Fifth Assignment:

Contents:

Requirement:

For this assignment we are going to need the next tools

- 3D printer

- Balances

- vernier

- Kinect XBOX 360

Group project

For this assignment we did an amazing work group

Tecsup team:

- Armando Sarco

- David Maita

- Midori Nuñez

- John Lozano

|

|---|

Group goals:

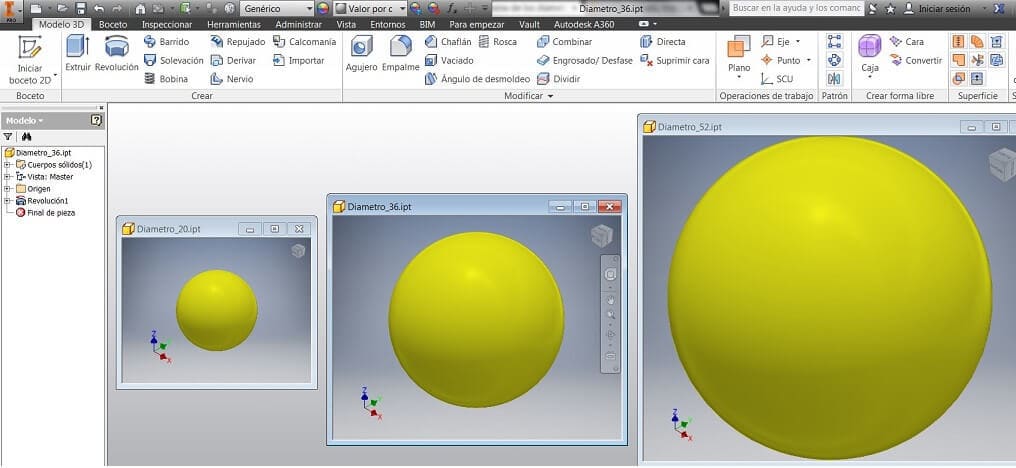

- Design and make spheres with 20, 36 and 52 mm diameter

- Identify the advantages and limitations of 3D printing technology

- Compare the diferences between 3D printers

The first step is to make the designs in inventor and after, use two different 3D printers, the first a Stratasys Object 30 Prime and the seconth a MakerBot Replicator 2.

|

|---|

Stratasys Object 30 Prime used VeroGray RGD 850 as raw and infill material. You can see the print process in this gif,

as you can appreciate These spheres have to be washed because we need take out the infill material.

MakerBot Replicator 2 used PLA material.

