Assignment 9 & 11

Mechanical DESIGN and machine design

Have you:

- Design a machine (mechanism+automation), including the end effector

- Build the passive parts and operate it manually

- Document the group project and your individual contribution

CLIP HERE FOR THE GROUP WEBPAGE

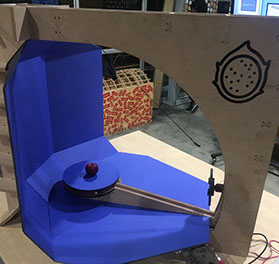

For this group project, we had to design and automate a machine. Every member of our group was assigned to an individual task, in my case I was in charge of milling in full size the Scanner ,in the Shopbot, and assembling it. In addition I was commissioned to use the vinyl cutter to add some extras.

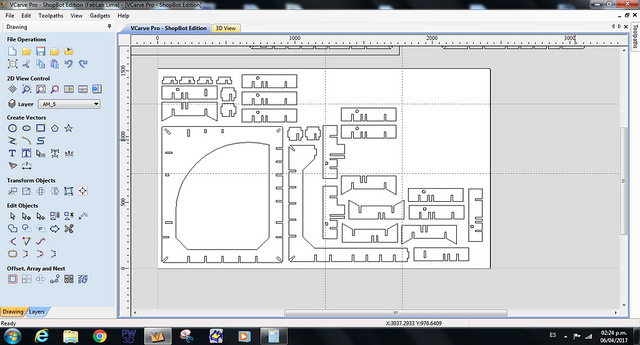

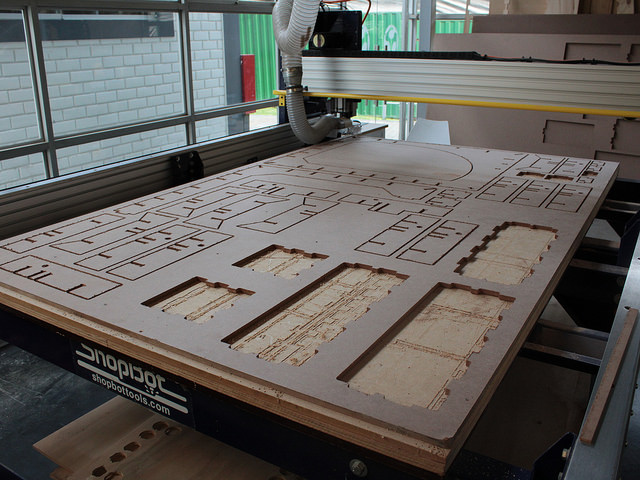

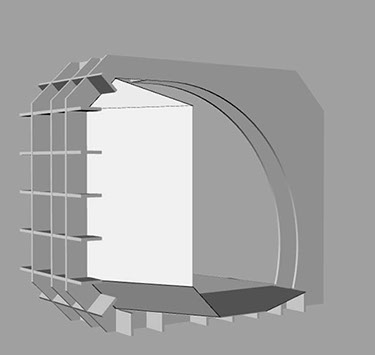

SHOPBOT CNC: For this, I received the designs in CAD for Eddy and imports the software to V carve for adapt it for manufacturing.

First, I check the tolerances of the prefits, I did tests and add the "ears" to the prefits so that I can perfectly fine. It is important to do it well because otherwise the prototype can not be assembled.

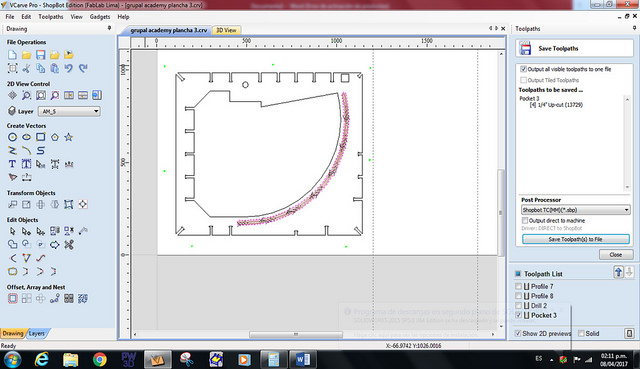

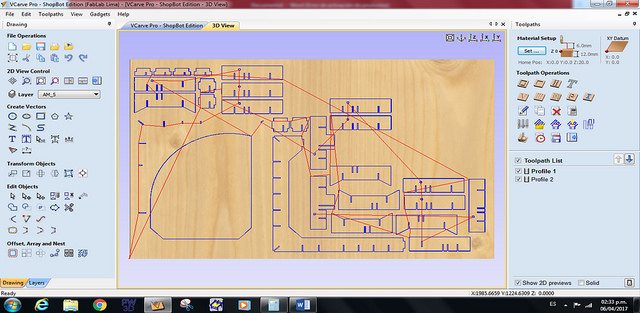

Then, as seen in week 7, create the orders that will have the machine.

