Assignment 13. Input Devices

For this week I will be control an LED by using a CDS/LDR ..

Week 13 checklist:

Input devices

An Input device is any peripheral that converts the real-world properties (light, touch, sound… etc.) into data that a microcontroller can process. An input sensor will measures a specific property data and sends a signal to output peripherals to be executed..

Examples of Input devices:

There are many Input devices avilable on the market,, I will mention the most device I might use:

1. Buttons and Switches:there are many types of buttons and switches, but all of them share the same concept, when the button/switch is pressed a signal is sent to the microcontroller.

2. LDR: Light Dependent Resistor, Photoresistor, or CDS, is a resistor which has a resistance that varies depending of the light intensity.

3. IR Sensors: Infrared is a form of light that can not be seen with human eyes, but can sometimes be sensed on the skin as heat.

4. Ultrasonic sensors: Ultrasound is sound waves with frequencies higher than the upper audible limit of human hearing..

5. Microphone, Temprture sensor, color sensor, variable resistors... etc

Electronics Design

For this week I will be control an LED by using a CDS/LDR ..

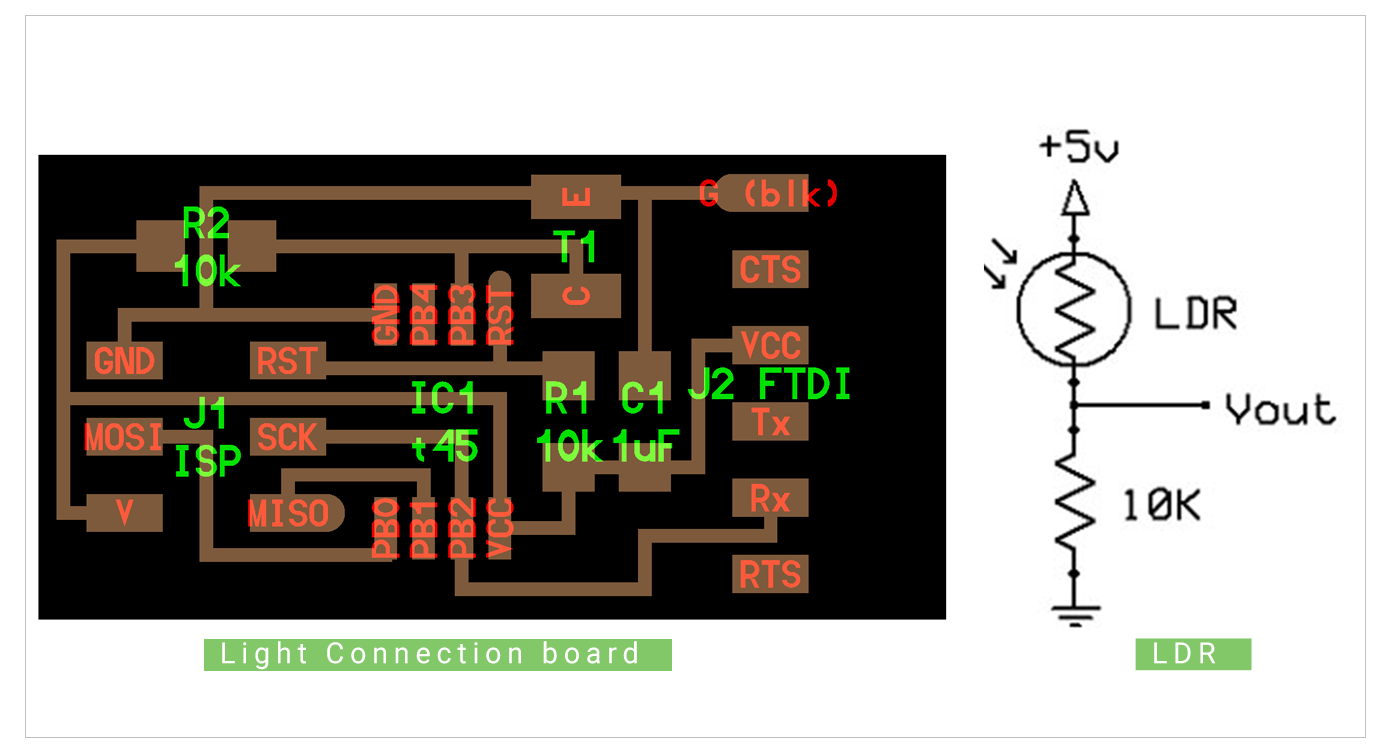

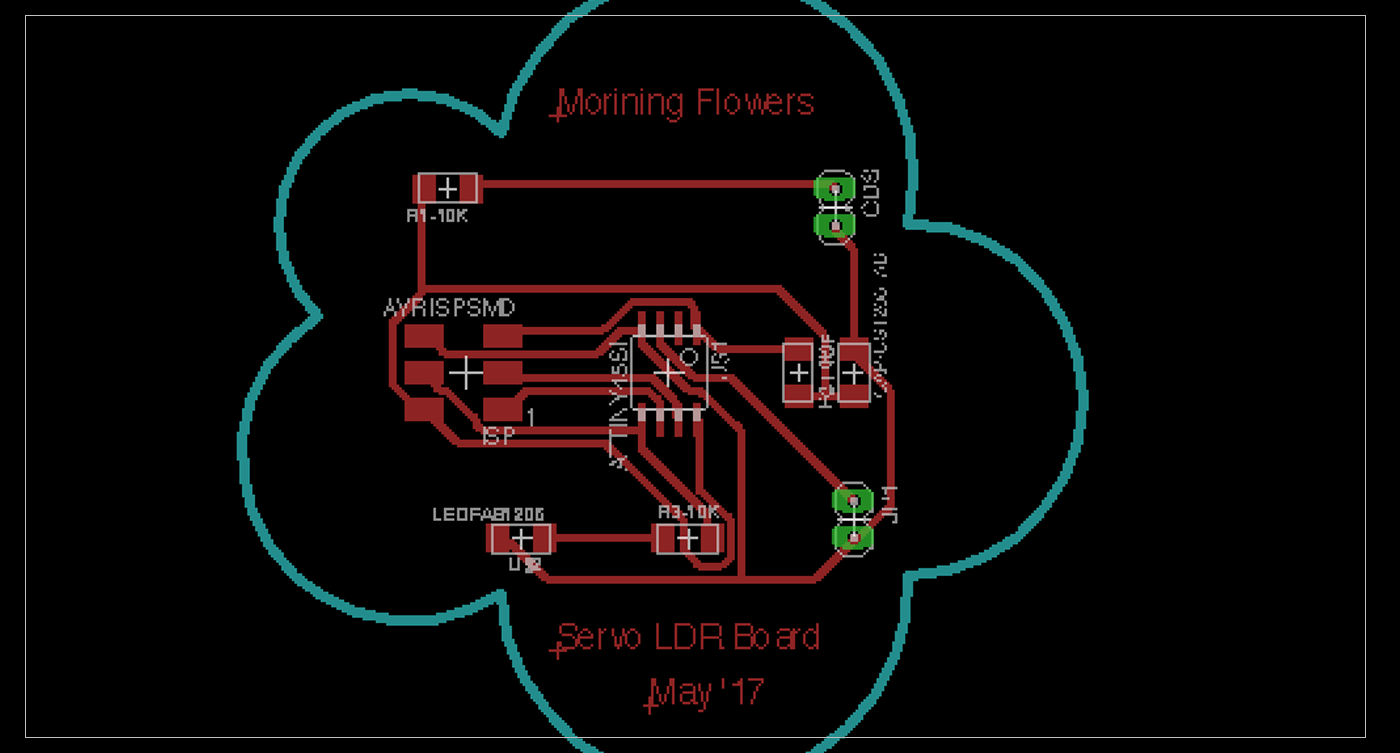

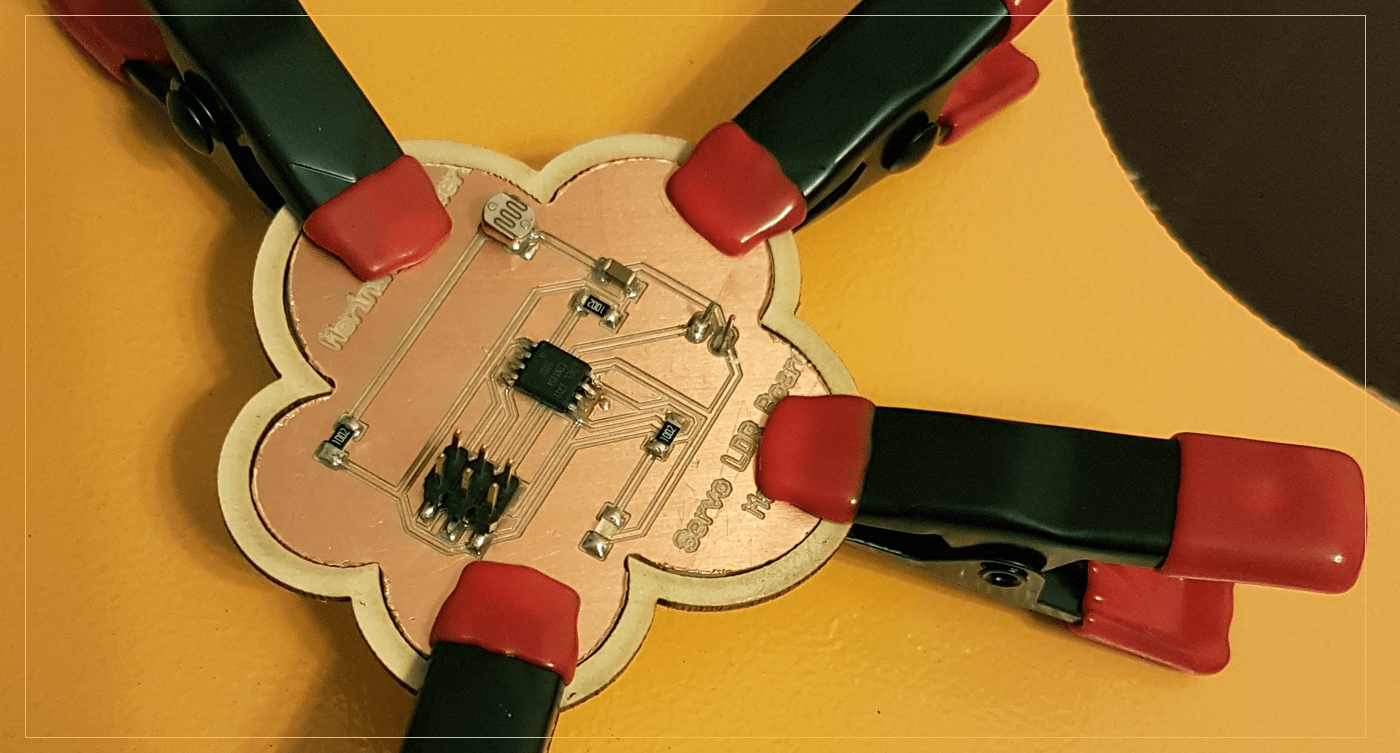

I used the light board from the references of this weeks to make my board as well as an LDR connection daigram, I was planning to add a servo, but I have discoverd a mistake I have made after milling the board, which is I have used 2 pins-head insted of 3! So I decided not to use the servo for this project, but I will practice with the board later to add it to my Final project ..