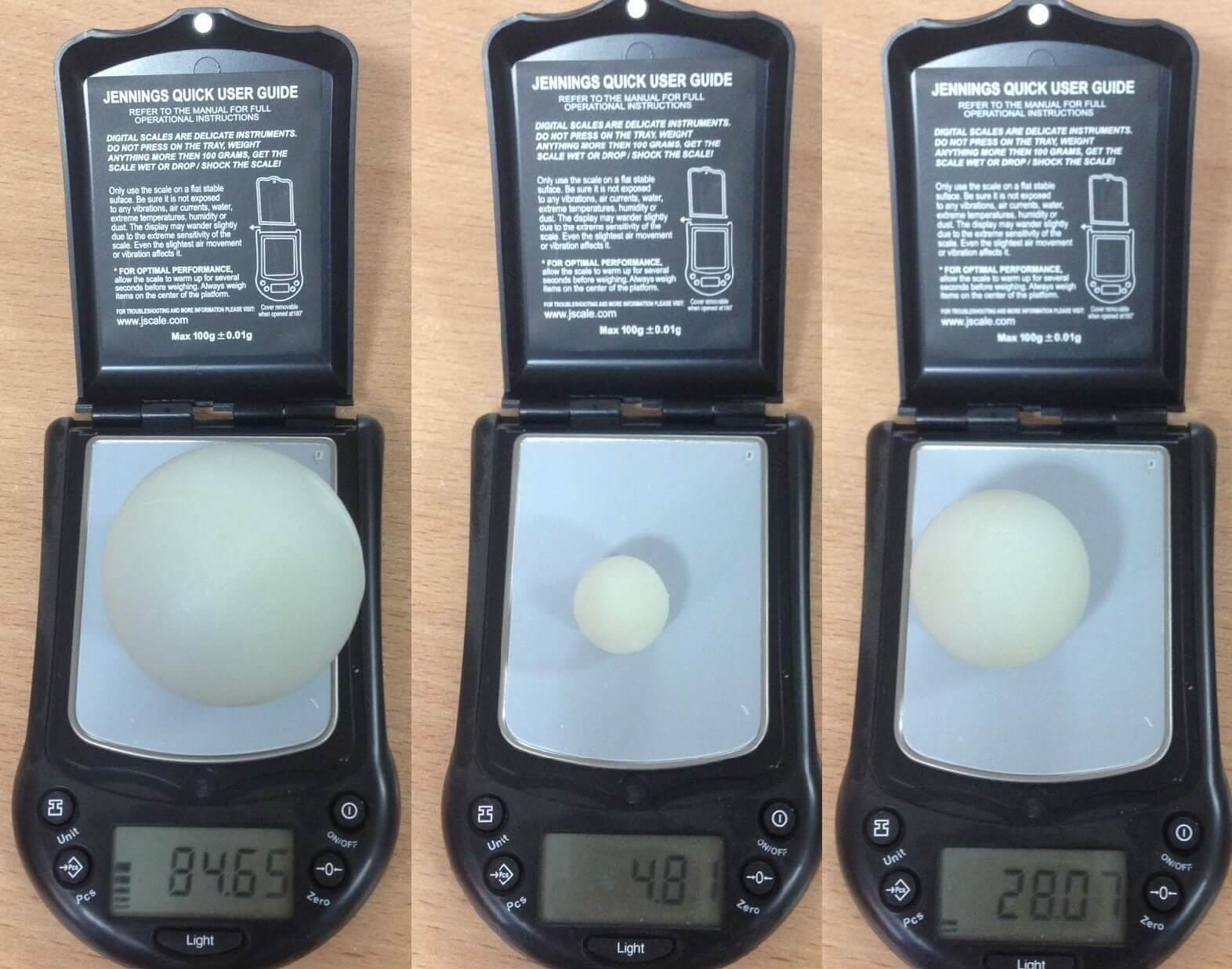

Comparing results

balls made with PLA in the MakerBot Replicator 2

|

|---|

balls made with resin in the Stratasys Object 30 Prime |  |

Now we are going to compare the size of the two balls |

|

Now we are going to compare the weights |  |

|

Conclusions and observations |

Comparing the two prints, we can observe and conclude that the "Stratasys Object 30 Prime", have more resolutión than the "MakerBot Replicator 2",

we can also observe That the PLA material is more roughness, and both have the same measurement but differents weights, because the infill material of

the Stratasys is more heavy and we could not extract it, another conclusion is that the PLA is more resistant than the liquid resin VeroGray RGD850. |

