To Make the FabISP In-circuit programmer and solder all the required components in the board.

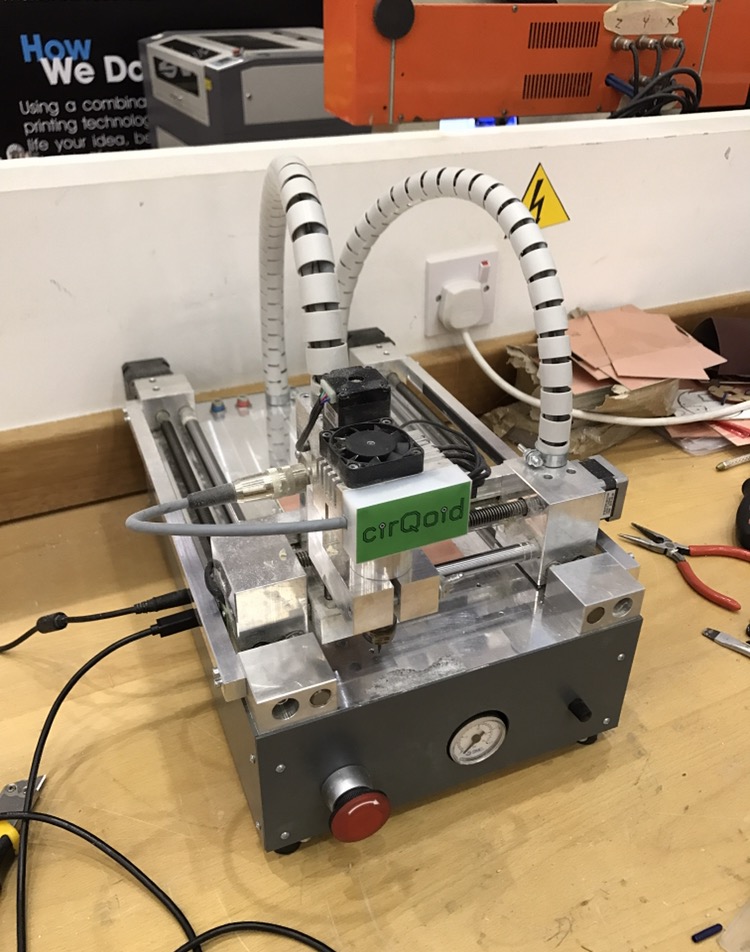

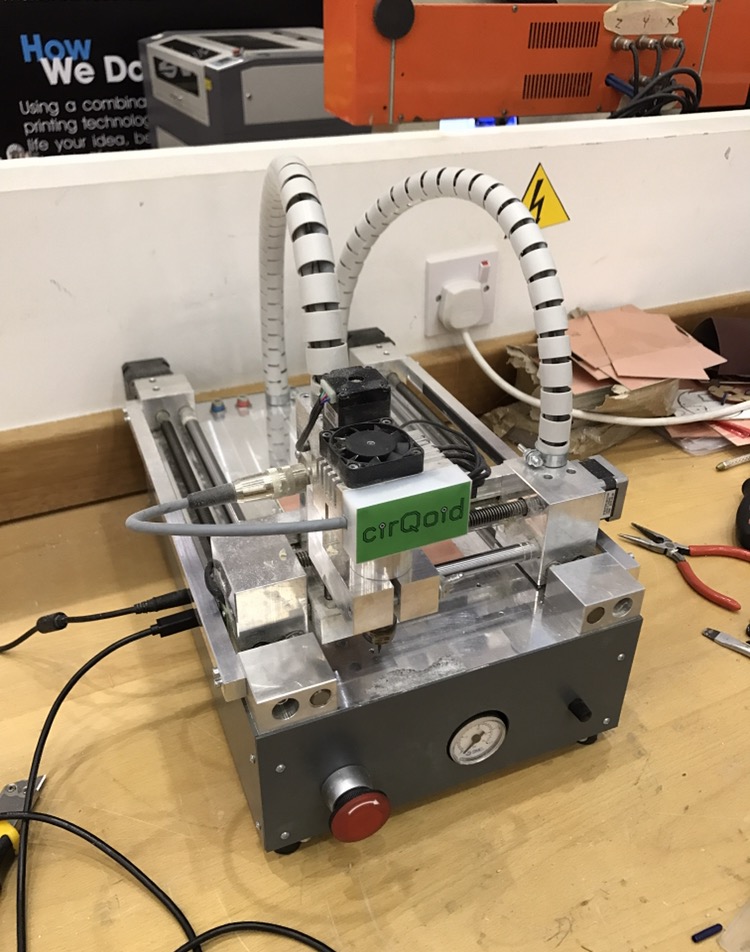

After creating a board for the electronic side of the project we need Eagle Cad program for converting the board file into a GERBER. And we need a hardware (PCB Milling machine) device called Criquid, and this device is for converting the file into the board by printing the electric circuit on the copper board itself. Later on, we used the EAGLE program to create the schematic design for the same PCB.