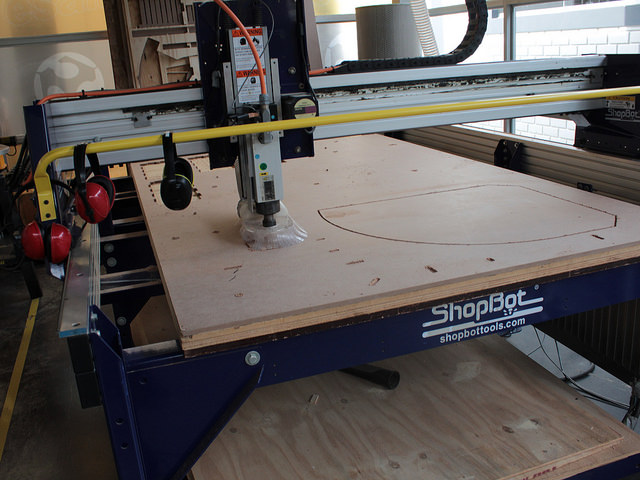

We calibrate the machine

Secure the board according to the design on the Vcarve

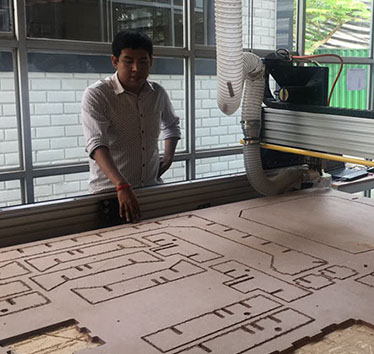

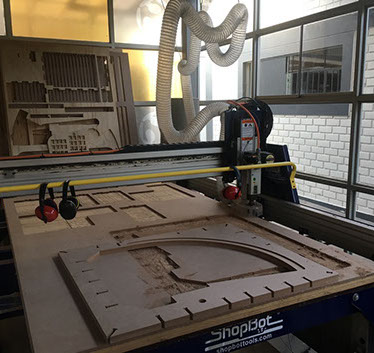

And we started milling

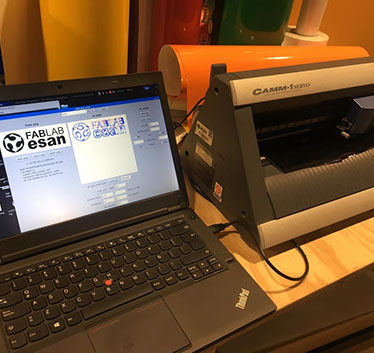

VINYL CUT: For this part, only find a slogan of FAB LAB ESAN and design a fruit in Corel. We chose a fruit because its a Food Scanner.

Finally, We assemble everything and present it ready to add the electronic part and that Luis and Marks start programming

Then I support in the tests of operation of the machine.

COMMENTS ABOUT GROUP WORK : In general terms, I think we were a multidisciplinary team because we had:

2 architects

1 Electrical Engineer

1 Computer Engineer specializing in Computational Vision

1 Industrial Engineer

1 student of Engineering

Initially, when I asked the idea of the machine to be manufactured, I proposed to make a scanner, because in week 5 I realized that it was very difficult to scan something evenly with the Kinect, it would be better to have the precision of a machine to turn around Of the object and could even control the rotation time between angles.

My colleagues liked the idea and were in charge of finding the right justification and approach to meet the requirements of the job.

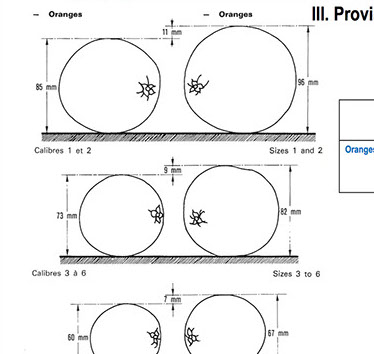

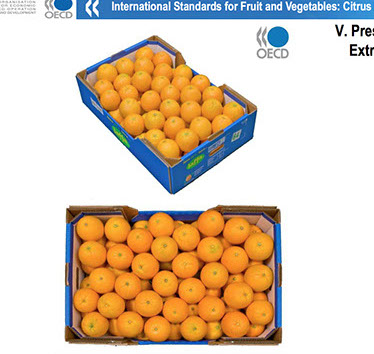

At the end it was decided that the machine would scan fruit because Eddy told us that for larger objects would require a greater distance between the scanner and the object and that would complicate more the size of the machine.

Marks mentioned that in the export of fruit there is a problem that the exact size of the packaging is not known, causing losses in costs and time; In addition, there are some scanners documented on the internet which would facilitate the mechanism.

The designers were Victor and Eddy, I was in charge of the machining, Luis and Marks of the electronic part and Vane of the documentation and the website.

The problem we had was that the design took longer than expected and I could not mill without the design, besides we had a holiday in Peru for Easter and I had scheduled to travel. I got to mill most of the pieces but those that were missing the mills my partner helped me, unfortunately they did not mill well and so they could not easily assemble the machine.

The next week I re-worked the pieces that did not fit well and we set up the machine structure easily, Luis and Marks were in charge of implementing the electronic part but Marks had prepared an extra creating an application and using computer vision to recognize the type of fruit And to be able to automatically process the images, but due to the stress of delivery time, the program did not run well and that is an opportunity for improvement for the machine

Finally, I think the work went very well because of the contribution of each member of the team and even the instructors were astonished that we finished with time.