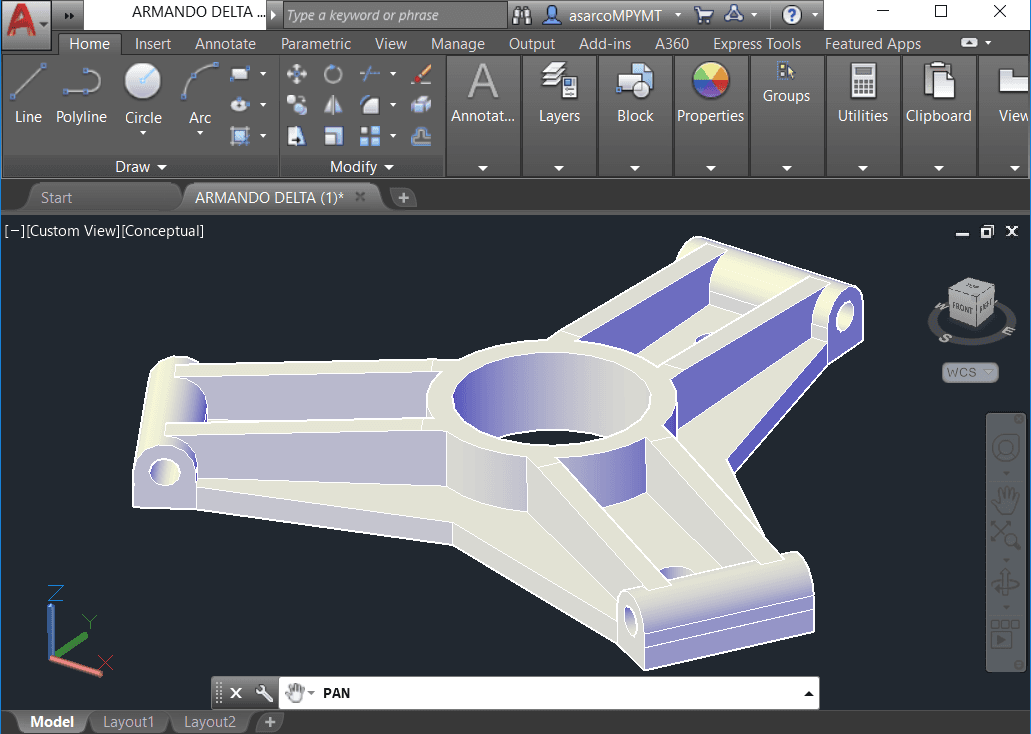

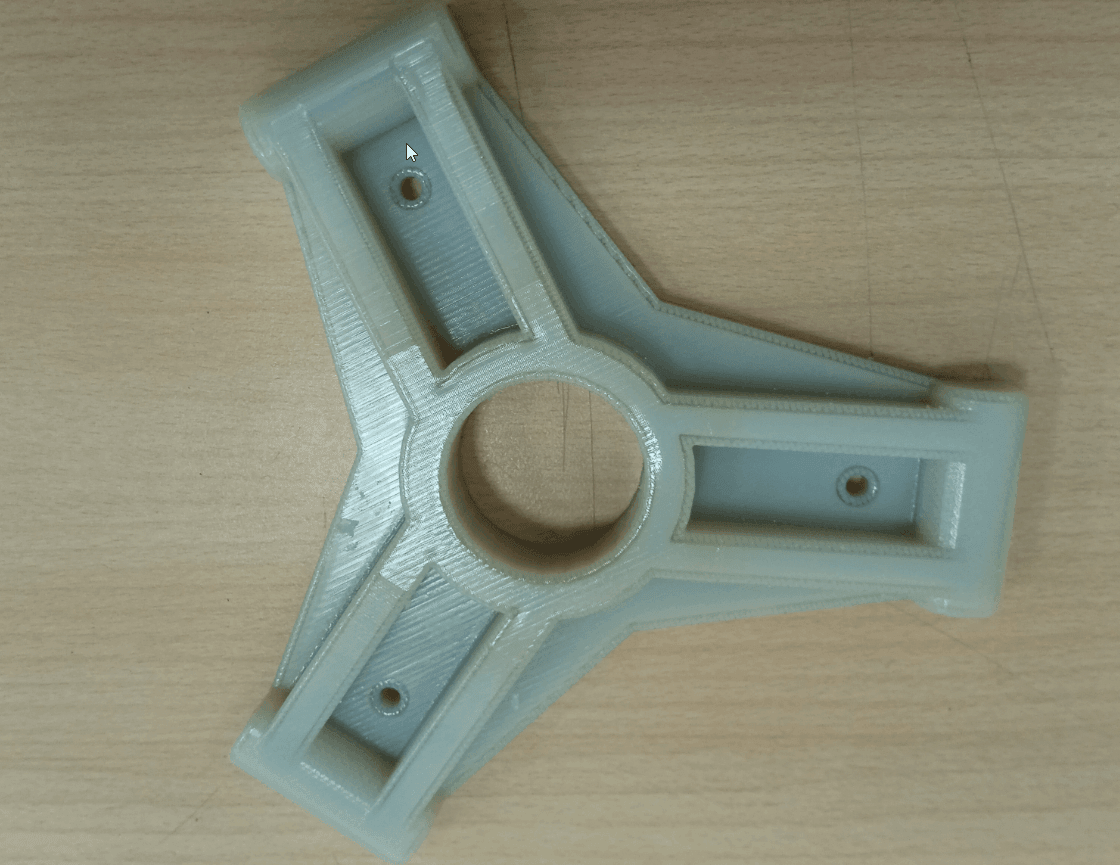

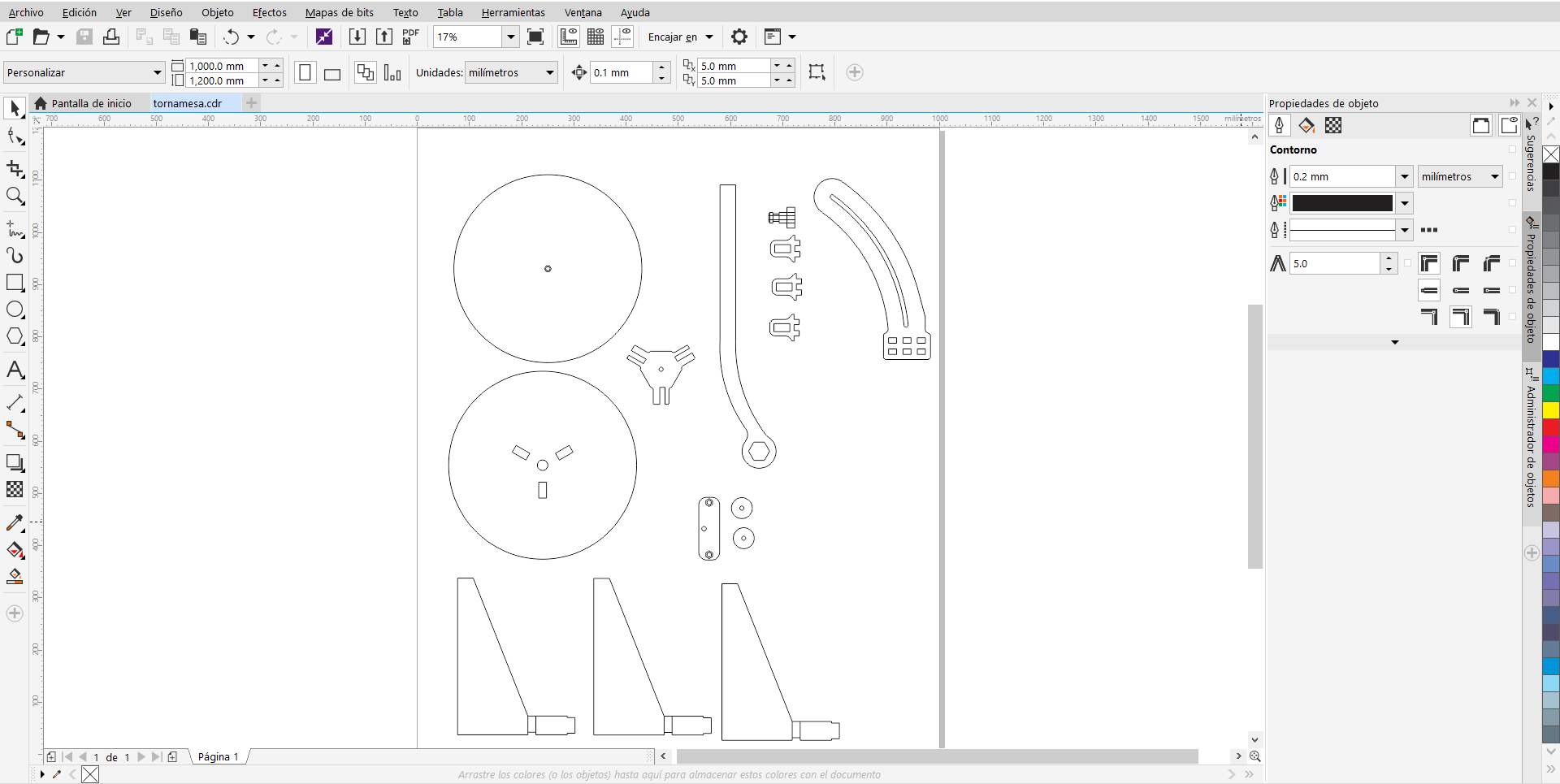

Design and 3D print an object

i designed in Autocad 3D a piece of my final project and I decide print this in the "Stratasys Object 30 Prime" as I show you in the picture below.

|

|---|

|

|

|---|

3D scan an objet

For this topic I used a "Kinect XBOX 360" with PC connection

|

|---|

I tried to take images with the KSCAN3D software, but the object was very little and the kinetic didn't recognize it.

|

|---|

Finally I did a 3D Scan, to myself

|

|---|

I tried other software called 3DSOM Pro, that make a 3D scan from photos

|

|---|

With the above two scan methods, I could not generate the STL file, because I couldn't take good shapes, I tried to improve the form of take images doing a platform as you can see below.

