Assignment : Make something big (on a CNC machine).

CNC router (Or Computer Numerical Control router) is a computer-controlled cutting machine related to the hand held router used for cutting various hard materials, such as wood, composites, aluminium, steel, plastics, and foams. CNC stands for computer numerical control. CNC routers can perform the tasks of many carpentry shop machines such as the panel saw, the spindle moulder, and the boring machine. They can also cut mortises and tenons. ( Wikipedia.org ).

The CNC machine in our lab is J-cut 1325B type and the bed size is 130 CM x 250 CM. Depending on the type of material and purpose we have to be very specific on selecting the ‘bits’,

There are several types of bits based on the swirls,no. of flutes and arrangement of the bit-pattern:

1-Up-cut

2-Stright

3-Down-cut

4-Compression

for my design here I use 3mm down-cut bit.

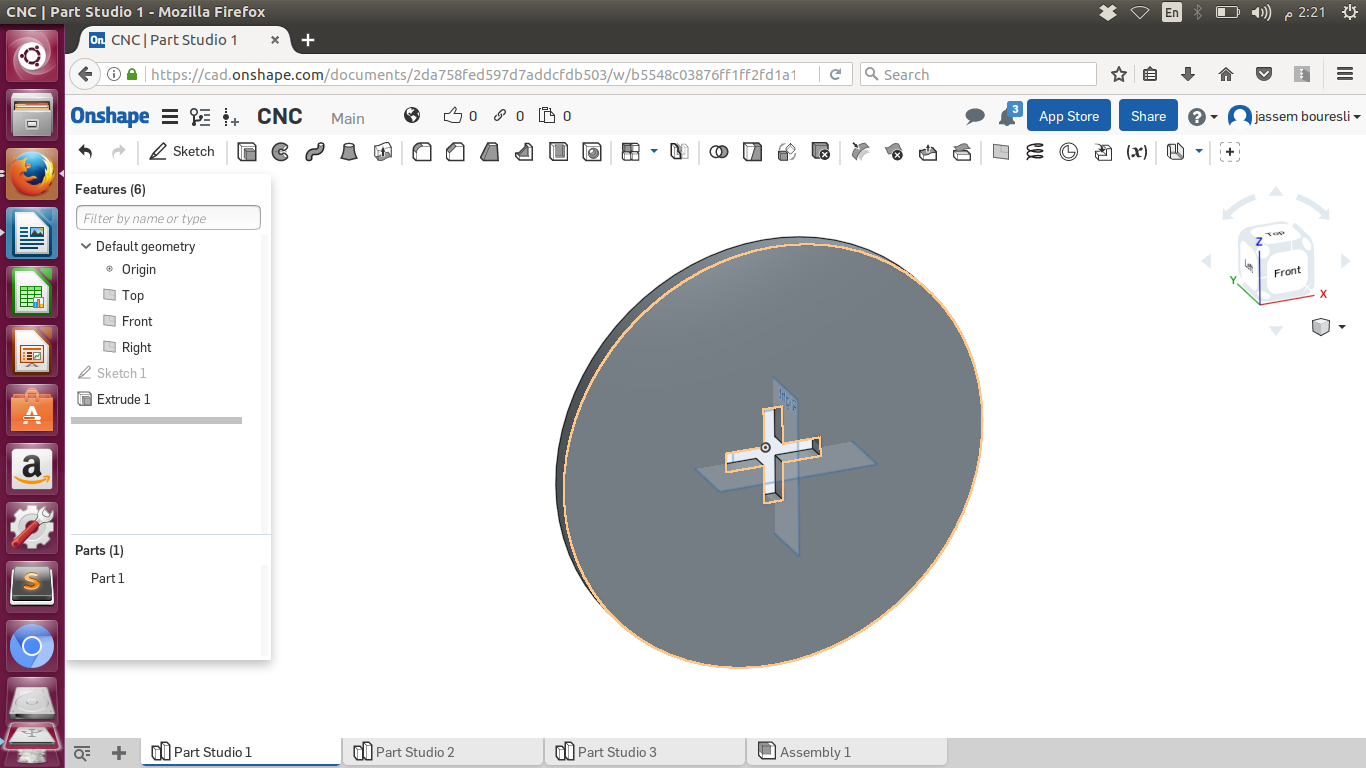

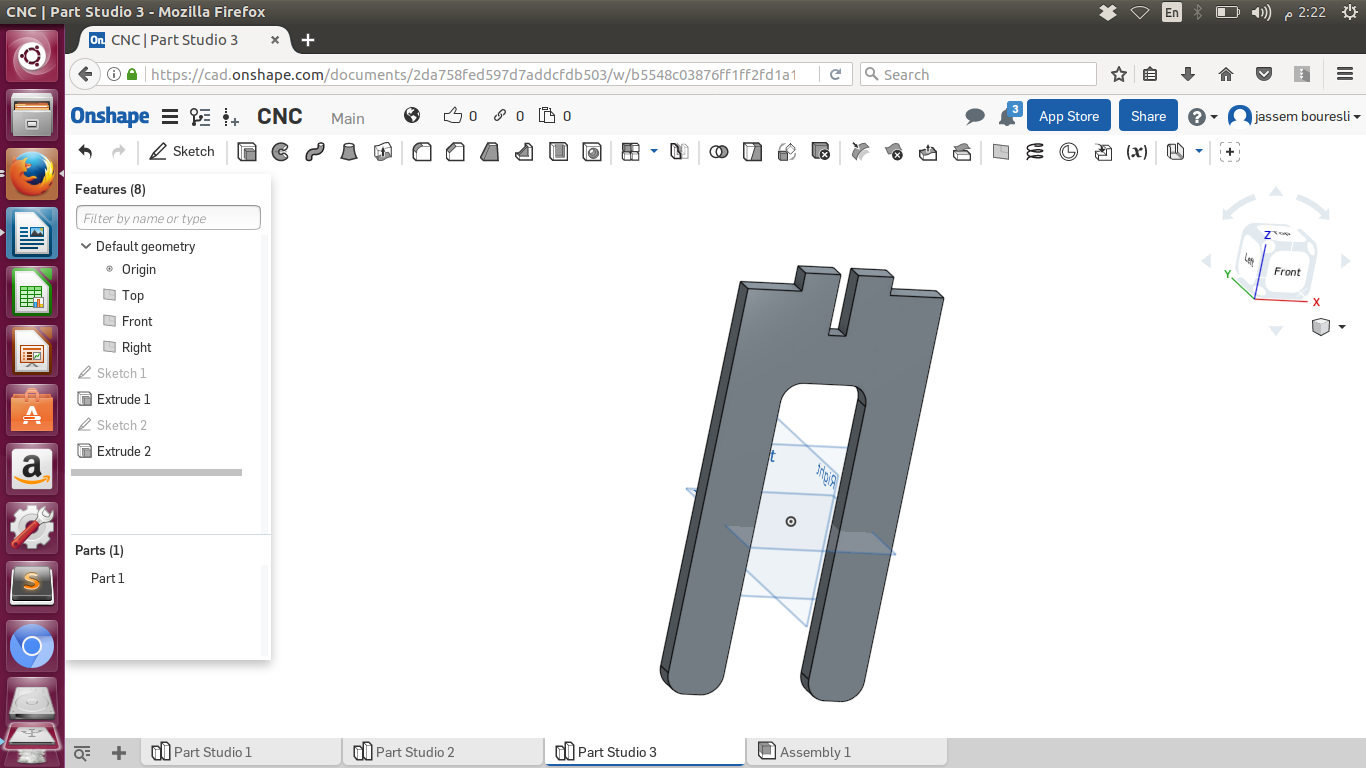

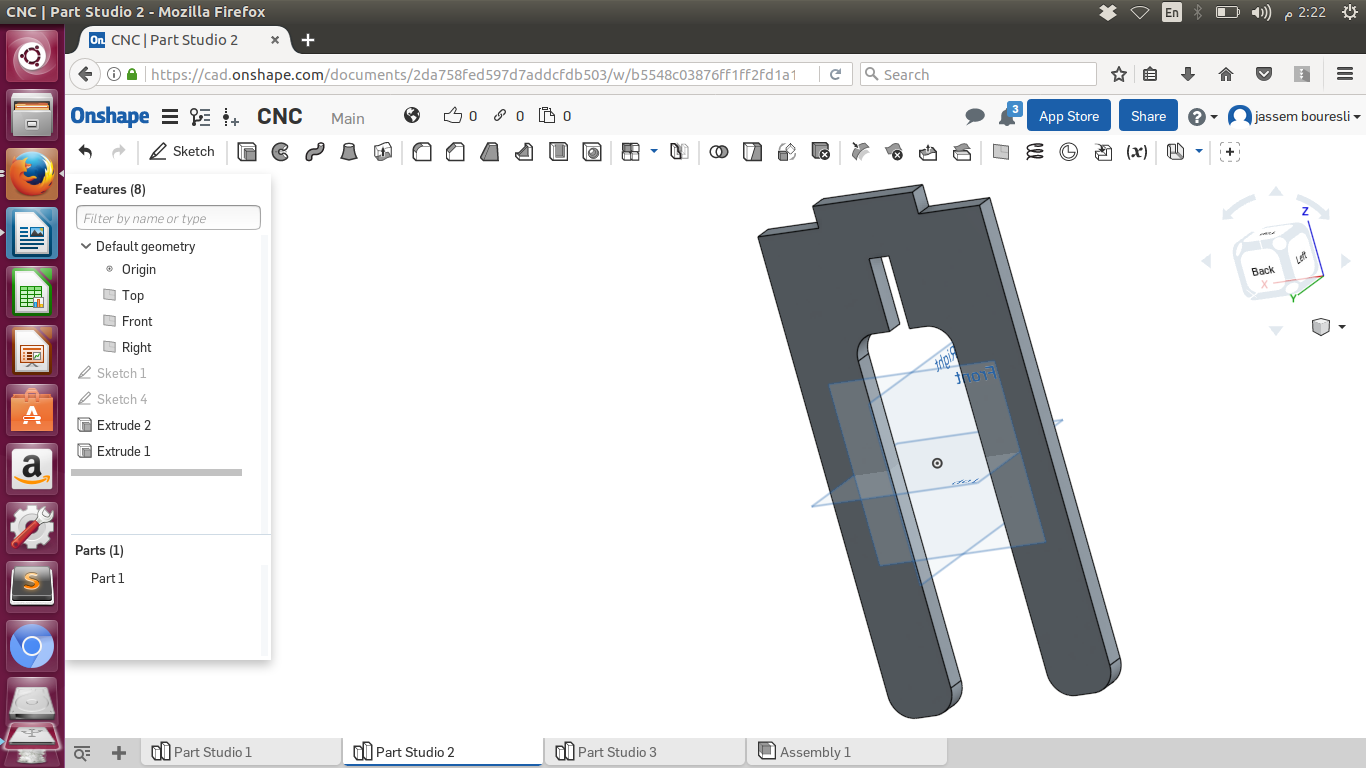

for my CAD design I used Onshape software https://www.onshape.com because it is free, web-based. easy to use program. My aim is to make a circular coffee table with four legs connected using press fit method, I choose centimeters as my measuring unite, with 40 CM diameter for the top table circle and 9 CM for the press-fit opining

the hight of the legs is 40 CM and the width of the (two-legs) part is 20 CM and since we are using 1.8 CM thickness boards the press-fit opining width is 1.8 CM all drawings exported as .dxf files.

