Final project

Requirements summary:

- be my own design

- include a fabbed input device and an output device of my own

design

- include other components made with additive and subtractive

techniques

- include 2D and 3D design elements.

I thought this task many times and many months earlier before the

Fab Academy started. I talked with my colleagues who participated

Fab Academy last year.

I had many choices and finally I took my ongoing project at home. I

am doing conversion to my car to camper use. And, I need controller

system [c] to guide heating system there.

Idea of my project

The control system might control heating of rear passenger

compartment. It has separate rear heating system [h] that

take energy from motor [m] cooling system.

When motor runs, the cooling system circulates the liquid and blower

circulates the air in the compartment.

But when I stop the motor, the cooling system still has the energy

available. And, I want utilize it. As well as, my car has electrical

preheating system for motor.

It is only 550 Watts, but I might be able to preheat little also the

compartment inside.

Now, I have plan to add an electrical pump [p] to the

cooling system and control both pump and the rear blower. So, I need

some temperature measurement system, control panel, controller and

motor drives do this.

In addition, I am interested in voltage level of my car's battery.

How much can I discharge it, so that the car can start anyway.

How much energy (E) I can utilize? Mass (m) of motor is about 200 kg

and typical temperature drop (△t) I can use is

about 80 to 20 °C. Further, specific heat capacity (c) of steel is

500 J/(kg K).

I guess I use this amount energy typically for one hour. Therefore,

I can stop one hour and enjoy warm car in winter time (~ 0 ºC).

Maybe some energy loss exists.

Let see can I do it.