|

|---|

|

|---|

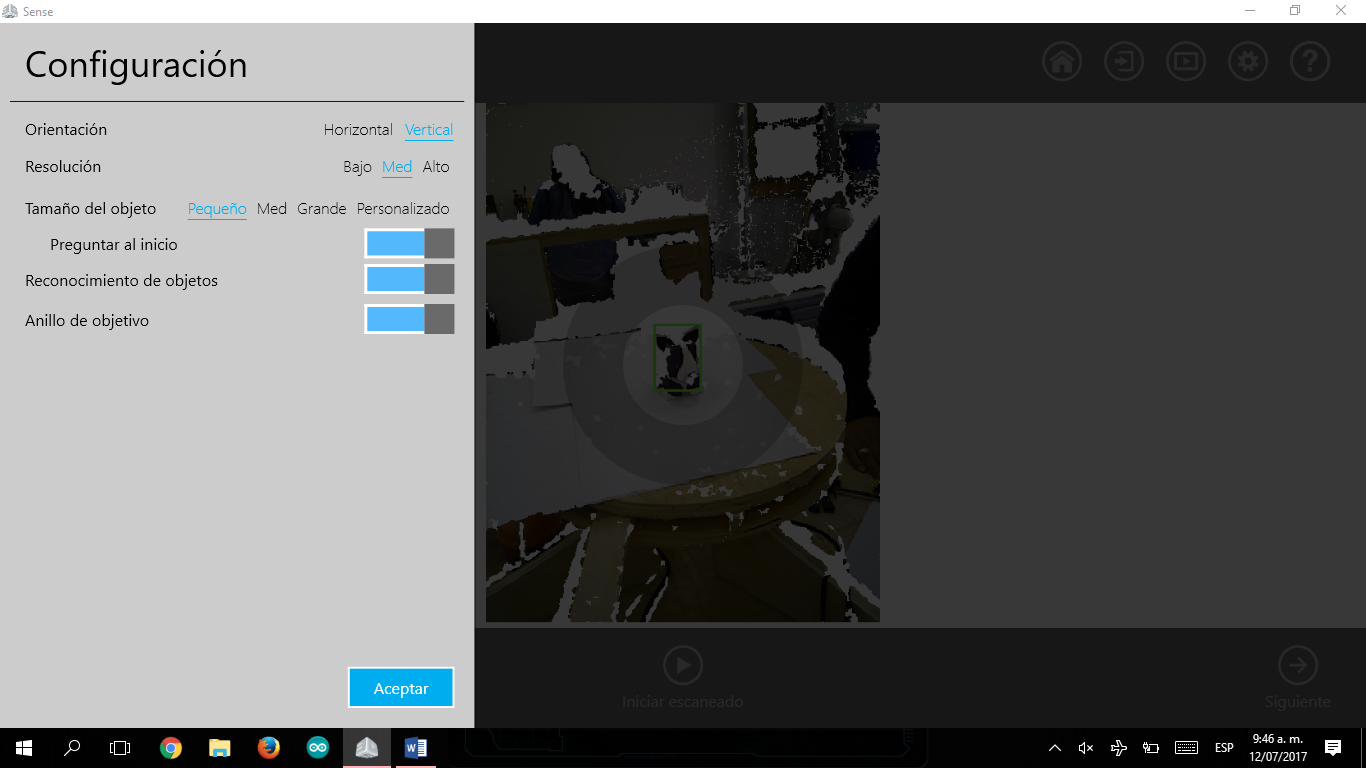

To perform the scan I used the SENSE 3D scanner, which has an intuitive and simple program