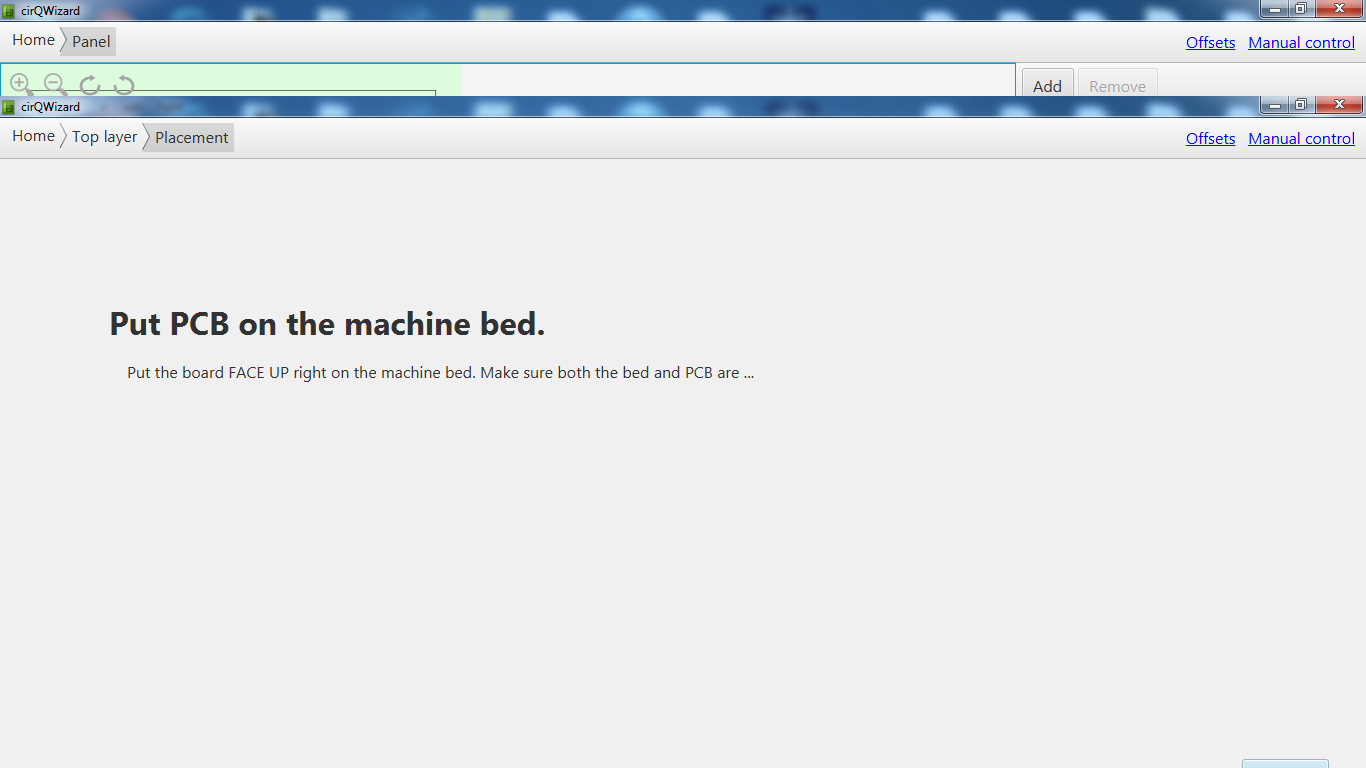

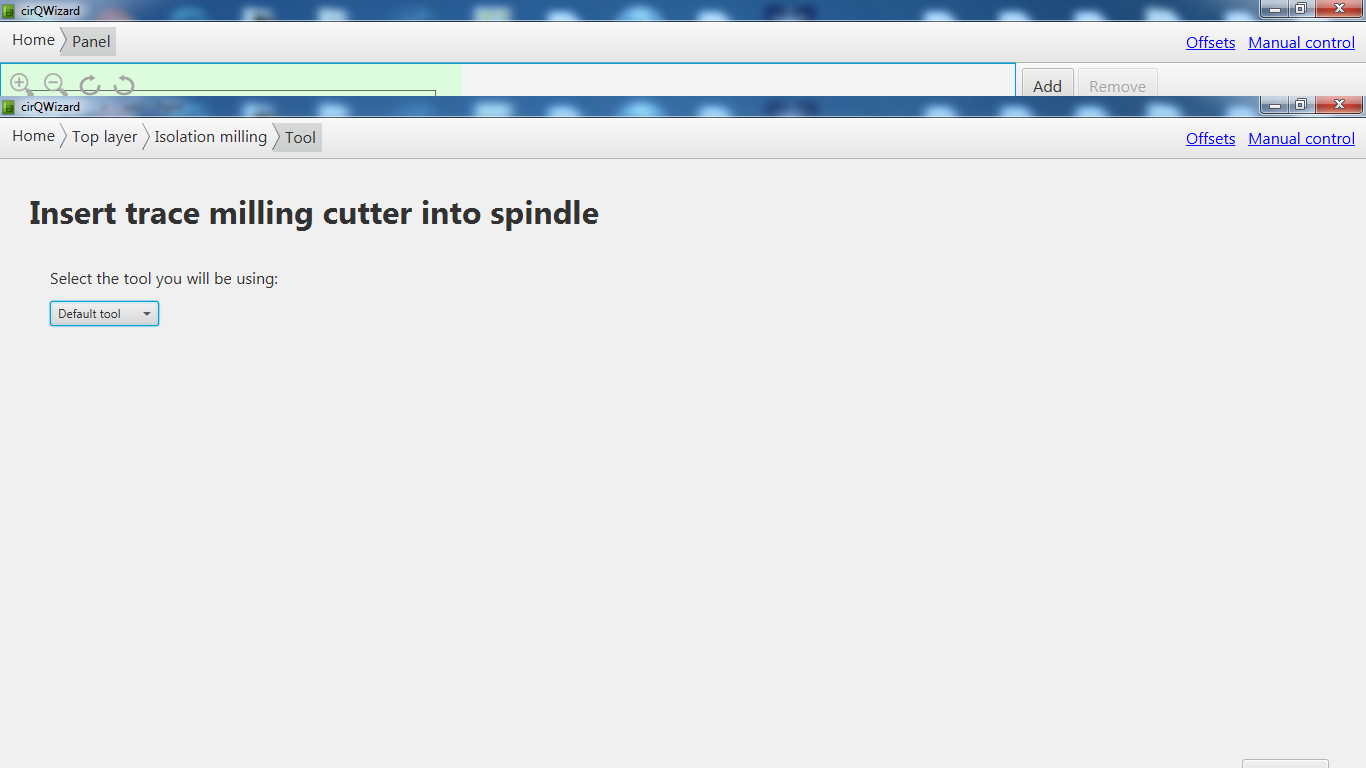

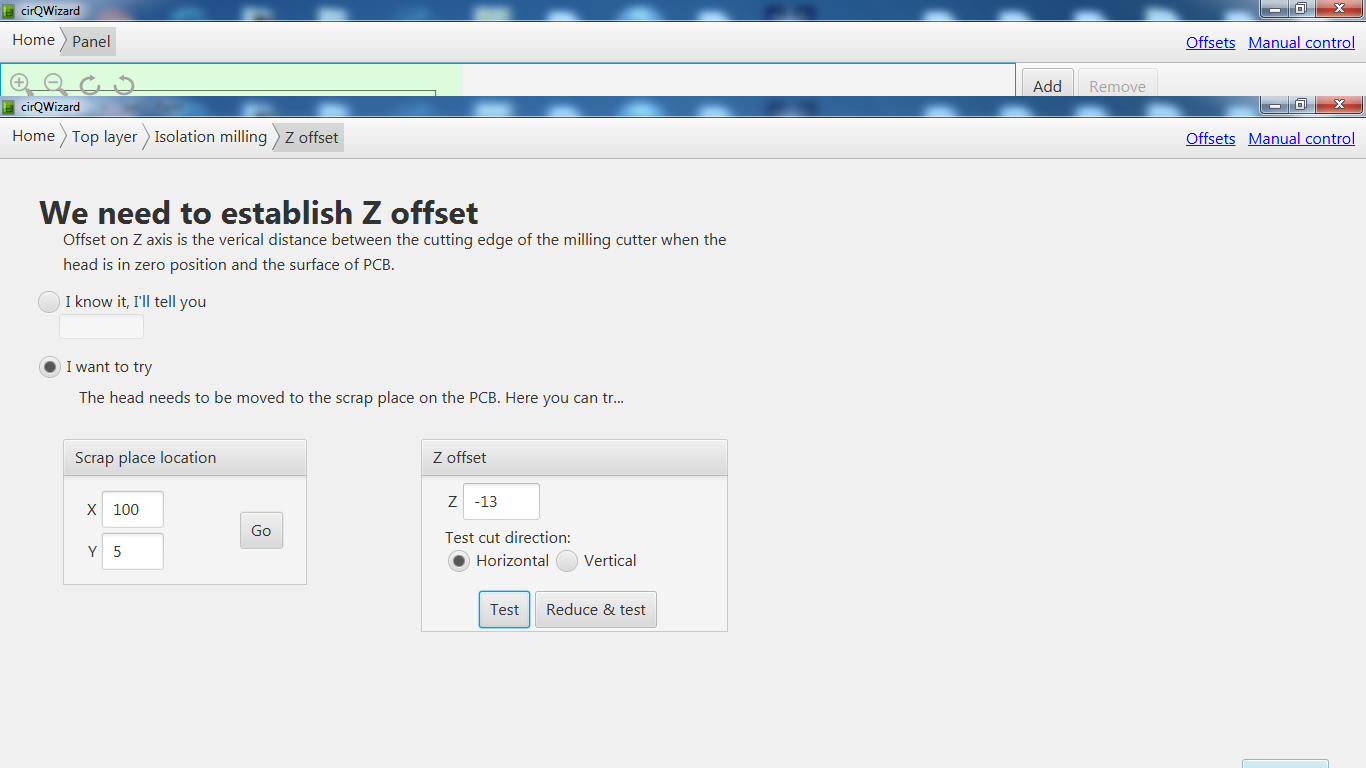

By using the milling machine I make the in-circuit programming by milling the PCB. Setting the Machine before the milling operation require checking the drill bit, adherence of the board add an additional sacrifice board if required while cutting. using the X-Axis and the Y-Axis to set the area and size of the PCB required. The Z-Axis set the level of the bit, deep for full cutting or medium for creating the routes, milling the board, Removing the additional material so that tracks could be build to connect.