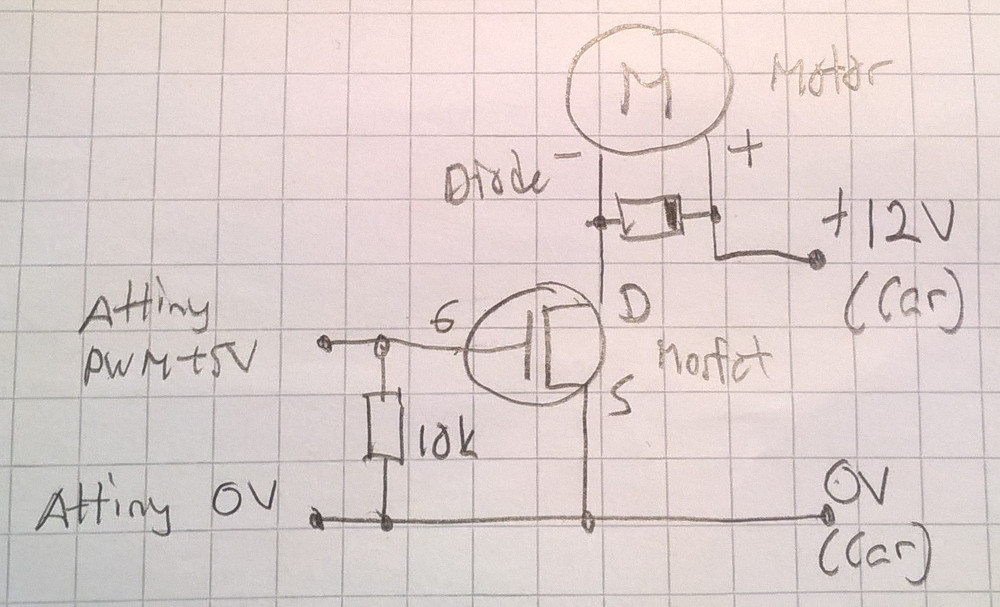

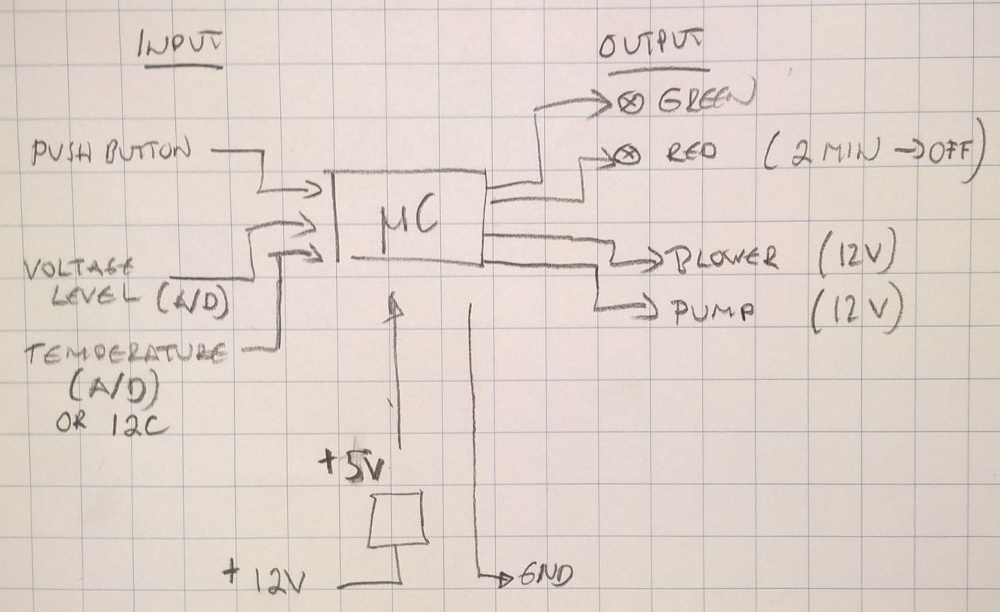

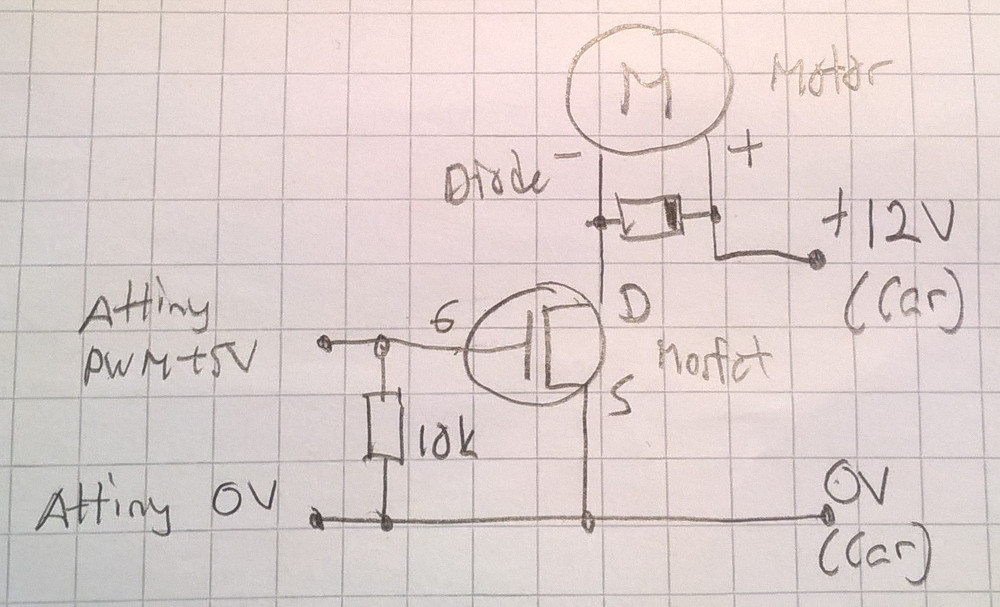

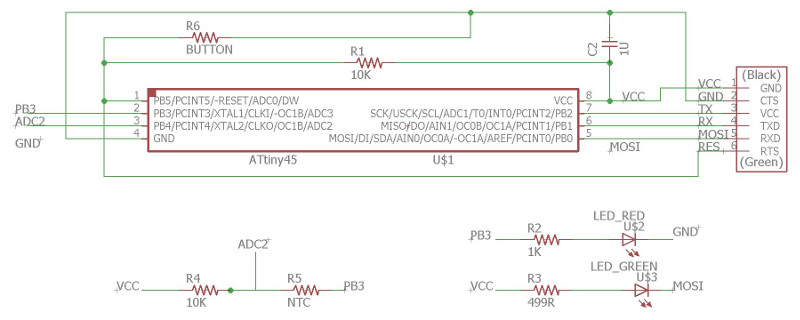

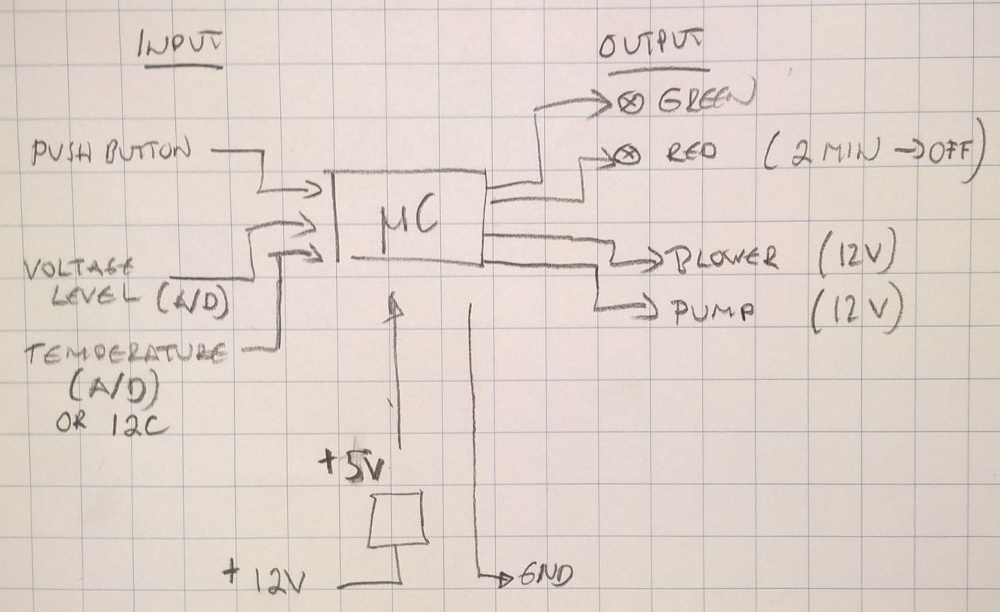

I drew a following sketch of electrical connections. There are two

leds, green and red, and one push button switch as a user interface

to the control system. I call it a user panel. Why so

little? I would like to use it, when I drive my car.

And, those are enough to keep my interest in driving. As second

reason, I try minimize energy consumption, when it operates as

battery-driven without help of motor.