|

|---|

The first step is setup the program

|

|---|

Then you have to carefully calibrate the distance

|

|---|

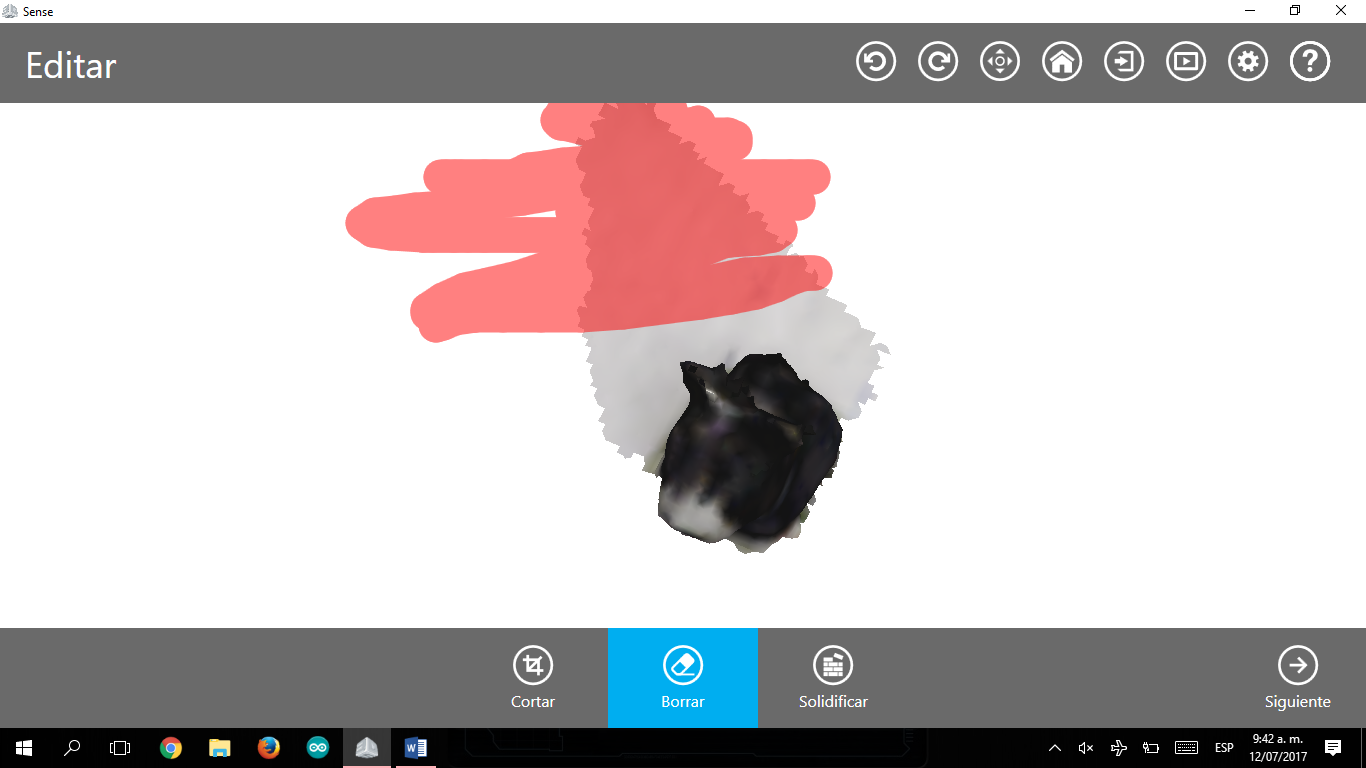

Now I going to do the 3D scan with carful

Then we do some retouching

|

|---|

We finally get the scanned image

Original  |

Scaned  |

|---|

