Assignment is to 3D print a non sub-tractable design, and to 3D scan an object.

A 3D printer is a computer controlled machine using layers of material to create a 3d object and the 3D Printer used in our lab is Weistek 2805 Printer with the REALvision application.

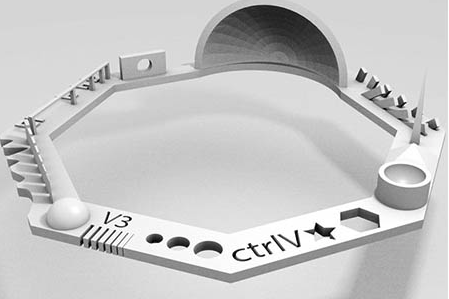

First we test the printer using the testfile stl downloaded from thingiverse.com from the link http://www.thingiverse.com/thing:1363023 and to print it

his is a test to check various parameters of 3d print

Nut, Size M4 Nut should fit perfectly:

perfect fit

Wave, rounded print:

Looks good

Star, Sharp Edges:

yes

Name, Complex Shapes:

Look good

Holes, Size 3, 4, 5 mm:

Good. Measured 2.8,3.74,4.7

Minimal Distance: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 mm:

0.5 mm was the minimum gap that was clearly visible, smaller than that wasn’t - this is probably because we were using the 0.4 mm nozzle size.

Wall Thickness: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 mm

Printed only 3 walls. This too would be because of the nozzle size.

Bridge Print: 2, 4, 8, 16 mm:

Dimensions match

Sphere, Rounded Print 4.8mm height:

Was around 4mm.

Overhang: 25, 30, 35, 40, 45, 50, 55, 60, 65, 70°:

It was able to print all

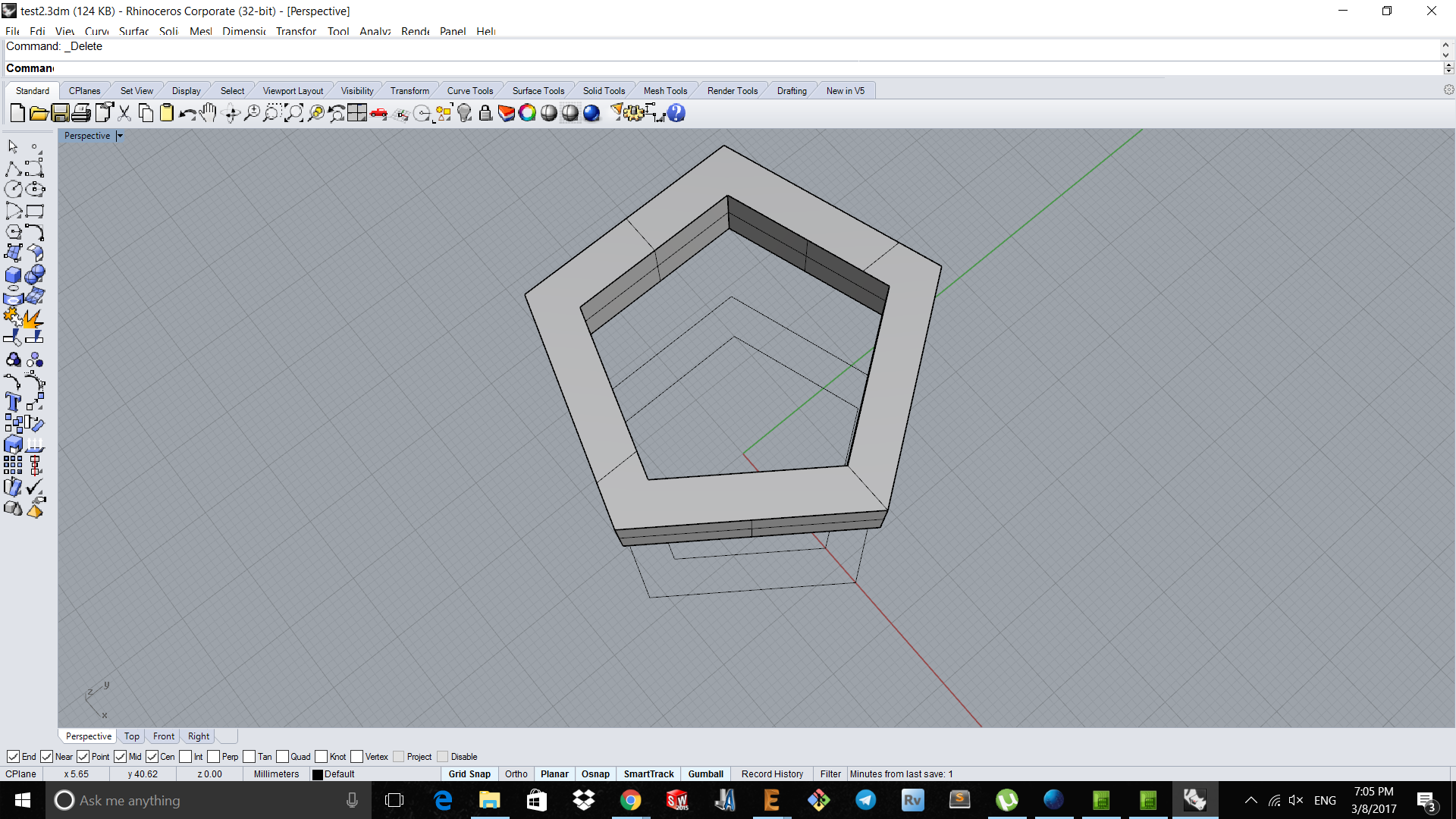

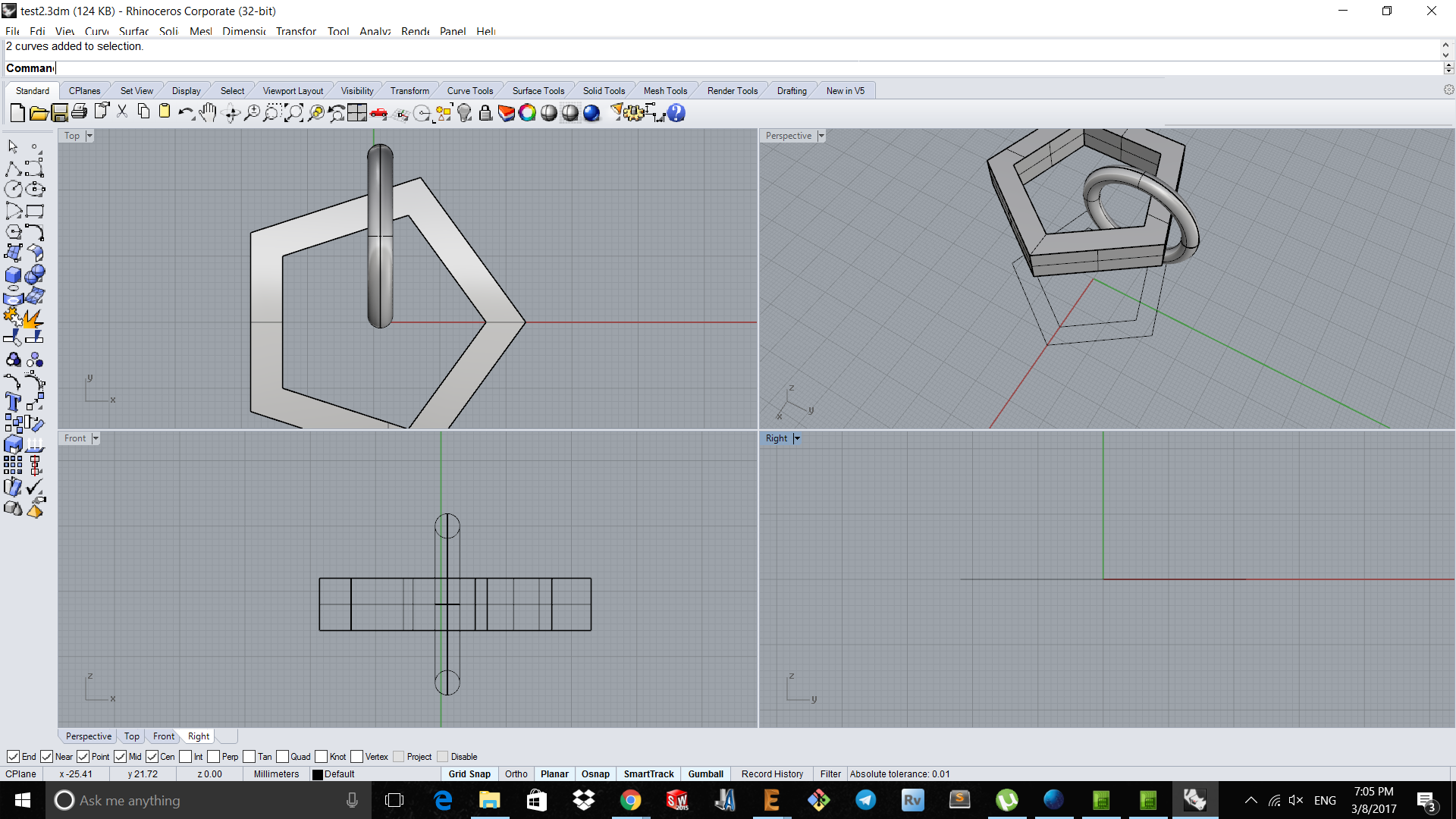

I Used Rhino 3D to design non sub-tractable object of a pentagon and a circle .

I choose Rhino because it is much easier and user friendly than one shape and it utilize my PC processor instead of being web-based.

First I used a tool called polylines to draw the shape shown

and then I used the extrude command to extrude it and it have 3 views top front and side view and if you click one f the views you can work with it which make life easier

After saving my design in a USB flash memory I started printing it with the aid of supporting materials by the 3d printer soft wear. The nozzle temperature is 240 C and the bed temperature is 40 C.

Then I cleaned it with a cutter and sand paper to reach the final step.

since we don’t have a 3D Scanner available in lab I used an IOS application on iPhone 7, the application is called Trnio and it works by taking 60 pictures of the scanned object and upload them to the server where they queue to be processed for hours, and then you have to trim the additional area and queue again