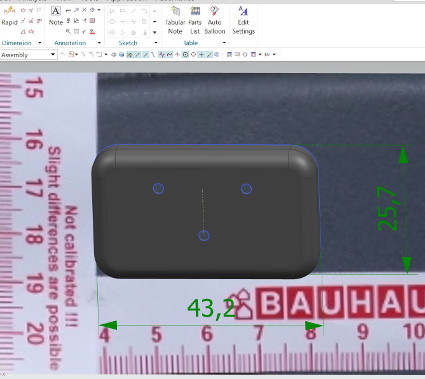

Modeling of the control panel

I have done 3D modeling of a cover part for my user panel as assignment 2. I can select

color for it and put in "place".

Here we go.

Thinking controller

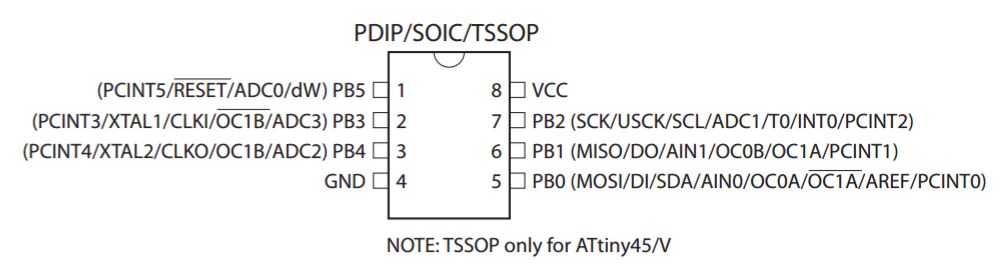

I think I can use ATtiny45 or ATtiny85 as my controller core.

Atmel describes ATtiny45V microcontroller as it combines 4KB ISP

flash memory, 256-Byte EEPROM, 256B SRAM, 6 general purpose I/O

lines, 4-channel 10-bit A/D converter, operation between 1.8 - 5.5

Volts. Power Consumption is 300 µA in active mode, 1 MHz and 1.8V.

My project needs 7 I/O lines. I must reduce them to 6 or change

microcontroller, for example, to ATtiny44 with 12 I/O lines.

- push button to control the operation e.g. start and stop the

system (Digital input)

- temperature measurement (A/D conversion)

- voltage measurement (A/D conversion)

- rear blower control (Digital output)

- external pump control (Digital output)

- communication LED (Digital output).

Output devices

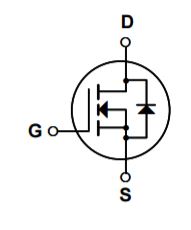

Further, I examined that I

can use MOSFET component to operate 12 V devices via 5 V control

voltage from ATtiny. Those MOSFETs need heat sink to cooling.

Further, I examined that I

can use MOSFET component to operate 12 V devices via 5 V control

voltage from ATtiny. Those MOSFETs need heat sink to cooling.

ATtiny operates 5 V voltage and it can be produced

from car 12 V voltage by a regulator.

For example, N-channel MOSFET FQP30N06L can control 60V or

30 A devices. ATtiny's any output connects to G pole with a 10k

pull-down resistor to GND.

S pole connects to GND and D pole to a pump or blower minus

(-) connector. A rectifier diode like the 1N4001 or SB560 connects

between motor connector as direction (white band) to +.

Pump needs about 5 W power. Blower needs maybe more about 40W.

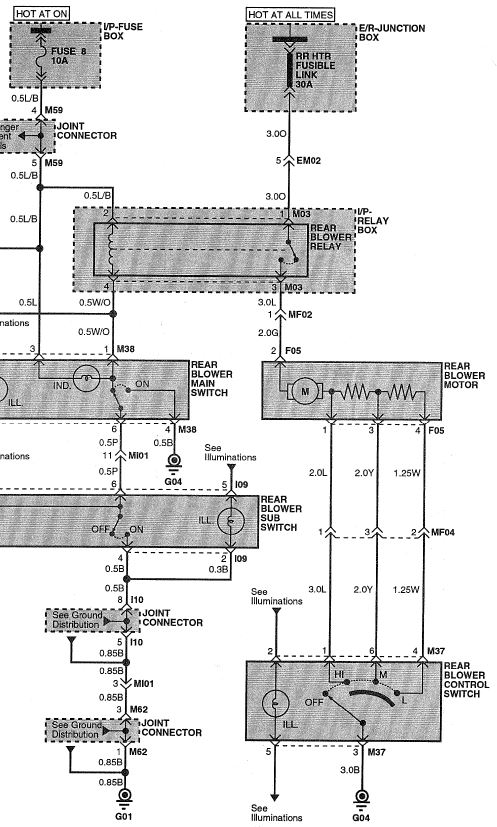

Following picture shows the wiring of the rear blower.

As a part of my new rear heating control I might change wiring by

connecting the on/off switch input of the rear blower (F05)

permanently to +12 V.

And, use my controller to connect the blower to ground (G04).

When I studied wiring schematic more carefully, I found blower is

controlled by a relay.

And, the relay input is powered always +12 V. Therefore, I need only

control this relay.

Further, it is done easily by adding connection to the ground via my

control system.

No, the third look explains that relay control get on only when

ignition key is turned position ON. Therefore, my control system

must connect +12 V to the relay control input to activate the blower

or I can add second relay as parallel to original relay. And, a user

can switch blower on and off normally by the switch. However, a

relay needs much less power to control than blower, about 5 W,

I guess.

I can use same relay to control pump and blower relay also.