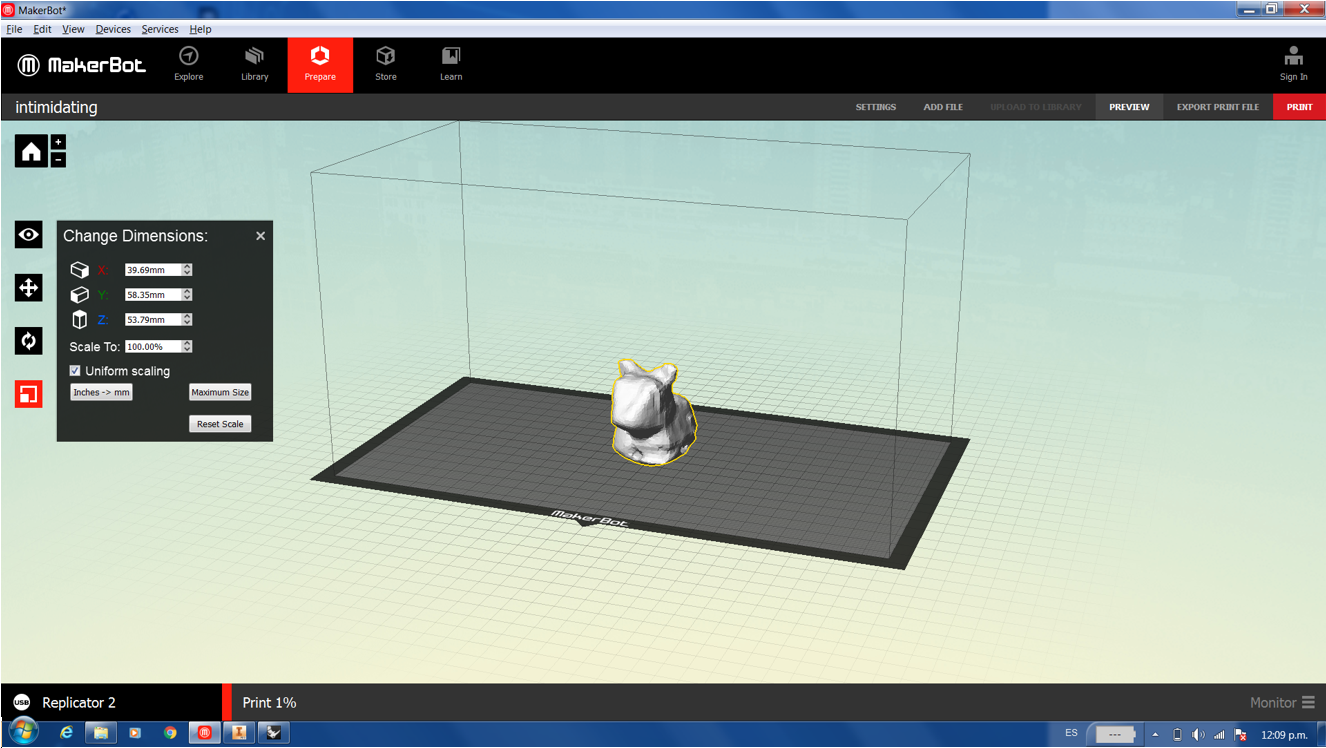

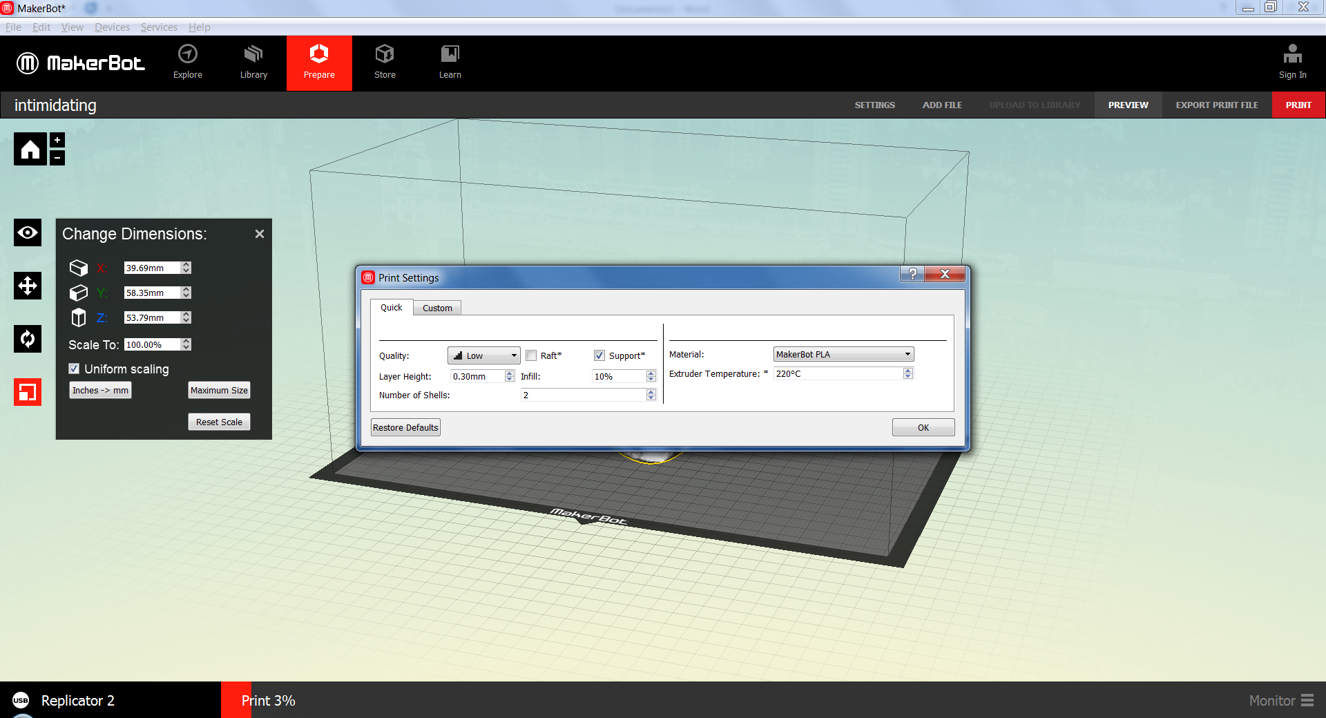

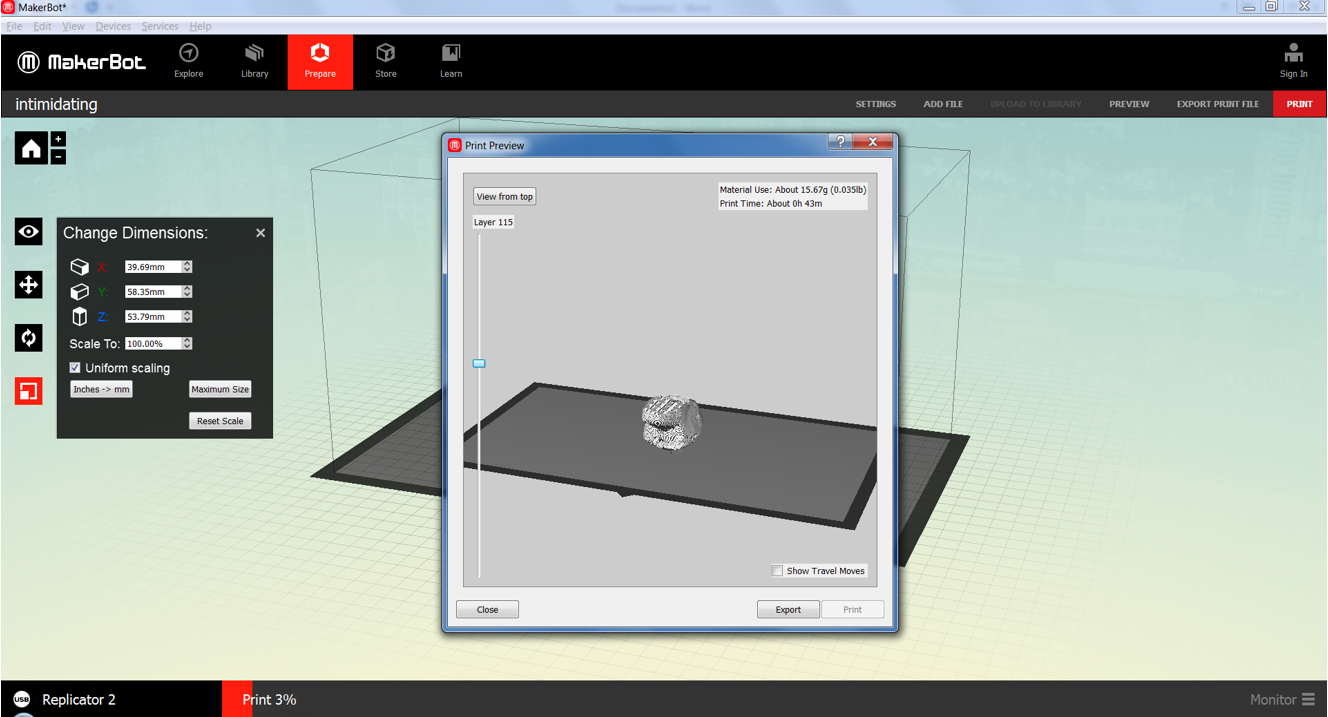

To print the scanned object in 3d we have to import the STL file into the program of the Makerbot and configurate all parameters like scale, quality, material, infill and outfill type.

