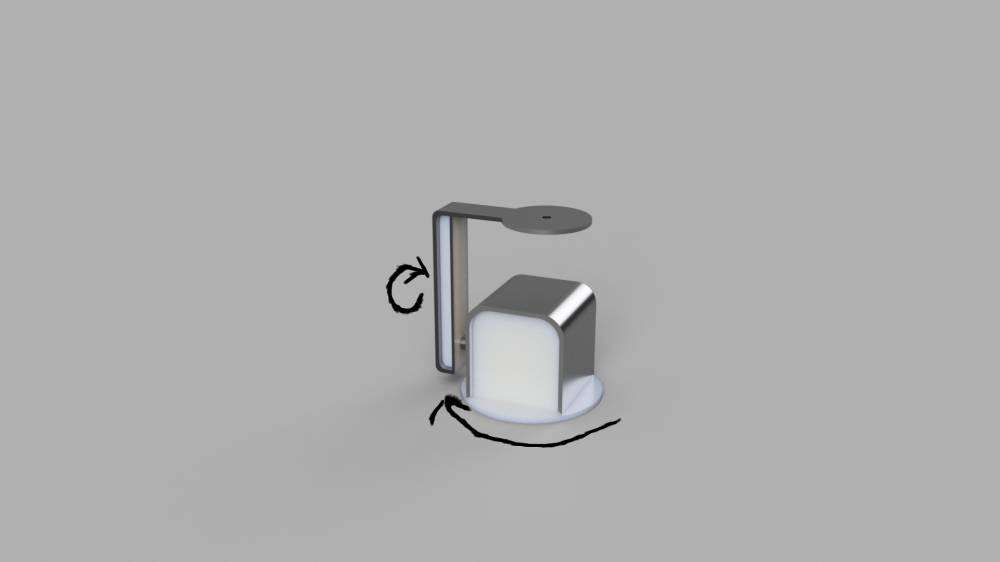

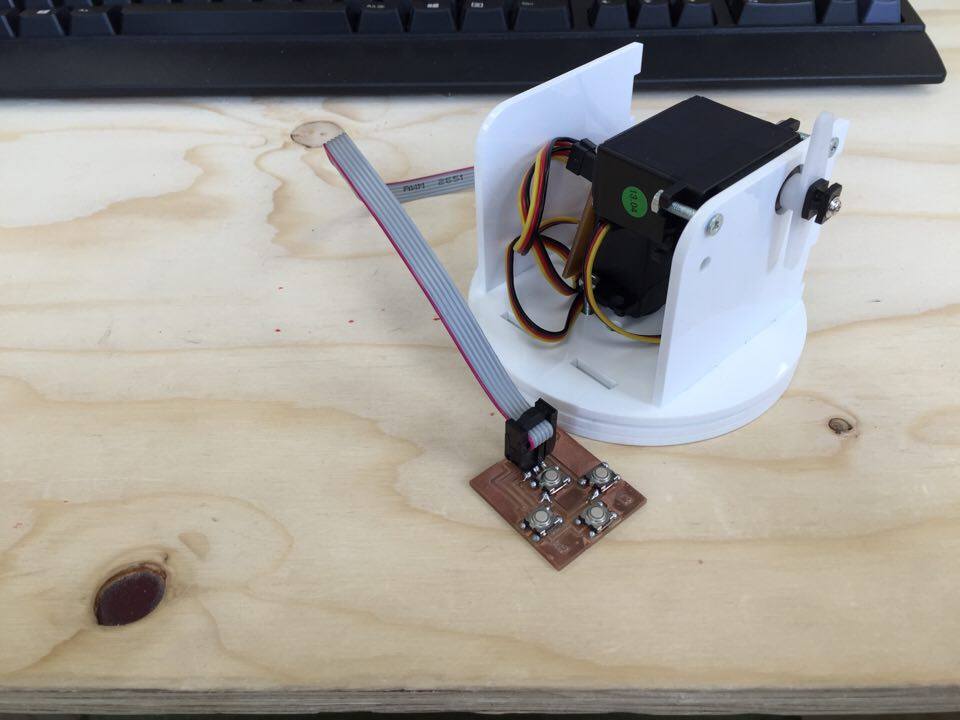

I wanted to get the boards done as fast as I could so I could get started sooner on the programming since I have little as no experience with programming. My plan was to get the programming of my back as soon as I could and get the servo’s functioning like I wanted, before doing the design of the whole thing.