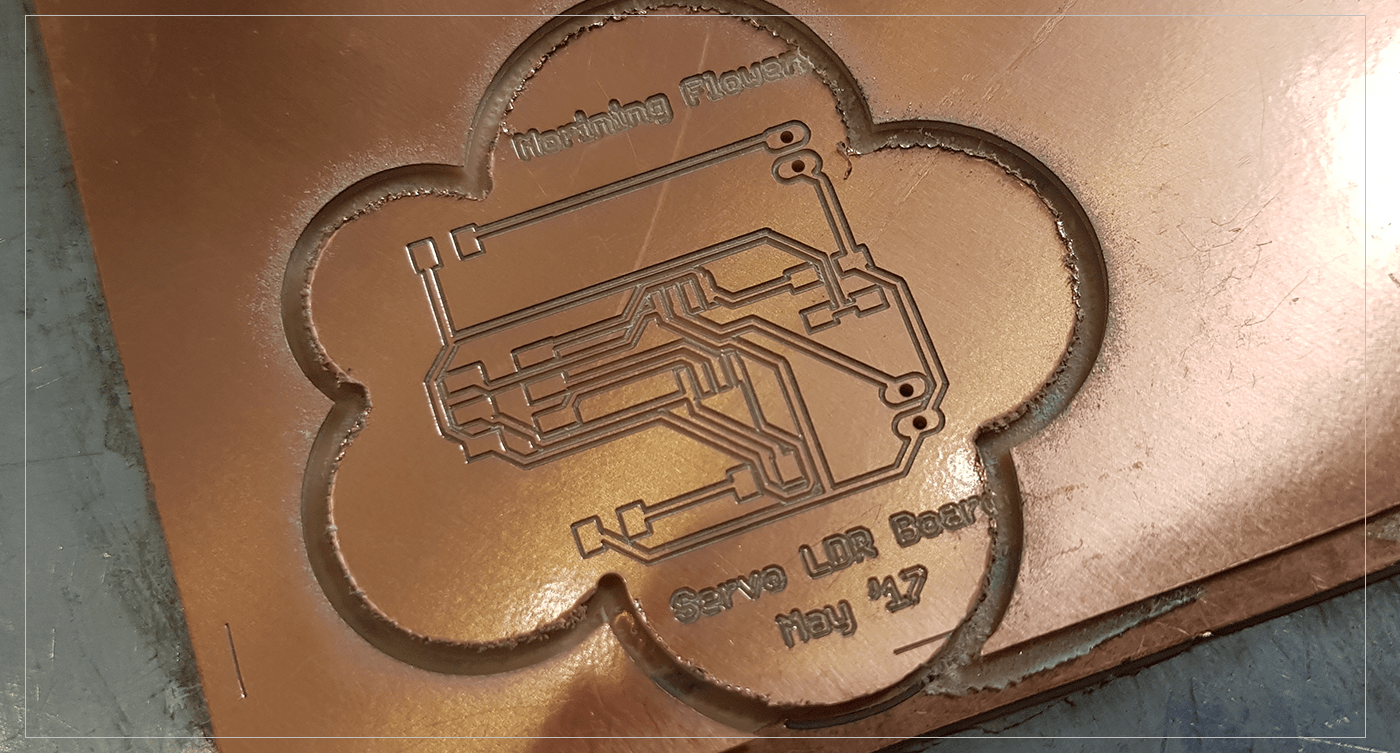

After that I have created the Grabber files, and mill the borad using our PCB Milling machine..

After that I have created the Grabber files, and mill the borad using our PCB Milling machine..

I used a new dilling bit to cut the boards frome,, and it was very harsh! The board's sides were very rough! .. I have tried to sand them with sanding paper, but I was afraid to scratch the board's surface becase of the curves,, So I decided to make a housing for my borad and it would look even neater : ) .. so I did design a frame and a bottom plate to hold the board, then cut them using Laser cutter.. then using glue to attach the frame to the bottom board.. it was a GREAT Soultion : )

I used a new dilling bit to cut the boards frome,, and it was very harsh! The board's sides were very rough! .. I have tried to sand them with sanding paper, but I was afraid to scratch the board's surface becase of the curves,, So I decided to make a housing for my borad and it would look even neater : ) .. so I did design a frame and a bottom plate to hold the board, then cut them using Laser cutter.. then using glue to attach the frame to the bottom board.. it was a GREAT Soultion : )

Programming the Board:

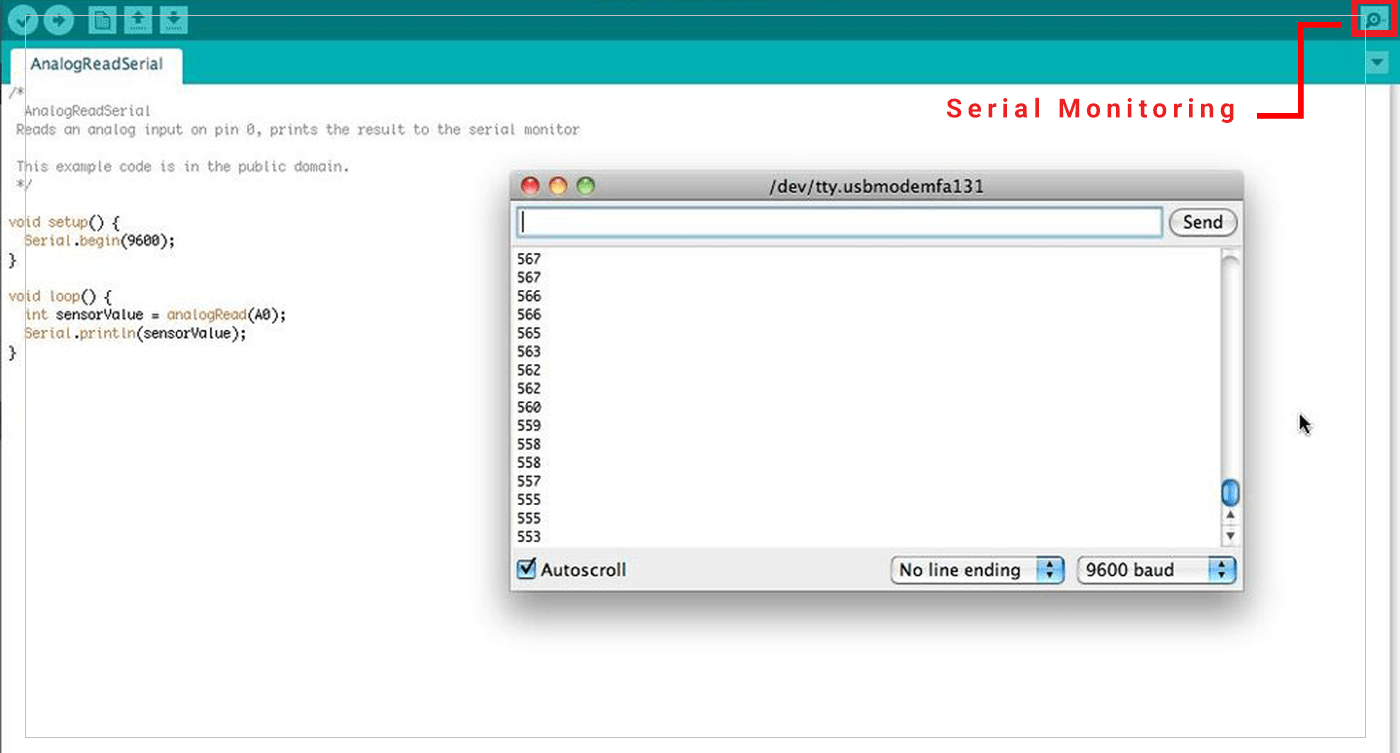

Serial Comunication:

The first step was to test my LDR by conncting it to Arduino Uno Board, then by using a simple code I could make sure that the LDR is working and at the same time get the readings of the around environment ..

void setup() {

Serial.begin(9600);

}

void loop() {

int sensorValue = analogRead(A0);

Serial.println(sensorValue);

I have searched for a LDR code on the web, then modify it to fit my project..

here is the code:

int sensorPin = 3;

int sensorValue = 0;

void setup() {

pinMode(0, OUTPUT);

}

void loop() {

sensorValue = analogRead(sensorPin);

if(sensorValue < 700)

{

digitalWrite(4,HIGH);

}

else digitalWrite(0,LOW); //turn LED OFF

delay(100);

}

[ Source File - BRD File ]

[ Source File - SCH File ]

Previous Week Home Next Week