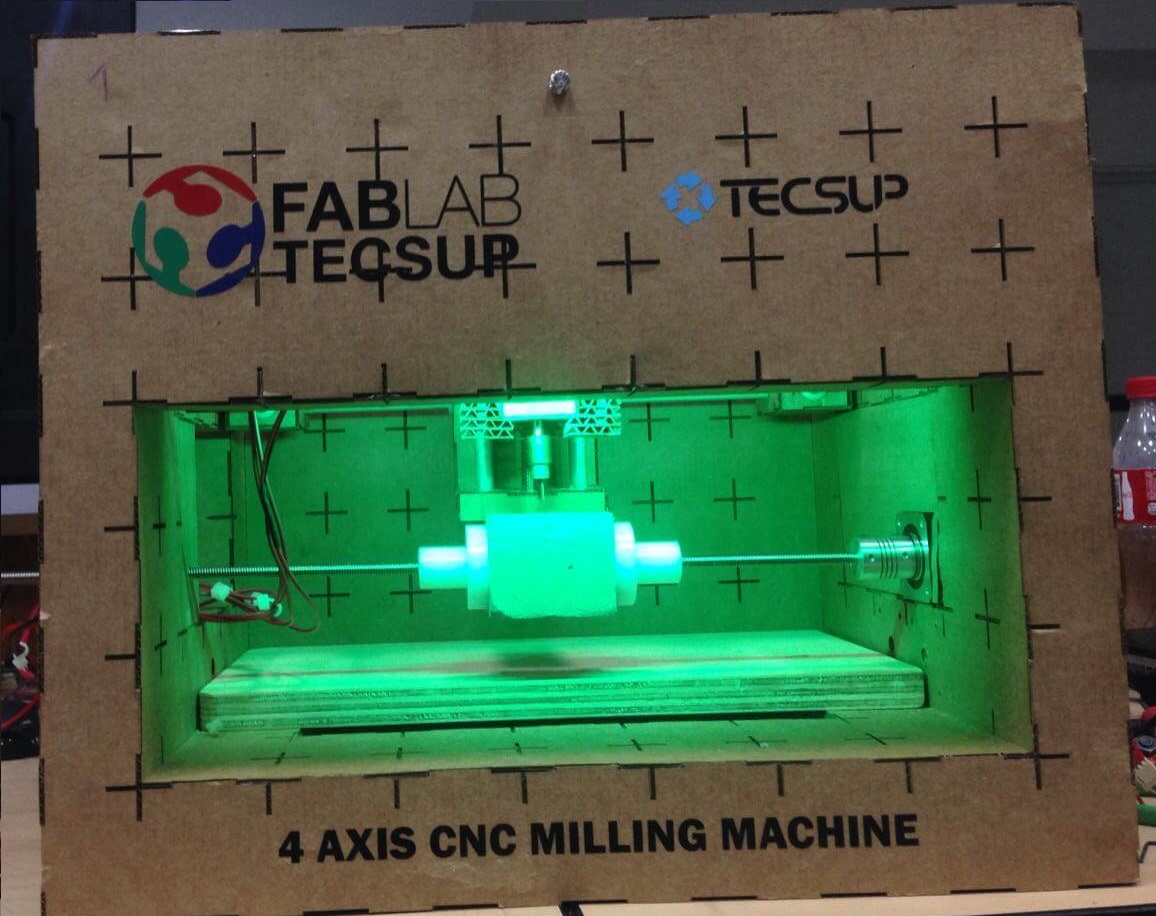

Plan the production of the machine 4-axis CNC machines. Cut the parts of the structure and assemble from the CNC machine. Program the Gestal to generate the movements of the coordinates. Automate the CNC machine. Machining a material in the 4 axis CNC machine.