I started of by modifying Neil’s original code and figure out how it worked. That wasn’t really going too well for me so I moved on to the arduino environment and found a library for servos.

The library is called RBD_Servo and you can find instructions on their side

With great help from Baz I was able to write a code that could demonstrate everything I wanted the servo’s to do.

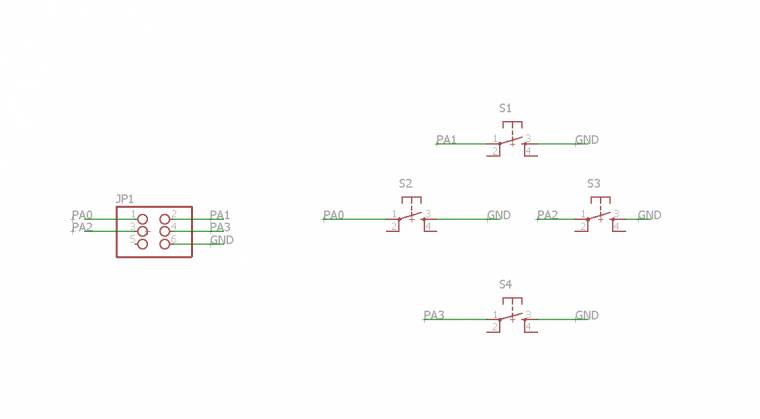

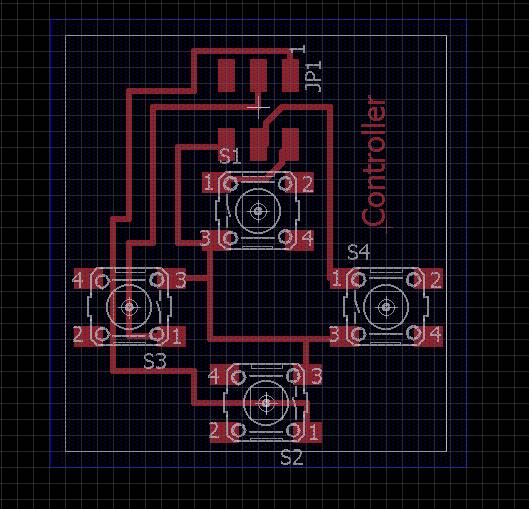

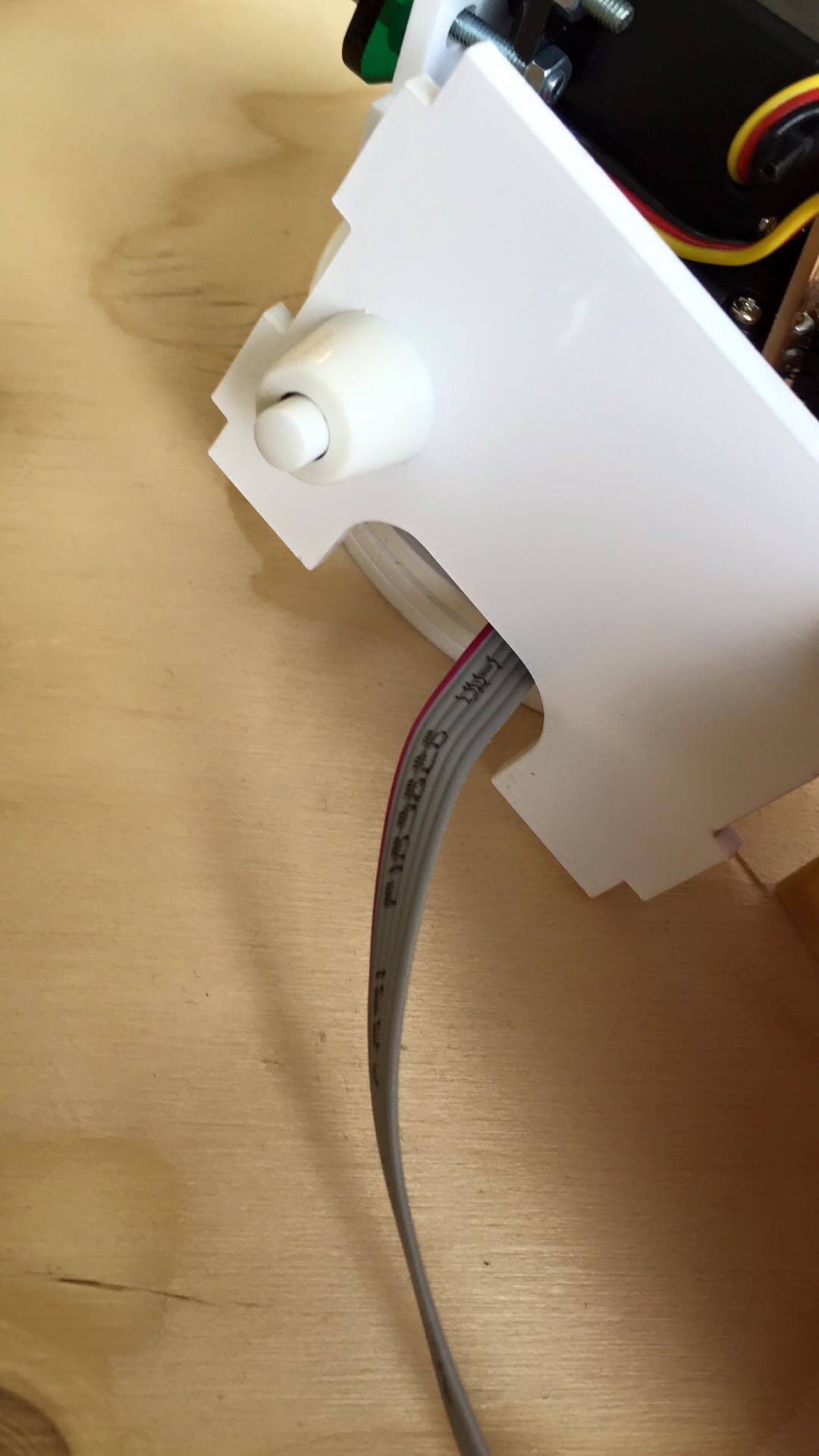

I did run into some problems and the servo’s were behaving strangely. I first tested the buttons to see if they would connect the pin to the ground and they did. In the code I had to add “INPUT_PULLUP” instead of just “INPUT” to get the buttons functioning properly.