|

|---|

|

|---|

|

|---|

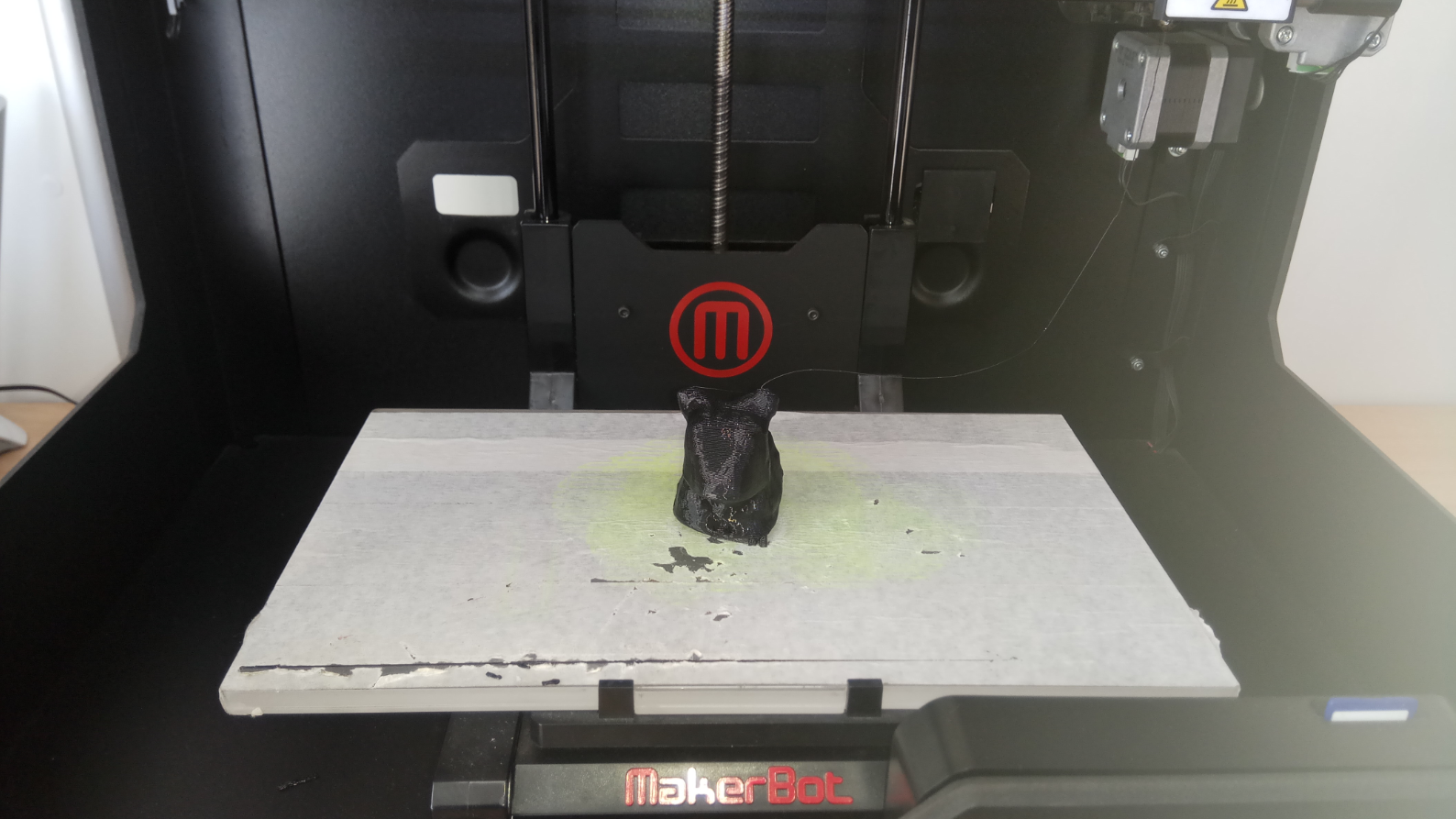

Finally we print our puppy with PLA material

|

|---|

|

|---|

Selft evaluation

- What worked:

- I printed a piece of my final project and I learn many difference between 3D printers, I took a 3D scan of myself

- What did not work:

- I couldn't take a 3D scan of a little piece with the Kinet, because it doesn't works well with little pieces, I couldn't create a stl archive from the two first scanners, because these didn't has a good shape

- Things to improve:

- To have more precision to the moment to do a success 3D scan, you have to consider the background and an appropriate light, and have a camera with good resolution.