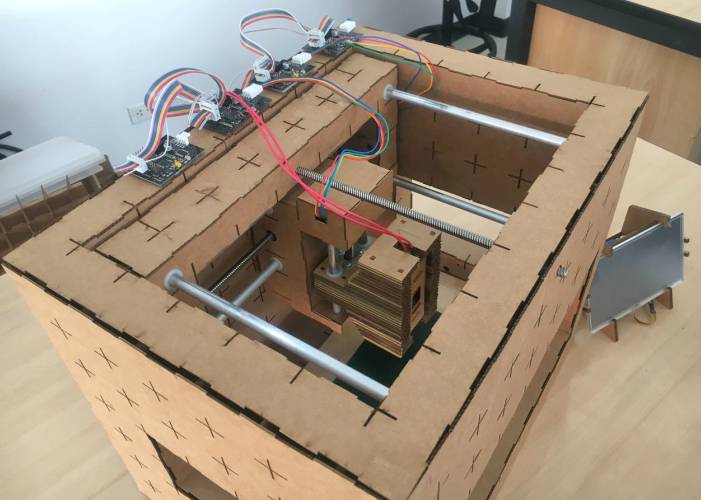

First, we make a brainstorming and define the machine concept. The 4 axis CNC milling machine will consist of X,Y,Z and a rotary axis that will allow the material block to work at different angles.

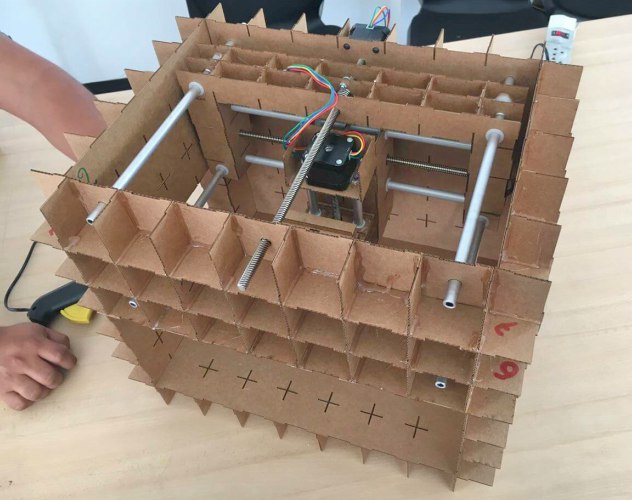

Then we choose cardboard to be the material of machine estructure and also defined that our machine will work with different materials.

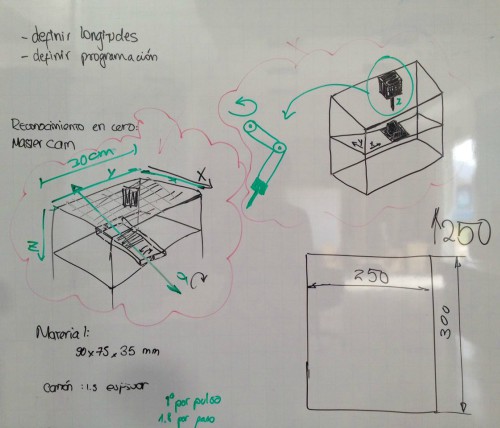

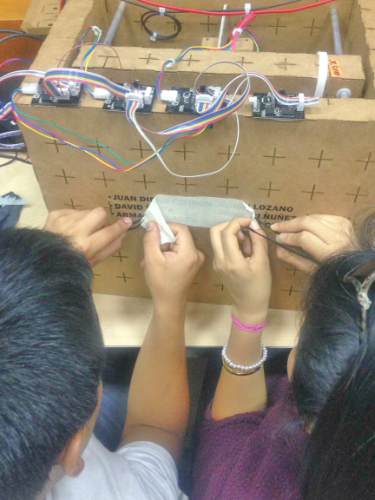

Here you can see what was drawn when we began to imagine what our machine would look like. Responsibilities were defined for the project development, having areas of design, programming, assembly and documentation. It was chosen to work with cardboard of 1.8 mm of thickness , as we want to continue with the line of machines made in cardboard here at Tecsup , we have a great reference, Fabio Ibarra, we recommend you to visit his page. Here we go, promoting collaborative work:

Design: Monica Copaja

Programming:Armando Sarco

Assembly: David Maita, Jhon Lozano and Juan Diego Cerron

Documentation and project management: Midori Nuñez

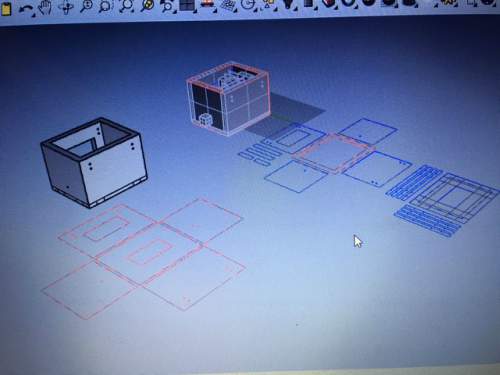

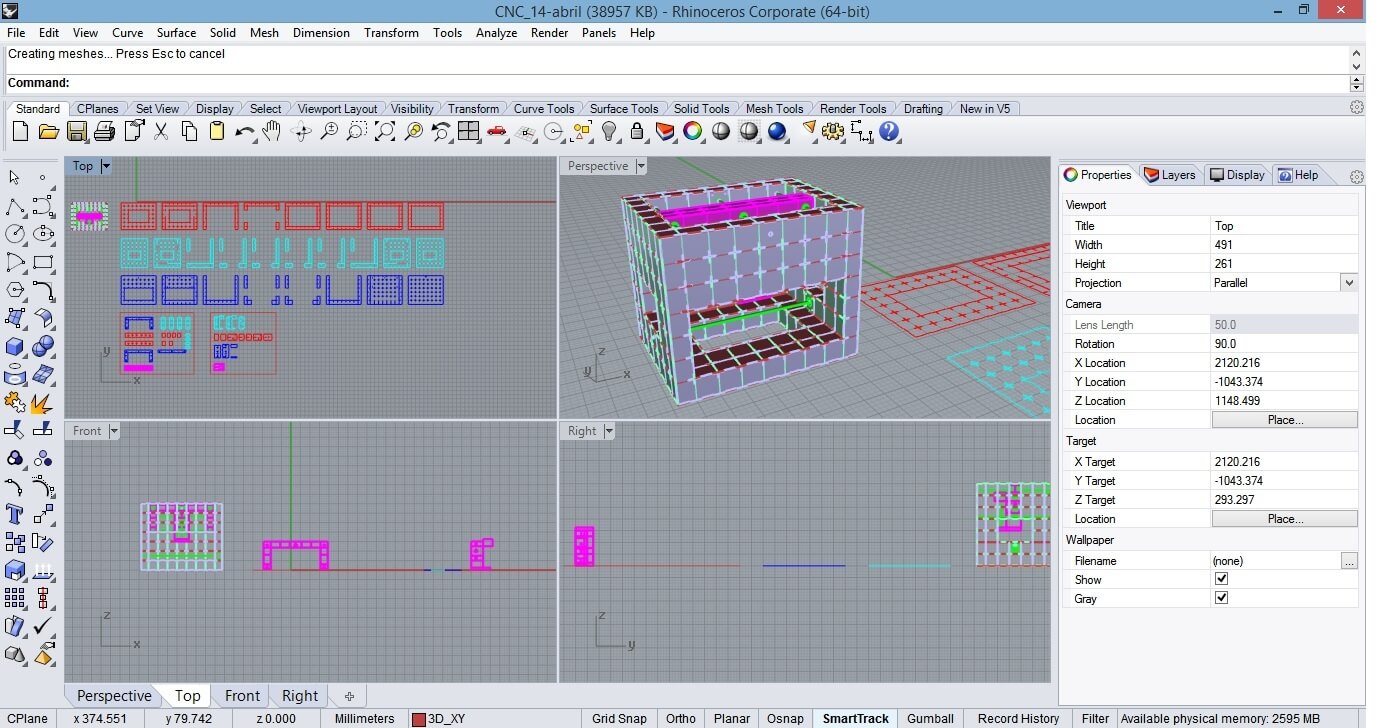

As I said before we defined our responsabilities, in this part we will explain how it works. Design area use Inventor and Rhinoceros software to desing our estructure.

There we show you how we designed it at the beginning:

...

...

...:

...:

...:

...:

To make lashes and joints.

We can use this machine with differents materials as: wax.