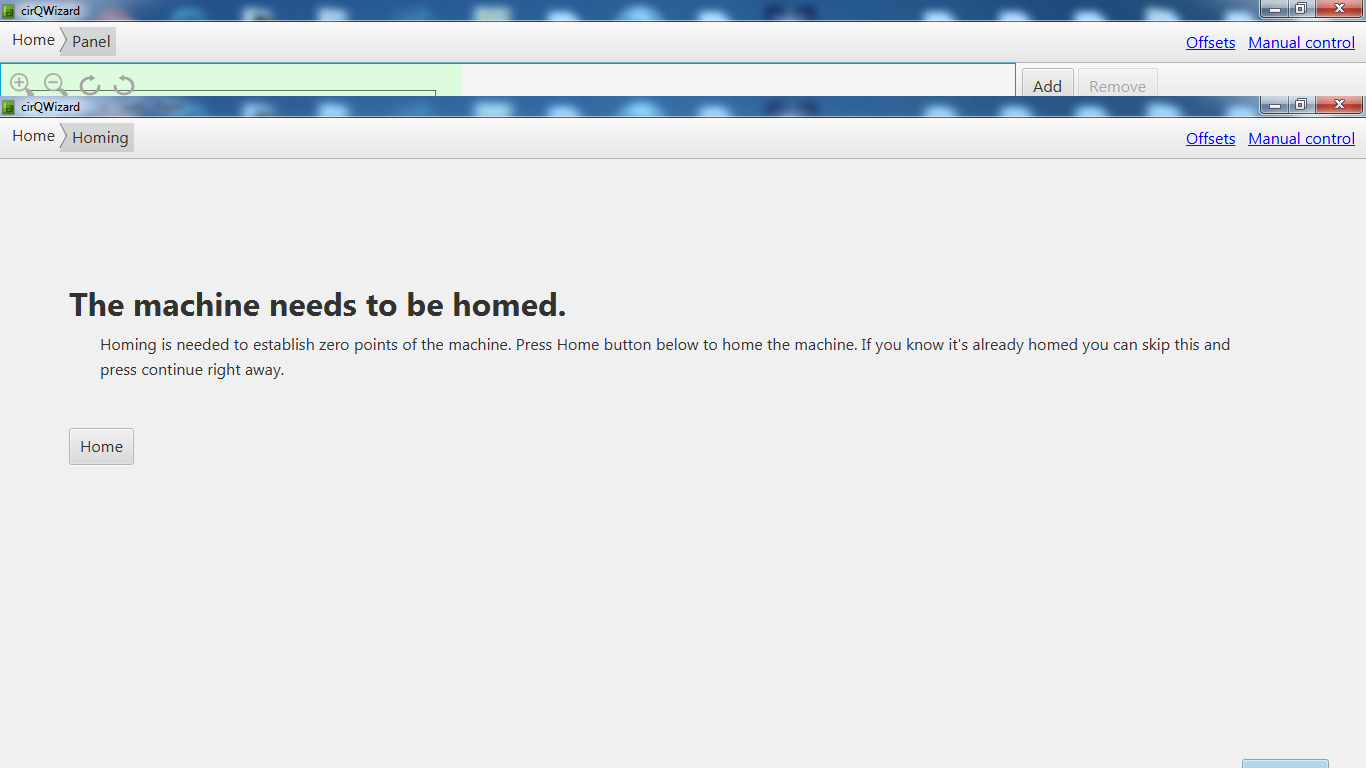

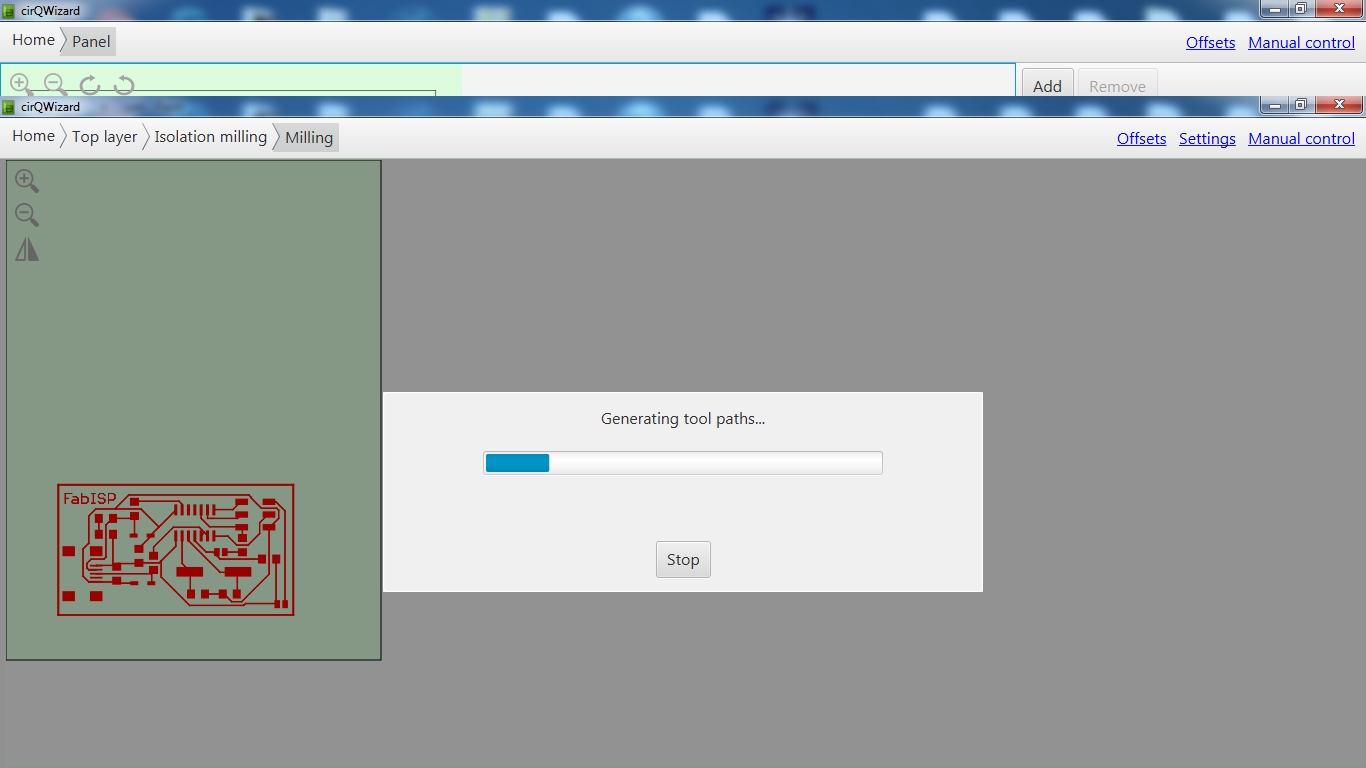

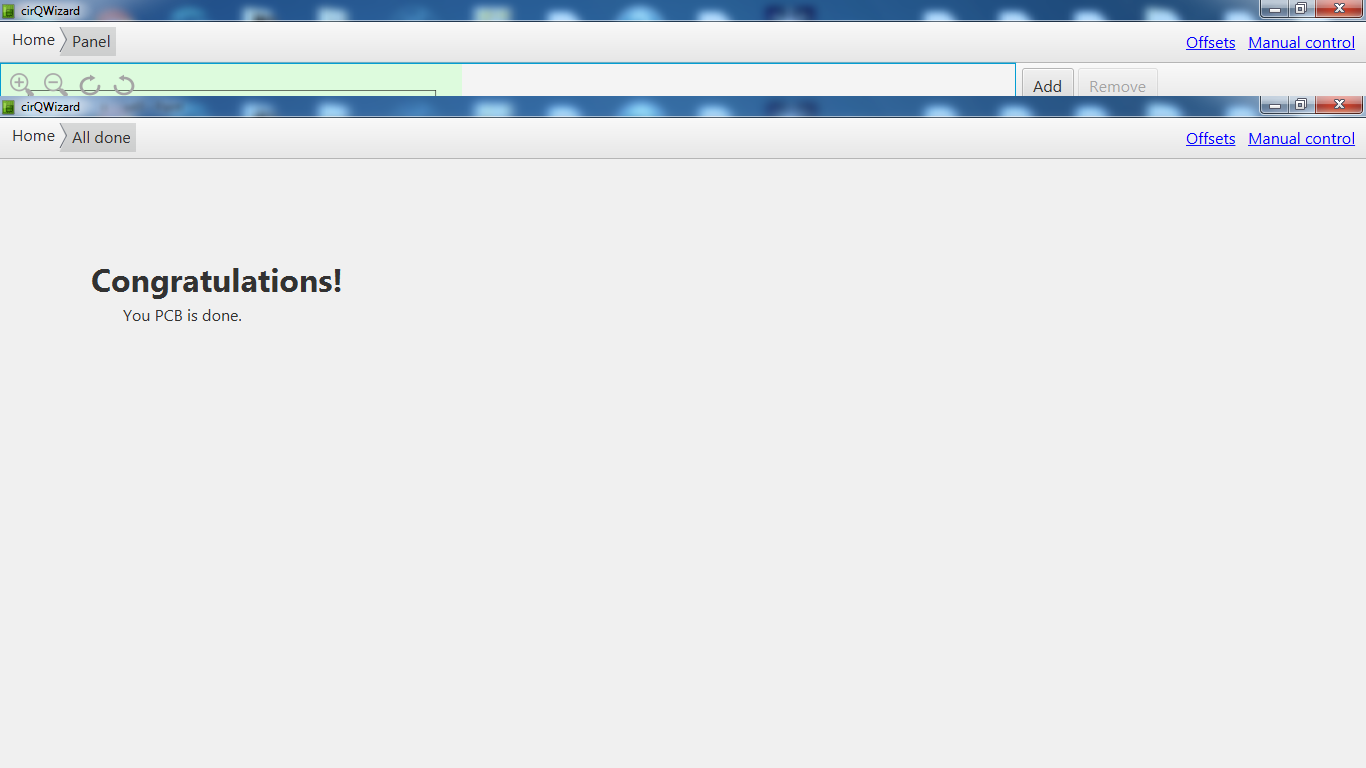