Members of the Fablab tecsup group:

* Armando Sarco

* David Maita

* Juandiego Cerrón

* Jhon Lozano

* Ingrid Nunez

* Monica Copaja

+ Francisco Camacho (Instructor)

+ Roberto Delgado (Instructor)

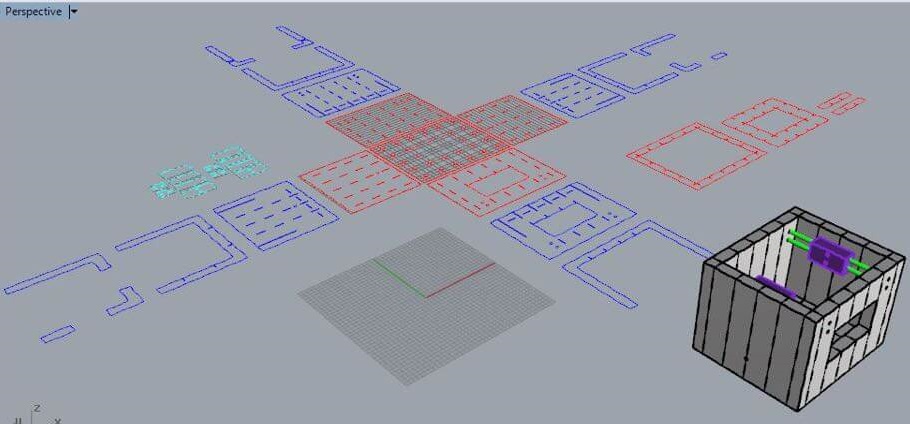