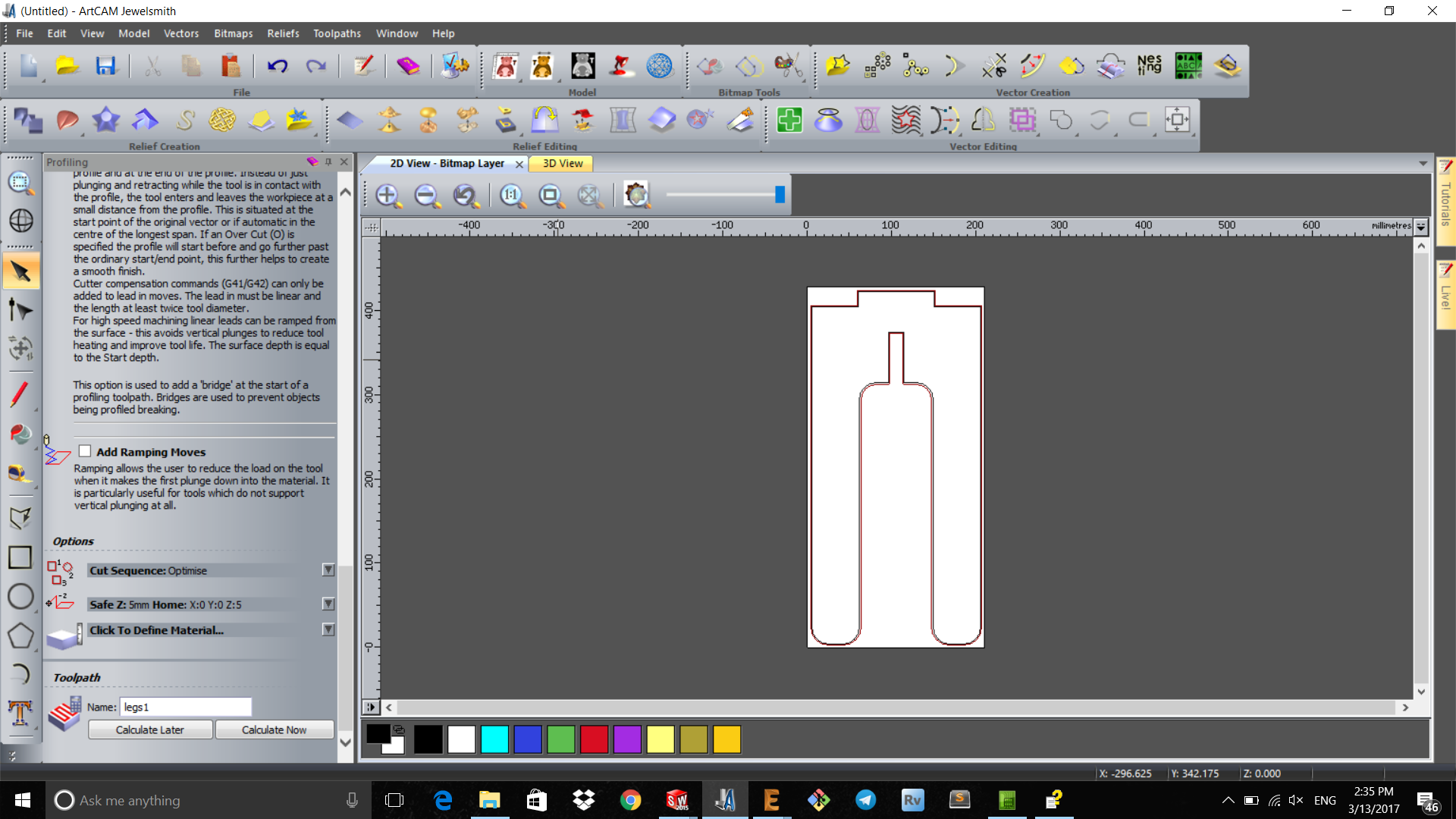

Using ArtCam software I imported the .dxf files to align the objects I wanted to cut on the wooden sheet placed on the Controlled Cutting Machine to cut, since the CNC machine is operating by .plt file type I fixed -0.3 mm as tolerance of the press fit opining in my coffee table to make sure that the parts will fit each others.

