Week 3 assignment is to convert 2D designs into tangible objects using Computer Controlled Cutting by Vinyl Cutting Machine to create stickers, and Laser Cutting Machine to create objects from acrylic board.

Is a process based on algorithmic thinking that enables the expression of parameters and rules that, together, define, encode and clarify the relationship between design intent and design response.

Parametric design is a paradigm in design where the relationship between elements is used to manipulate and inform the design of complex geometries and structures.

The term parametric originates from mathematics (parametric equation) and refers to the use of certain parameters or variables that can be edited to manipulate or alter the end result of an equation or system. While today the term is used in reference to computational design systems, there are precedents for these modern systems in the works of architects such as Antoni Gaudí, who used analog models to explore design space.

Parametric modeling systems can be divided into two main types:

Propagation-based systems where one computes from known to unknowns with a dataflow model.

Constraint systems which solve sets of continuous and discrete constraints. (Wikipedia)

The Vinyl Cutting Machine is a type of Computer Controlled Machines which use Small vinyl cutters look like computer printers. The computer controls the movement of a sharp blade. This blade is used to cut out shapes and letters from sheets of thin self-adhesive plastic (vinyl).

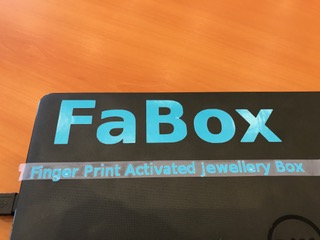

After designing my potential final project logo in Week 2 assignment using GIMP, I used (Silhouette Studio) program to print the sticker.

What I did :

1) Open the PNG file in the program.

2) I adjusted the size of the logo.

3) I aligned the printout position in the sheet.

4) I clicked on Object Tap – Trace then select the Trace area making sure to print all the designed logo traced area and discarding the rest.

5) I Send the job to the Silhouette CAMEO machine after loading the vinyl paper in it.

After the machine finished the job I unloaded the paper and removed the excess sticker keeping the litters and used an adhesive tape to move the logo and stick it on the back of my laptop.

Laser cutting machine is a machine that uses laser rays to cut materials, and is usually used for factories, and nowadays starting to be used by small businesses, schools and Amateurs, and it works by directing high-power laser into the material to cut it.

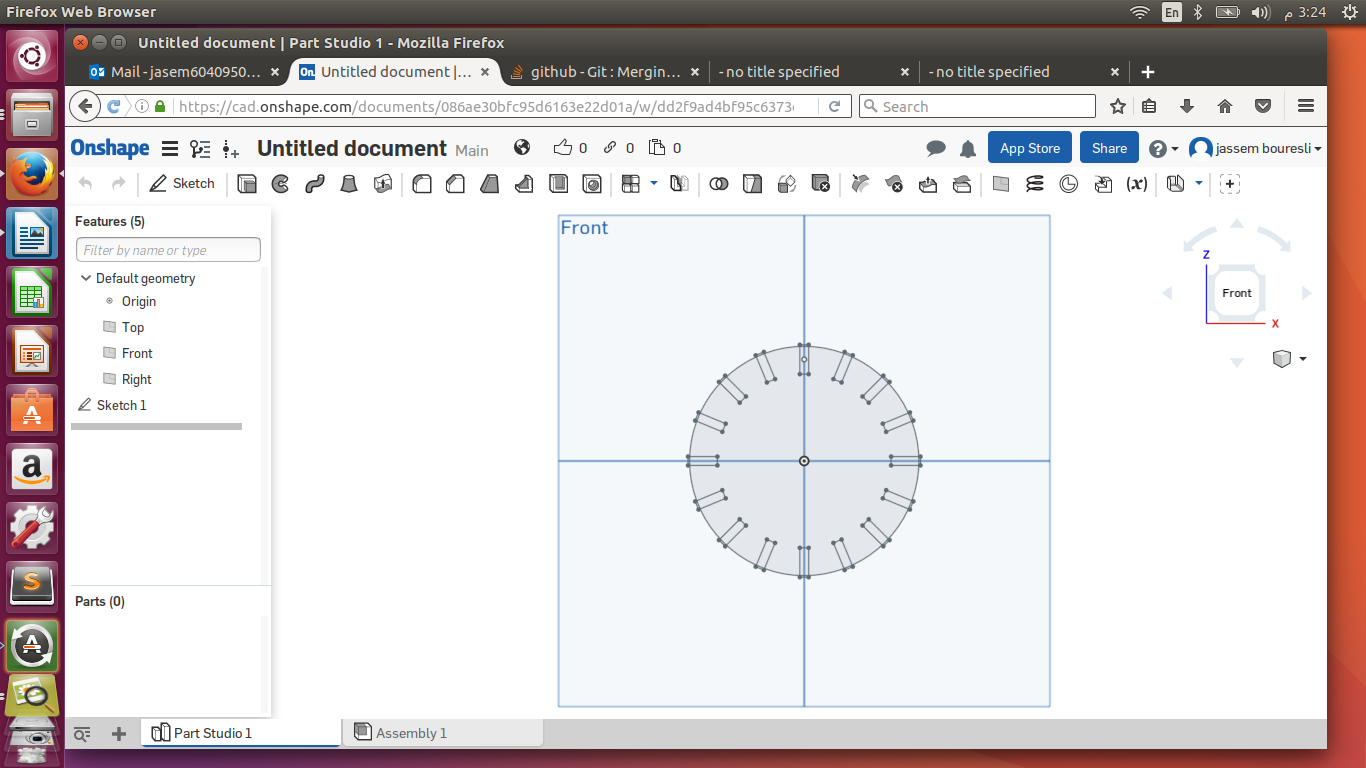

I used Onshape software

https://www.onshape.com

for my design because it is free, web-based. easy to use program.