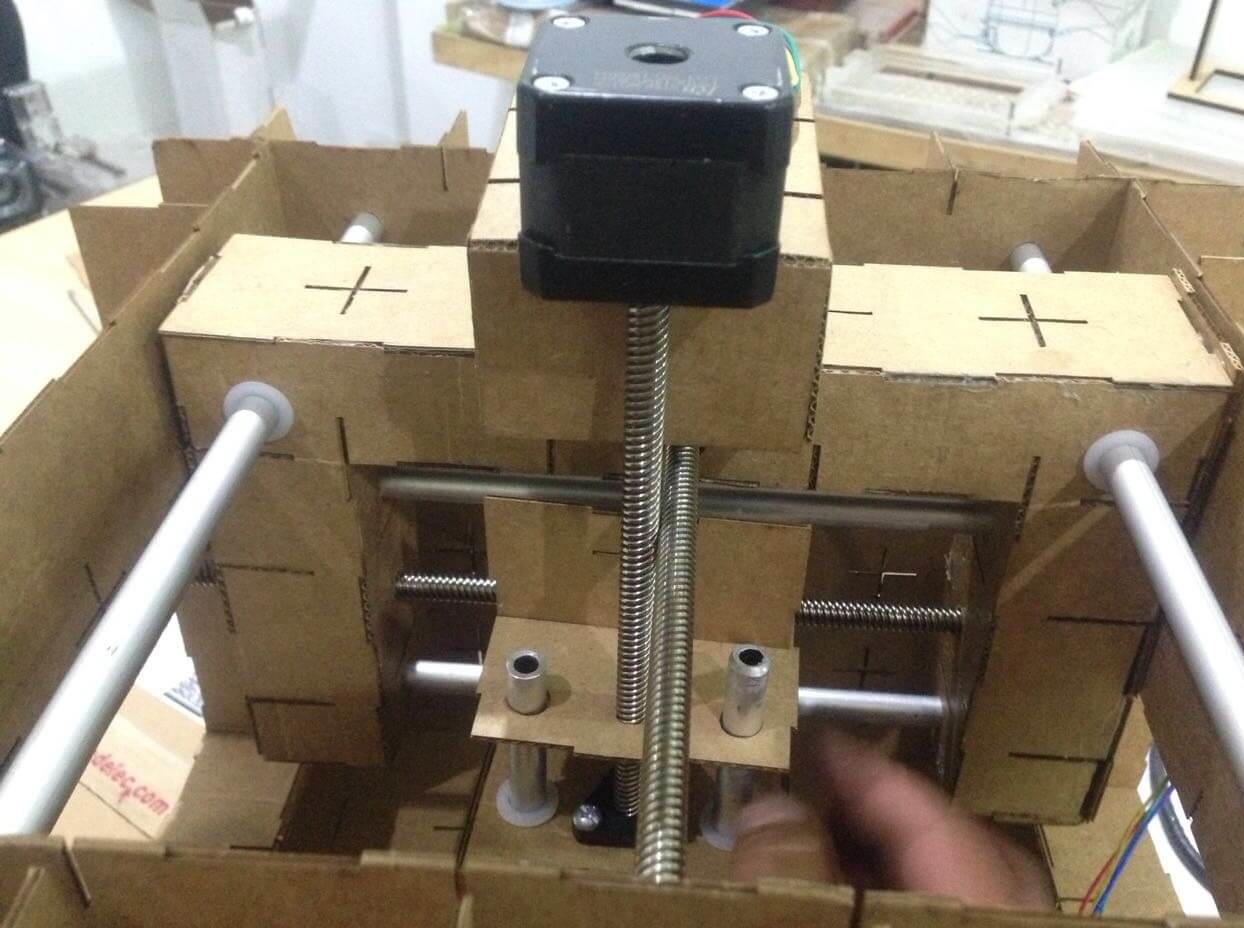

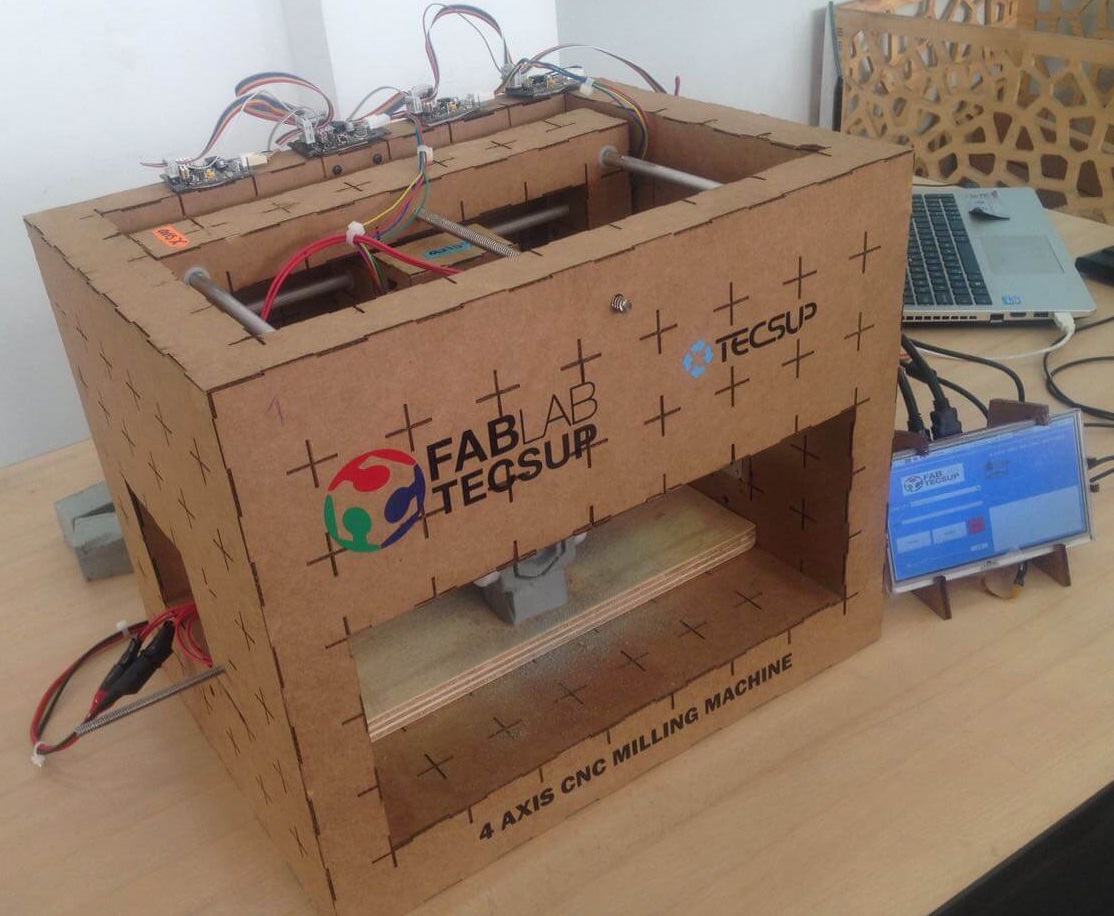

The manufacture of the 4-axis milling machine continued The dimensions and final shape could be defined after the tests