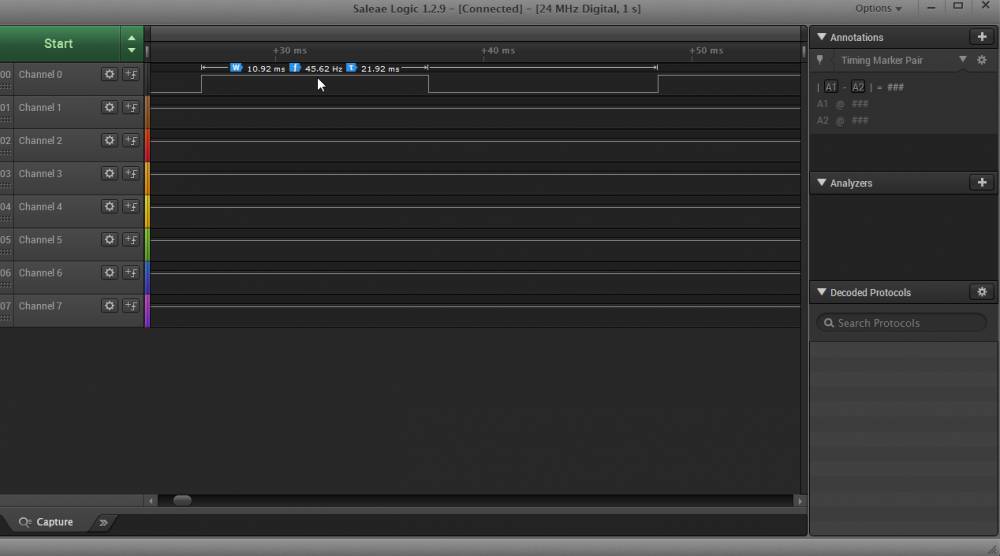

Still they were a little strange and with an logic analyzer I was able to detect the problem.

The servo’s go to a set degrees based on the length of the signal they receive. But they also need a minimum pulse signal to make them move. What I saw in the logic analyzer was that the minimum pulse signal was too long for the servo’s making them think they had to move more than 180 degrees.

Also I had delay in the code that was of no use. I removed the delays and shortened the minimum pulse length to 0,5 ms instead of 1 ms.

Then the servo’s started going where I wanted them to and was able to finish the code.