I used millimeters as my measuring unite and since the acrylic board used is 3mm thick and there is amount of error in the laser cutting I tried press-fit opining dimension of 2.7mm

Then I exported my design as dxf file the cut it from a 3mm acrylic by Laser Cutting Machine and cut it.

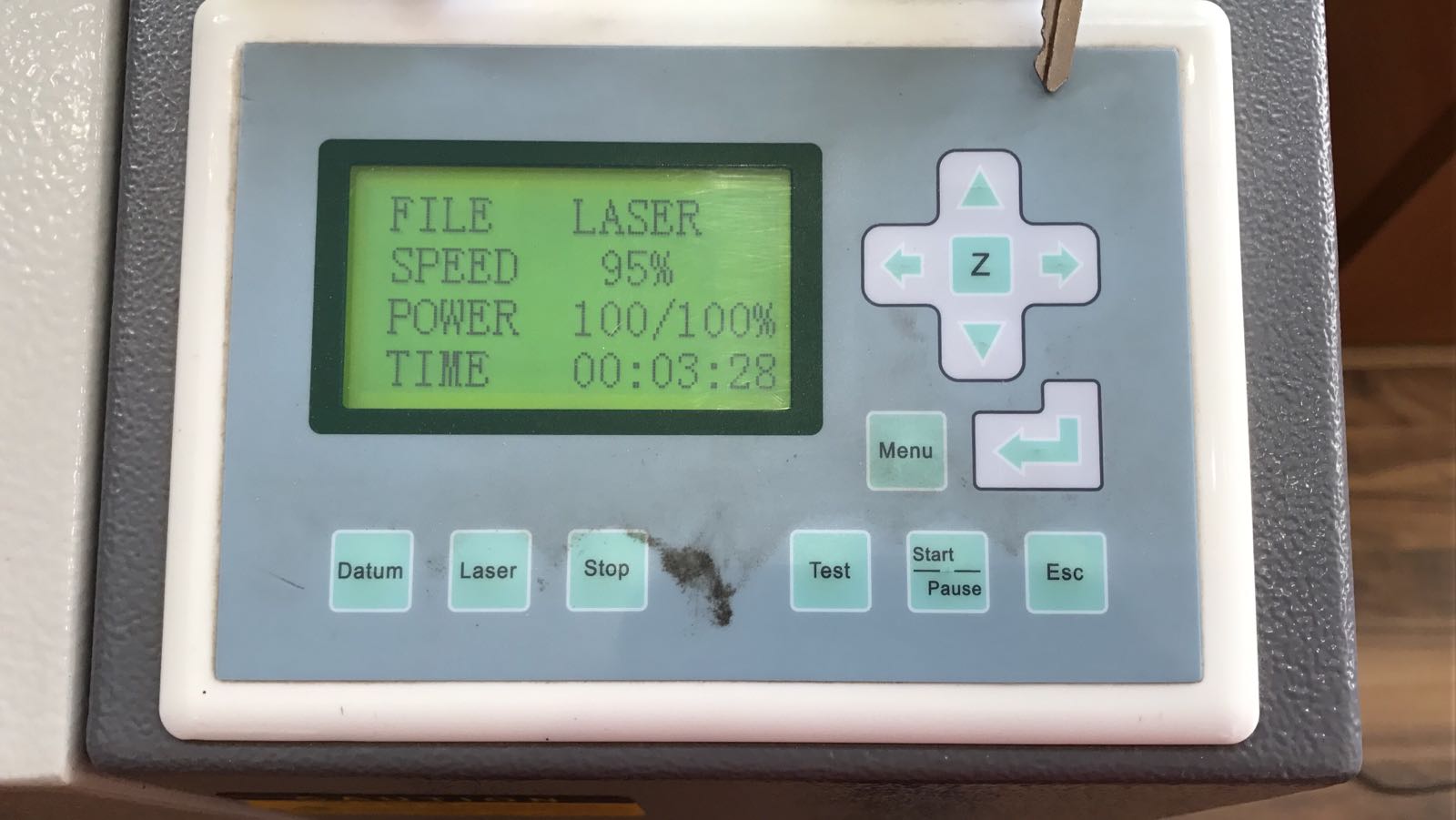

This is the Laser Cutting Machine.

The control panel of the machine is very direct and easy to use, it have six main buttons as follows :

1) Datum

2) Laser

3) Stop

4) Test : to know the frame of the cutting

5) Start/Pause

6) Esc : to exit

along with the arrows, enter button, menu and a screen, in addition to Switch key, and Emergency stop.

The press-fit is good and the pieces fit each others.

Files:

1) This is the

link to onshape file

2) Download 2d.png file here

3) Download 2d.xcf file here