I sketched a storage box for my camper car and milled end plates of

it as an assignment 7.

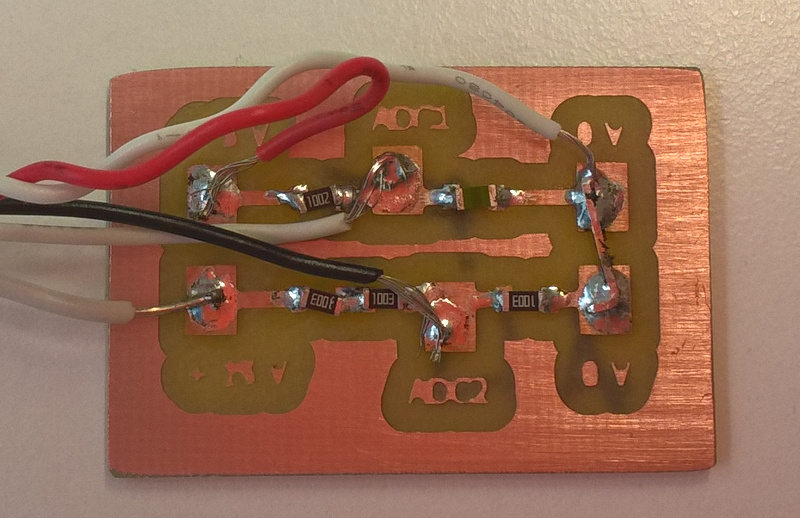

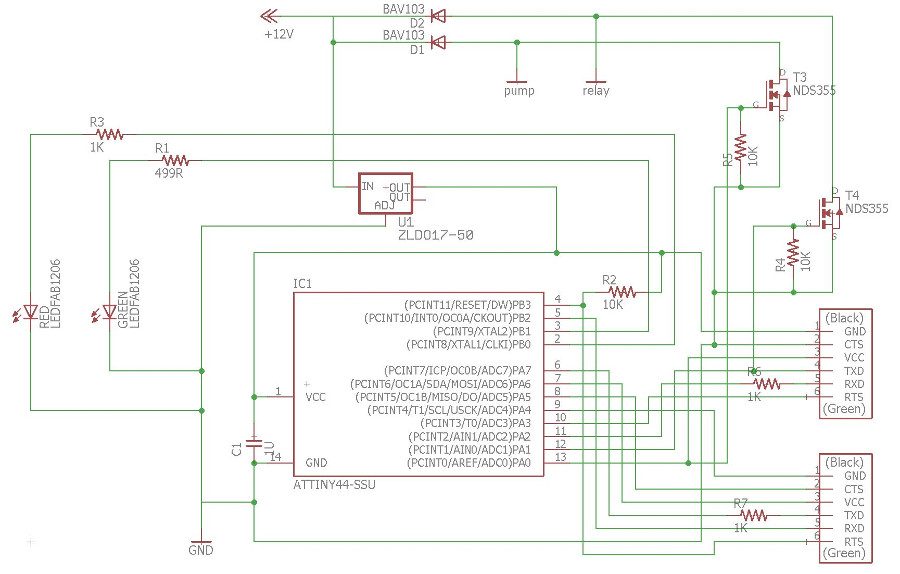

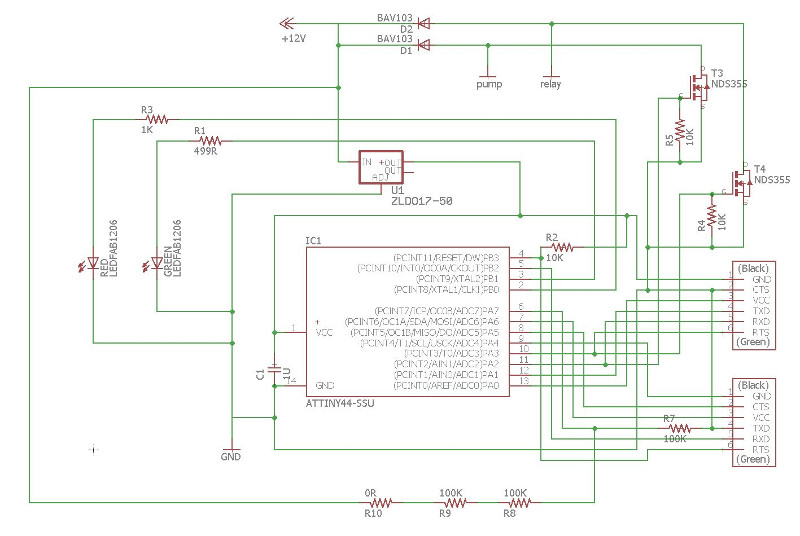

I designed a pump and relay control as an assignment 10. The pump

rotates only to one direction. The relay controls the blower as

described earlier.

My solution uses 12 V operating voltage from my car. It is lowered

to 5 V for Attiny44 use by regulator ZLDO17-50. Maximum supply input

voltage for this regulator is 18 V and current 1 A. I changed

the microcontroller to Attiny44, because it has 12 I/O pins, enough

for my application. I simplified my board using in-circuit clock. A

motor and a relay are controlled by two N-MOSFETs, of type

NDS355ANCT. They have maximum values as 30 V and 1.7 A. Further, I

protected them by diodes BAV103 for reverse spike voltages. It's

reverse voltage is 200 V and forward continuous current 250

mA. Big connector plates are needed for 12V control wires I

solder there. All other connections are handled by 1x12 pin header,

because I want flatten the board and need programming pins MISO,

MOSI and SCK for other purposes, maybe.