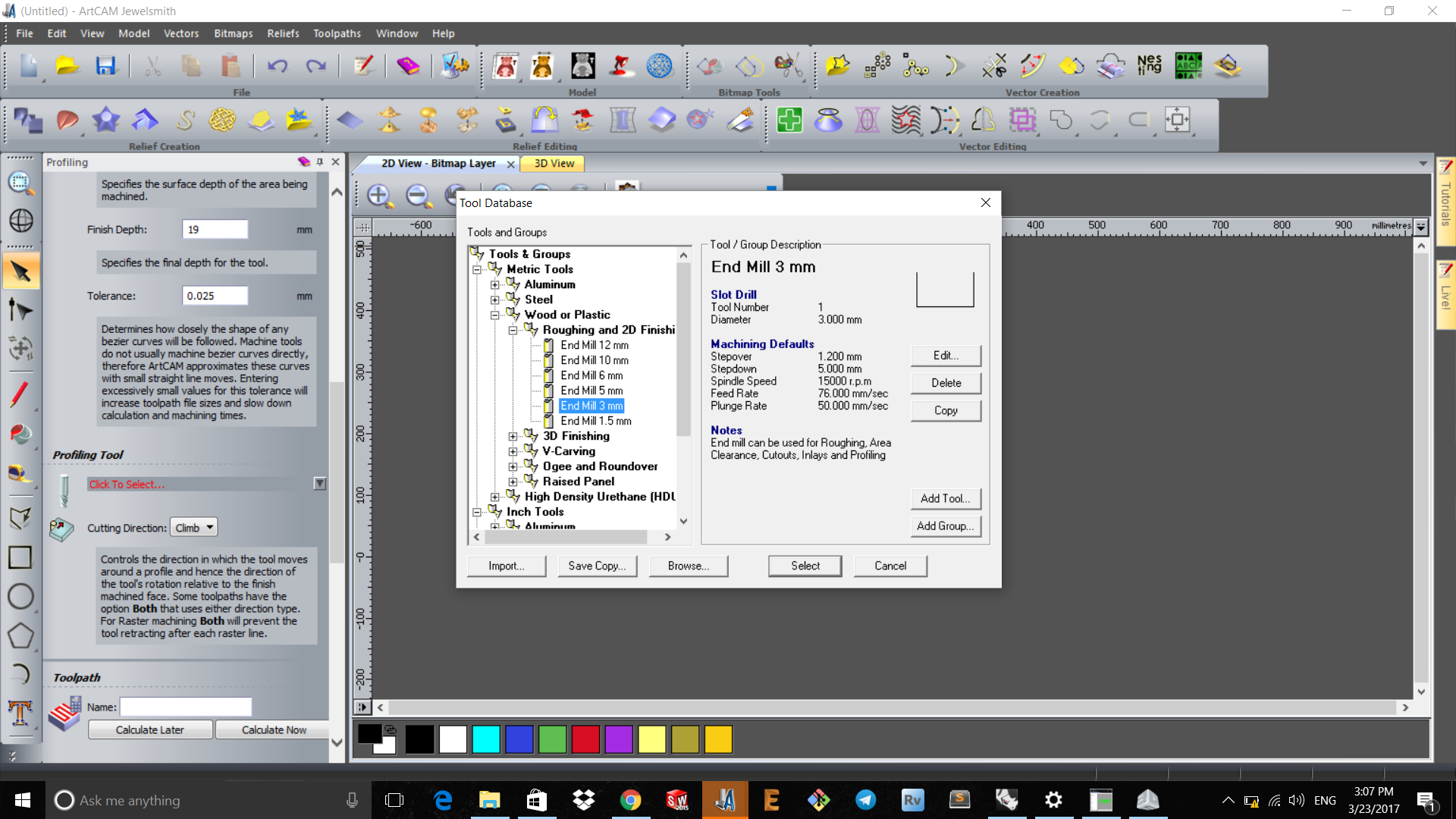

after that choose tool-path by Toolpaths then New 2D toolpath . Then I fixed the cutting (finish) depth to be 1.9 CM since the wooden sheet is 1.8 CM to make sure it will cut all the way through and I put another old used wooden sheet below the one I am cutting for safety, clicked select tool and choose 3 mm as a bit, calculated the tool path to cut my coffee table and I saved tool paths, Then I exported the files as .plt

The settings as shown in the following screenshot are:

1-Stepover 1.2 mm

2-Stepdown 5 mm

3-Spindle Speed 15000 r.p.m

4-Feed Rate 76 mm/sec

5-Plunge Rate 50 mm/sec

Using the machine controller I loaded the .plt file and set the 3 axis X,Y & Z and started cutting