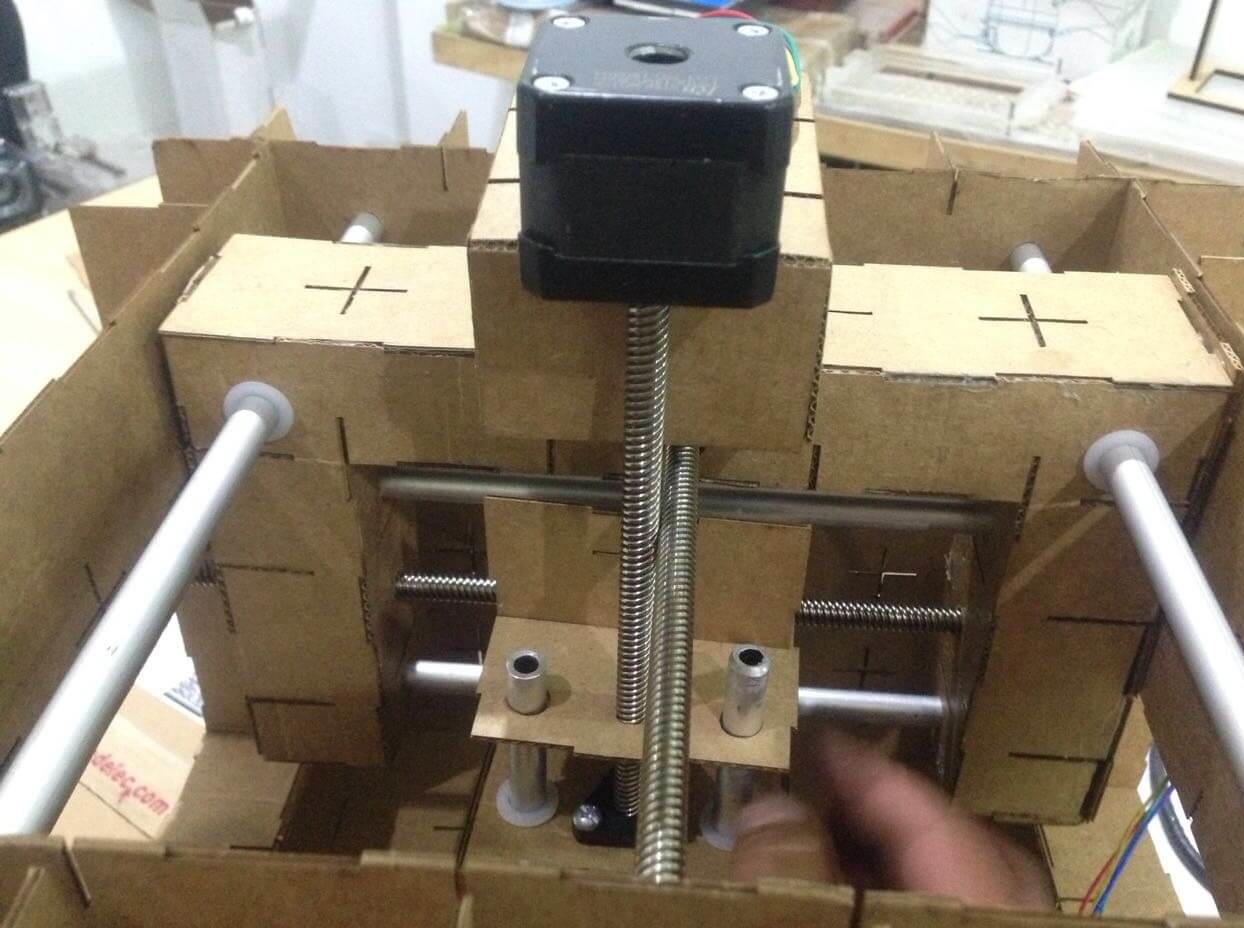

Make the cuts of the card in the laser cutter for later the assembly

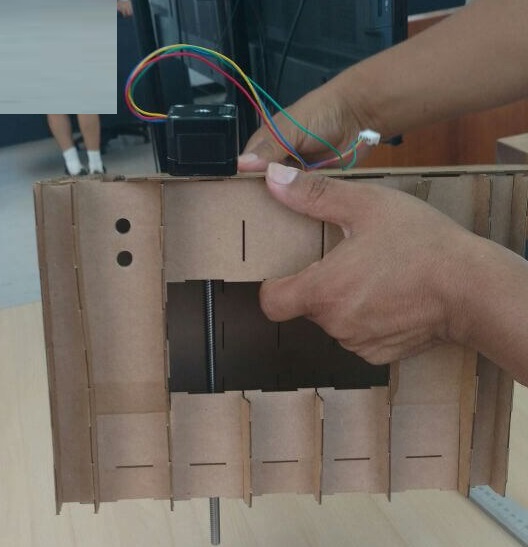

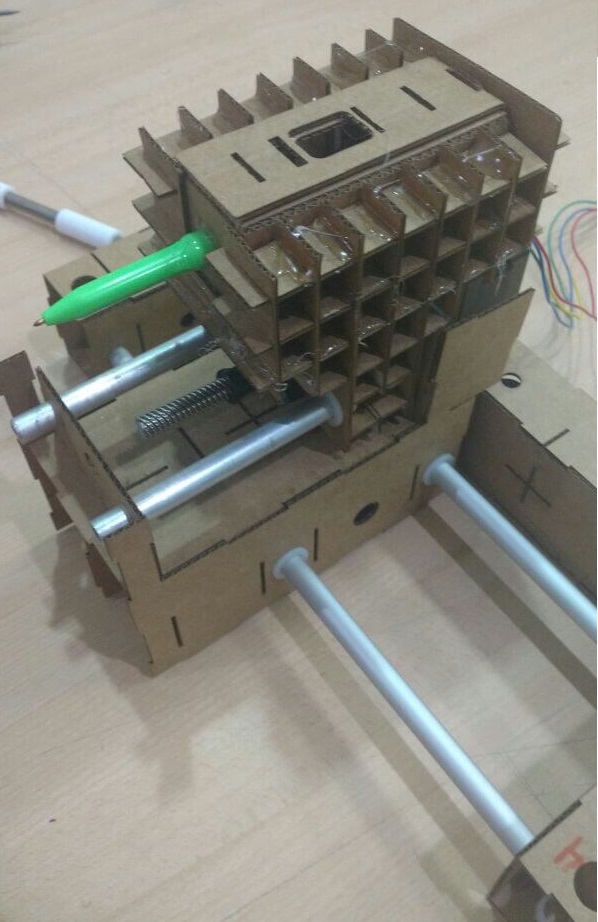

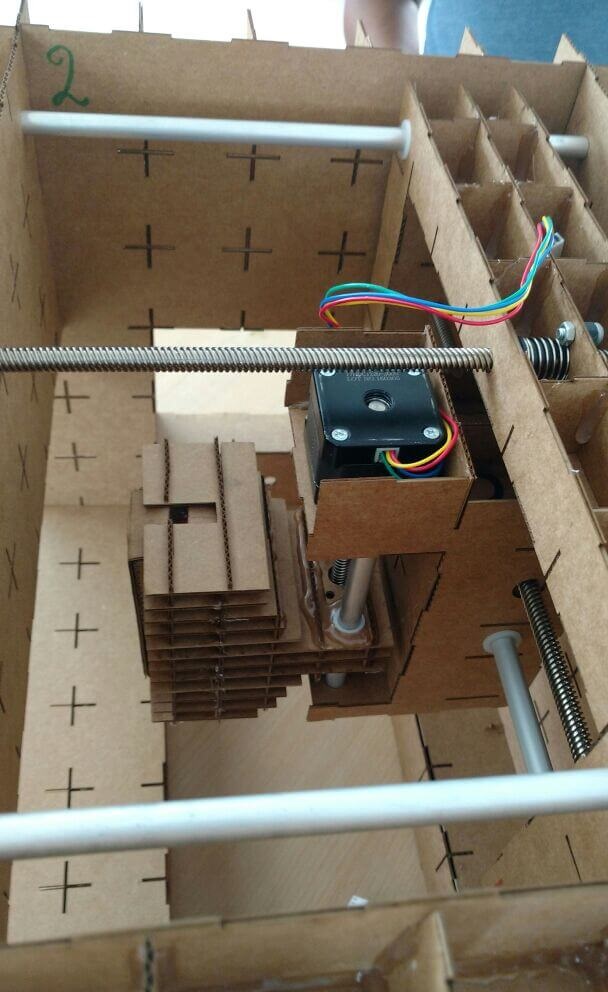

I began to arm with the axles and motors to verify the spaces available

Check the distances established to avoid collisions

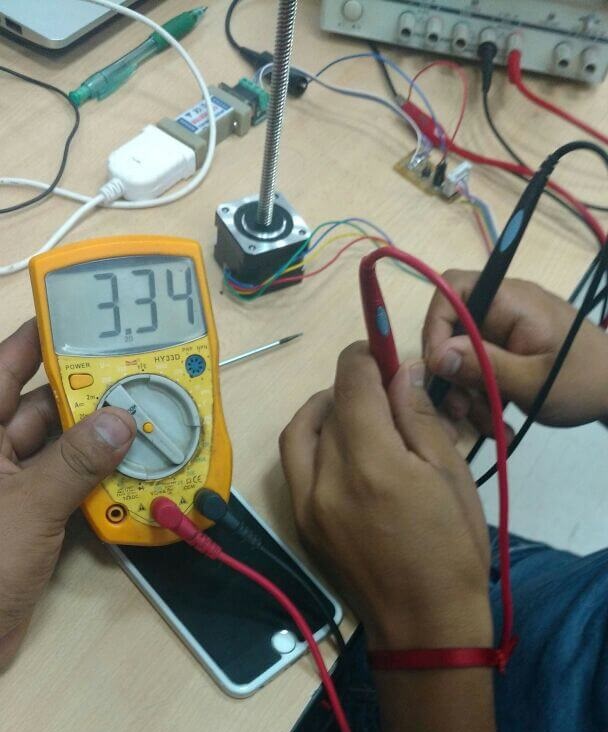