I use pins PA0 and PA1 for pump and relay use. Pin PB2 can be

used as interrupt (INT0) and wake-up purposes. And, PA2, PA3 or

PA7 can be used for analog-to-digital conversion (ADC) purposes.

Hence, they can be used for temperature and battery voltage

measurements. Minimum voltage level could be detected by certain

Zener diode also. Finally, I connected two leds to pins PB0 and

PB1.

Note:

RED LED is connected to PB1 and

GREEN LED to PB0 in final board

(see note in Assignment 10).

Input devices

Analog-to -digital conversion is totally new thing for me. Attiny44

has 10 bit resolution of ADC and 8 channels. I made test board to

study more of this feature as assignment

13. I want measure supply voltage (12 V) of my car battery and

temperature inside the car. My test board include two voltage

dividers: One use 2x100k resistors to drop voltage from maximum 15 V

to Attiny44's measurable level 5 V on ADC pin and then 100k resistor

from ADC pin to ground. The second use 10k resistor from 5 V to ADC

pin and from there NTC thermistor to ground. NTC type is NAQ103B

375T10. Thus, it's parameters are R25 10 kΩ and B (25/85) 3750.

Power consumptions of these voltage dividers are 50 µA for voltage

measurement and 250 µA for temperature measurement. Both together

take 300 µA. Not much, but still I might use a main switch for the

system. Then, I can switch it off when I don't need it.

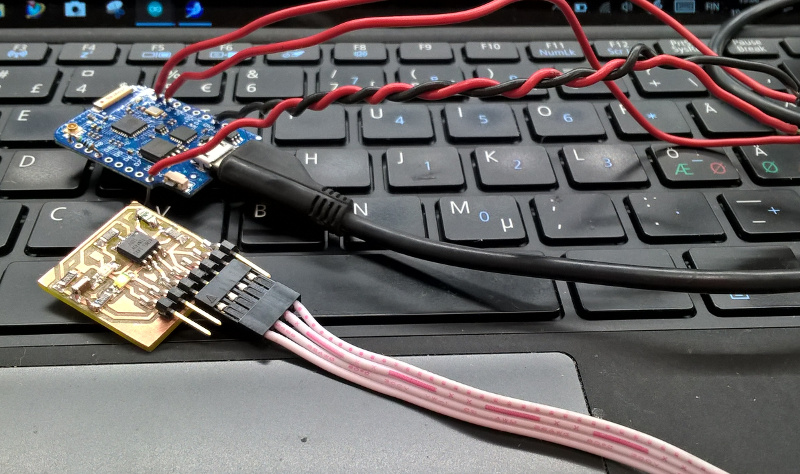

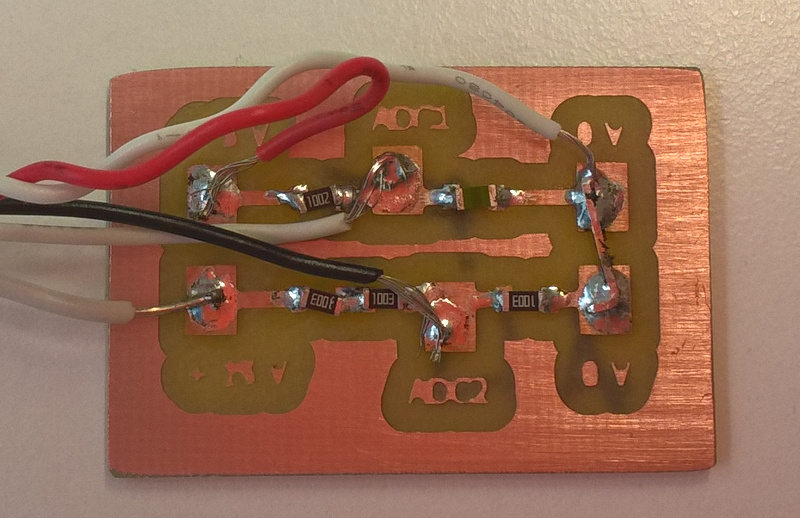

During assignment

15, networking and communication, I made a board for

communication but also for testing of ADC, user interface and serial

communication together. My original ADC code needed some

modifications to work also in Attiny45. One difference

exists as ADLAR set in ADMUX |register for attiny45 and ADCSRB

register for Attiny44.

This schematic is for Node_F1.

I must change pins TX and RX that I can use direct cable between

units.

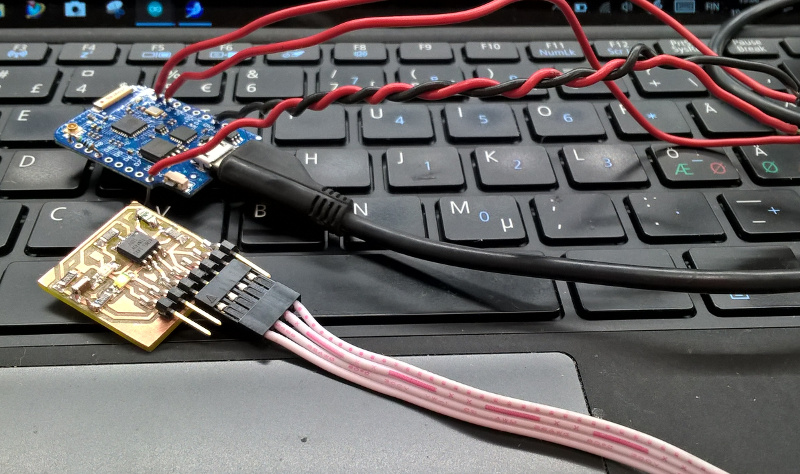

I used Wemos D1 Mini Pro as serial interface to my computer. It's

operating voltage and I/O levels are 3.3 V, but I used it's 3.3 V

pin as voltage source for Attiny45. Therefore, Attiny45 operated

also as I/O levels 3.3 V. Empty code programmed to Wemos

served as serial interface to my Node board.