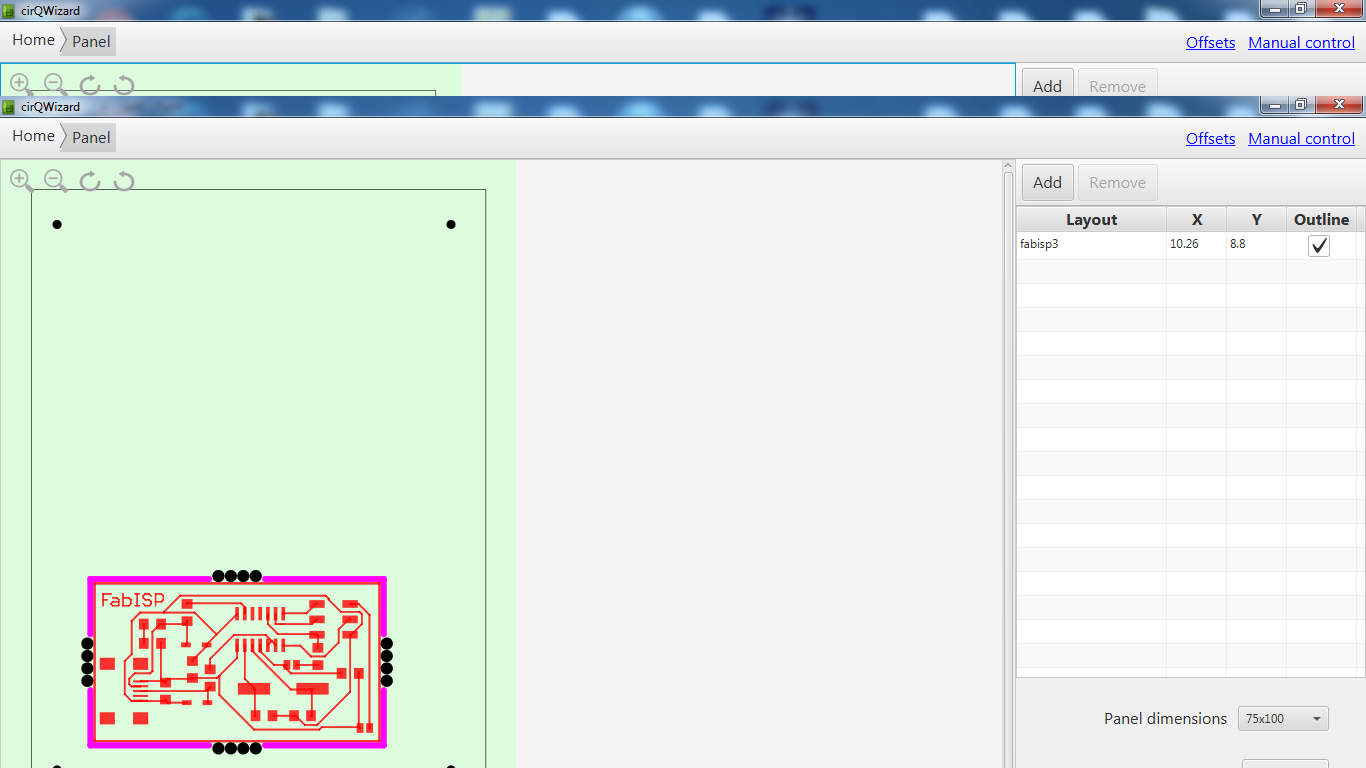

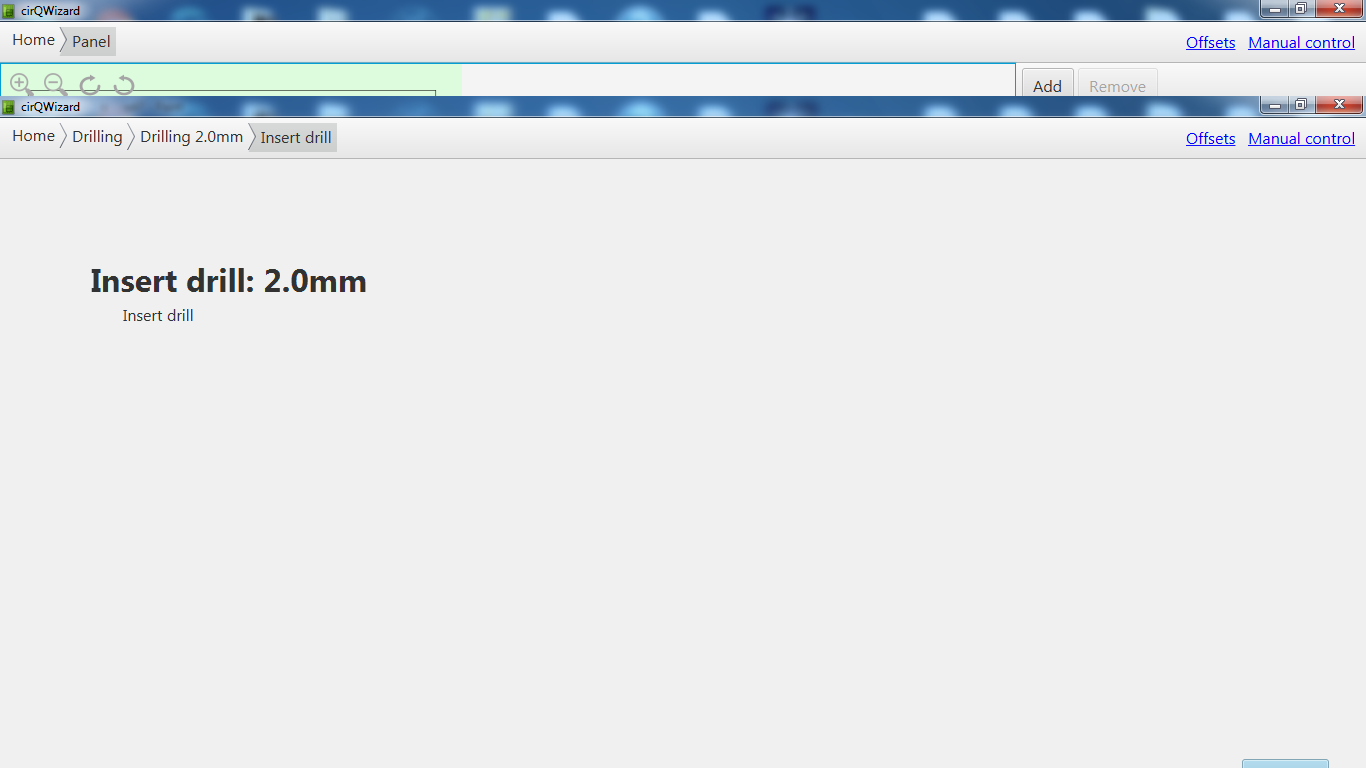

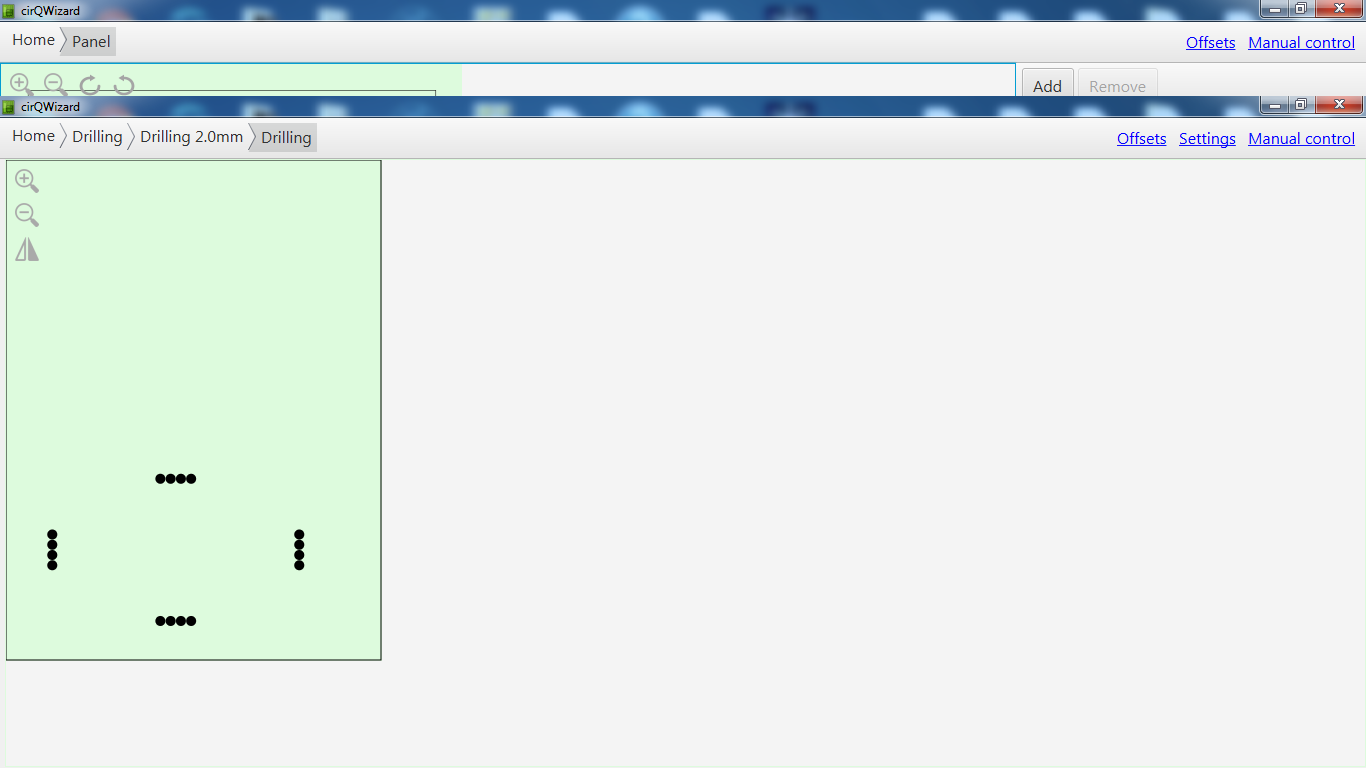