I checked the conditions that are the electronic cards

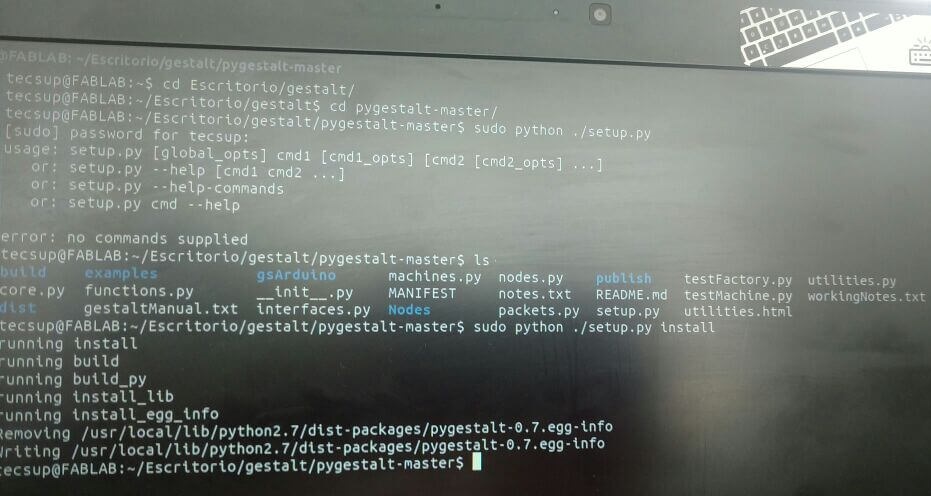

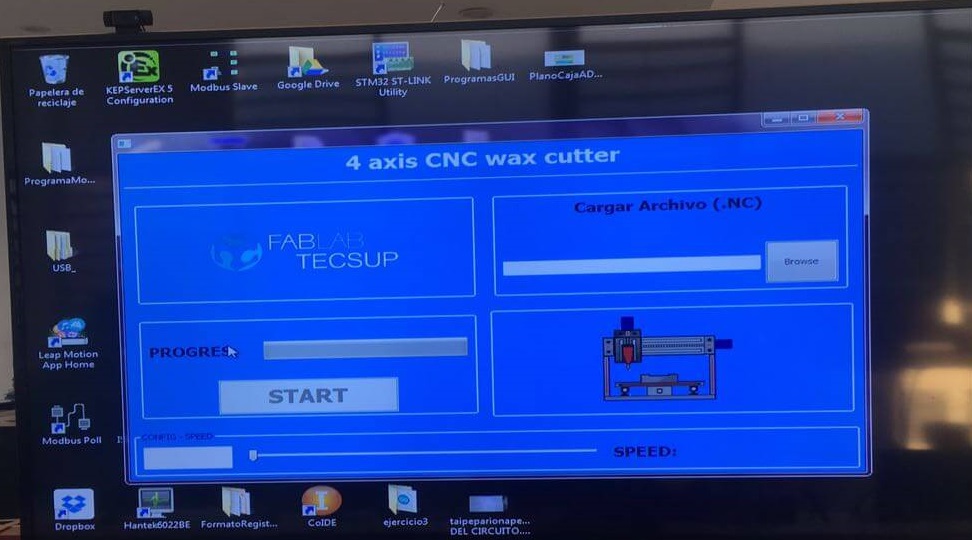

My Gestalt programming group

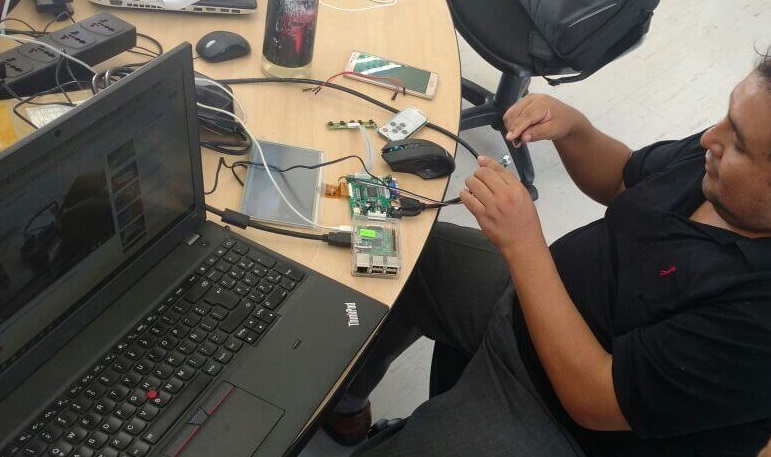

Installing the raspberry screen

Setting the raspberry display

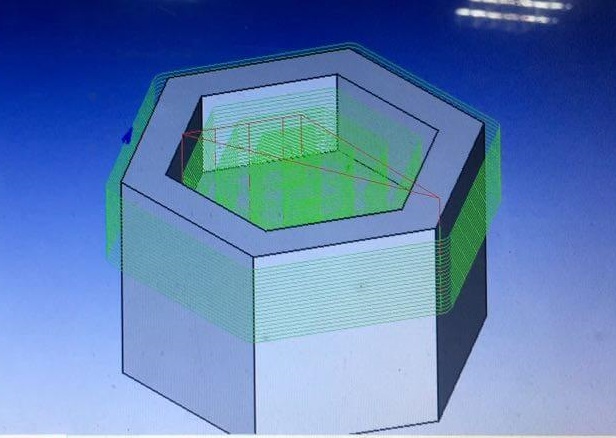

Simulating the machining program

Final presentation of the assembly

Presentation on the Fab Tecsup website

