Edward Octavio Muñoz Sandoval Contact: edw_ard0@hotmail.com

Week 4 Assignment: Electronics Production

Make an in-circuit programmer

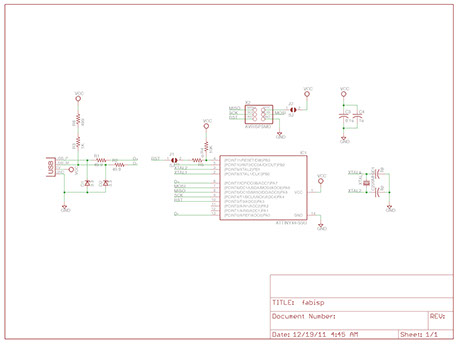

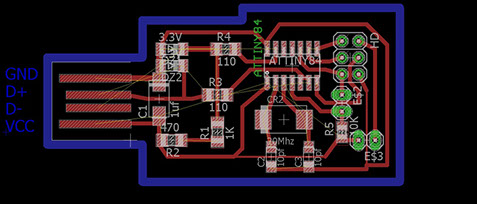

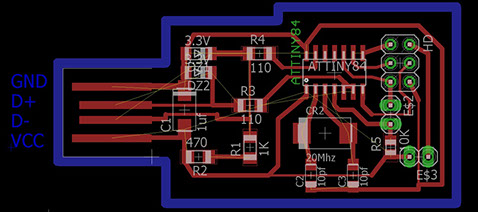

In this assignment i based in Andy´s design, but i had to redesign the whole circuit because i couldn't find all the components for surface welding, so this are the steps in order to get the in-circuit programmer designed by myself:

1.-Design the circuit in Eagle

2.-Machining the PCB

3.-Welding the PCB

4.-Programming

As my design is based on Andy's, I used her schematic for do a to buy list:

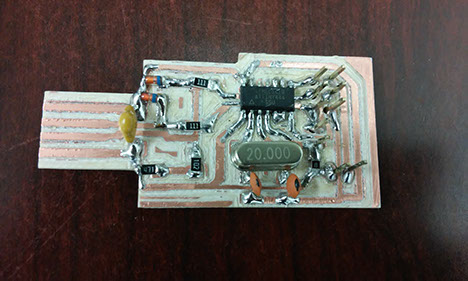

I couldn't get the capacitors and the crystal in surface welding, so I bought them in through hole presentation. What I did in the software was put a surface component with the dimensions of the device for I can weld it by bending the wires of the component.

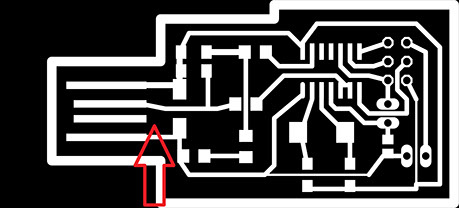

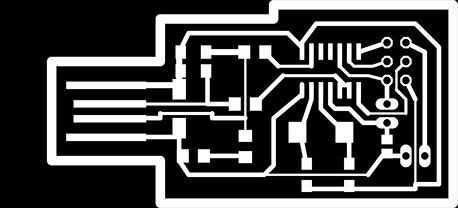

I Used Eagle software for draw my board, In my first design i forgot the connection on the D- pin, but I realized when it was machined, so I had to redesign it and machining again.

I fix that in my second design:

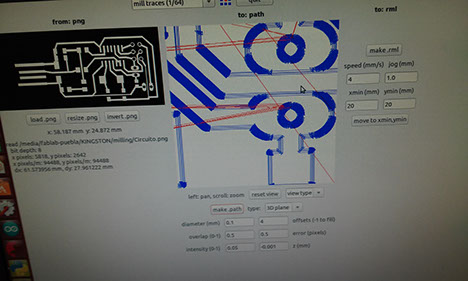

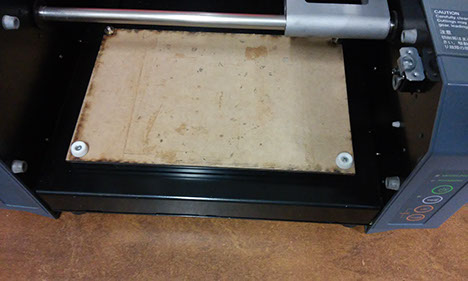

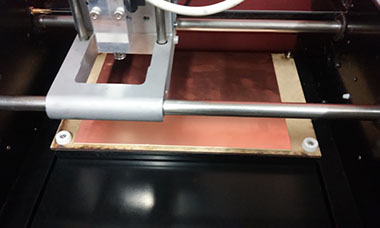

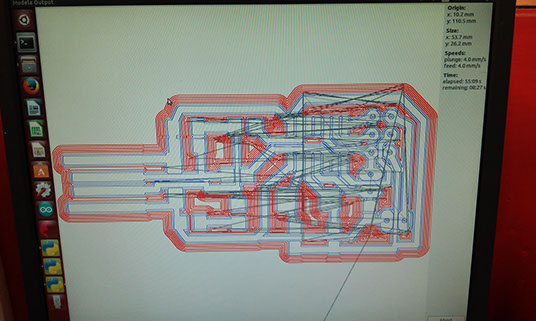

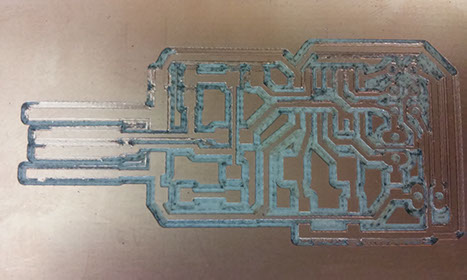

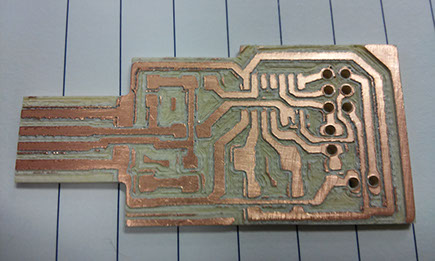

I used the Ronald Modela MDX-20 for machining my PCB an the Fab modules software. First i had to prepare the modela by setting a "bed sacrifice" (3mm MDF), a copper plate and the cutter. Instead of a normal cutter I had to use a "V" cutter, it was a huge problem because i had to play with the diameter, overlap and "Z" parameters in order to get an acceptable result.

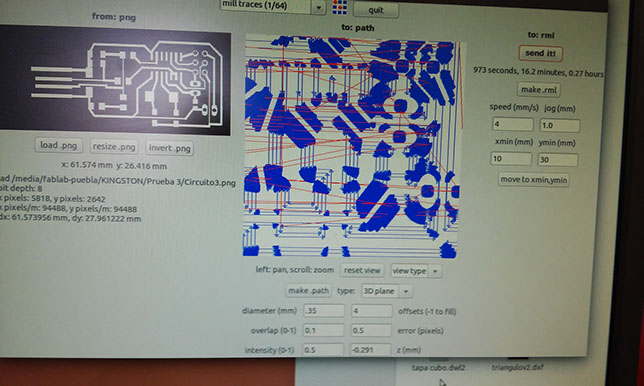

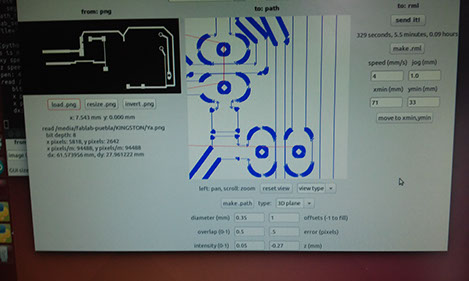

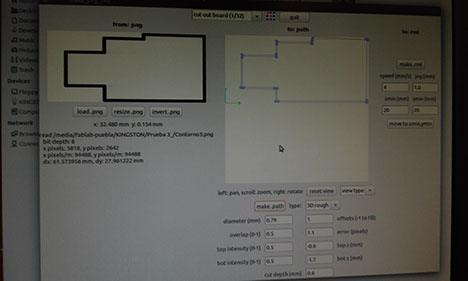

In the software I had to configure the parameters depending on the tool, in my case I obtained the best results with the values shown in the image:

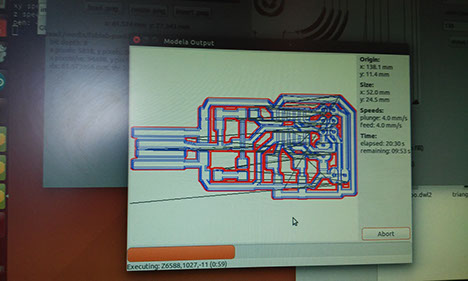

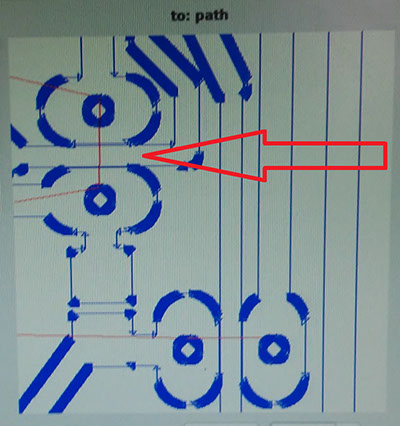

Once I loaded the picture in the software and configured the parameters, had to put special attention to "critical paths" that may the tool couldn't pass thru. When you send the path to the machine, can see the progress, the remaining and the elapsed time.