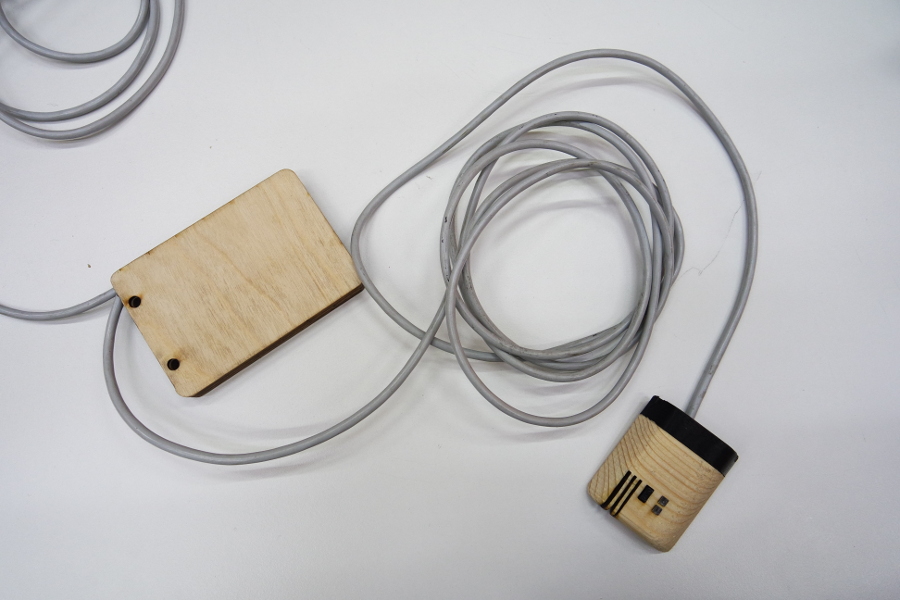

It is RESIDUAL HEAT CONTROLLER

Now is time to document the final project plan. I need two boards,

one (Node_F1) for user interface and temperature measurement

and the second (MainB_F1) for voltage conversion from 12 V to

5 V, battery voltage level measurement and control of pump and

blower. I want use a serial bus between units and such a way that I

can add more boards if needed.

Hardware

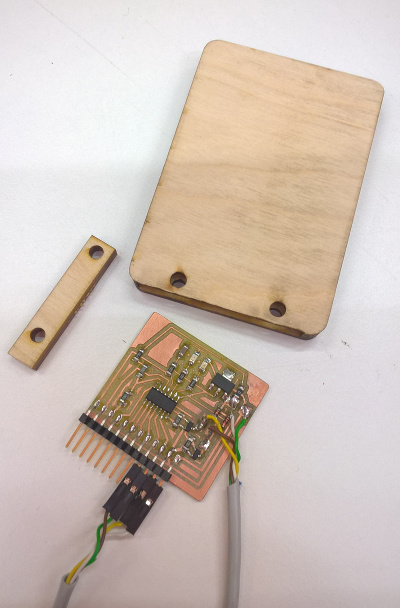

Node_F1 board was presented above. I made it during

assignment 15 as I told earlier.

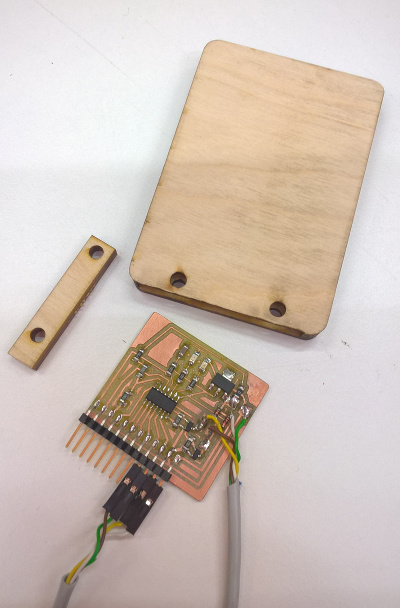

MainB_F1 board is a evolution of boards made during

assignment 10 and 13. It is presented below.

This schematic is for MainB_F1.

These two boards are handmade soldered and work now. They measure,

communicate and control as designed. Some problems existed. Attiny44

as a core of MainB_F1 took too much power and I changed the chip.

Current consuming was 140 mA and it heated much. After change

current dropped to 14 mA. Also, serial communication needed

different bit delay times. MainB_F1 needed value of 100 and

Node_F1 105. And, I changed TX and RX pins to Node_F1 that I can

use direct cable between units.