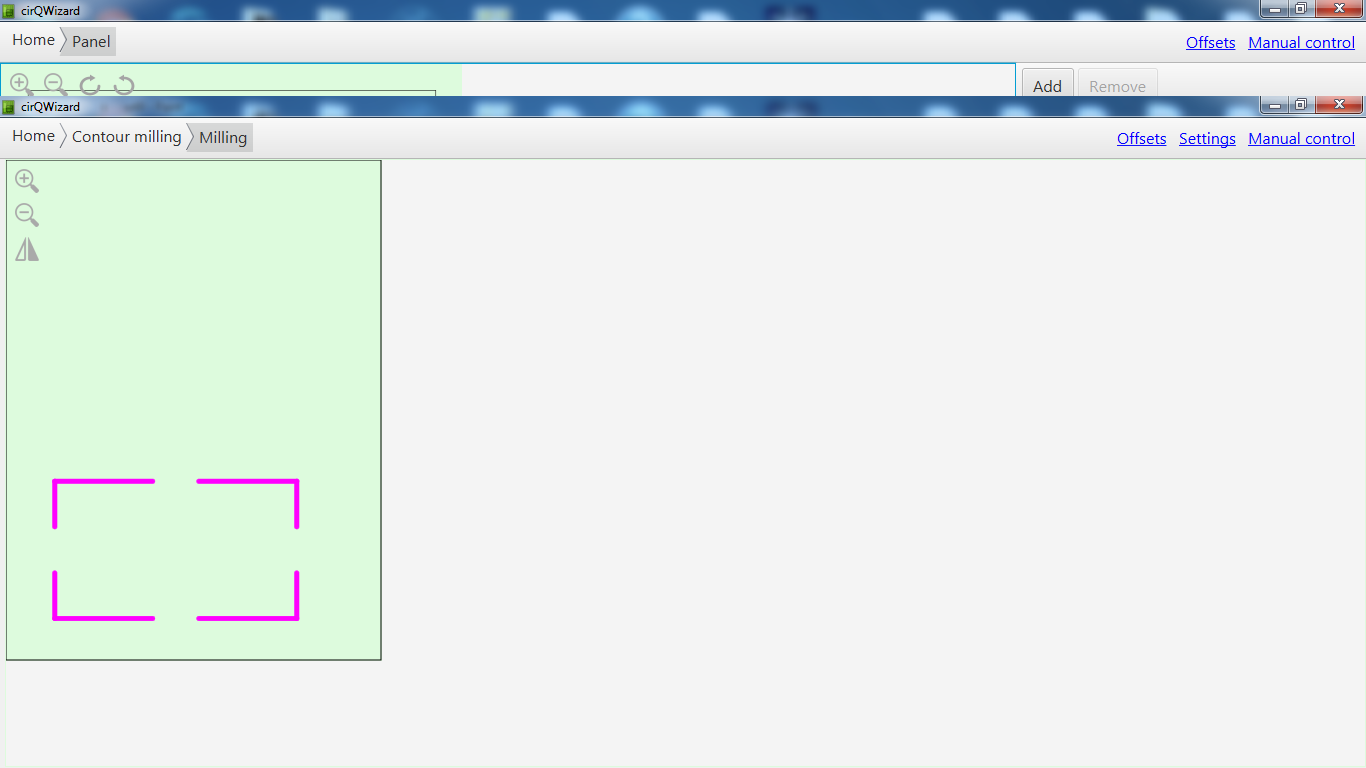

Below are the steps of using the pcb machine

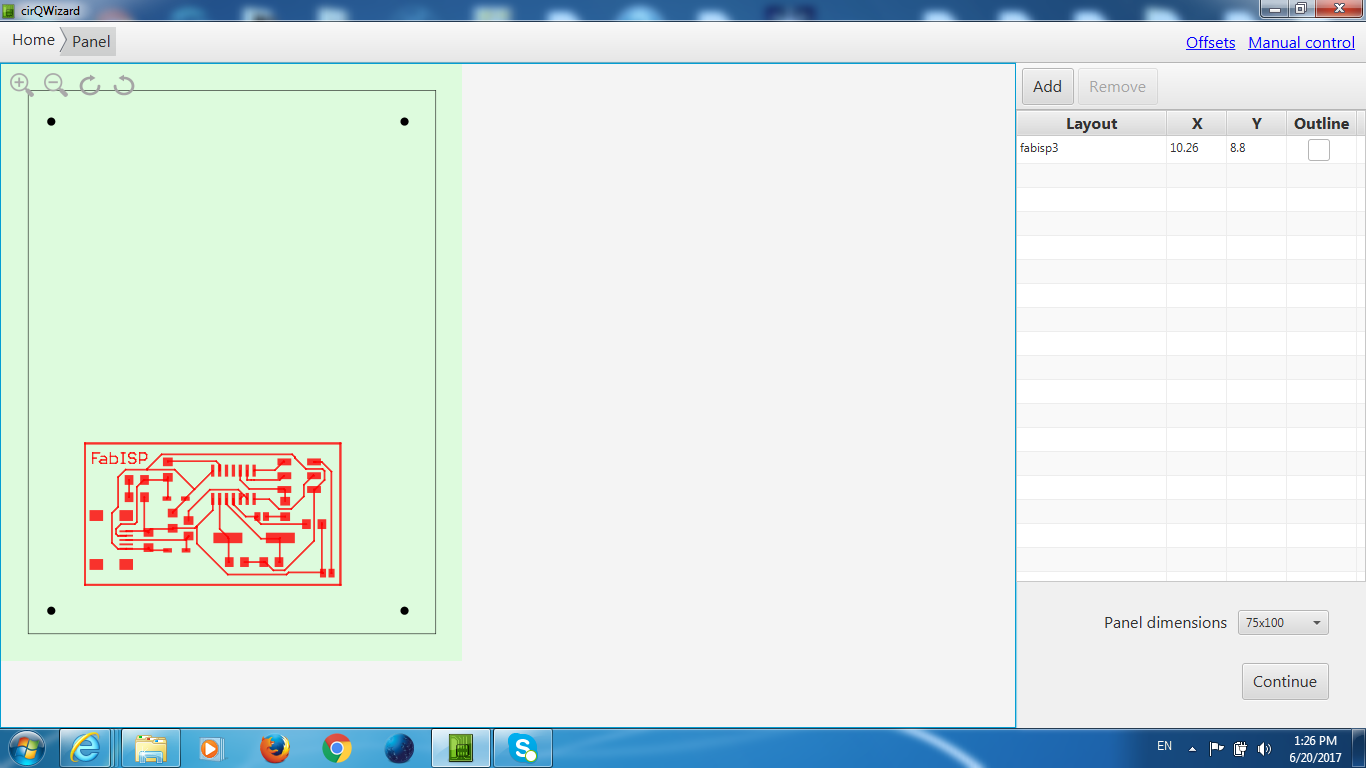

Open the CirQWizard then open the fabisp file in the program and choose your panel size then continue