In my second attempt the tool didn´t remove the copper in some paths. To ensure that the copper paths don´t touch, I modified the image so the machine didn´t do it all again. In this step you have to put just "1" in the offset value because if you don´t, may the machine remove some copper you need.

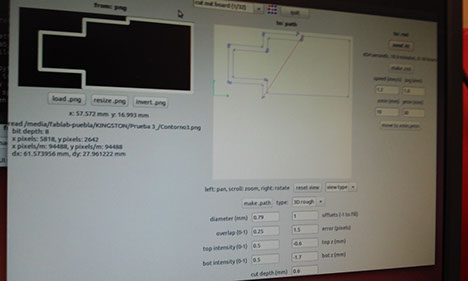

The last step in the machining is the cutting of the board, I did it also with the modela machine. The process is similar to the engraving, first load the .PNG image, then configure the parameters and send it to start the cutting. I had to put special attention to the "bot Z" and the cut depth, which are important values so the tool didn´t break.

The last step in the machining is the cutting of the board, I did it also with the modela machine. The process is similar to the engraving, first load the .PNG image, then configure the parameters and send it to start the cutting. I had to put special attention to the "bot Z" and the cut depth, which are important values so the tool didn´t break.

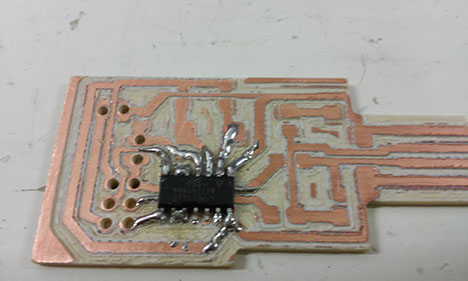

I never had welded a surface component, so it was a little complicated, but basically is the same as a through hole component.

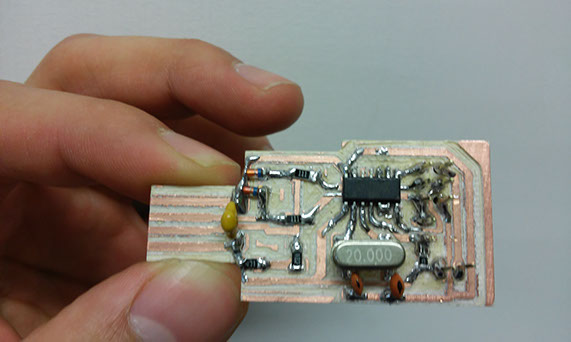

After some hours of work, the circuit looks like this:

Programming

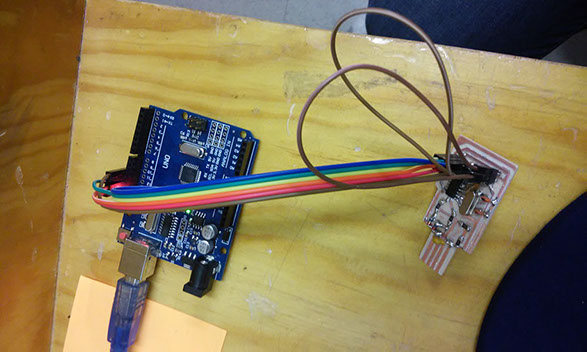

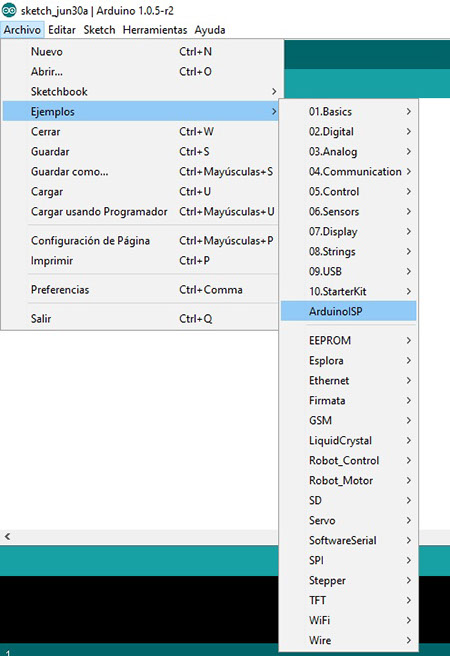

For programming the Attiny 44A, I loaded the code "Arduino as ISP" to an Arduino one, which is a free code set in examples when install the Arduino software.

The Arduino one function as programmer for the Attiny.

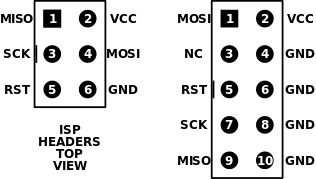

For programming the circuit, I connected the 6 pin ISP header of the circuit to the Aurduino UNO:

I used Cable to connect the SJ1 and SJ2 and then just remove them easly