Edward Octavio Muñoz Sandoval Contact: edw_ard0@hotmail.com

Week 9 Assignment: Mechanical Design

1.- Make a machine, including the end effector build the passive parts and operate it

manually, document the group project and your individual contribution

Mechanism design

For this assignment my team build a Metal Engraver machine, it would be able to slightly engrave the metal by electric arc.

The first step in this design process was to test the concept by connecting a pencil and a metal plate to some voltage, we didn't know how much.

We start with 127 Vac and it was a mess because the graphite heated too much and set on fire, so the next tests were with 20 to 30 Vcd supplied with a voltage source, but the graphite was still heating too much, so the solution to this problem was buying the graphite bar shown in the image:

This test also helped us to realize that the mechanism should engrave the metal by dots, because if the graphite touch the metal and slide through it, only in the point the graphite touch the metal it is engraved. So the mechanism should allow the graphite touch and take off the metal fast enough so the machine can be moving and engraving the metal.

Inspired by the mechanism shown in the image, we designed some 3D printed pieces so the graphite could move up and down very fast.

In the next pictures is shown this mechanism, the left one shows the motor is running free and the right shows the motor stopped by the force of the spring, which actually is very week, so it didn't work.

I tried to fix this by redesigning the cam, my idea was design a 3D piece that 3/4 of the turn the edge move away of the center and only 1/4 of the turn the edge bring close to the center as shown in the image. But it didn't work either.

The solution to this problem was replace the motor for a motor with gearbox integrated, below are the images of the new 3D printed support for the motor and how it looks.

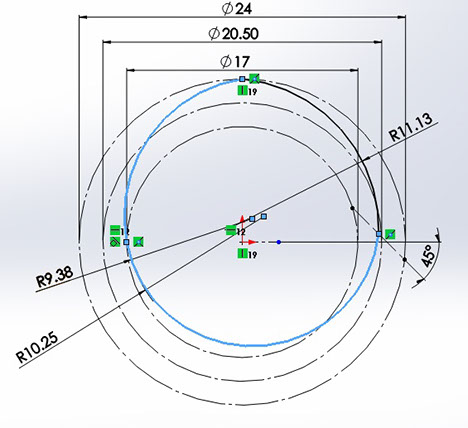

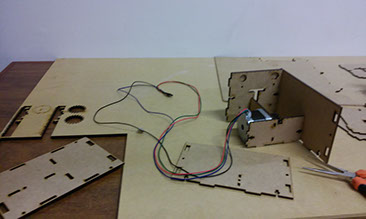

I designed the box and the gear rack mechanism with the space for the steppermotor,

This design could be improved because the building process was difficult and it suppose to be easy, beside that, it work well.

The rest of the mechanical design was made by my class mate Alma, buy I helped her with some 3D parts.