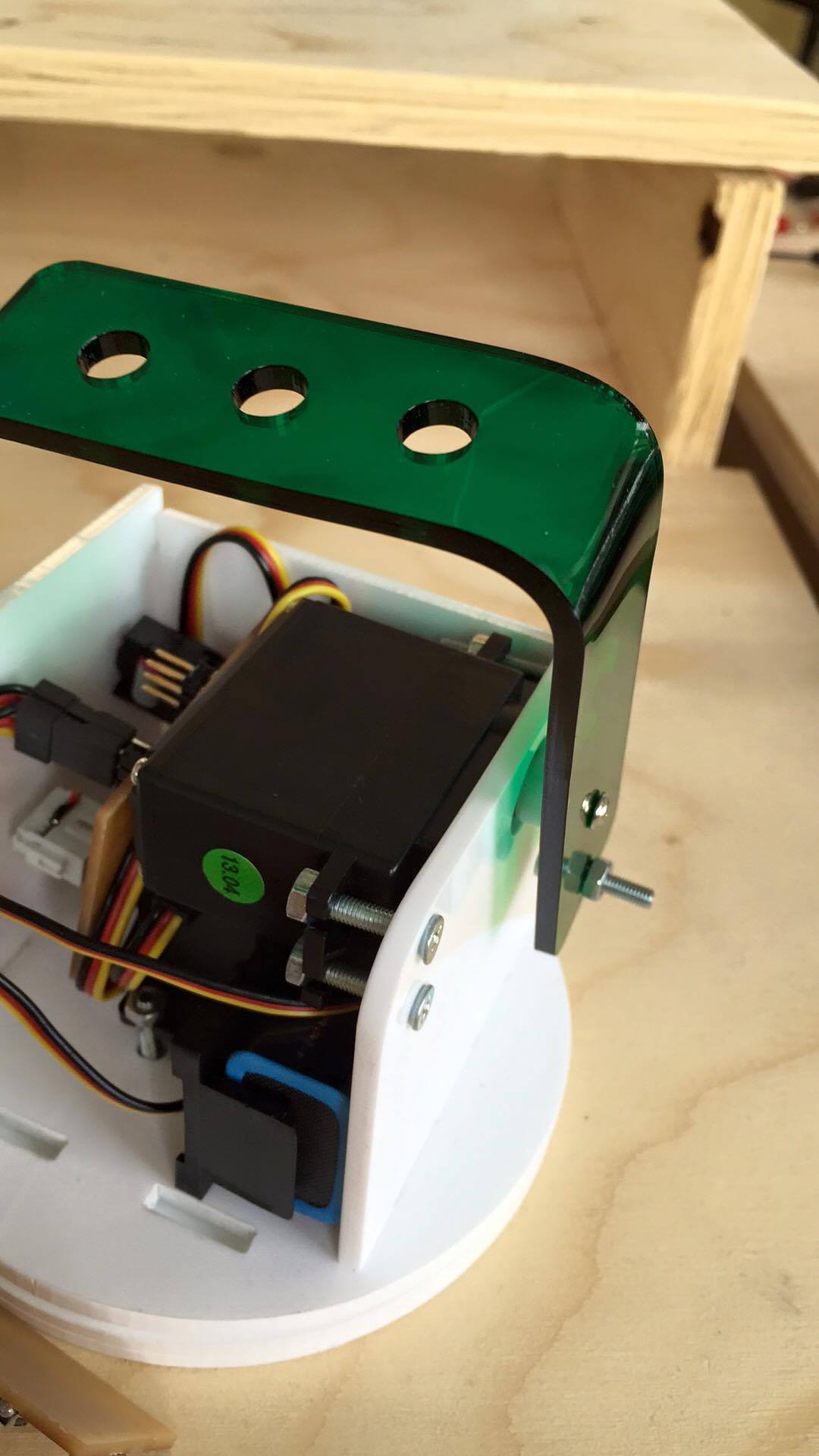

Since the servo’s were going to be holding gear I had to constantly send updates to them to keep them still in the same place. Here is the code:

// Arduino RBD Servo Library v1.0.1 Example - Move a servo with a 1-2ms pulse and 20ms interval to 90 degrees.

// https://github.com/alextaujenis/RBD_Servo

// Copyright 2015 Alex Taujenis

// MIT License

#include // https://github.com/alextaujenis/RBD_Servo

//telling the program which pins the servos connect to, and minimum pulse lenght

RBD::Servo servoP(6, 500, 2000); //pin 6, 0,5ms - 2ms pulse

RBD::Servo servoT(7, 500, 2000); //pin 7, 0,5ms - 2ms pulse

//giving every button a name, buttonLeft etc.

#define BL 2

#define BR 3

#define BU 0

#define BD 1

void setup() {

servoP.moveToDegrees(90); //servo pan starting point to 90

servoT.moveToDegrees(90); //servo tilt starting point to 90

pinMode(0,INPUT_PULLUP);

pinMode(1,INPUT_PULLUP);

pinMode(2,INPUT_PULLUP);

pinMode(3,INPUT_PULLUP);

}

void loop() {

servoP.update(); //constant updates to keep the servos in place

servoT.update();

//

//

// FOR LEFT

//

//

if (digitalRead(BL) == LOW) {

servoP.moveToDegrees(180);

while (digitalRead(BL) ==LOW){

servoP.update();

servoT.update();

