APPLICATIONS AND IMPLICATIONS

Assignment For This Week

Propose a final project that integrates the range of units covered.

projects can be separate or joint, but need to show individual mastery of all of the skills where possible, you should make rather than buy the parts of your project

My Proposed Final Project

I have proposed two Ideas initially, and decided to work on the second one for the final project. The idea is to develop an IoT Based Control & Monitoring for Water Quality Measurement Platform. I have been working on developing water quality measurement products for real world applications based on the enquiries we ( IIITMK -- Thats where I work as Technical Officer ) received. As I had very limited time to both work and attend my fab academy course, most of the time I have been strugglig to keep up with the pace the classes were going on. This made me think in the direction of combining my Commercial project with the Fab one. I had already done most of the work in data acquistion from the sample water to be measured and the rest of the cotrol part was left to be completed. I discussed this with my Remote Tutor Mr Franciso and he agreed to my idea of clubbing the projects, thats how I started working on this projecct for FAB.

Now let me answer the qns one by one..

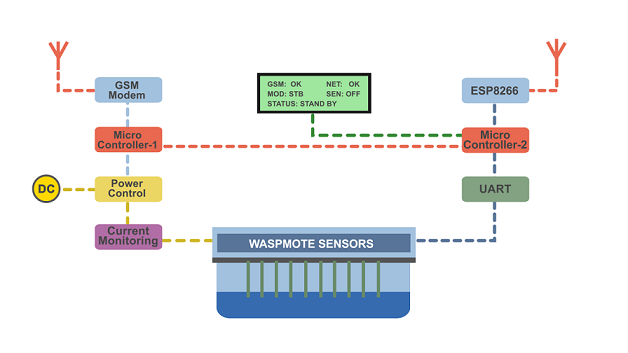

It is said that "A picture is worth a thousand words".. so let me first introduce you my project with its functional block diagram,

I have integrated a Waspmote Based Water Quality Measuring System which will measure the following Basic water parameters such as.. pH, Temperature, Conductivity, Oxygen reduction Potential and also the Ion concentrations of Chlorine,Fluride,Calcium,Cupric,Nitrate and Silver. The requirement that I had was to make a product that can be deployed in remote places such as a remote water distribution system. The product should keep monitoring the water quality and send the live values to a cloud. There should also be provision to control the operation of this remotely. In addition to this it must also have a self health check and feedback mechanism. So in a nutshell I will be making this IoT Based Control Mechanism as my Fab Project.

Water Quality measuring Platforms are made for Aquariams and other water bodies. But this particular project is a customised version of it with added features and facilities with stateof art connectivity onboard.

The enclosure for the platform will be made out of acrylic. The water container will be fabricated with glass to keep it inert. Basic control boards will be fabricated in Fab. The required mechanical assembly for holding the probes are also planned to be 3D printed. The microcontrollers, GSM MODEM and wIfi modules will be ordered online.

As the complete system is not completly designed and is still evolving, I can give a rough estimate based on the confirmed deisgns, The control modules that I develop and materials that I use in Fab should cost me less than $100. This is excluding the Waspmote platform as it is only considered as a input source for the Fab project.

The control modules consisting of custom made FAB PCBs, The enclosures, and assembly accessories will be made in the Fab. In short every thing other than the Waspmote platform.

1. Custom PCB Design and Milling

2. Laser Cutting & Engraving

3. 3D Printing

4. Networking & Communication

5. Customised Cloud based Interface design

1. Final calibration of the sensors.

2. Automatic water input and output mechanism for remote depolyment.

1. Longivity of sensors.

2. Availability of alternate sensors.

3. Sensors for biological parameters.

After the completion of inhouse testing the platofrm will be deployed in a public lab from where the data will be evaluated for a period of two weeks. On sucessful completion of the validation, customimsed products as per clients requirement will be designed.

The measured values will be cross checked with the standard lab readings for a period of two weeks initially after that required calibration/ modification will be made.