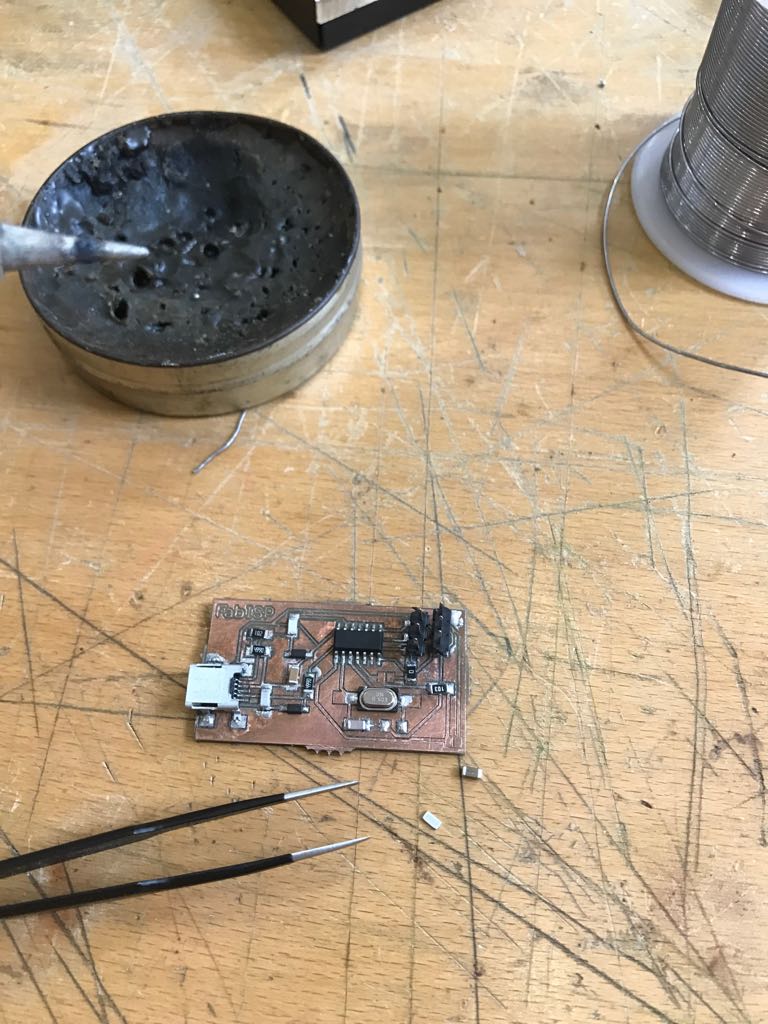

Assembly components are picked with tiny tweezers and soldered on the ISP board Soldering is a process in which two or more metal items are joined together by melting and then flowing a filler metal into the joint—the filler metal having a relatively low melting point. Soldering is used to form a permanent connection between electronic components.

and if something is soldered wrongly it must be removed by the hot air gun and re-soldered correctly.

I soldered the components one by one starting with the attiny 44 and it was hard because of the small soldering area then the resisters and capacitors and 2x3 connection pins, crystal, USB connection .. etc

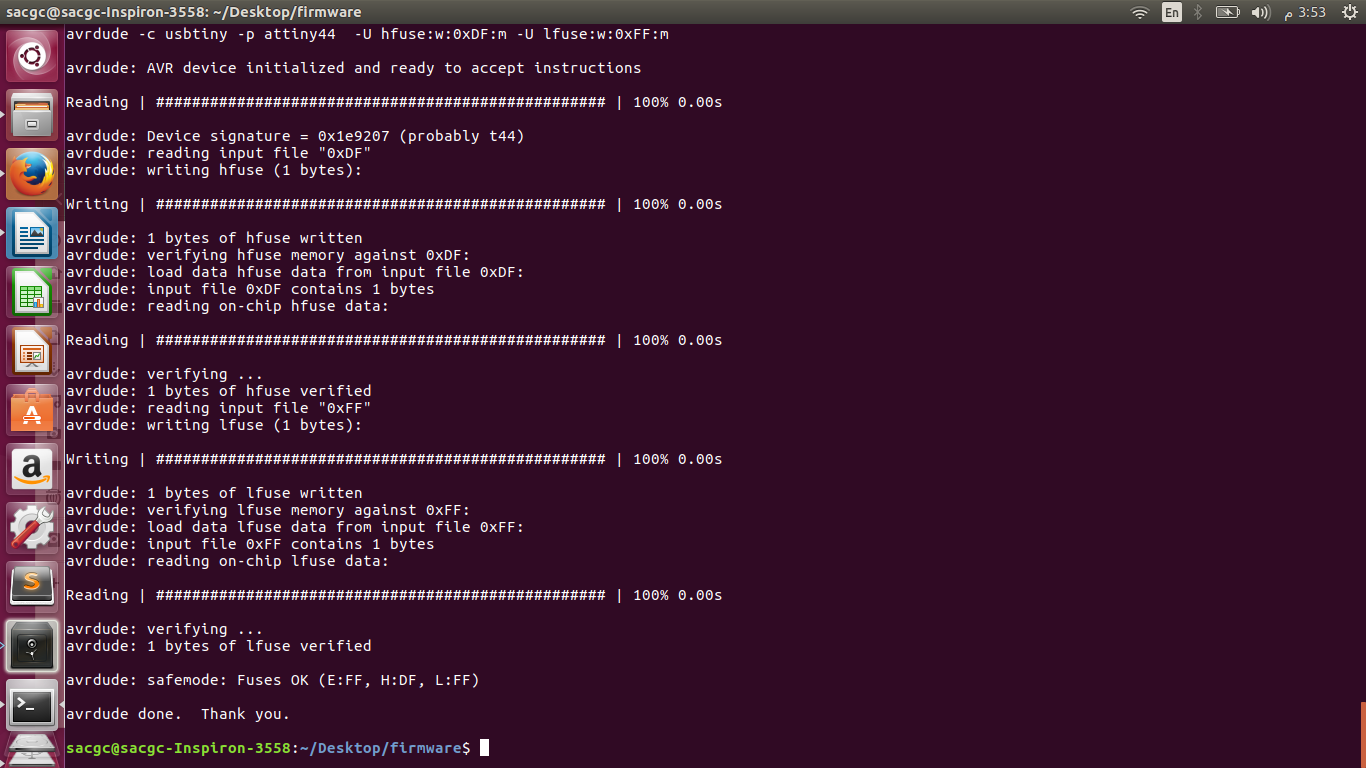

Install all dependencies to make sure , some of them may be already installed using the following :

sudo apt-get install flex byacc bison gcc libusb-dev avrdude

sudo apt-get install gcc-avr

sudo apt-get install avr-libc

sudo apt-get install libc6-dev

CD to Firmware Folder (Make Sure all operations in Unzipped (Firmware Folder)

Then:

make clean

make hex

After connecting programmer

make fuse

make program

Done (if have any error double check connections)