Power consuming of two boards was about 12 V 25 mA and it dropped to

12 mA when both boards slept. I done more measurements and saw that

Node_F1 took 5 V and less than 1 mA current. when it slept. And,

MainB_F1 took 5 V, 12 mA even it might sleep. Why? It doesn't sleep

anymore or sleeps shortly and wakes up again. I studied my code and

found error. MainB_F1 sleeps before Node_F1 and it wakes MainB_F1

before sleeps. I corrected my code and now power consumption during

sleep is 12 V 5 mA and during idle 12 V 25 mA. It might be even

lower by some code changes.

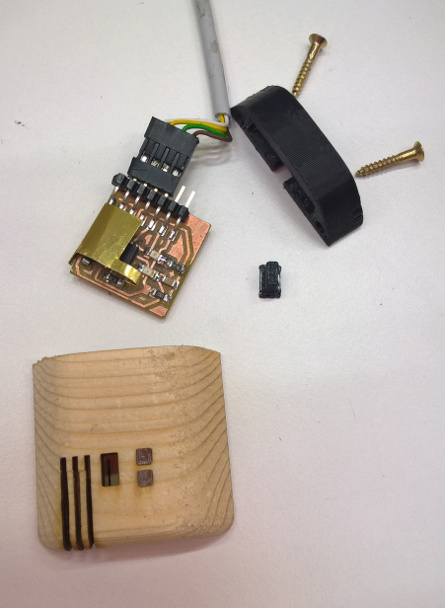

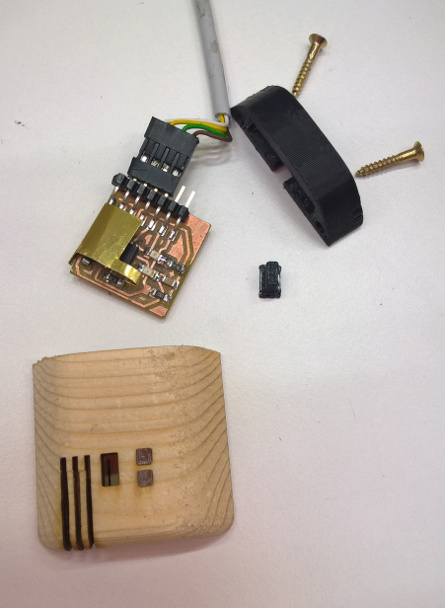

Cover for Node_F1 (left) consists of three parts: the wood box was

made by long Ø3.18 mm bit as two sided. The outer form was milled

first. Then the block was rotated upside down and milled the

inner pocket. I used two holes for targeting means. Then, led and

ventilation holes was cut by laser. Also, two small windows were

laser cut from 3 mm PMMA sheet. The cap and button were 3D printed

from ABS by Statasys Fortus 380mc printer. The brass spring was

handmade by scissors.

Cover for MainB_F1 (right) is more simpler. It consists of two

parts: the plywood box was laser cut as four parts and glued

together. The cap was made similarly from two parts.

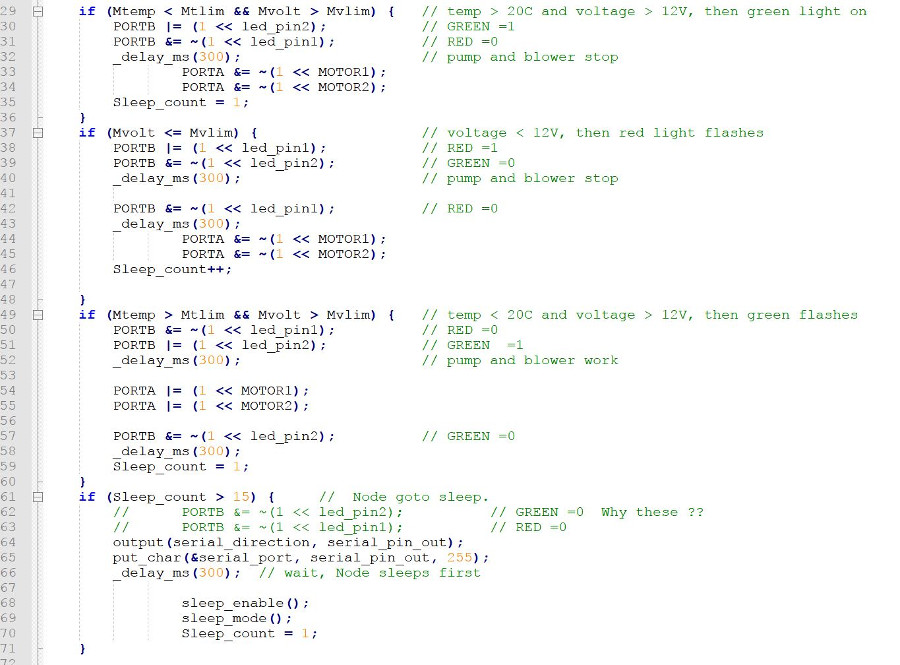

Software

I developed and tested many software parts earlier. I coded LEDs and

Mosfets for pump and relay control as assignment

10, ADC input during as

assignment 13 and serial communication as assignment

15, This communication code originates from Neil's

hello.bus.45.c code from Fabacademy 2017 pages. Also, I tested sleep

and wake-up functions during assignment

8.

Here, I describe final part, operations how software works in

different situations. The both boards have very similar functioning.

Voltage (Mvlim) and temperature (Mtlim) limits are not final and may

change later, when I install the system to my car.

Bill of materials (BOM)

Source column in following list documents the source where component

or material were purchased. Abbreviation FL means from Fab Lab Oulu

and OT means other source.