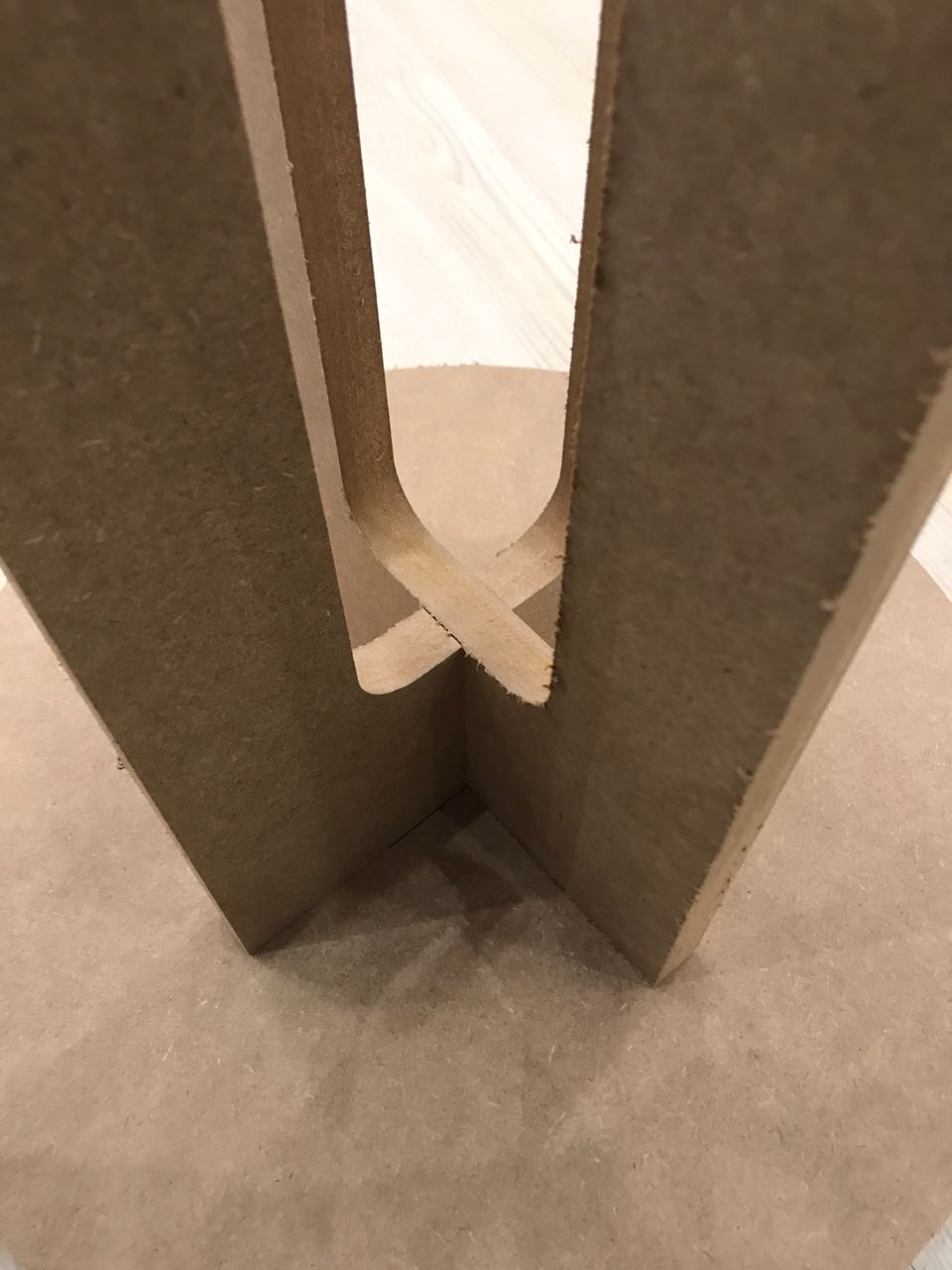

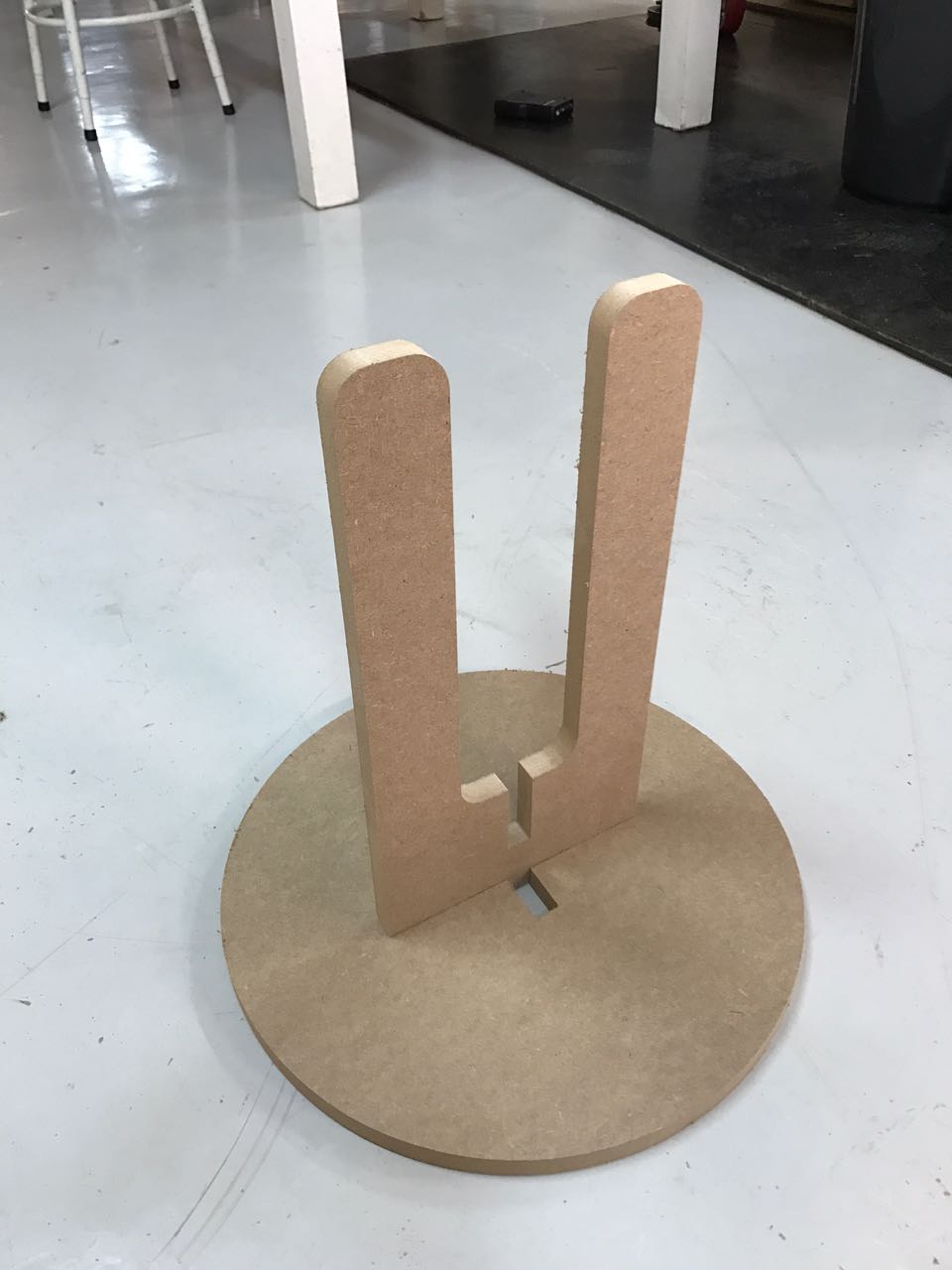

After cutting the first legs part i tries the press-fit and it was perfect.

So i advanced ahead and started cutting the other legs part.

I assemple all three parts and it fits very good