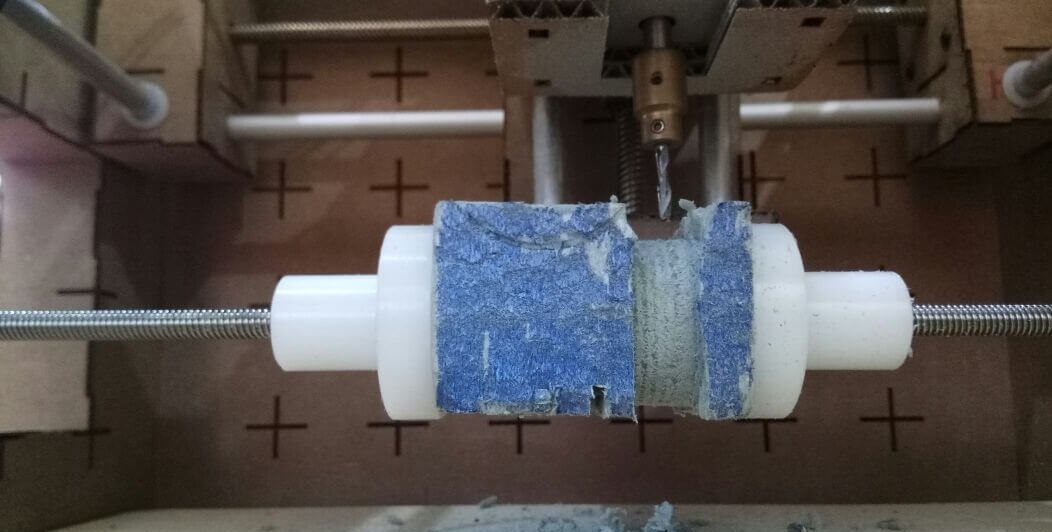

Machining of the 4th axis.

Collaborate in the conceptualization of the machine of 4 axes. Make the cut of the structuring. Machining with the winch the horn of polyamide material Assemble most of the part of the router frame.

Difficulty presented in teamwork:

The lack of commitment of a participant and offering to perform, arriving the moment I present nothing.

Try to reinforce with the expanded polyurethane material, if the resistance increases but do not forget the objective for that is the cardboard and with its cuts increases the reinforcement and increasing the resistance.

Http://archive.fabacademy.org/archives/2017/fablabtecsup/students/446/MechanicalDesignGroupAssignment.html

Click here to check the Tecsup's team work

Difficulty presented in teamwork:

The lack of commitment of a participant and offering to perform, arriving the moment I present nothing.

Try to reinforce with the expanded polyurethane material, if the resistance increases but do not forget the objective for that is the cardboard and with its cuts increases the reinforcement and increasing the resistance.

Http://archive.fabacademy.org/archives/2017/fablabtecsup/students/446/MechanicalDesignGroupAssignment.html

Click here to check the Tecsup's team work