MainB_FI:

Part

Value

Device

Package

Description

PROD_ID

SOURCE

PRICE EUR

C1

1U

CAP-UNPOLARIZEDFAB

C1206FAB

FL

0.07

D1

BAV103

DIODESOD123

SOD123

DIODE

OT

0.35

D2

BAV103

DIODESOD123

SOD123

DIODE

OT

0.35

GREEN LEDFAB1206

LEDFAB1206

LED1206FAB

LED

FL

0.15

IC1 ATTINY44-SSU

ATTINY44-SSU

SOIC14

FL 1.18

R1 499R

RES-US1206FAB R1206FAB

Resistor (US

Symbol)

FL

0.01

R2 10K

RES-US1206FAB R1206FAB

Resistor (US

Symbol)

FL

0.01

R3 1K

RES-US1206FAB R1206FAB

Resistor (US Symbol)

FL 0.01

R4 10K

RES-US1206FAB R1206FAB

Resistor (US Symbol)

FL 0.01

R5 10K

RES-US1206FAB R1206FAB

Resistor (US Symbol)

FL 0.01

R7

100K

RES-US1206FAB R1206FAB

Resistor (US Symbol)

FL 0.01

R8

100K

RES-US1206FAB R1206FAB

Resistor (US Symbol)

FL

0.01

R9

100K

RES-US1206FAB R1206FAB

Resistor (US Symbol)

FL 0.01

R10 0R

RES-US1206FAB R1206FAB

Resistor (US Symbol)

FL

0.01

RED LEDFAB1206

LEDFAB1206

LED1206FAB

LED

FL 0.13

T3

NDS355

NMOSFETSOT23

SOT-23 MOS

FET

FL 0.26

T4

NDS355

NMOSFETSOT23

SOT-23 MOS

FET

FL 0.26

U$2 FTDI-SMD-HEADER FTDI-SMD-HEADER

1X06SMD

FL

0.60

U$3 FTDI-SMD-HEADER FTDI-SMD-HEADER

1X06SMD

FL 0.60

U1 ZLDO17-50

V_REG_LM1117SOT223 SOT223 Voltage Regulator

LM1117 VREG-08170 FL

0.34

Total

4.38 eur

Node_F1:

Part

Value

Device

Package

Description

SOURCE

PRICE

C2

1U

CAP-UNPOLARIZEDFAB

C1206FAB

FL

0.07

R1

10K

RES-US1206FAB R1206FAB

Resistor (US Symbol)

FL

0.01

R2

1K

RES-US1206FAB

R1206FAB Resistor (US Symbol)

FL

0.01

R3

499R

RES-US1206FAB R1206FAB

Resistor (US Symbol)

FL

0.01

R4

10K

RES-US1206FAB R1206FAB

Resistor (US Symbol)

FL

0.01

R5

NTC

THERMISTOR10K 10% R1206FAB Resistor (US Symbol)

FL

2.50

RES FTDI-SMD-HEADER FTDI-SMD-HEADER

1X06SMD

FL

0.60

U$1 ATTINY45SI

ATTINY45SI

SOIC8

FL

1.23

U$2 LED_RED

LEDFAB1206

LED1206FAB LED

FL

0.13

U$3 LED_GREEN

LEDFAB1206

LED1206FAB LED

FL

0.15

Total

4.72 eur

PCB boards 24x25 mm and 38x45 mm

FL

1.00

4 wire cable 4 m

OT

2.00

BOSH water circulating pump 12 V 4.5 W

OT

49.90

Relay 12 V

OT

0 (from old VW)

Wood block Finish pine 25x80x45 mm

FL

1.00

Blywood 3x86x240 mm

FL

0.02

Spring material CuZn37 (Brass) 0.2x20x50 mm

FL

0.10

Wood screw 2x Ø3x15 mm

OT

0.50

Total

54.52 eur

All

together 63.62 EUR

Original design files and codes:

Board schematics: fabnode02.sch

and FABcamper02.sch.

Board layouts: fabnode02.brd and

FABcamper02.brd.

Boards as png files: fabnode_track02.png

and FABcamper21.png.

Control codes: Fab_node_F1_main.c

and Fab_MainB_F1_main.c.

Design files:

Node_F1 as original FAB_node04.prt,

as dxf format FAB_node04.dxf and as

stl format FAB_node040.stl.

Button for Node_F1 as original Fab_node_bt.prt, as dxf format Fab_node_bt.dxf and as stl format

Fab_node_bt2.stl.

Cap for Node_F1 as stl format FAB_node04hat.stl.

MainB_F1 as original FAB_MainB01.prt

and as dxf format FAB_MainB01.dxf.

Cap for MainB_F1 as original FAB_MainB02.prt and as dxf format FAB_MainB02.dxf.

Presentation slice and video

Summary slide

Video clip

Residual

Heat Controller by Yrjö Louhisalmi is licensed

under a Creative

Commons Attribution-NonCommercial 4.0 International License.

Note: Residual heat controller is a part

of bigger project: MY CAMPER VAN

Used pump and blower exist as

demonstration purposes in my presentation slice and video. It is a

big work to assemble cooling liquid circulation pump as well as do

connections to rear blower of my car. Therefore, I decided to keep

these out of my final project. And, I present only the controller

as my final work. It is the brain that operates the circulation pump

and rear blower in future.

Further, I examined that I

can use MOSFET component to operate 12 V devices via 5 V control

voltage from ATtiny. Those MOSFETs need heat sink to cooling.