//

// if left and right

//

if (digitalRead(BR) == LOW) {

while ((digitalRead(BL) ==LOW) && (digitalRead(BR) ==LOW)){

servoP.update();

servoT.update();

servoP.moveToDegrees(90);

}

}

}

}

//

//

// FOR RIGHT

//

//

if (digitalRead(BR) == LOW) {

servoP.moveToDegrees(10);

while (digitalRead(BR) ==LOW){

servoP.update();

servoT.update();

//

// if right and left

//

if (digitalRead(BL) == LOW) {

while ((digitalRead(BL) ==LOW) && (digitalRead(BR) ==LOW)){

servoP.update();

servoT.update();

servoP.moveToDegrees(90);

}

}

}

}

//

//

// FOR DOWN

//

//

if (digitalRead(BD) == LOW) {

servoT.moveToDegrees(120);

while (digitalRead(BD) ==LOW){

servoP.update();

servoT.update();

//

// if down and up

//

if (digitalRead(BU) == LOW) {

while ((digitalRead(BU) ==LOW) && (digitalRead(BD) ==LOW)){

servoP.update();

servoT.update();

servoT.moveToDegrees(90);

}

}

}

}

//

//

// FOR UP

//

//

if (digitalRead(BU) == LOW) {

servoT.moveToDegrees(60);

while (digitalRead(BU) ==LOW){

servoP.update();

servoT.update();

//

// if right and left

//

if (digitalRead(BD) == LOW) {

while ((digitalRead(BD) ==LOW) && (digitalRead(BU) ==LOW)){

servoP.update();

servoT.update();

servoT.moveToDegrees(90);

}

}

}

}

}